Simulation yarn dynamic breaking strength testing equipment and testing method

A technology for breaking strength and testing equipment, which is applied in the direction of applying stable tension/pressure to test material strength, measuring devices, and strength characteristics. It can solve problems such as expensive equipment, complex equipment structure, and functional redundancy, and reduce testing. The effect of cost, simplified operation process and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

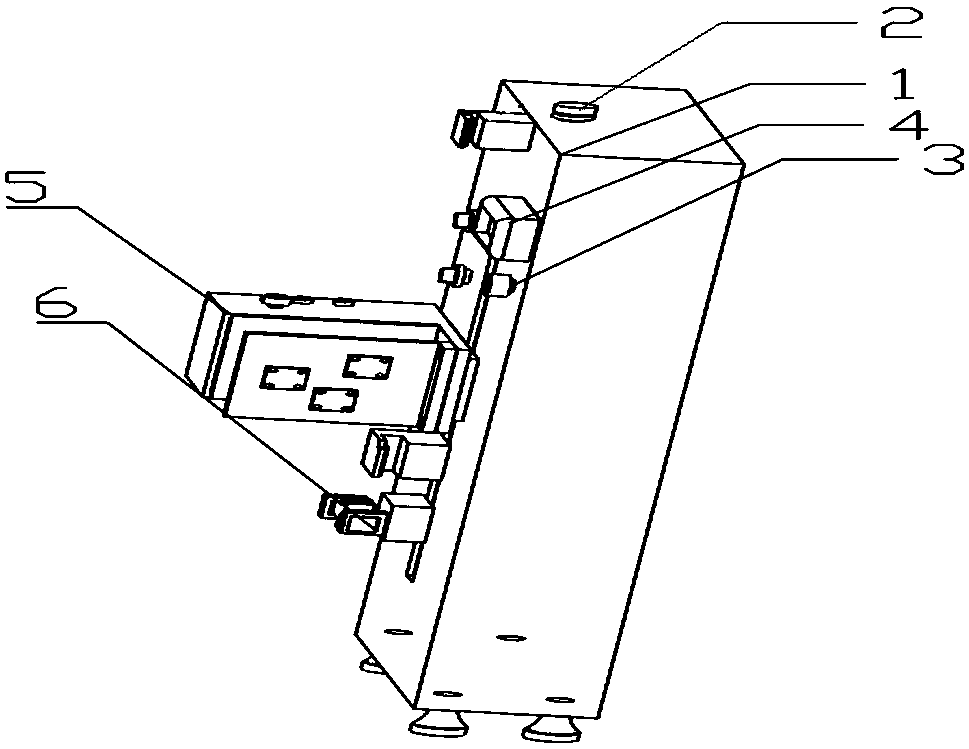

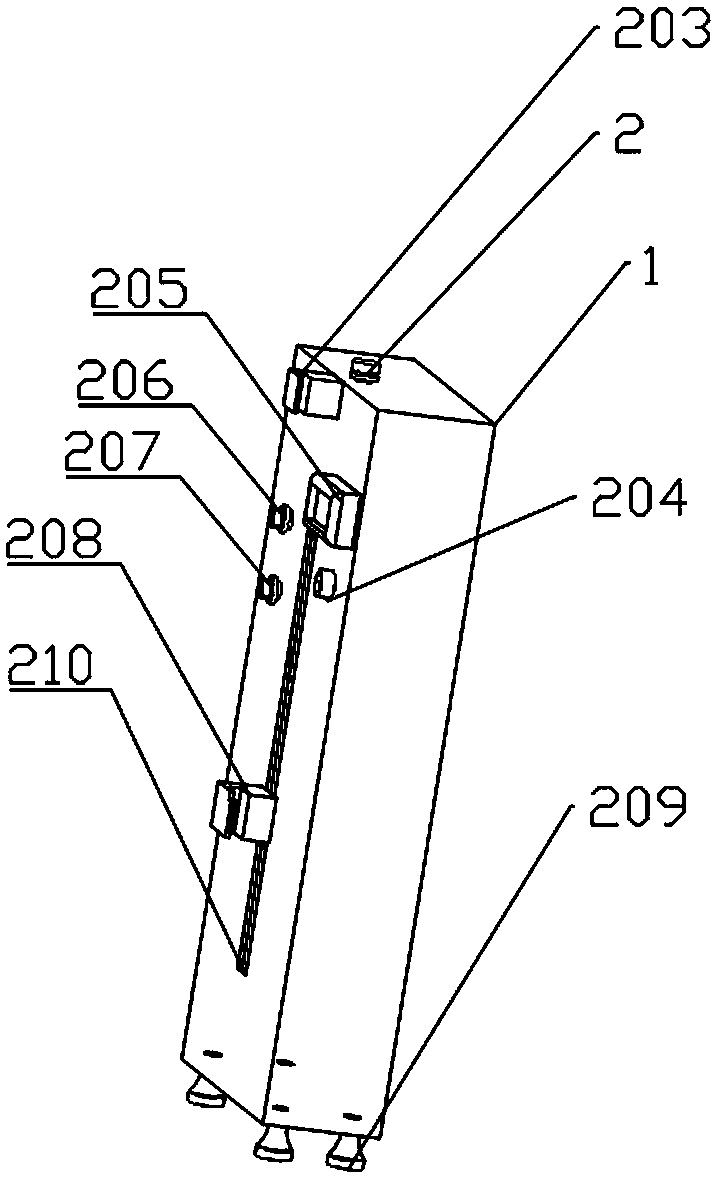

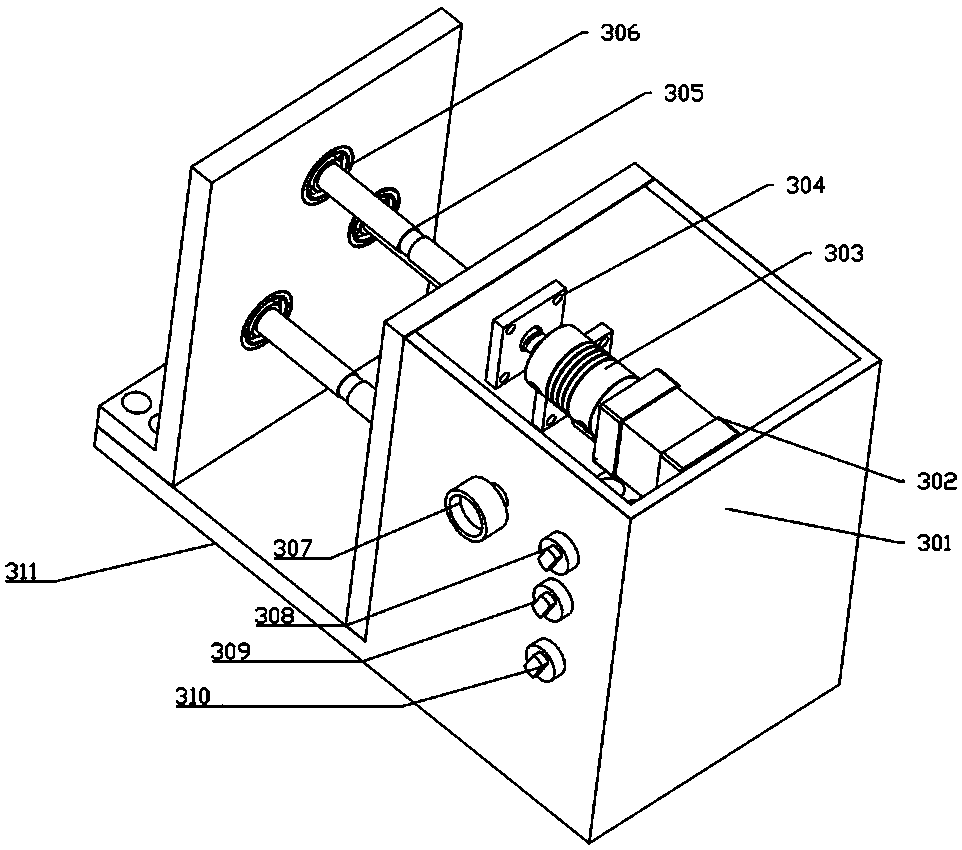

[0036] like Figure 1-4 As shown, the present invention includes a strength machine chassis 1, a microcomputer control system 4, a dynamic simulation system 5 and a yarn balancer 6. The top of the strong machine case 1 is provided with a yarn fixer 2, and the side of the strong machine case 1 is provided with a clamp 203 on the yarn, a microcomputer control system 4, a yarn stretching slideway 210, a power simulation system 5, and a yarn Lower clamp 208 and yarn balance weight 6. The yarn upper clamp 203 is located directly above the yarn stretching slideway 210; the dynamic simulation system 5 is fixedly installed on this side, and is located between the yarn upper clamp 203 and the yarn lower clamp 208. The end of the yarn lower clamp 208 is located in the yarn stretching slideway 210, and can slide along the yarn stretching slideway 210 to realize pre-tensioning a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com