Preparation method of electrostatic spinning membrane for tissue defect repair

An electrospinning and tissue technology, which is applied in the field of electrospinning membrane preparation, can solve the problems of difficult cell adhesion and ingrowth, fast degradation speed, and large pollution, so as to reduce the matching requirements of process equipment and be operable Increased time, stable and controllable viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In an exemplary embodiment of the present invention, the preparation method of an electrospinning film specifically includes the following steps: preparing a gelatin solution and a glyoxal solution, mixing the gelatin solution and the glyoxal solution in real time, and performing electrospinning to obtain electrospinning Silk film, dry-cut electrospinning film, inner packaging, sterilization, outer packaging.

[0035] In an exemplary embodiment of the present invention, preparing the gelatin solution includes the following steps: dissolving a certain proportion of gelatin in a pre-prepared mixed solvent, and the mixed solvent can be composed of formic acid, acetic acid, purified water, ethanol, and ethyl acetate. Mixed, wherein formic acid and acetic acid account for 10wt% to 100wt%, purified water accounts for 10wt% to 50wt%, and ethanol and ethyl acetate account for 10wt% to 50wt%. Optionally, the mixed solvent can also be formic acid A single-component solvent of ace...

Embodiment 1

[0051] Example 1 provides a preparation method for preparing an electrospinning film by needle spinning electrospinning equipment.

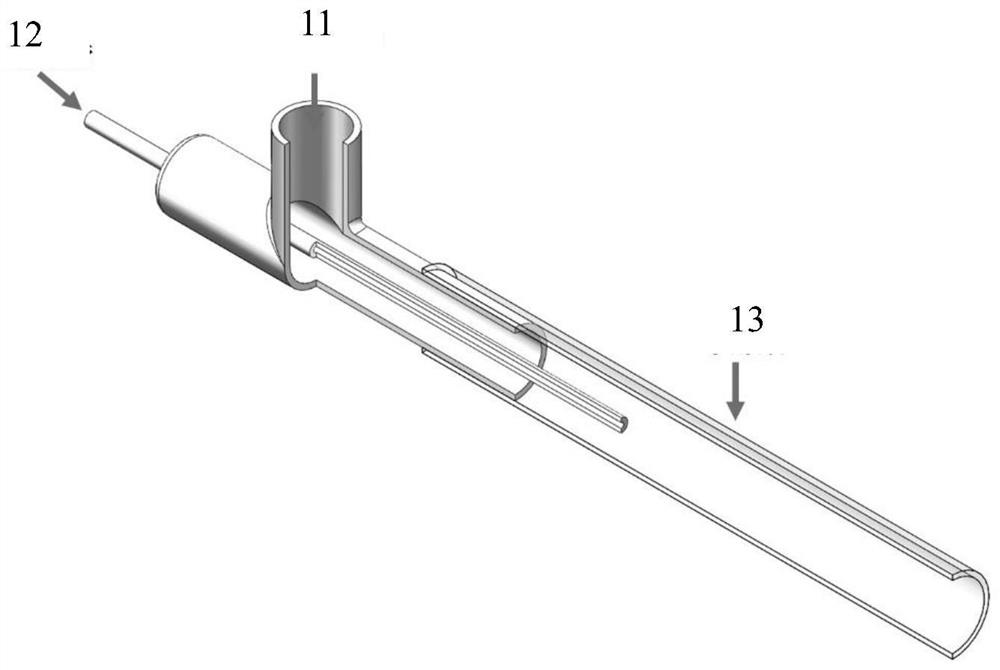

[0052] In this embodiment, the electrospinning equipment used includes a real-time mixing unit (structured as figure 1 shown), the real-time mixing unit includes a first liquid supply pipe 11, a second liquid supply pipe 12 and a main liquid supply pipe 13 located downstream of the first liquid supply pipe and the second liquid supply pipe, wherein the first liquid supply pipe The downstream end of 11 and the downstream end of the second liquid supply pipe 12 are both inserted into the main liquid supply pipe 13, so that the fluid conveyed therein can be mixed in real time when it is conveyed from the downstream end into the main liquid supply pipe.

[0053] The preparation method in this embodiment comprises the following steps:

[0054] (i) The gelatin solution is continuously delivered through the first liquid supply pipe 11 using a syringe p...

Embodiment 2

[0066] Example 2 provides a preparation method for preparing an electrospinning film by a needle-free electrospinning device. Compared with Example 1, the difference is that the spinning is performed using a needleless spinning device and the concentration of the gelatin solution used is different.

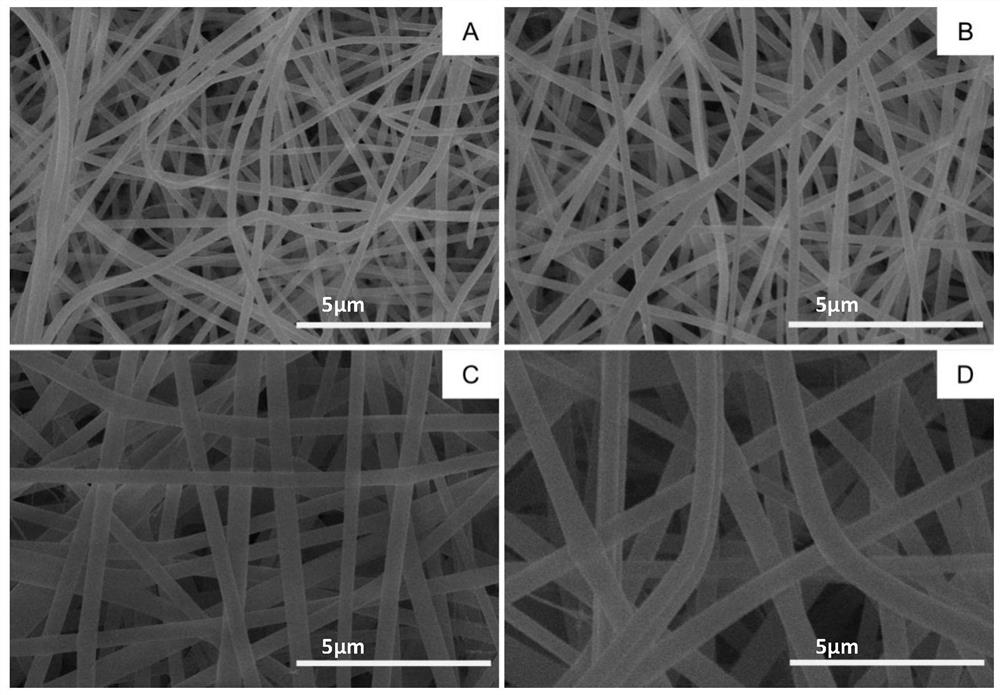

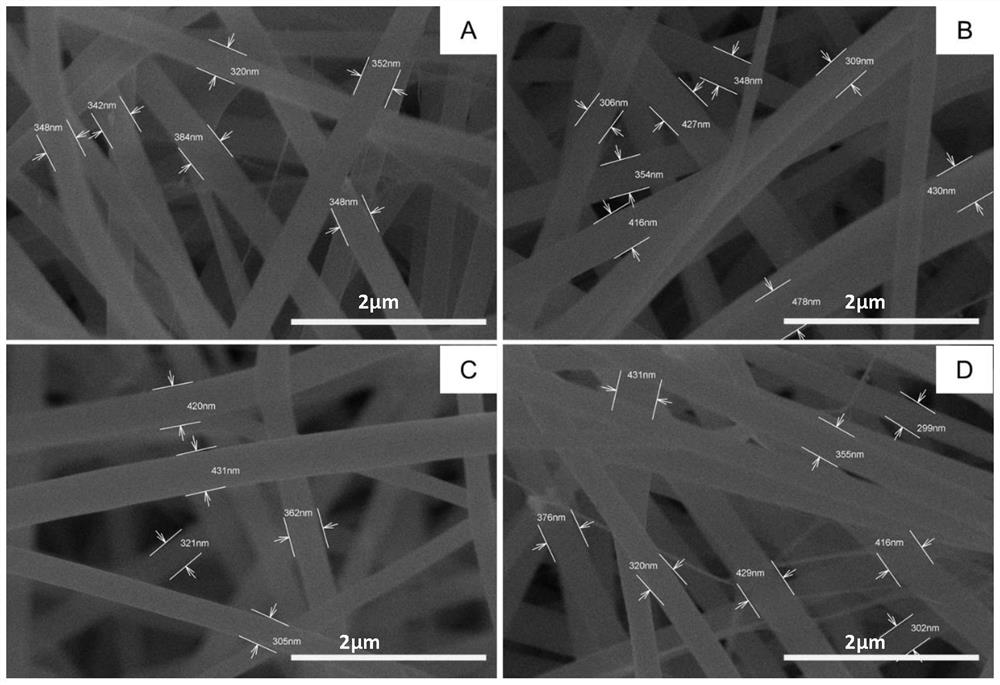

[0067] Specifically, in this example, gelatin with a freezing strength of 110-120 bloom g was selected and dissolved in a mixed solvent of acetic acid, water and ethyl acetate to prepare 14.0wt%, 15.5wt%, 16.5wt%, 17.5wt% The four concentrations of gelatin solutions at 20°C were 120-130mPa·s, 150-170mPa·s, 170mPa·s-190mPa·s, and 220mPa·s-250mPa·s, respectively. A glyoxal solution with a concentration of 40 wt% was prepared, and the molar / mass ratio of glyoxal to gelatin was 32×10 -5 mol / g. The spinning parameters of the non-needle electrospinning equipment used were maintained at a spinning temperature of 30° C., a humidity of 35% RH, a spinning distance of 20 cm, and a linear s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com