Method and device for preparing large-size bulk amorphous composite materials

An amorphous composite material and large-size technology, which is applied in the field of fiber/amorphous composite materials, can solve problems such as size and interface reaction limitations, and achieve the effects of reducing interface reactions, controlling mechanical properties, and precise pressure control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

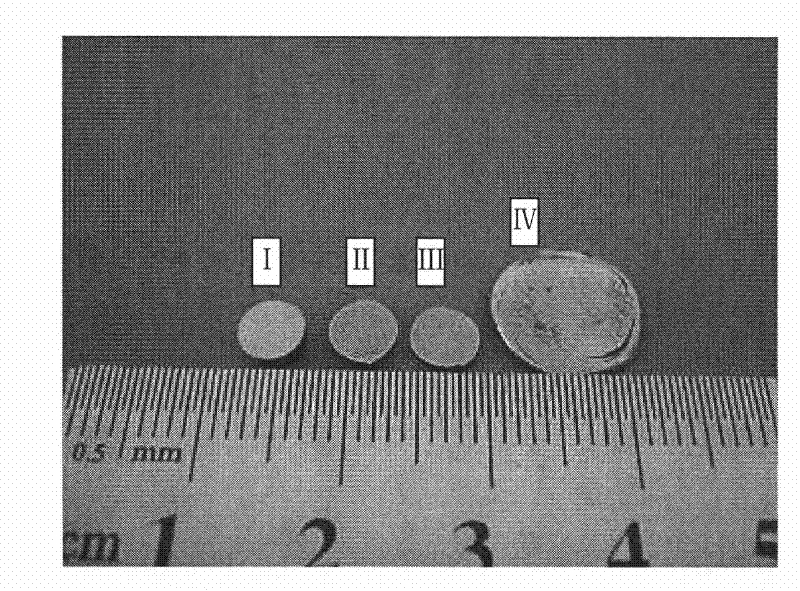

[0024] Example 1. A number of VIT1 amorphous flakes with different thicknesses were prepared by copper mold suction casting method. Take out three of them, such as figure 2 The I, II, and III non-wafers shown, the overlapping height of the three non-wafers is 4.7mm, and they are polished sequentially with 400-1000# sandpaper, and cleaned in acetone and alcohol using ultrasonic waves, and placed on the mold after overlapping superior. The indenters at both ends of Gleeble apply an initial pressure of 150MPa (pressure 294kgf), blow high-purity argon gas on the surface of the amorphous sheet for protection, and heat at a heating rate of 20K / min, with a heating upper limit of 410°C, and keep warm after the temperature reaches 410°C. During the test, the pressure is always maintained at 150MPa. The compression plastic deformation is very fast, and the holding time is very short. After the plastic deformation, the temperature is raised within a few degrees, and then unloaded, and...

Embodiment 2

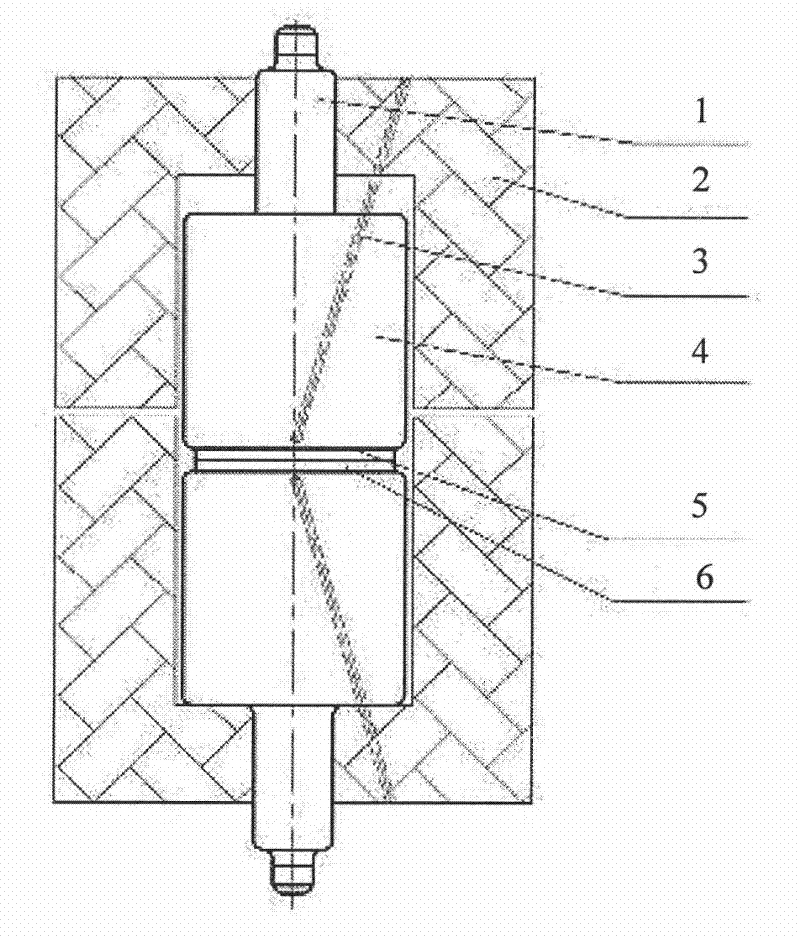

[0026] In the experiment, the polished and cleaned VIT1 bulk amorphous and tungsten composite wires were layered and wrapped in an orderly manner. Three layers of amorphous wafers sandwiched two layers of composite monofilaments (0.2 mm in diameter), and the two layers of composite monofilaments were placed The directions are perpendicular to each other. figure 1 The upper and lower heating furnaces are first heated to a certain temperature, and then the bag is put into figure 1 In the backing plate mold, heat at a heating rate of 40K / min, and then keep warm and pressurize. The relationship between heating temperature and heating time is as follows Figure 4 As shown in (a), the relationship between heating time and displacement is as follows Figure 4 As shown in (b), the relationship between loading load and heating time is as follows Figure 4 (c) shown. In the test, the final compressive stress is 100MPa pressure. The morphology of the prepared composite material is a...

Embodiment 3

[0028] Others are the same as in Example 2. In the test, five layers of 0.2mm amorphous sheets are sandwiched by four layers of tungsten composite twin wires (amorphous composite twin wires with a cross-sectional shape of 0.2mm×0.4mm are selected), and the final compressive stress is 50MPa. The morphology of the prepared composite material is as follows Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com