Testing method for dynamic shear complex modulus of bulk-phase asphalt rubber paste by considering substrate-adhesive cement interaction effect

An interactive, complex modulus technique used to test material strength, flow properties, measuring devices, etc. using a stable shear force, which can solve problems such as modulus errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

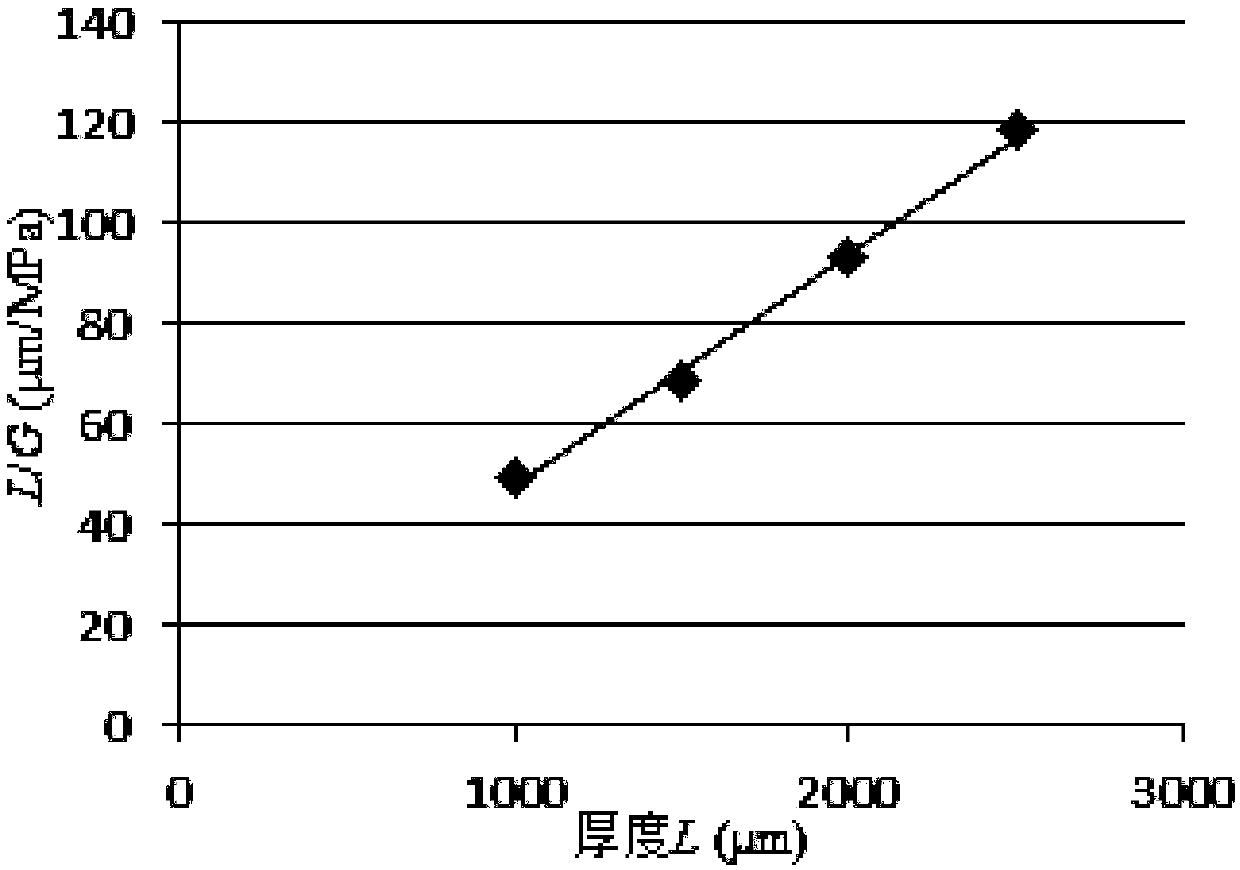

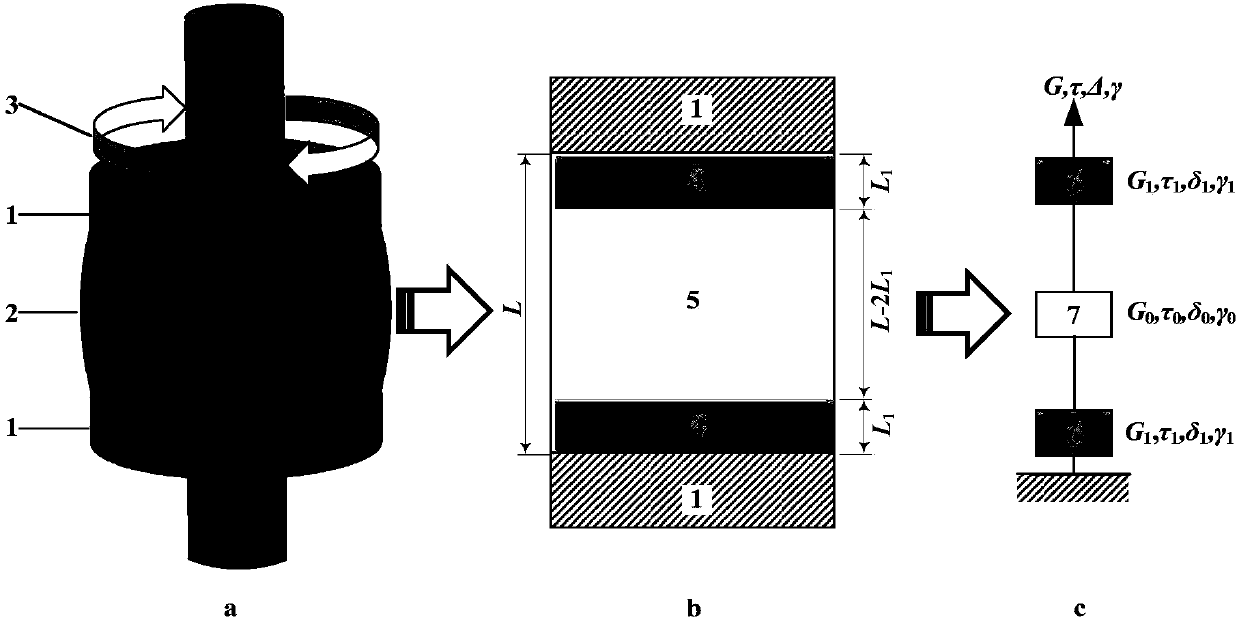

[0057] Specific implementation mode 1: In this embodiment, the dynamic shear complex modulus test method of the bulk asphalt mortar considering the interaction between the substrate and the mortar is carried out according to the following steps:

[0058] 1. Dry the mineral powder in an oven at a temperature of 100°C to 110°C, then place the dried mineral powder and asphalt in an oven at a temperature of 155°C to 165°C, and heat for 4h to 6h to obtain heating mineral powder and heating bitumen;

[0059] 2. Put the heated asphalt in a constant temperature container with a temperature of 155°C to 165°C, and under the condition of a stirring speed of 350r / min to 450r / min, add the heated mineral powder to the heated asphalt in portions, and stir evenly to obtain asphalt mortar;

[0060] 3. Pour the asphalt mortar into the dynamic shear rheology test mold, and obtain the cylindrical original asphalt mortar specimen with a thickness of L' after the mortar specimen in the mold is coo...

specific Embodiment approach 2

[0072] Embodiment 2: This embodiment is different from Embodiment 1 in that: the mineral powder described in step 1 is limestone mineral powder. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0073] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the asphalt described in step one is 70# base asphalt. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com