Mechanical property analysis method of blade and cartridge receiver system under rub-impact fault

An analysis method and technology of mechanical properties, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve the problem of not considering the elastic support of the blade root, and achieve the effect of accurate mechanical properties and improved calculation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

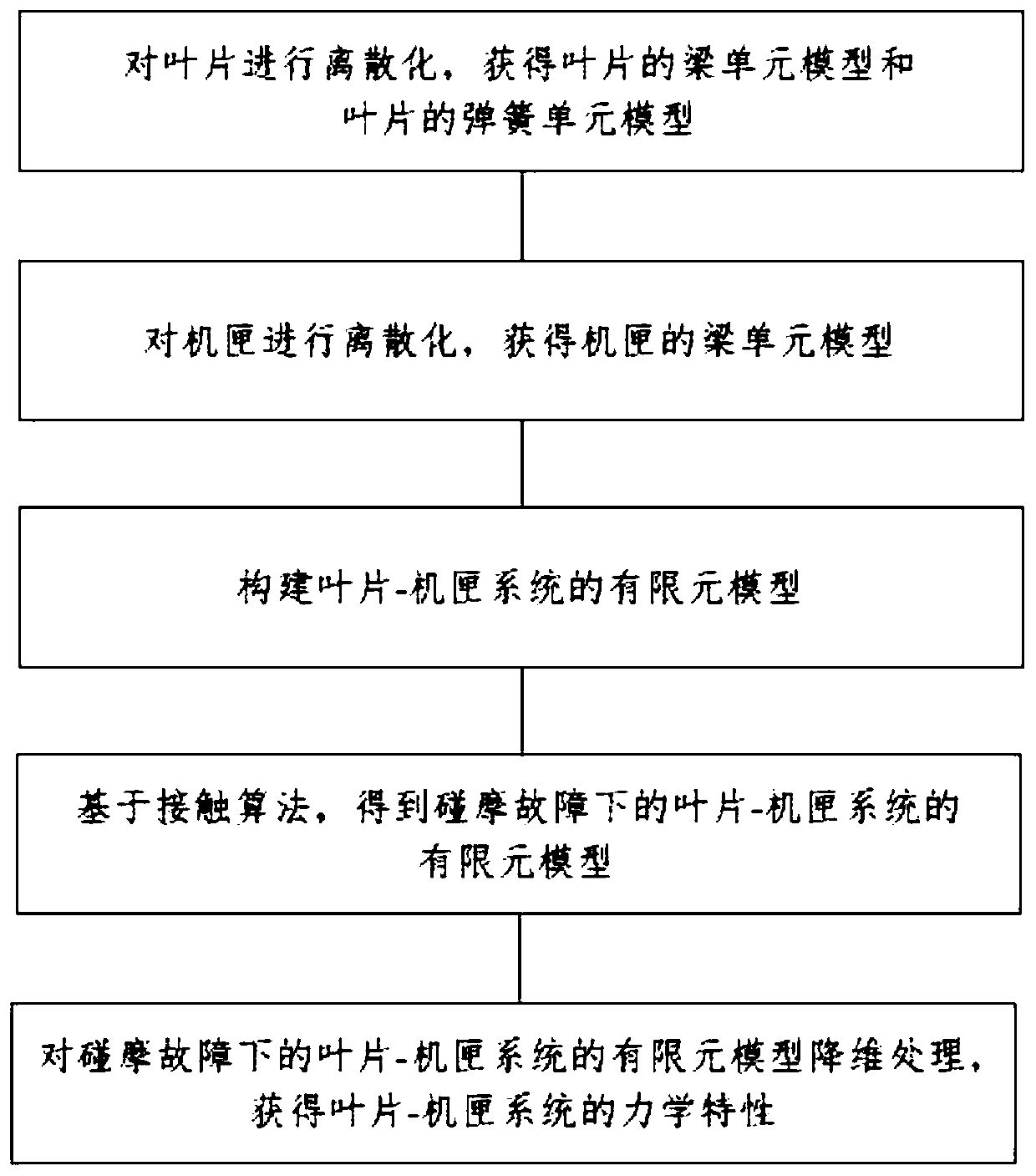

Method used

Image

Examples

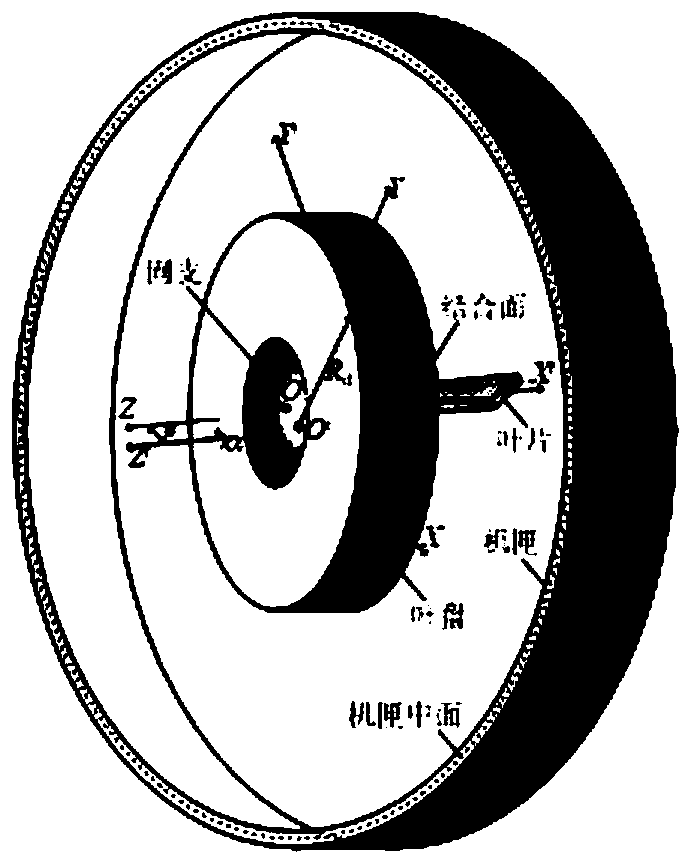

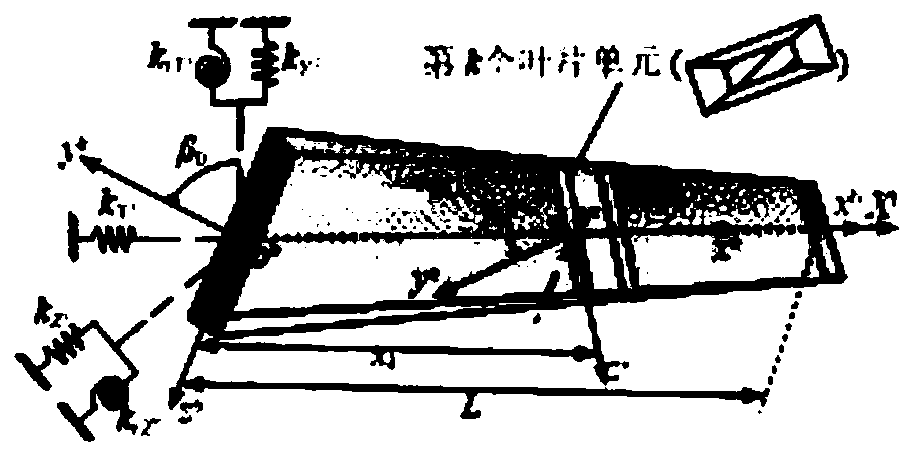

Embodiment Construction

[0069] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below in conjunction with the accompanying drawings and through specific embodiments.

[0070] The letters and their corresponding meanings involved in the present invention are as follows:

[0071] A Tip point

[0072] A 0 blade cross-sectional area

[0073] Projection of A′ onto the intersection of lines BC and OA on the XOY plane

[0074] A″ Final position of A after eliminating immersion

[0075] b 0 ,b c blade root width; casing width

[0076] B,C is the node of the case unit BC in contact with A

[0077] B c,n ,B c,t ,B c,s Contact constraint matrices in the normal, tangential and axial directions, respectively

[0078] C b , C c Damping matrix for blades and casing

[0079] D The damping matrix of the blade-casing system includes the Rayleigh damping matrix and the Coriolis force matrix

[0080] System damping matr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com