Manufacturing method of real rock specimen having through cracks

A technology of rock specimen and manufacturing method, applied in the field of rock specimen manufacturing, can solve the problem of inability to manufacture real rock specimens with transparent cracks, etc., and achieve the effect of accurate mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

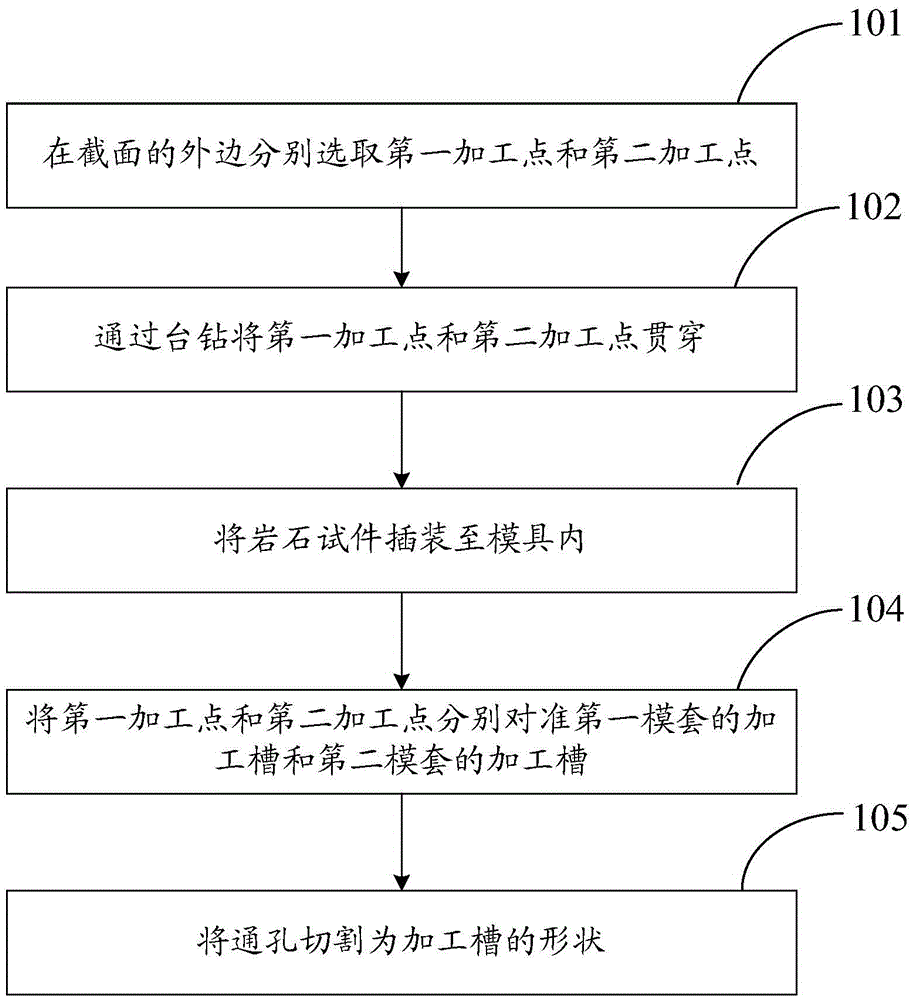

[0036] The embodiment of the present invention provides a method for manufacturing a real rock specimen with transparent cracks, such as figure 1 As shown, the production method includes:

[0037] Step 101: Select a cross section parallel to the bottom surface on the real rock specimen of the cylinder, and select the first processing point and the second processing point on the outside of the cross section, and the connection line between the first processing point and the second processing point Pass through the center of the section.

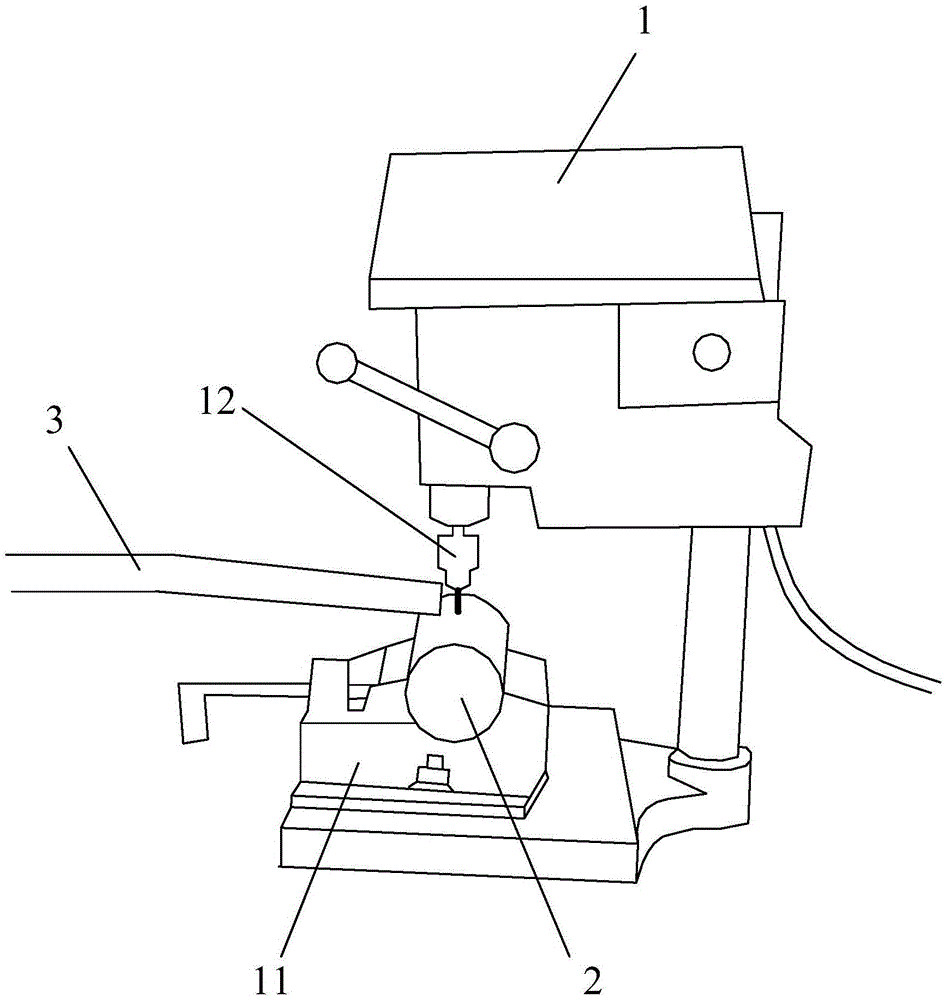

[0038] Step 102: Clamp the real rock test piece on the bench drill, and penetrate the first processing point and the second processing point through the bench drill to form a through hole.

[0039] Step 103: Insert the real rock test piece into the mold, where the mold includes a first mold sleeve and a second mold sleeve. Both the first mold sleeve and the second mold sleeve are provided with processing grooves. The second mold set is used to clamp...

Embodiment 2

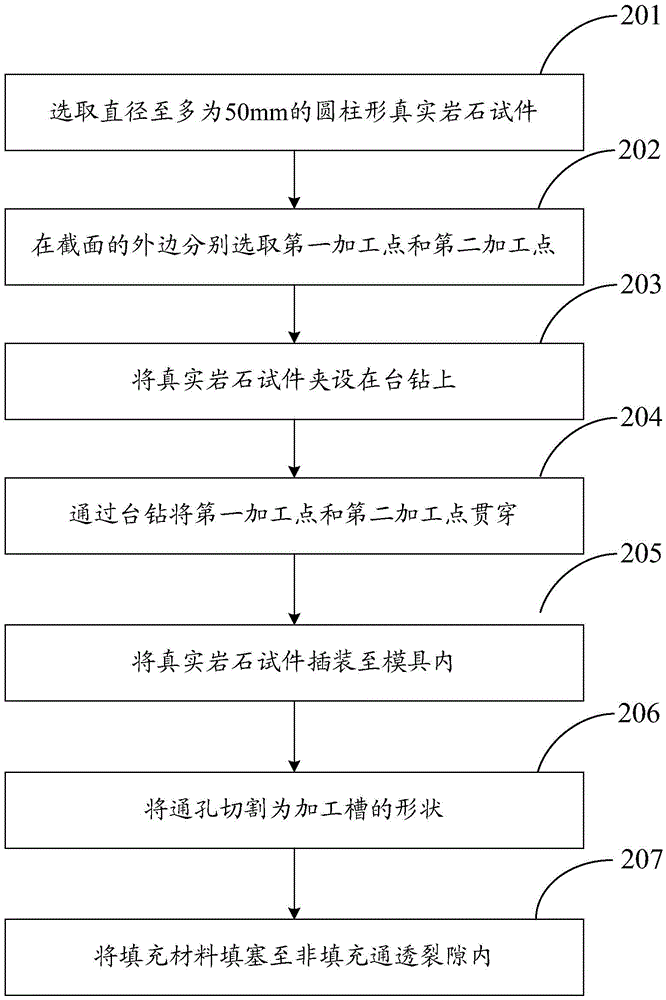

[0044] The embodiment of the present invention provides a method for manufacturing a real rock specimen with filled permeable cracks, see figure 2 , The method includes:

[0045] Step 201: Select a cylindrical real rock specimen with a diameter of at most 50mm. Preferably, the length of the real rock specimen may be 100 mm. It should be noted that in other embodiments, the length of the real rock specimen is not limited to the above-mentioned preferred value, but may also be other resins, which is not limited by the present invention.

[0046] When realizing, real rock specimens can be made by carving and polishing the whole piece of rock. It should be noted that the specific material of the real rock specimen can be changed according to actual needs, and the present invention does not limit this.

[0047] Step 202: Select a cross section parallel to the bottom surface on the real rock specimen of the cylinder, and select the first processing point and the second processing point ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com