Preparation method of M6C type alloy carbide Fe3W3C

A carbide and alloy technology, which is applied in the field of preparation of M6C alloy carbide Fe3W3C, can solve the problems of difficult control and inaccurate performance, and achieve the effects of improving purity, accurate mechanical properties and accurate testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

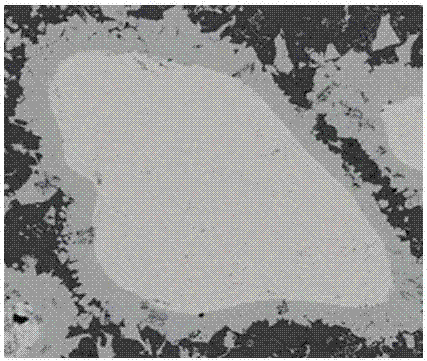

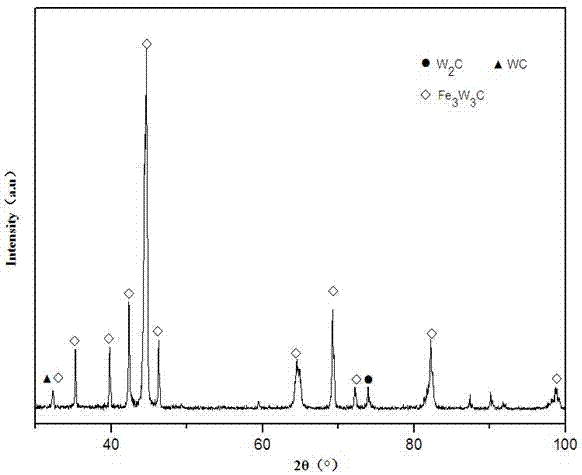

Image

Examples

Embodiment 1

[0026] A kind of M described in this embodiment 6 C-type alloy carbide Fe 3 W 3 The preparation method of C specifically comprises the following steps:

[0027] (1) Weigh the reduced iron powder (purity 99.9%, particle size less than 150 μm) and WC powder (purity 99.9%, particle size less than 150 μm) respectively. The stoichiometric ratio of the two powders is Fe / WC=2:1.

[0028] (2) Powder mixing: use XQM-4L planetary ball mill to mix WC particles and sodium silicate (the mass is 2% of the mass of WC particles) evenly, and the duration of powder mixing is 0.5h, and then Fe powder and WC powder The mixed powder of sodium bicarbonate is mixed with balls, and the duration of powder mixing is 20h. The other conditions of the two ball milling processes are: the mass ratio of balls is 3:1, and the diameters of large and small grinding balls are 12mm and 7mm respectively. Steel balls, the ratio of the number of large grinding balls to small grinding balls is 1:5, and the speed o...

Embodiment 2

[0033] A kind of M described in this embodiment 6 C-type alloy carbide Fe 3 W 3 The preparation method of C specifically comprises the following steps:

[0034] (1) Weigh the reduced iron powder (purity 99.9%, particle size less than 150 μm) and WC powder (purity 99.9%, particle size less than 150 μm) respectively, the stoichiometric ratio of the two powders is Fe / WC=3:1.

[0035] (2) Powder mixing: XQM-4L planetary ball mill is used to mix WC particles and CMC-Na (the mass is 2.5% of the mass of WC particles) evenly. The duration of powder mixing is 1h, and then Fe powder and WC powder are mixed with CMC-Na The mixed powder of Na was mixed by ball milling, and the duration of the powder mixing was 30h. The other conditions of the two ball milling processes were: the mass ratio of the ball to material was 5:1, and the diameters of the large and small balls were 11mm and 8mm respectively. The ratio of the number of steel balls, large grinding balls and small grinding balls i...

Embodiment 3

[0040] A kind of M described in this embodiment 6 C-type alloy carbide Fe 3 W 3 The preparation method of C specifically comprises the following steps:

[0041] (1) Weigh the reduced iron powder (purity 99.9%, particle size less than 150 μm) and WC powder (purity 99.9%, particle size less than 150 μm) respectively, and the stoichiometric ratio of the two powders is Fe / WC=1:1.

[0042] (2) Powder mixing: XQM-4L planetary ball mill is used to mix WC granules and starch (the mass is 3% of the mass of WC granules) evenly, the duration of powder mixing is 1.5h, and then Fe powder, WC powder and starch are mixed The powder is mixed by ball milling, and the duration of the powder mixing is 50h. The other conditions of the two ball milling processes are: the mass ratio of the ball to material is 7:1, and the large and small grinding balls use steel balls with diameters of 10mm and 9mm respectively. The ratio of the number of large balls to small balls is 1:6, and the speed of the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Micro vickers hardness | aaaaa | aaaaa |

| Average width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com