Clamp and method for detecting mechanical property of rolled composite material thermal simulation test sample

A technology for rolling composite materials and test samples, which is applied in the direction of analyzing materials, measuring devices, scientific instruments, etc., can solve the problems of inaccurate test results and inconvenient mechanical property test operations, and achieve wide application range, simple structure and pertinence strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

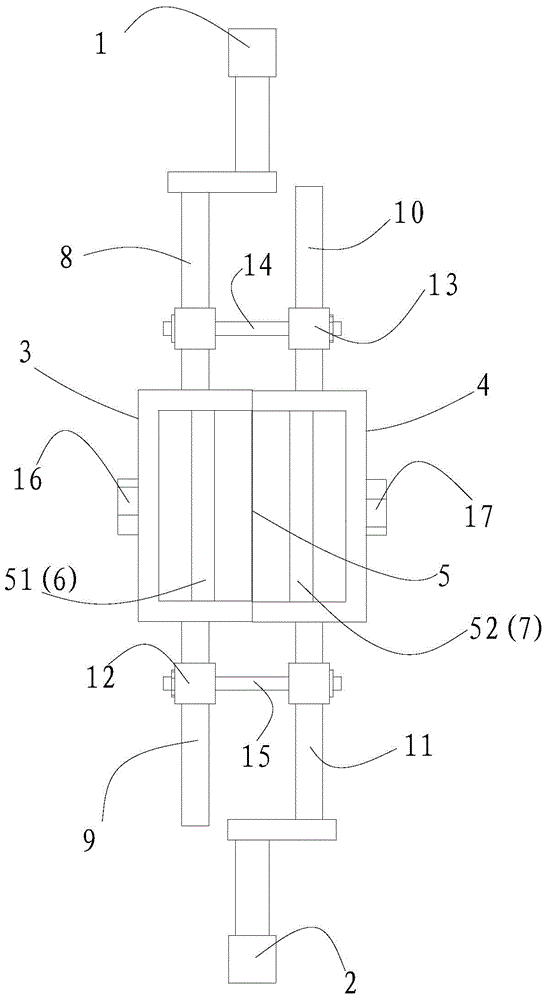

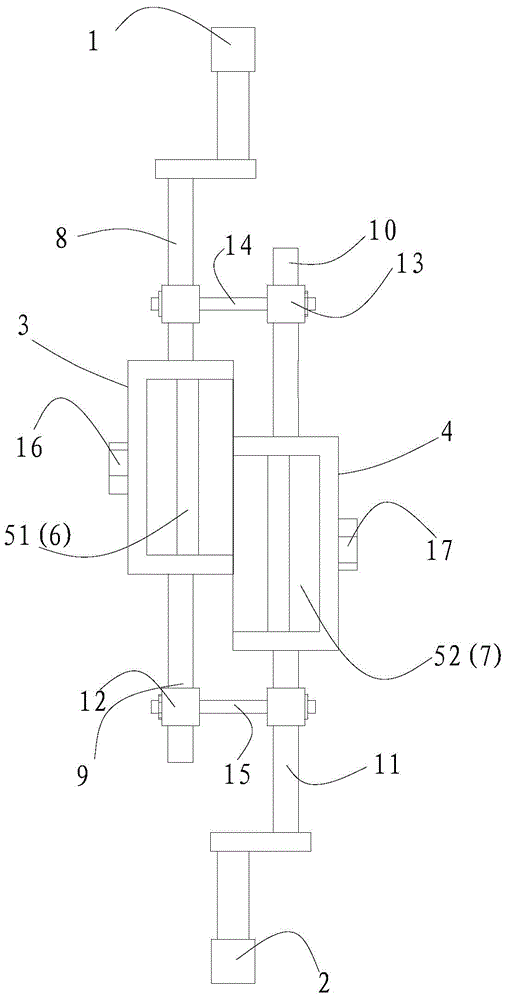

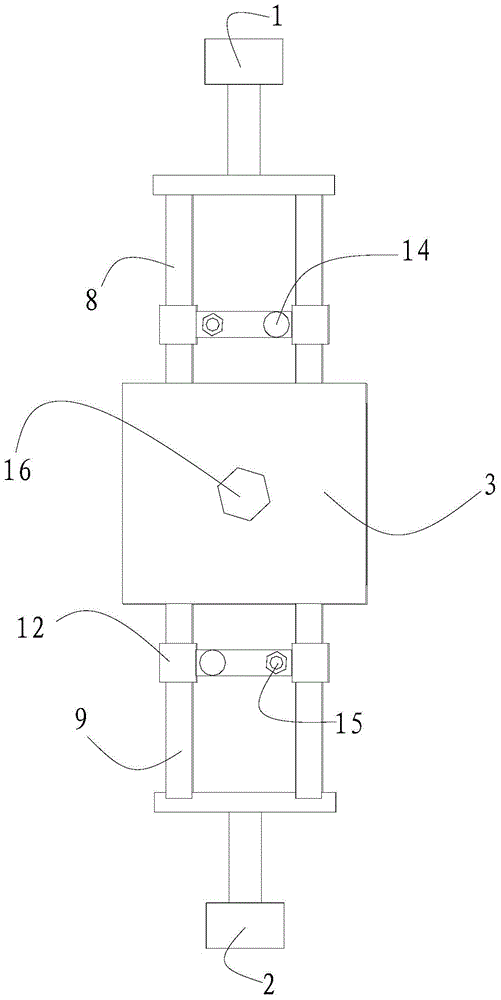

[0021] A fixture for testing the mechanical properties of a thermal simulation test sample of a rolled composite material, comprising a first fixture cover 3 with a first accommodation groove 6 on the side of the middle part, a second fixture cover 4 with a second accommodation groove 7 on the side of the middle part, and The opening of a receiving groove 6 is arranged opposite to the opening of the second receiving groove 7, and a first vertical guide post 8 is provided on the upper end of the first clamp cover 3, and a first vertical guide post 8 is provided on the upper end of the first vertical guide post 8. Collet 1 is provided with a second vertical guide column 9 at the lower end of the first clamp cover 3, a first slide block 12 is sleeved on the second vertical guide column 9, and a second vertical guide column 9 is set at the upper end of the second clamp cover 4. There is a third vertical guide post 10, a second slide block 13 is sleeved on the third vertical guide p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com