Method for preparing alkyd resin for dyed veneers and application thereof

A technology of alkyd resin and wood veneer, which is applied in wood treatment, manufacturing tools, wood processing appliances, etc. It can solve the problems of yellowing and discoloration, easy discoloration, and overall performance not meeting customer requirements, achieving high response speed and communication Effect of joint density, improved safety and controllability, excellent anti-tarnish performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

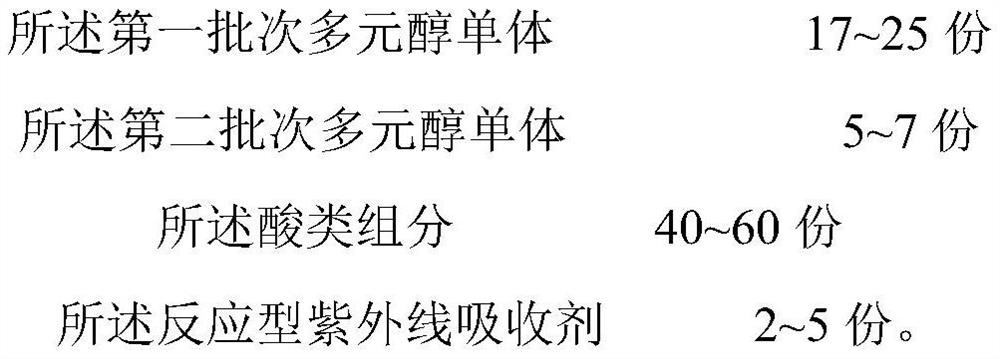

[0038] The raw materials and parts by mass used to prepare the alkyd resin for stained veneer in this implementation are shown in Table 1.

[0039] The raw material composition of the dyed veneer alkyd resin of table 1 embodiment 1

[0040]

[0041]

[0042] Prepare the alkyd resin for stained veneer of the present embodiment according to the following steps:

[0043] 1. Esterification copolymerization reaction.

[0044] (1) take each raw material component by formula quantity, stand-by;

[0045] (2) The polyol components contained in the first batch of polyol monomers, benzotriazole reactive ultraviolet absorbers, hypophosphorous acid, and xylene are sequentially dropped into the reactor, and the temperature is raised to 80°C under the condition of nitrogen gas. Incubate at ±2°C for 1 hour.

[0046] (3) Put isononanoic acid, isooctanoic acid, benzoic acid, phthalic anhydride, maleic anhydride, adipic acid into the reaction kettle successively, continue to heat up und...

Embodiment 2

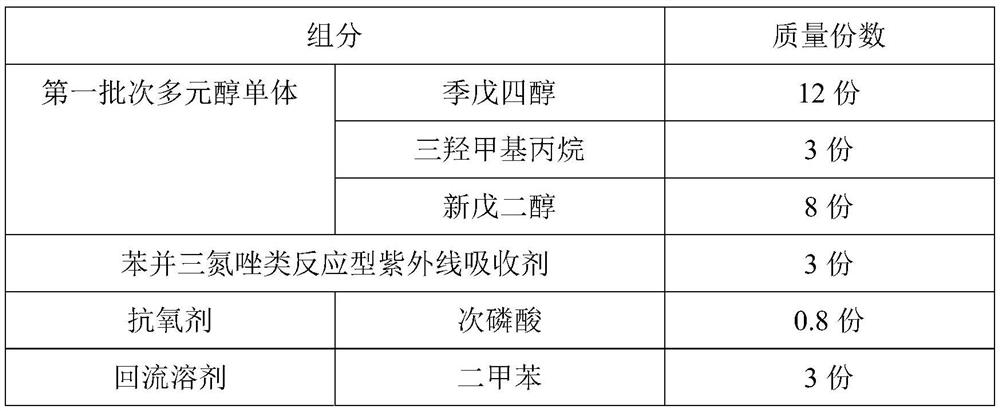

[0053] The raw materials and parts by mass used to prepare the alkyd resin for stained veneer in this implementation are shown in Table 2.

[0054] The raw material composition of the dyed veneer alkyd resin of table 2 embodiment 2

[0055]

[0056] Prepare the alkyd resin for stained veneer of the present embodiment according to the following steps:

[0057] 1. Esterification copolymerization reaction.

[0058] (1) take each raw material component by formula quantity, stand-by;

[0059] (2) The polyol component contained in the first batch of polyol monomers, benzotriazole reactive ultraviolet absorbers, hypophosphorous acid, phosphite antioxidants, and xylene are sequentially dropped into the reactor, Raise the temperature to 80±2°C for 1 hour under nitrogen gas.

[0060] (3) Isononanoic acid, lauric acid, benzoic acid, phthalic anhydride, maleic anhydride, and adipic acid are dropped into the reactor successively, and the temperature is raised under the situation of c...

Embodiment 3

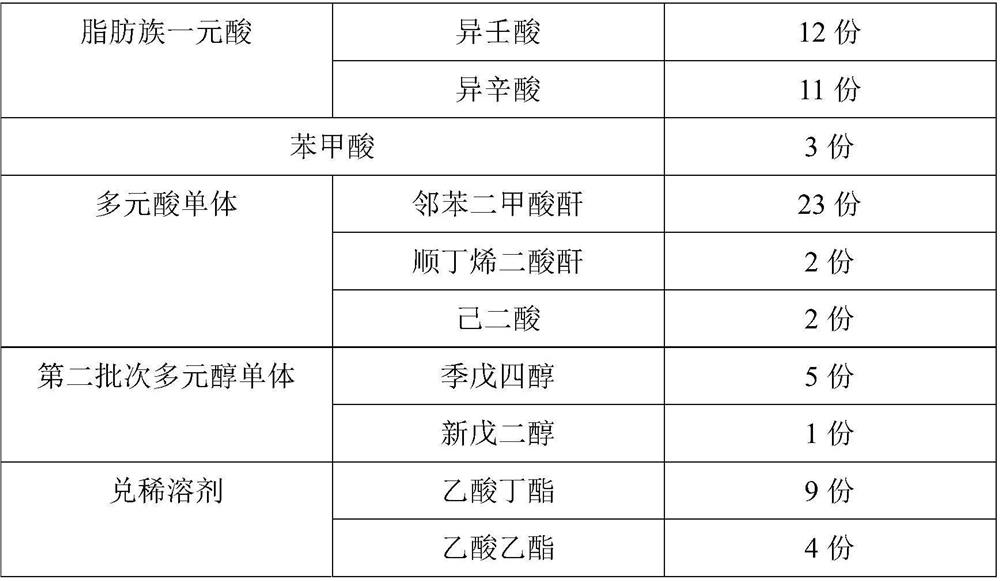

[0067] The raw materials and parts by mass used to prepare the alkyd resin for stained veneer in this implementation are shown in Table 3.

[0068] The raw material composition of the dyed veneer alkyd resin of table 3 embodiment 3

[0069]

[0070]

[0071] Prepare the alkyd resin for stained veneer of the present embodiment according to the following steps:

[0072] 1. Esterification copolymerization reaction.

[0073] (1) take each raw material component by formula quantity, stand-by;

[0074] (2) The polyol component contained in the first batch of polyol monomers, benzotriazole reactive ultraviolet absorbers, phosphite antioxidants, polybasic hindered aminophenol antioxidants, and xylene are sequentially Put it into the reaction kettle, and raise the temperature to 80±2°C for 1 hour under the condition of blowing nitrogen.

[0075] (3) lauric acid, stearic acid, coconut oleic acid, benzoic acid, phthalic anhydride, maleic anhydride, adipic acid are dropped into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com