A kind of sulfone polymer composition and its preparation method and thermoplastic molding composition composed of it

A polymer and composition technology, applied in the field of thermoplastic molding compositions, can solve the problems such as the unresearched influence of the color and transparency of the residual monomer of the salt-forming agent, the color influence is not clearly announced, and the chlorine content is low in PPSU. Reduced polymerization time, improved clarity and color, reduced content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

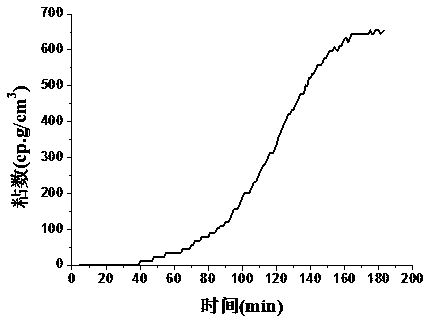

[0040] Add 7.508kg (30mol) of 4,4'-dihydroxydiphenylsulfone, 8.787kg (30.6mol) of 4,4 '-Dichlorodiphenyl sulfone, then add 32.62kg of sulfolane, stir and heat up to 100°C to dissolve the monomer until the solution is transparent, 3.396kg (32.039mol) salt-forming agent Na 2 CO 3 and 132.6g (0.961mol) salt-forming agent K 2 CO 3 , then add 2L of xylene, continue to stir and heat up until the salt-forming reaction begins, the azeotrope formed by the water produced in the system and xylene is blown out by the protective gas into the condenser, condensed and dropped to the water separator for stratification, the upper layer Xylene was refluxed into the system again; maintain the temperature in the range of 200°C-210°C, when the collected water was close to the theoretical value (540g), continue to reflux for another 20 minutes, no water drops were observed, proving that the salt formation was complete, and then Distill and release xylene, gradually heat up to 230°C to start the ...

Embodiment 2

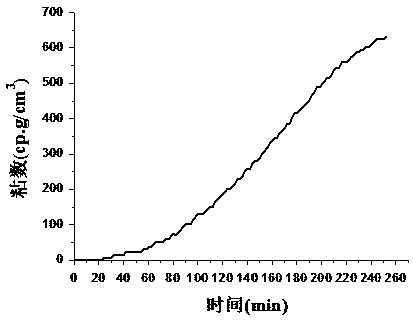

[0042] Among them, add 3.446kg (32.512mol) salt-forming agent Na 2 CO 3 and 67.4g (0.488mol) salt-forming agent K 2 CO 3 , the rest are the same as in Example 1. After 3 hours at constant temperature, the viscosity of the system is completely constant. Polyethersulfone PES was obtained after the polymer was dried, and the performance test results are shown in Table 1.

Embodiment 3

[0044] Among them, then add 3.412kg (32.195mol) salt-forming agent Na 2 CO 3 and 111.242g (0.805mol) salt-forming agent K 2 CO 3 , the rest are the same as in Example 1. After 3.5 hours at constant temperature, the viscosity of the system is completely constant. Polyethersulfone PES was obtained after the polymer was dried, and the performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

| yellowness index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com