Electric arc method for exciting ultrasonic waves

An ultrasonic and electric arc technology, which is applied in the field of melting and non-melting electrode arc welding and metal arc smelting, to achieve the effect of improving welding or smelting effect, real-time parameters, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, describe content of the present invention in detail:

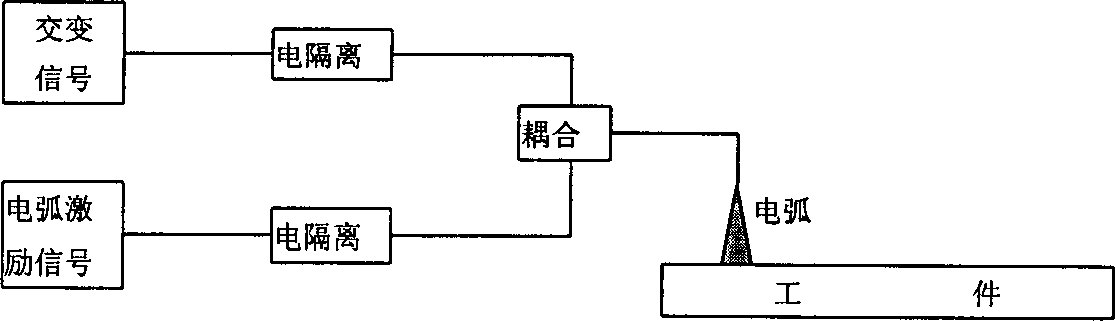

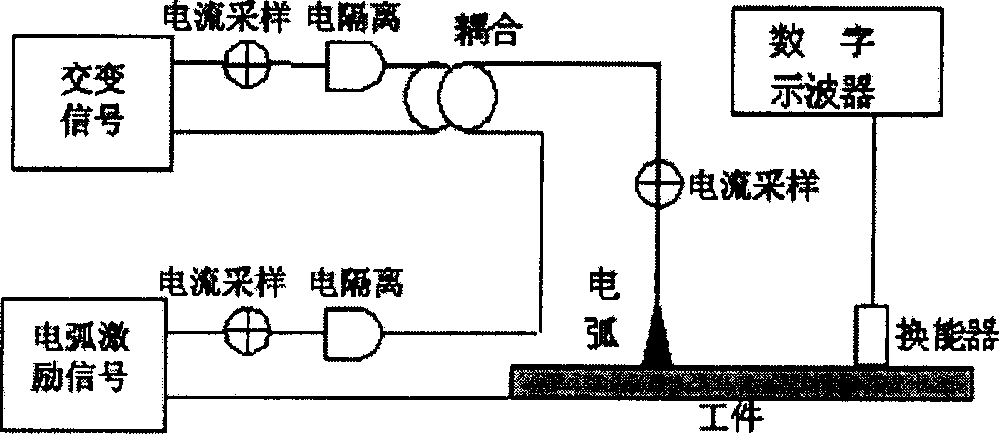

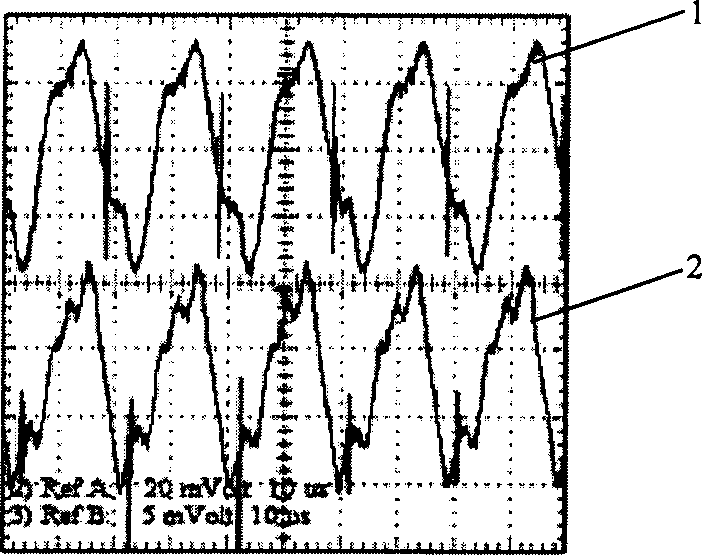

[0017] The alternating signal used to excite the arc to generate ultrasonic waves is pressed figure 2 The method shown is coupled into the melter arc excitation signal. The alternating signal generating device used to excite the arc to generate ultrasonic waves is composed of a signal generating circuit, a power amplifier driving circuit, a high-speed high-power switch tube and a corresponding coupling device, which can generate alternating signals with a frequency ranging from several thousand cycles to one megacycle, and can The frequency and amplitude of the signal can be flexibly adjusted. Adjust the power of the alternating signal to 0W, 100W, and the frequency to 30kHz, 50kHz, and 80kHz respectively. Then, the welding is performed according to the conventional arc welding method, and the welding arc excites ultrasonic waves. The ultrasonic wave acts on the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com