Insulation systems for covering facades of buildings

A technology for isolation systems and buildings, applied in the field of isolation systems, can solve problems such as poor acceptance, heavy isolation board weight, and increased isolation system prices, and achieve good isolation characteristics and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

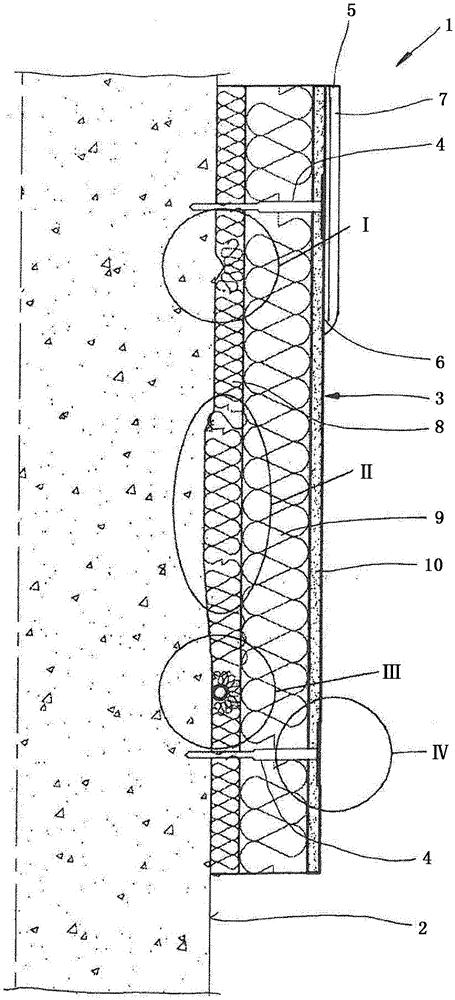

[0045] figure 1 A part of an insulation system 1 for covering a facade 2 of a building is shown. The isolation system consists of several isolation elements 3, of which only one isolation element 3 is in figure 1 shown in . The spacer elements 3 are fixed to the façade 2 only with mechanical fasteners 4 . These mechanical fasteners 4 will be described later.

[0046] Moreover, the isolation system is composed of a plastering system 5, which is only figure 1 The center is partially shown and consists of a base coat 6 and a finish coat 7 . The rendering system 5 is mortar based and can be modified with binder resins.

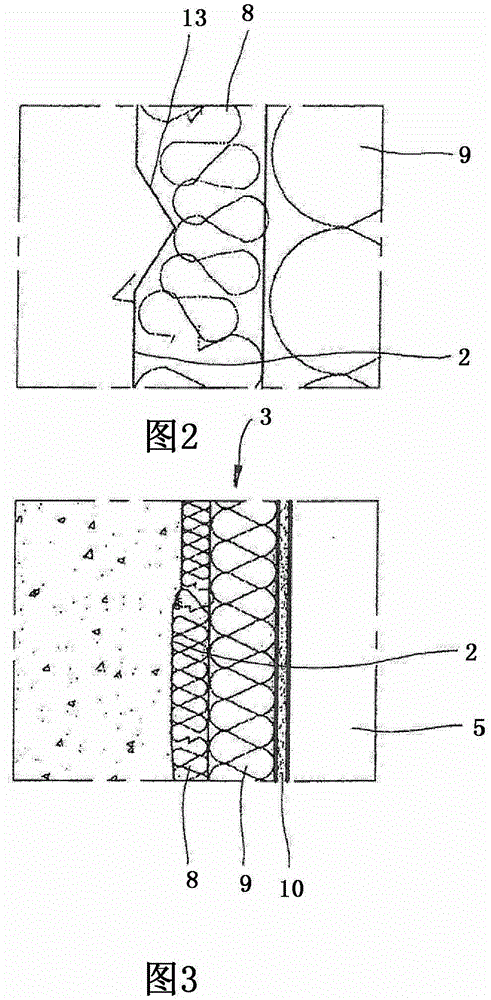

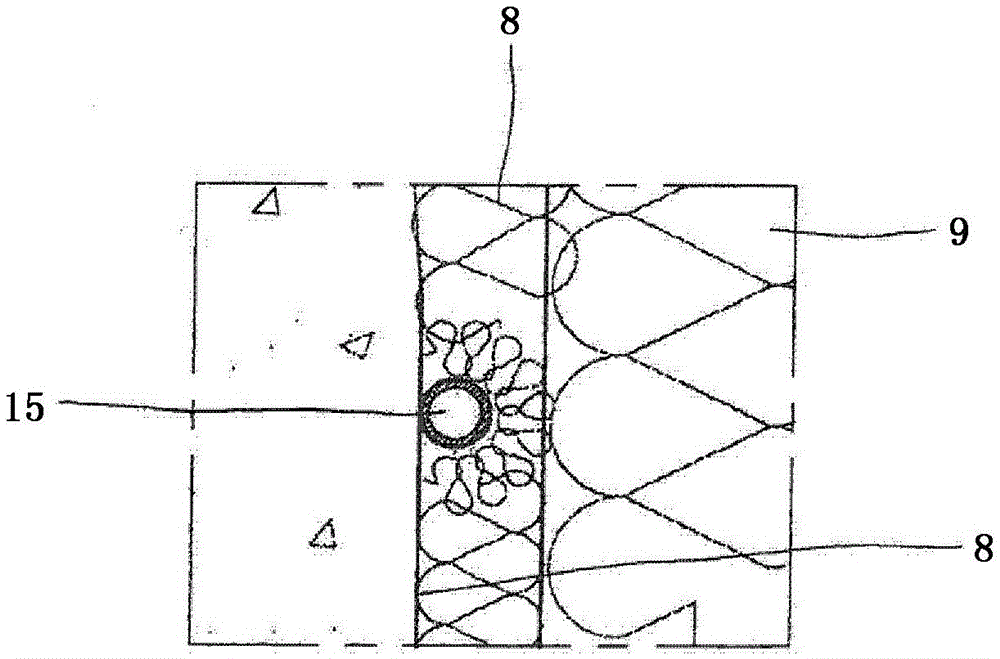

[0047] The insulating element 3 consists of a first layer 8 , a second layer 9 arranged on the first layer 8 and a third layer 10 arranged on the second layer 9 . The third layer 10 is made of mineral fibers and a binder and has a bulk density greater than that of the second layer 9, which is made of mineral fibers and a binder. The bulk density of the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com