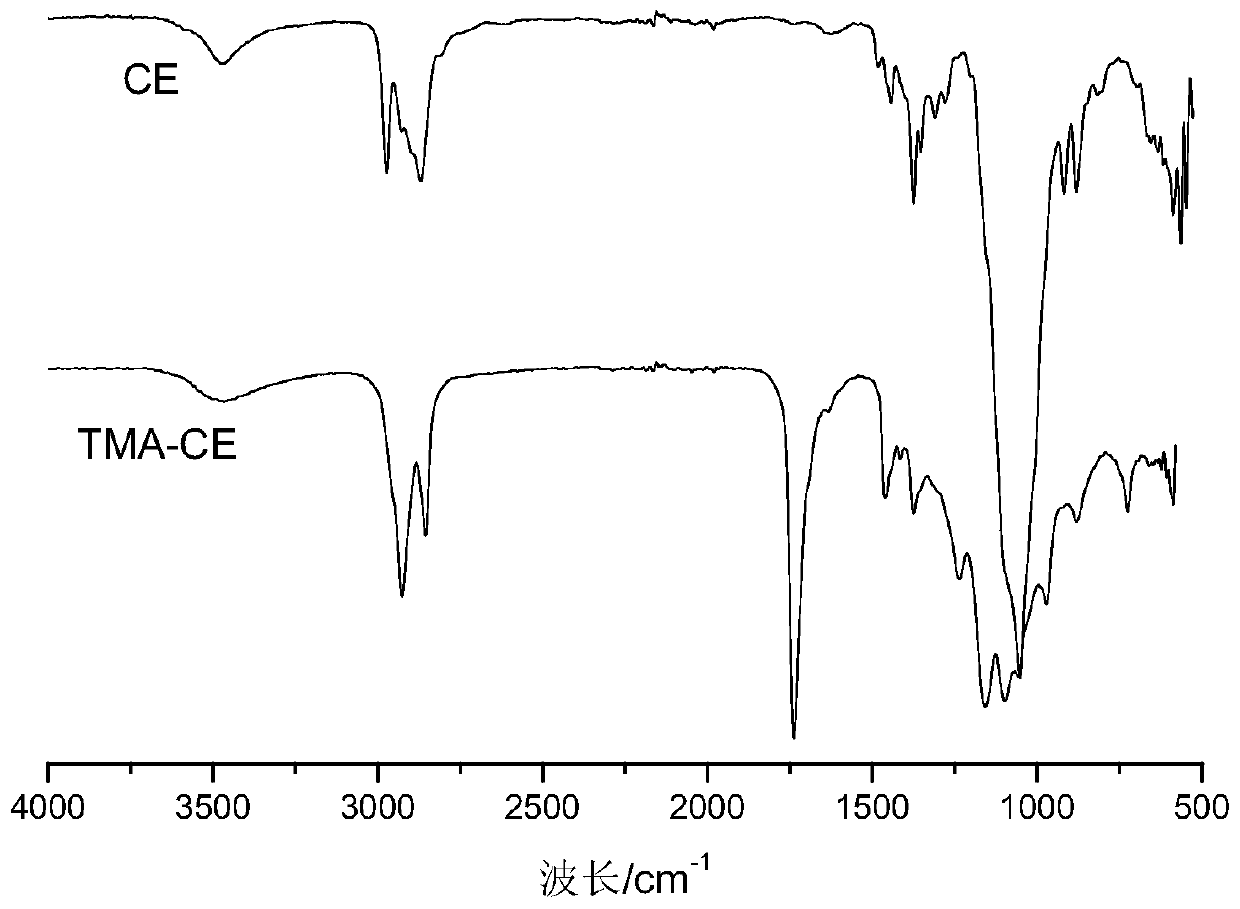

A kind of tung oil modified ethyl cellulose membrane and preparation method thereof

A technology of ethyl cellulose and modification, which is applied in the field of materials, can solve the problems of low wrinkle resistance and poor toughness of ethyl cellulose film, and achieve the effects of controllable flexibility, simple synthesis and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

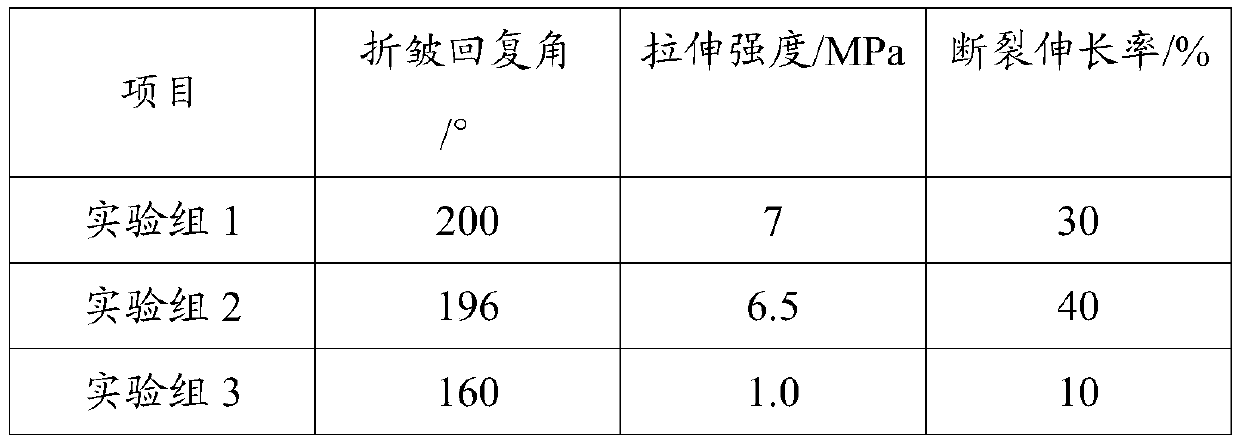

Embodiment 1

[0014] Add methyl chelate to the reaction container, then add maleic anhydride according to the molar ratio of 1:1.1 between methyl licate and maleic anhydride, react at a constant temperature of 180°C, stir for 2.0h, after the reaction is completed, raise the temperature to Extract the unreacted maleic anhydride under reduced pressure at 200°C. After the extraction is complete, TMA is obtained; weigh ethyl cellulose in a reaction vessel, and then add it according to the mass ratio of ethyl cellulose / glacial acetic acid of 1:17 With glacial acetic acid, raise the temperature to 60°C, keep stirring for 6 hours, after the ethyl cellulose is completely dissolved, cool to room temperature to obtain the ethyl cellulose solution; add TMA and 0.1% hydroquinone to the reaction vessel According to the molar ratio of TMA to ethylcellulose 0.1:1, ethylcellulose solution was added, and when heated to 120°C, anhydrous sodium acetate was added thereto in an equimolar amount to TMA, and the r...

Embodiment 2

[0016] Add methyl chelate to the reaction container, then add maleic anhydride according to the molar ratio of 1:1 between methyl lyceate and maleic anhydride, react at a constant temperature of 175°C, stir for 2.5h, after the reaction is completed, raise the temperature to Extract the unreacted maleic anhydride under reduced pressure at 210°C. After the extraction is complete, TMA is obtained; weigh ethyl cellulose in a reaction vessel, and then use ethyl cellulose / glacial acetic acid at a mass ratio of 1:12 glacial Acetic acid, heat up to 65°C, keep stirring for 5h, after ethylcellulose is completely dissolved, cool to room temperature to obtain ethylcellulose solution; mix TMA and 0.05% di-tert-butylhydroquinone Add it into the reaction vessel, then add the ethyl cellulose solution according to the molar ratio of TMA to ethyl cellulose 0.5:1, when heated to 110°C, add anhydrous sodium acetate which is equal to the molar number of TMA, and stir for 5 hours. After the reactio...

Embodiment 3

[0018] Add methyl chelate to the reaction container, then add maleic anhydride according to the molar ratio of 1:1.2 between methyl licate and maleic anhydride, react at a constant temperature of 178°C, stir for 1.5h, after the reaction is completed, raise the temperature to Extract the unreacted maleic anhydride under reduced pressure at 205°C. After the extraction is complete, TMA is obtained; weigh ethyl cellulose in a reaction vessel, and then add it according to the mass ratio of ethyl cellulose / glacial acetic acid of 1:15 Glacial acetic acid, heat up to 55-65°C, keep stirring for 7 hours, after the ethyl cellulose is completely dissolved, cool to room temperature to obtain the ethyl cellulose solution; add TMA and 0.06% hydroquinone In the reaction vessel, ethyl cellulose solution was added according to the molar ratio of TMA to ethyl cellulose 0.2:1, and when heated to 118°C, anhydrous sodium acetate was added thereto in an equimolar amount to TMA, and the reaction was s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com