Smelting furnace of non-ferrous metals oxygen side blow fused bath

A molten pool smelting furnace, non-ferrous metal technology, applied in the direction of lighting and heating equipment, etc., can solve problems such as unsuitable copper concentrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

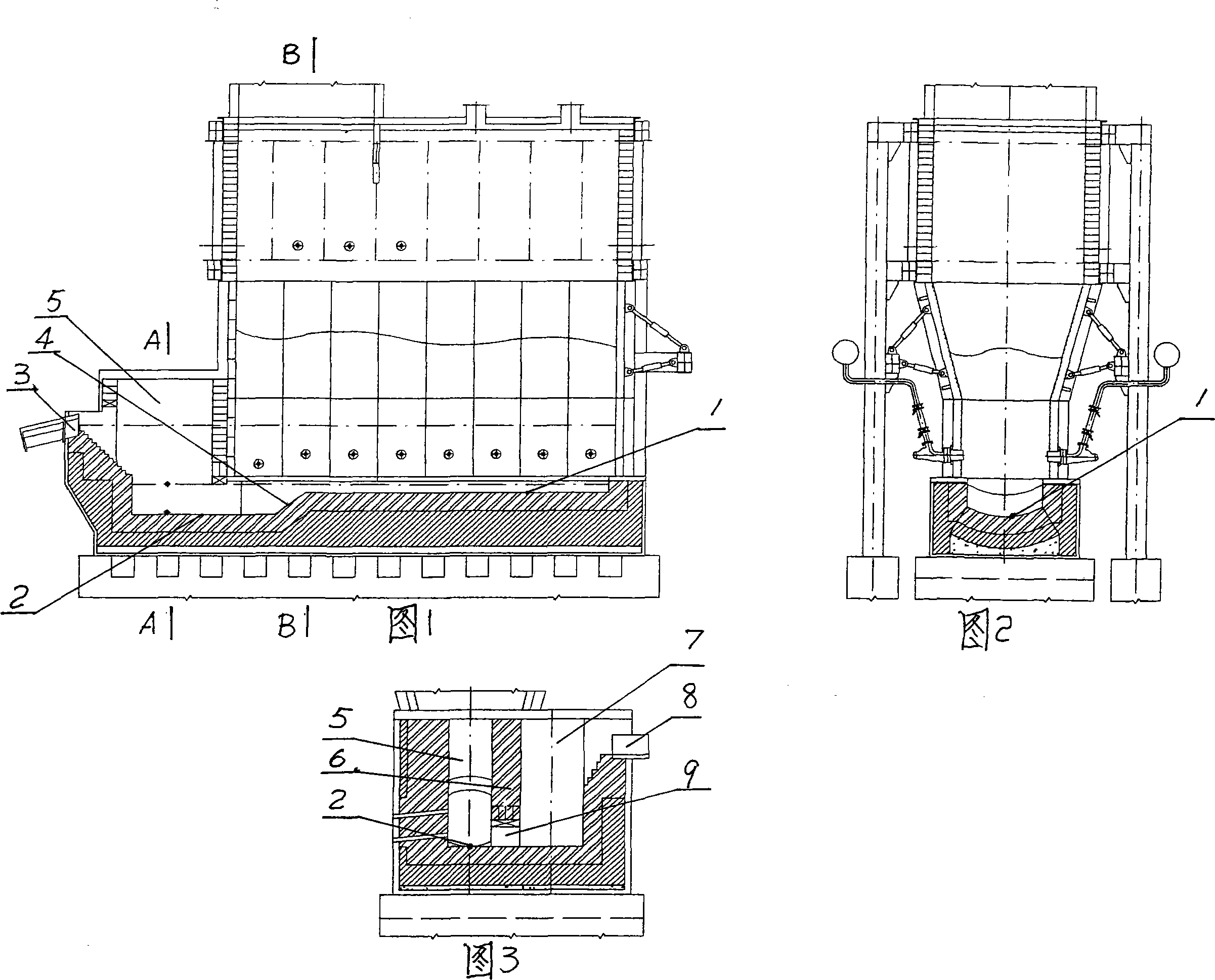

[0005] The present invention is described in detail in conjunction with the above drawings. The oxygen side-blowing direct lead smelting furnace disclosed in the 032462131 utility model patent adopts a high and a low furnace bottom 1, 2 and the inclined bottom 4 between them. There is a lead discharge port at the siphon well, and there is an oblique channel between the lead liquid discharge port and the bottom of the siphon well. This structure is more suitable because the melting point of lead is low. But for the non-ferrous metals whose melting point is up to thousands of degrees, such as copper and copper alloys, etc., this lead port and the slag port 3 share a siphon well and cannot effectively separate from the slag. In order to solve this problem, the present invention has made the following improvements on the structural basis of the above-mentioned utility model patent. A partition wall 6 is set in the original siphon well 5, forming two siphon wells 5, 7, which are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com