Titanium clinker for smelting high-titanium slag

A high-titanium slag and clinker technology, applied in the field of titanium clinker, can solve the problems of high energy consumption and environmental pollution, and achieve the effects of good air permeability, elimination of environmental pollution, and reduction of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The present invention is a new type of raw material that can be used in the smelting process of high titanium slag to produce high titanium slag, which is formed by the following substances in mass ratio:

[0029] Titanium concentrate: 60% to 80%;

[0030] Coke powder: 10% to 30%;

[0031] Bentonite: 5% to 15%;

[0032] Wherein, the bentonite described in this embodiment is sodium bentonite.

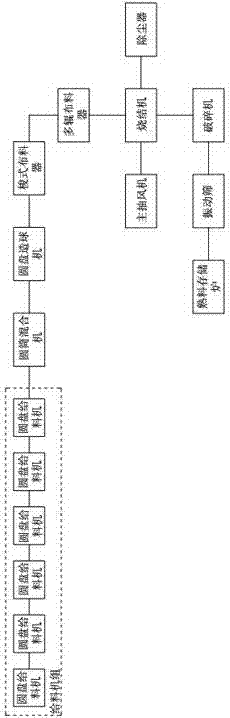

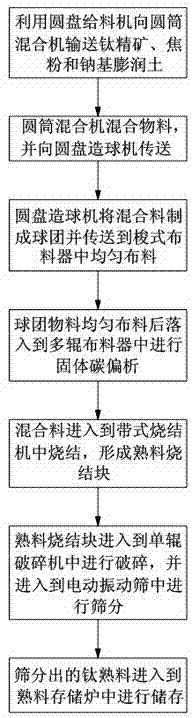

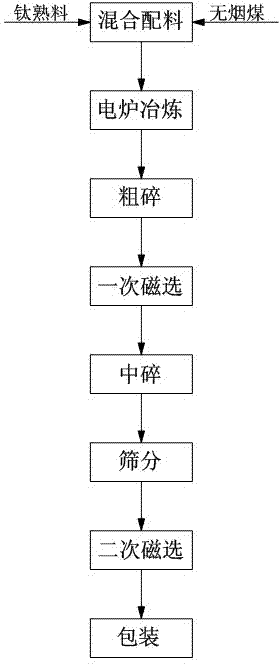

[0033] Prepare the hardware equipment that the present invention adopts such as figure 1 As shown, it includes a feeding unit, a cylinder mixer, a disc pelletizer and a shuttle distributor connected in sequence by a belt conveyor. The melting device located under the shuttle distributor is arranged on the shuttle distributor. A multi-roll distributor arranged obliquely between the burner and the melting device, a crusher connected to the melting device, a vibrating screen connected to the crusher, and a clinker storage furnace connected to the vibrating screen, wherein, The fe...

Embodiment 2

[0053] The difference from Example 1 is that in this example, the ratios of titanium concentrate, coke powder and sodium bentonite are 70%, 20% and 10% respectively. The preparation process of this embodiment is consistent with that of Embodiment 1.

[0054] As in Example 1, under the conditions of producing high titanium slag with the same output (one furnace), the experimental results of this example are shown in Table 3:

[0055] experimental project The high titanium slag smelting process uses titanium clinker as raw material to produce high titanium slag Power consumption (°) 1550 Coal consumption (KG) 120 Smelting time (min) 22

[0056] table 3

[0057] As can be seen from the comparison of Table 3 and Table 2, the ratio of the present embodiment is used to make titanium clinker, and it is used to smelt high-titanium slag, which also greatly reduces energy consumption and greatly saves operating costs. The slag smelting process uses th...

Embodiment 3

[0059] The difference from Example 1 is that in this example, the ratios of titanium concentrate, coke powder and sodium bentonite are 70%, 15% and 15% respectively. The preparation process of this embodiment is consistent with that of Embodiment 1.

[0060] As in Example 1, under the condition of producing high titanium slag with the same output (one furnace), the experimental results of this example are shown in Table 4:

[0061] experimental project The high titanium slag smelting process uses titanium clinker as raw material to produce high titanium slag Power consumption (°) 1538 Coal consumption (KG) 124 Smelting time (min) 24

[0062] Table 4

[0063] As can be seen from the comparison between Table 4 and Table 2, adopting the ratio of this embodiment to make titanium clinker, and using it to smelt high-titanium slag also greatly reduces energy consumption, and greatly saves operating costs, while high-titanium slag The slag smelting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com