Preparation of hollow nanosilica white sphere

A nano-silicon oxide, hollow technology, applied in the direction of silicon oxide, silicon dioxide, etc., can solve the problems of difficult to obtain hollow nano-silicon oxide balls, time-consuming, complicated preparation process, etc., and achieve simple operation, low energy consumption, and synthetic method simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A method for preparing hollow nano-silica spheres, the specific preparation steps are as follows:

[0033] 1) Dissolving the structure directing agent, water and inorganic electrolytes of different concentrations to form a clear solution I;

[0034] 2) Add the silicon source precursor to solution I under vigorous stirring, stir the mixture at 12-40°C for 10-48 hours, transfer the mixture into a reaction kettle, and conduct hydrothermal crystallization at 60-120°C for 24-48 hours;

[0035] 3) The product is filtered and washed with water until the filtrate is clarified and then dried at room temperature;

[0036] 4. The structure-directing agent of the obtained product was extracted with a mixed solution of ethanol and HCl at 60-70° C. for 6 hours. Add 200 mL of ethanol and 2 g of concentrated hydrochloric acid to 1 g of the product to obtain the product of the present invention.

Embodiment 1

[0038] Under stirring at 20°C, dissolve 0.8g of F127 in 28mL of 0.04M NaH 2 PO 4 -Na 2 HPO 4 Buffer solution (pH=6.86), after the solution is clarified, add 2.7g (MeO) 3 SiCH 2 CH 2 Si(OMe) 3 , and aged at 20°C for 24h with stirring. The obtained mother liquor was transferred to the reactor for crystallization at 100°C for 24h. After the product was filtered, washed with water and dried, it was extracted with a mixed solution of absolute ethanol and HCl at 70°C for 24 hours. After the product was filtered and dried, a white lumpy light solid was obtained.

[0039] Respectively using FEI Tecnai G 2 Spirit transmission electron microscope (TEM) and ASAP2020 specific surface analyzer of Mike Company of the United States were used to characterize the samples.

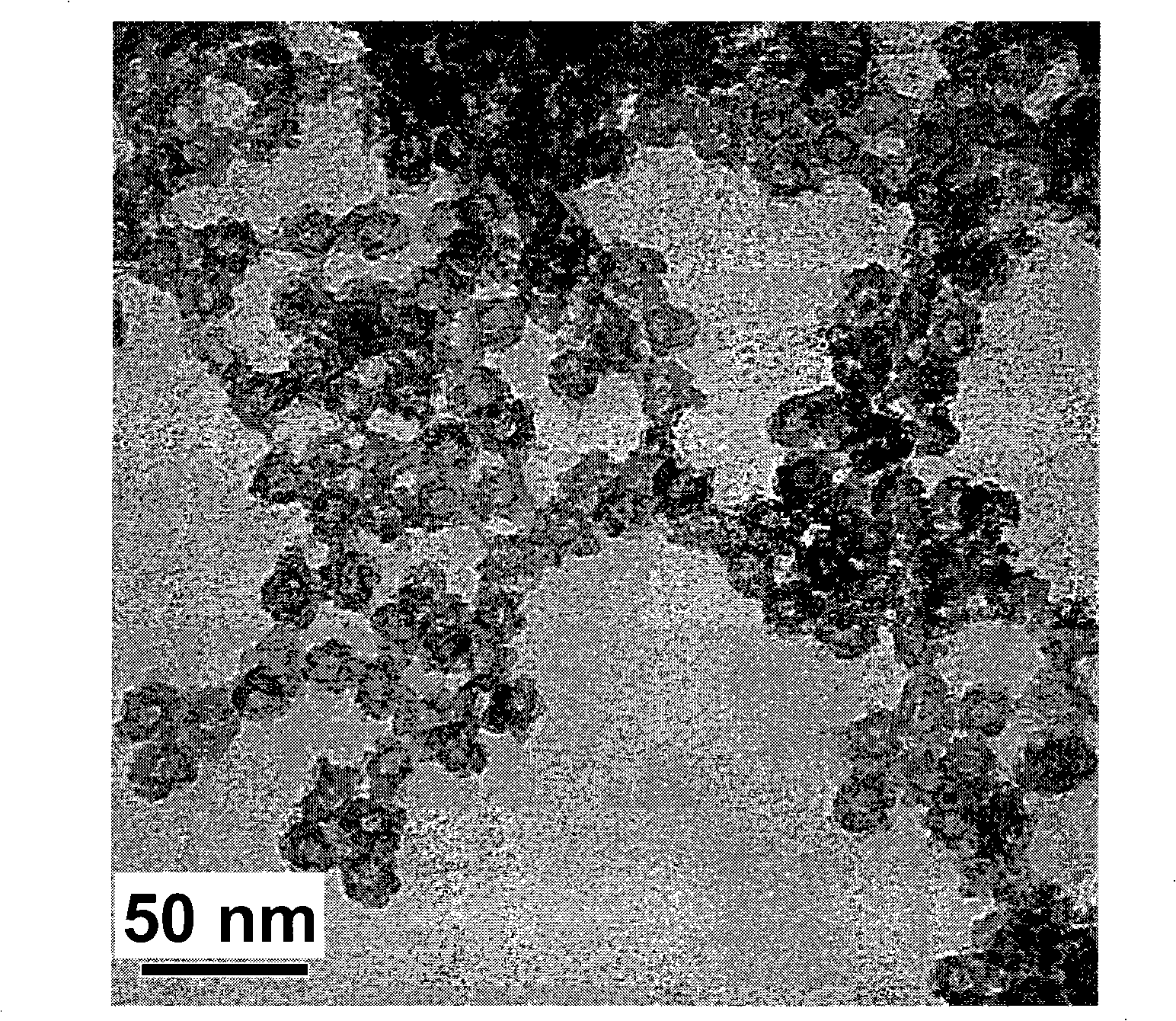

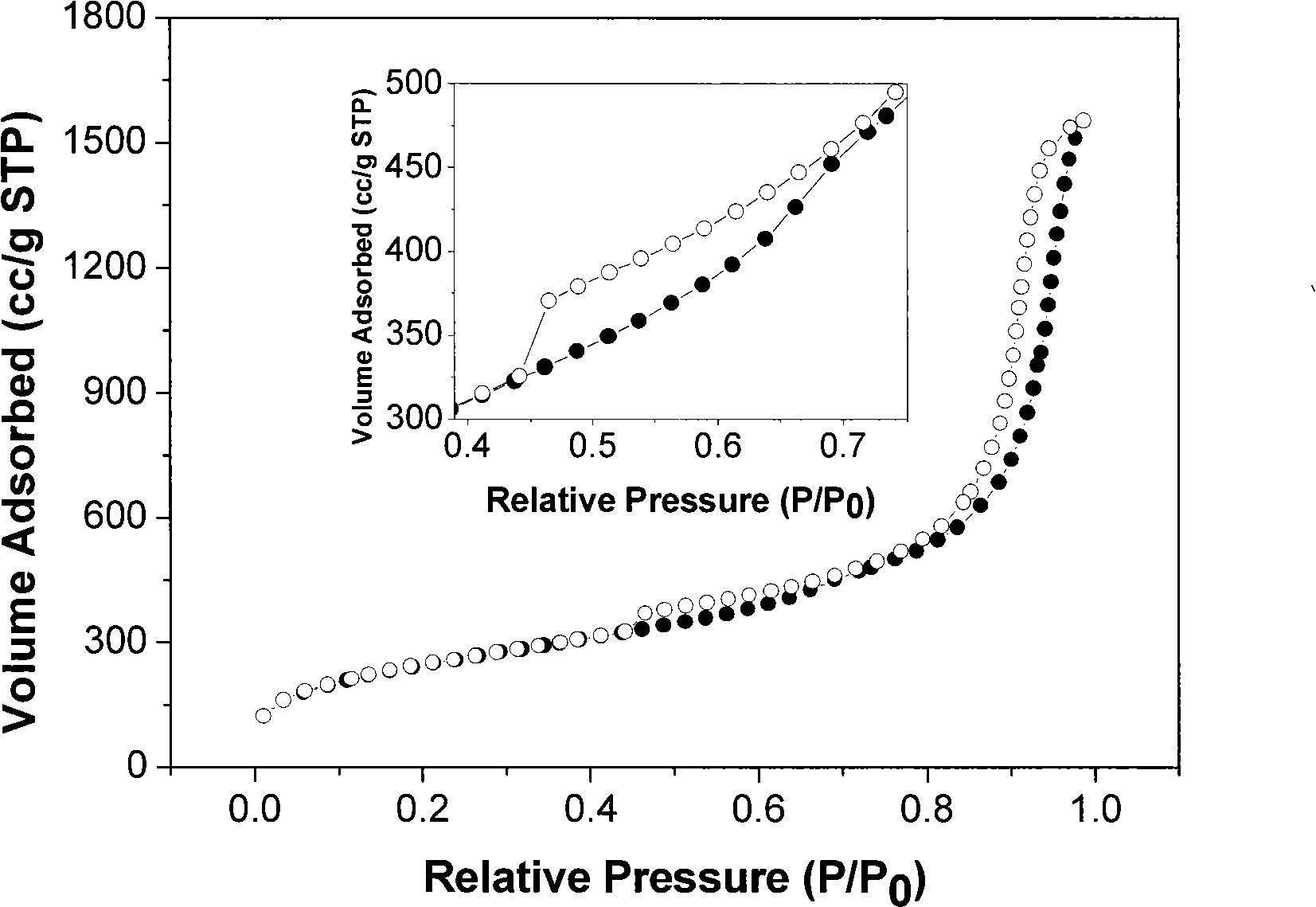

[0040] figure 1 The transmission electron microscope (TEM) photo of the product obtained in the present embodiment 1 is provided; TEM result shows that the product obtained is a hollow nanosphere with uniform pa...

Embodiment 2

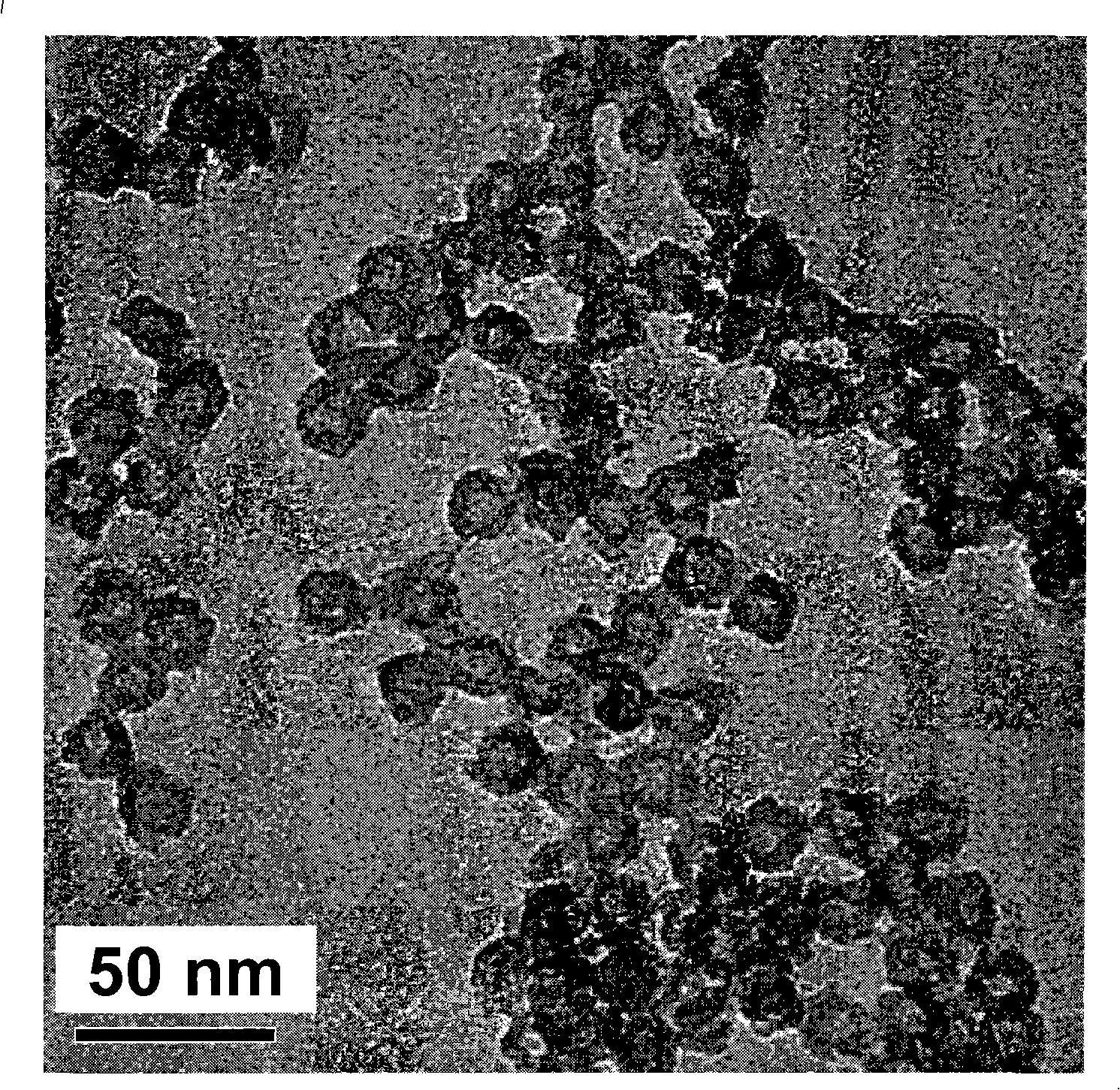

[0042] Adopt the preparation process of embodiment 1, its difference is that, add 1.08g (MeO) 3 SiCH 2 CH 2 Si(OMe) 3 as a silicon source. A white lumpy light solid was obtained. The representation method is the same as above. TEM results show that the obtained product is a hollow nanosphere with uniform particle size and good dispersion; the size of the hollow nanosphere is 15nm, the inner diameter is 8nm, and the wall thickness is 7nm. The BET specific surface area of the material is 969m 2 g -1 ; Pore volume is 2.91cm 3 g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com