Laterite briquetting device for wrapped nickel alloy

A technology of nickel alloy and laterite ore, which is applied in the field of nickel alloy, can solve the problems of ore powder scattered inside the smelting furnace, the outer part of the ore powder group is loose, and cannot be effectively enriched and refined.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

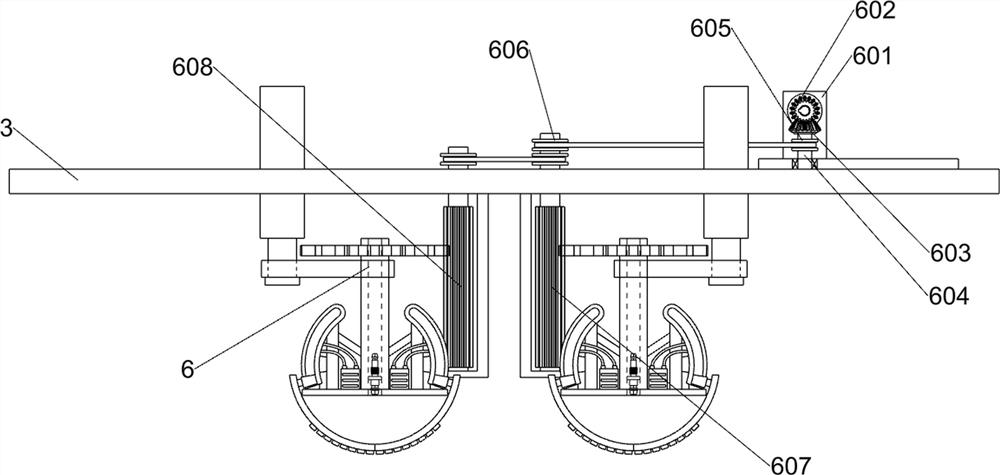

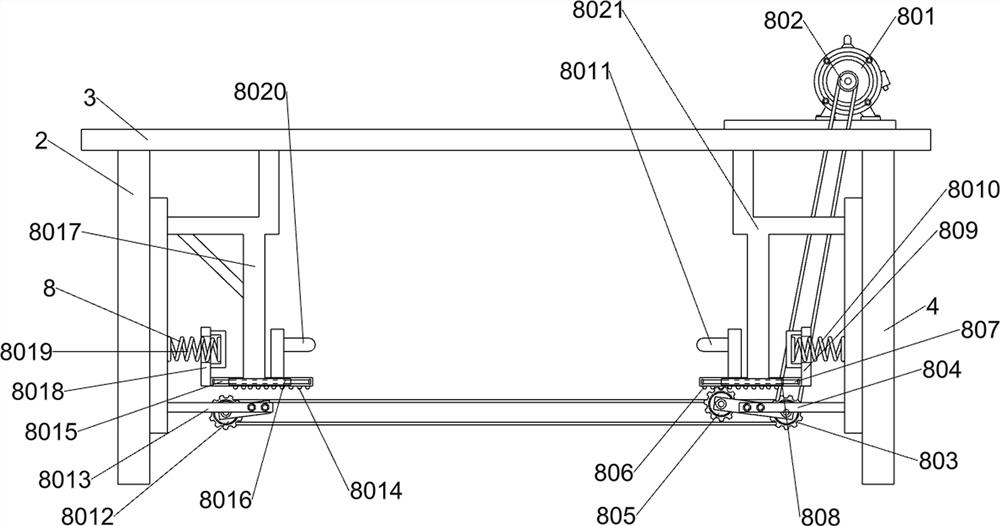

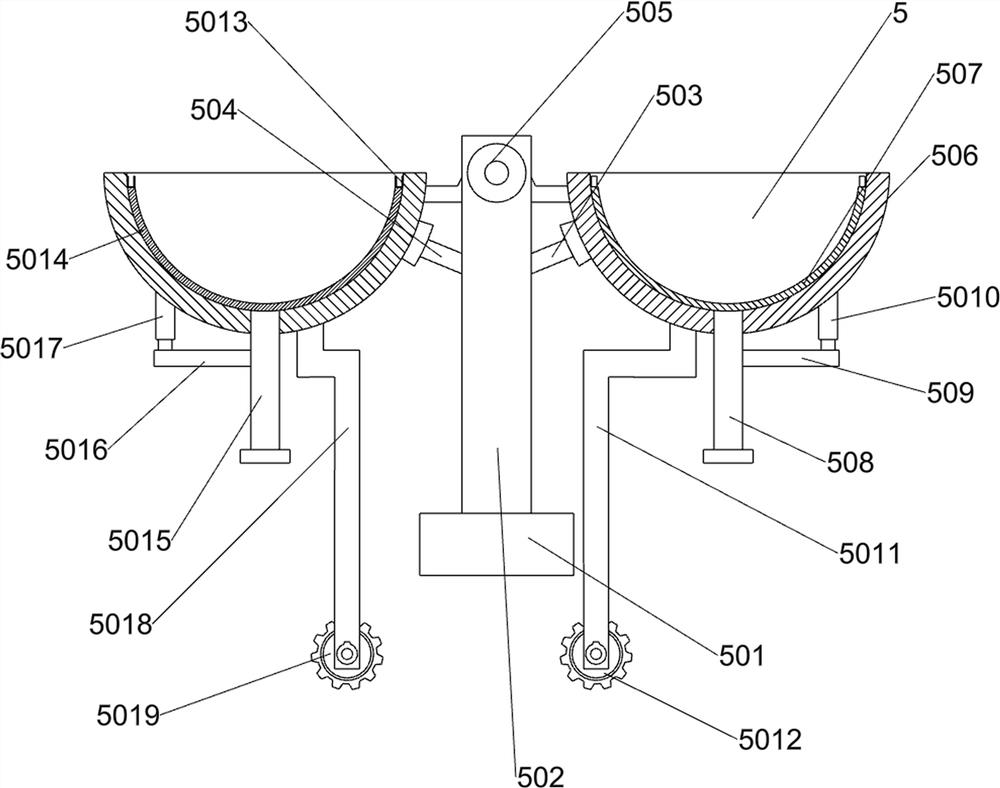

[0029]A packaged nickel alloy laterite ore lump-making device, such asFigure 1-7As shown, it includes working machine bottom plate 1, first installation side plate 2, first installation top plate 3, second installation side plate 4, ball forming system 5, press forming system 6, trimming flush system 7, extrusion control System 8, the third installation side plate 9, the operation control panel 10 and the long-distance electric sliding column 11; the upper part of the working machine bottom plate 1 is welded to the first installation side plate 2; the upper part of the working machine bottom plate 1 is welded to the second installation side plate 4 Welding; the upper part of the working machine bottom plate 1 is welded to the third mounting side plate 9; the lower part of the first mounting top plate 3 is welded to the first mounting side plate 2 and the second mounting side plate 4 in turn; the upper part of the working machine bottom plate 1 is connected to the long-distance elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com