Amorphous-nanocrystalline Fe-based composite soft magnetic alloy and preparation method thereof

An amorphous nanocrystalline and soft magnetic alloy technology, applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., can solve the problems of large coercivity and affect the performance of soft magnetic alloys, and reduce the coercivity. , facilitate the smelting process, improve the effect of magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

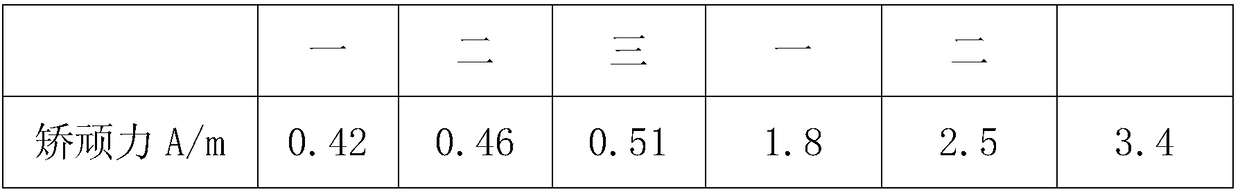

Embodiment 1

[0021] An amorphous nanocrystalline iron-based composite soft magnetic alloy proposed by the present invention is composed of iron-based soft magnetic alloy A and iron-based soft magnetic alloy B according to a mass ratio of 1:3. The iron-based soft magnetic alloy A includes raw materials in the following weight percentages: Al8%, Si 1%, B 0.65%, and the balance is Fe and unavoidable impurities. The iron-based soft magnetic alloy B includes the following raw materials in weight percentages: Al 4%, Si 0.4 %, Ni 3%, Co 3%, Cr 1.1%, Ti 0.09%, Mo 0.3%, Sm 0.46%, B 0.9%, composite rare earth metal 0.9%, the balance is Fe and unavoidable impurities.

[0022] Its preparation method comprises the following steps:

[0023] S1. According to: Al 8%, Si 1%, B 0.65%, the balance is Fe and unavoidable impurities to prepare the raw materials of iron-based soft magnetic alloy A, and place the prepared raw materials of iron-based soft magnetic alloy A in smelting furnace to obtain smelting so...

Embodiment 2

[0029] An amorphous nanocrystalline iron-based composite soft magnetic alloy proposed by the present invention is composed of iron-based soft magnetic alloy A and iron-based soft magnetic alloy B according to a mass ratio of 1:4. The iron-based soft magnetic alloy A includes raw materials in the following weight percentages: Al10%, Si 1.2%, B 0.8%, and the balance is Fe and unavoidable impurities. The iron-based soft magnetic alloy B includes the following raw materials in weight percentages: Al 5%, Si 0.3 %, Ni 4%, Co 4%, Cr 0.8%, Ti 0.12%, Mo 0.4%, Sm 0.3%, B 0.8%, composite rare earth metal 0.6%, the balance is Fe and unavoidable impurities.

[0030] Its preparation method comprises the following steps:

[0031] S1. According to Al 10%, Si 1.2%, B 0.8%, the balance is Fe and unavoidable impurities to prepare the raw material of iron-based soft magnetic alloy A, and place the prepared raw material of iron-based soft magnetic alloy A in the melting furnace Carry out smelting...

Embodiment 3

[0037] An amorphous nanocrystalline iron-based composite soft magnetic alloy proposed by the present invention is composed of iron-based soft magnetic alloy A and iron-based soft magnetic alloy B according to a mass ratio of 1:2. The iron-based soft magnetic alloy A includes raw materials in the following weight percentages: Al6%, Si 0.8%, B 0.5%, and the balance is Fe and unavoidable impurities. The iron-based soft magnetic alloy B includes the following raw materials in weight percentages: Al 3%, Si 0.5% %, Ni 2%, Co 2%, Cr 1.3%, Ti 0.06%, Mo 0.2%, Sm 0.6%, B 1.0%, composite rare earth metal 1.2%, and the balance is Fe and unavoidable impurities.

[0038] Its preparation method comprises the following steps:

[0039] S1. According to Al 6%, Si 0.8%, B 0.5%, the balance is Fe and unavoidable impurities to prepare the raw materials of iron-based soft magnetic alloy A, and place the prepared raw materials of iron-based soft magnetic alloy A in the melting furnace Carry out sme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com