A kind of red mud pellet and preparation method thereof

A technology of red mud and pellets, which is applied in the field of red mud treatment in alumina production, can solve the problems of small particle size and inability to directly add and use, and achieve the effects of easy operation, elimination of impact and hidden dangers of accidents, and good smelting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

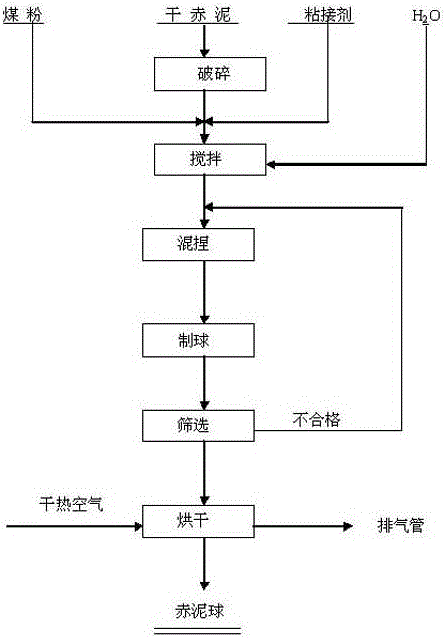

Image

Examples

Embodiment 1

[0030] Red mud 800g;

[0032] Organic adhesive 2g;

[0033] 150g of water.

[0034] The organic binder is cassava flour.

[0035] The preparation method of the red mud pellets includes the following steps: crushing the red mud, then adding coal powder and a binder, gradually adding water during the stirring process, further stirring and mixing evenly, and kneading in a kneading machine, Then it is pressed into balls by pair of rollers, and finally baked at 180°C for 3 hours.

[0036] The prepared red mud pellets are oval in shape, 3 cm long, 1 cm thick, and have a compressive strength of 0.25 kN.

[0037] Produce 100 tons of red mud pellets according to the above formula and method, and mix them with iron ore in a ratio of 1:3 for ironmaking, and the Fe content of iron ore 2 o 3 The percentage content of the red mud is 81.05%, and the Fe in the red mud 2 o 3 The percentage composition is 35.6%, obtains pig iron 200.18 tons, and pig iron iron c...

Embodiment 2

[0039] Red mud 1200g;

[0040] Coal powder 100g;

[0041] Inorganic adhesive 50g;

[0042] water 200g

[0043] The inorganic binder is slaked lime.

[0044] The preparation method of the red mud pellets includes the following steps: crushing the red mud, then adding coal powder and a binder, gradually adding water during the stirring process, further stirring and mixing evenly, and kneading in a kneading machine, It is then pressed into balls by pair of rollers, and finally baked at 300°C for 4 hours to obtain the product.

[0045] The prepared red mud pellets are oval in shape, 5 cm long, 2 cm thick, and have a compressive strength of 4 kN.

[0046] Produce 100 tons of red mud pellets according to the above formula and method, and mix them with iron ore in a ratio of 1:3 for ironmaking, and the Fe content of iron ore 2 o 3 The percentage content of the red mud is 81.05%, and the Fe in the red mud 2 o 3 The percentage composition is 35.6%, obtains pig iron 178.2 tons, ...

Embodiment 3

[0048] red mud 1000;

[0049] Coal powder 50;

[0050] Organic adhesive 10g;

[0051] 180g of water.

[0052] The inorganic binder is sodium silicate.

[0053] The preparation method of the red mud pellets comprises the following steps: crushing the red mud, then adding coal powder and a binder, gradually adding water during the stirring process, further stirring and mixing evenly, and kneading in a kneading machine, Then it is pressed into balls by pair of rollers, and finally baked at 240°C for 3.5 hours.

[0054] The prepared red mud pellets are oval in shape, 4 cm long, 1.5 cm thick, and have a compressive strength of 2 kN.

[0055] According to the above formula and method, 500 tons of red mud pellets are produced, and the pellets are used for ironmaking, and the Fe content of red mud 2 o 3 The percentage composition is 35.6%, and 183.61 tons of pig iron are obtained, and the pig iron iron content is 93.88%, and the iron recovery rate is: 96.84%, and the pig iron qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com