Heating and ventilating air-conditioning system and control method thereof

A HVAC system and control unit technology, applied in air handling equipment, heating/cooling equipment, transportation and packaging, etc., can solve the problems of lowering, increasing noise, increasing energy consumption, etc., to improve comfort and reduce Effects of local pressure loss and air volume increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

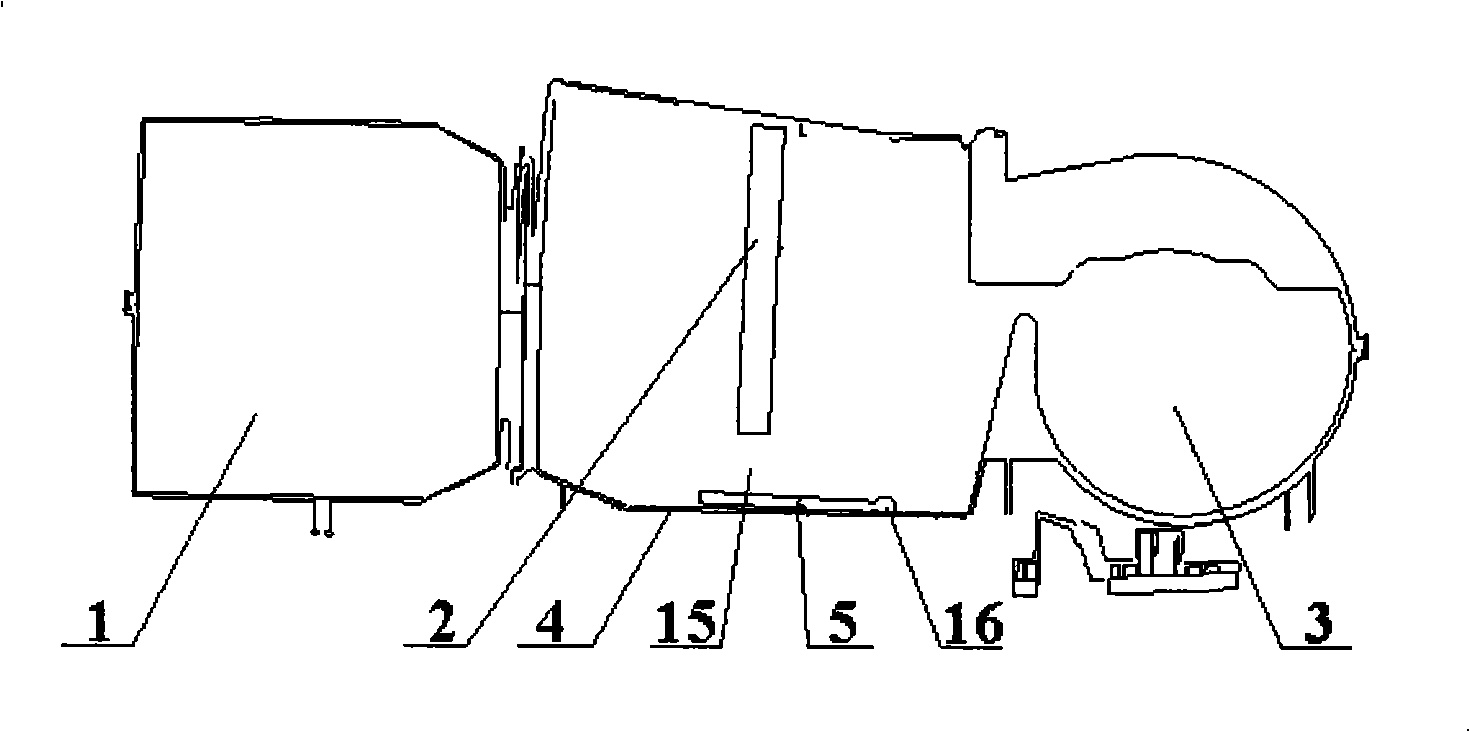

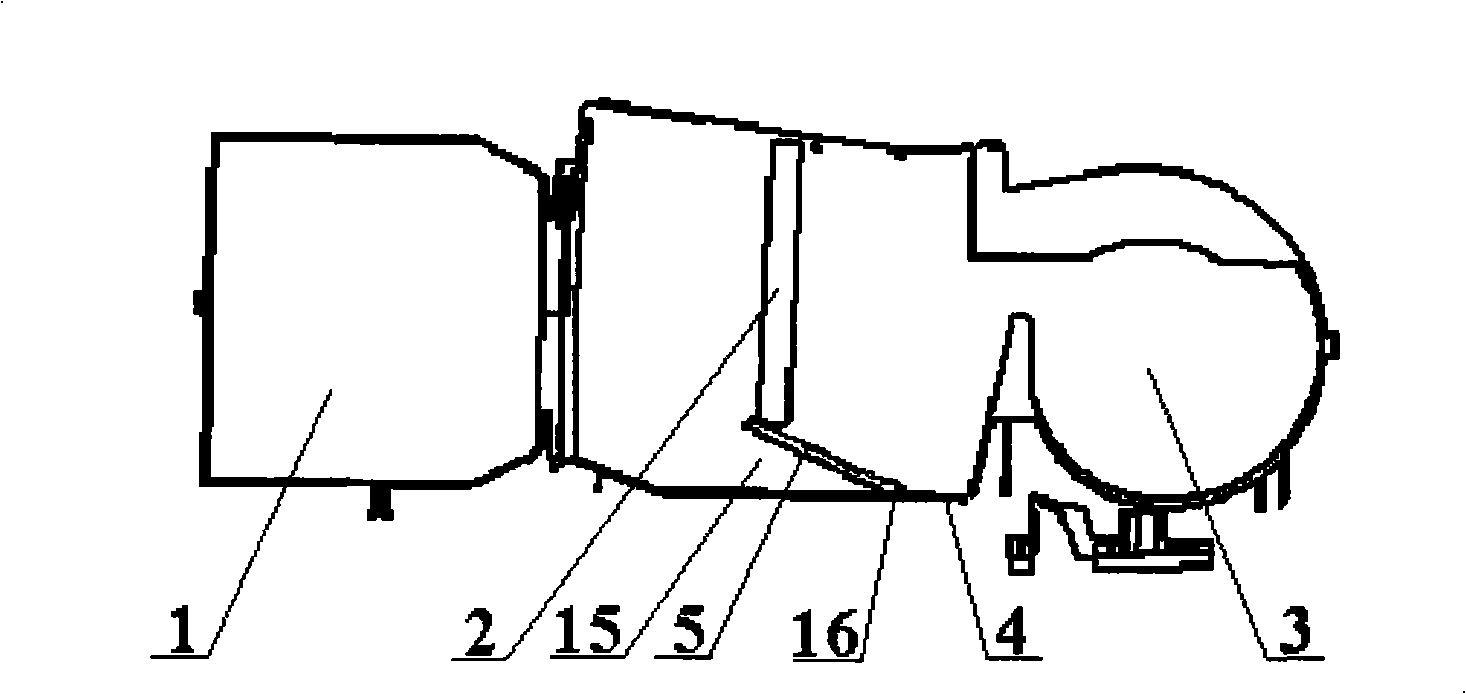

[0045] On the basis of the above technical solution, the evaporator bypass air door 5 is provided with a bypass air door rotating shaft 16 connected as a whole, and the bypass air door rotating shaft 16 is installed on the evaporator shell 4, so that The evaporator bypass air door 5 can rotate with the axis of the rotating shaft as the center of rotation.

[0046] The bypass air door rotating shaft 16 constitutes the rotation center of the evaporator bypass air door 5 and can be installed on the evaporator housing 4 .

Embodiment 2

[0048] The bypass air door rotating shaft 16 is set at the position of the evaporator shell 4 and staggers a certain distance from the evaporator core 2 and is biased towards the direction of the blower 3; the axis of the bypass air door rotating shaft 16 is perpendicular to the gas flow in the evaporator shell. The direction in which the body 4 flows; the evaporator bypass air door 5 forms an oblique angle with the cross section of the evaporator shell 4 when it is closed, and after the evaporator bypass air door 5 is completely closed, its edge and the evaporator core 2 close.

[0049] The purpose of the above structure setting is to make the evaporator side air door 5 completely closed, and under the action of the air flow, it can be tightly attached to the evaporator core 2, forcing the air flow to pass through the evaporator core 2 to better reduce the air flow. temperature. And after the evaporator bypass air door 5 is fully opened, the resistance to air flow is reduced...

Embodiment 3

[0052] The bypass air door rotating shaft 16 extends out of the evaporator housing 4, and a bypass air door driving motor is arranged outside the evaporator housing 4, and is connected with the bypass air door rotating shaft 16 through a mechanical transmission mechanism.

[0053] The mechanical transmission mechanism mentioned above may be a gear transmission mechanism, or a worm gear transmission mechanism, or other mechanical transmission mechanisms. The mechanical transmission mechanism is used for deceleration, and when the shaft of the drive motor of the bypass door rotates, the opening and closing of the bypass door 5 of the evaporator is driven.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com