A coal mine buried rotary steerable drilling tool assembly and industrial control method

A technology of rotary steering and drilling tool assembly, which is applied in directional drilling, driving devices for drilling in boreholes, and earthwork drilling and production. It can solve problems such as low drilling efficiency and uneven drilling trajectory, and achieve improved depth and efficiency. , Shorten the well construction period and reduce the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

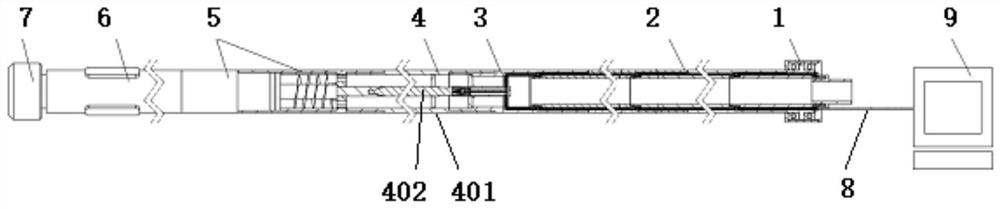

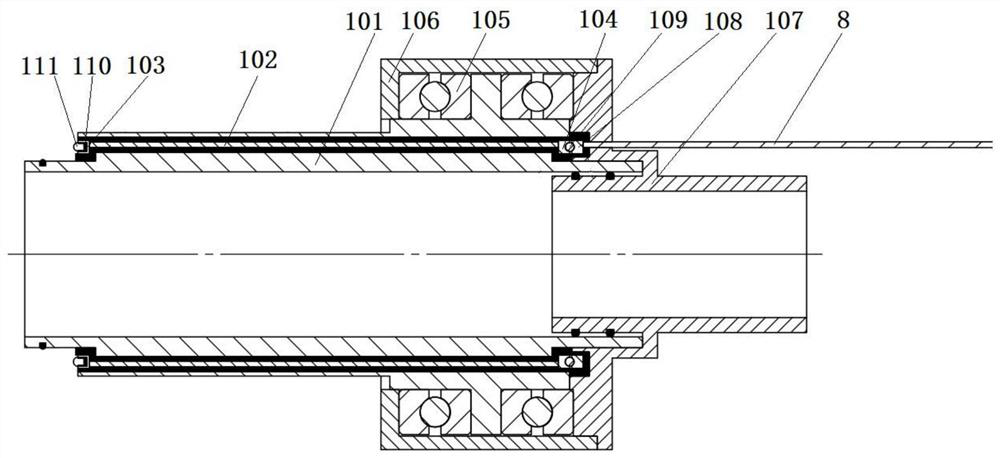

[0048] Such as Figure 1 to Figure 14 As shown, this embodiment provides an underground coal mine buried rotary steerable drilling tool assembly, including a buried water feeder 1, a buried drill pipe 2, a conversion joint 3, a measurement short 4, and a control short connected sequentially coaxially. 5. Rotate the steerable drilling tool 6 and the drill bit 7.

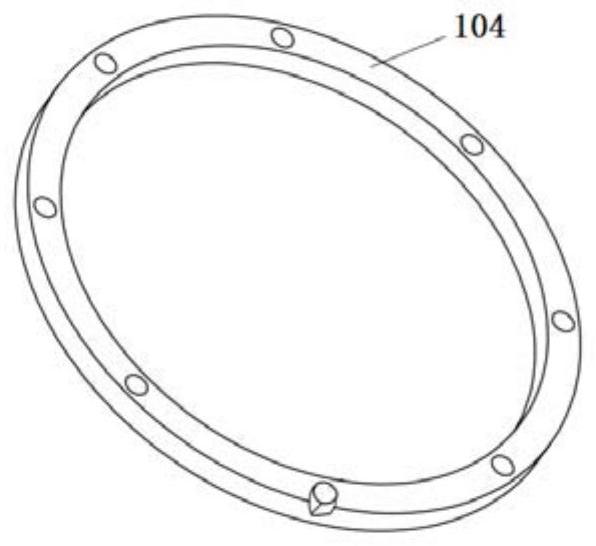

[0049] Among them, the buried water feeder 1 includes a mandrel 101, and a plurality of insulated wires V102 are embedded in the side wall of the mandrel 101; the buried drill pipe 2 includes an outer tube III 201, and a plurality of insulated wires are embedded in the wall of the outer tube III 201 IV202, and the insulated wire IV202 is connected to the insulated wire V102; the conversion joint 3 includes the outer tube II301 and the inner tube 302 located in the outer tube II301, and a plurality of insulated wires III303 are embedded in the wall of the outer tube II301, and the plurality of insulated wires One end ...

Embodiment 2

[0063] This embodiment provides an industrial control method for underground coal mine rotary steerable drilling tool assembly, the method includes:

[0064] Control signal transmission steps: the control center (i.e., the orifice computer) sends the rotation steering control command, and the control command is transmitted to the conversion joint through the insulated wire V in the buried water feeder and the insulated wire IV in the buried drill pipe in the form of a carrier wave, and the conversion The insulated wires III in the joint are gathered into a bundle and continue to transmit instructions to the measuring probe inside the short-circuit and the rotary steerable drilling tool at the front end; the measuring probe can measure the attitude value of the current rotary steerable drilling tool and return it to the control in the form of carrier wave In the center, the rotary steerable drilling tool can regulate the action of the hydraulic cylinder according to the control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com