Diphase integrated multi-gradation internal circulation anaerobic bioreactor

An anaerobic biological and reactor technology, applied in the field of organic wastewater, waste, and sludge treatment equipment, can solve the problems of easy clogging and aging of filter materials, low availability of by-products, and unstable volume load, so as to achieve thorough treatment and avoid production. Acid problem, stable effect of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

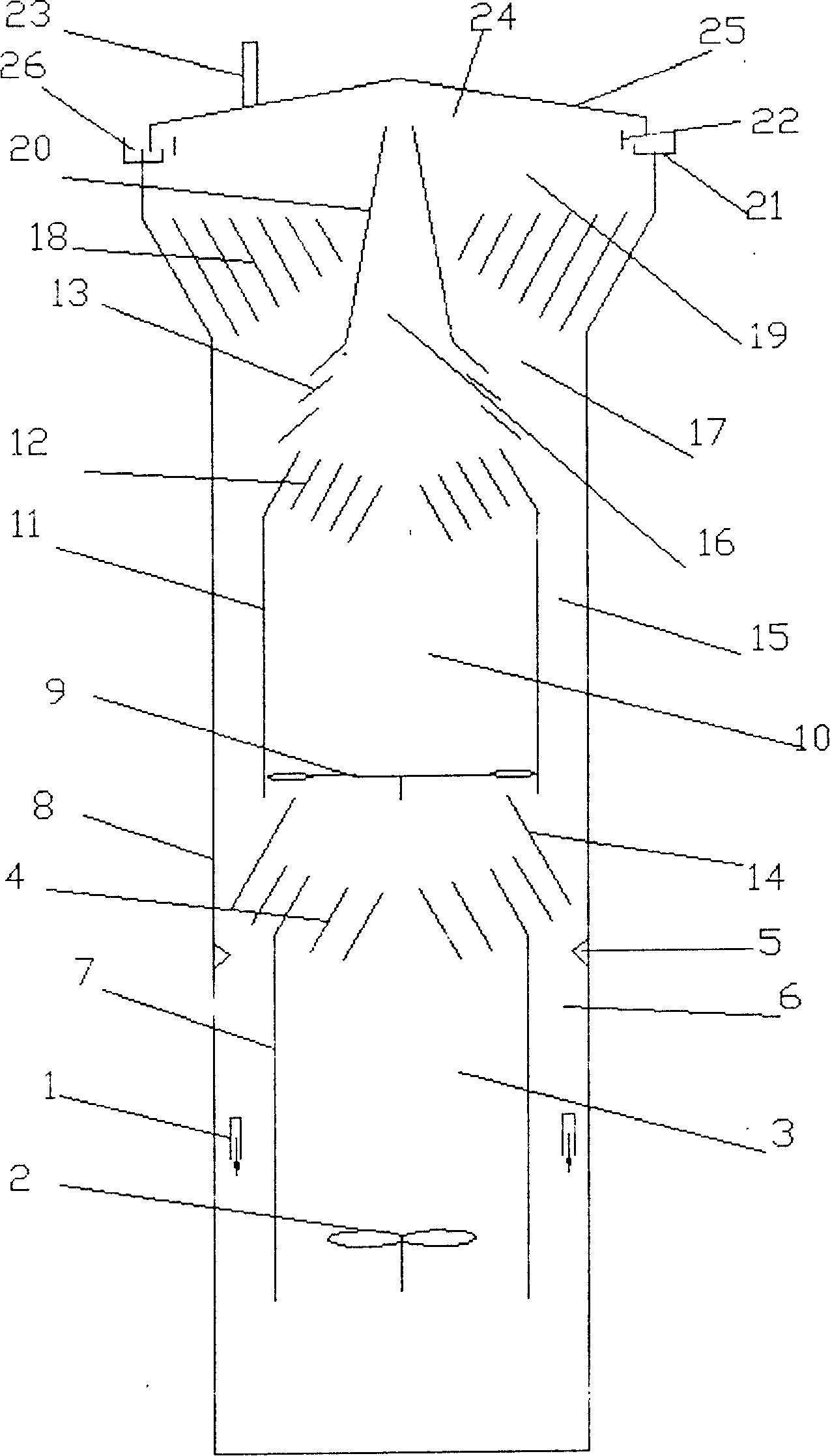

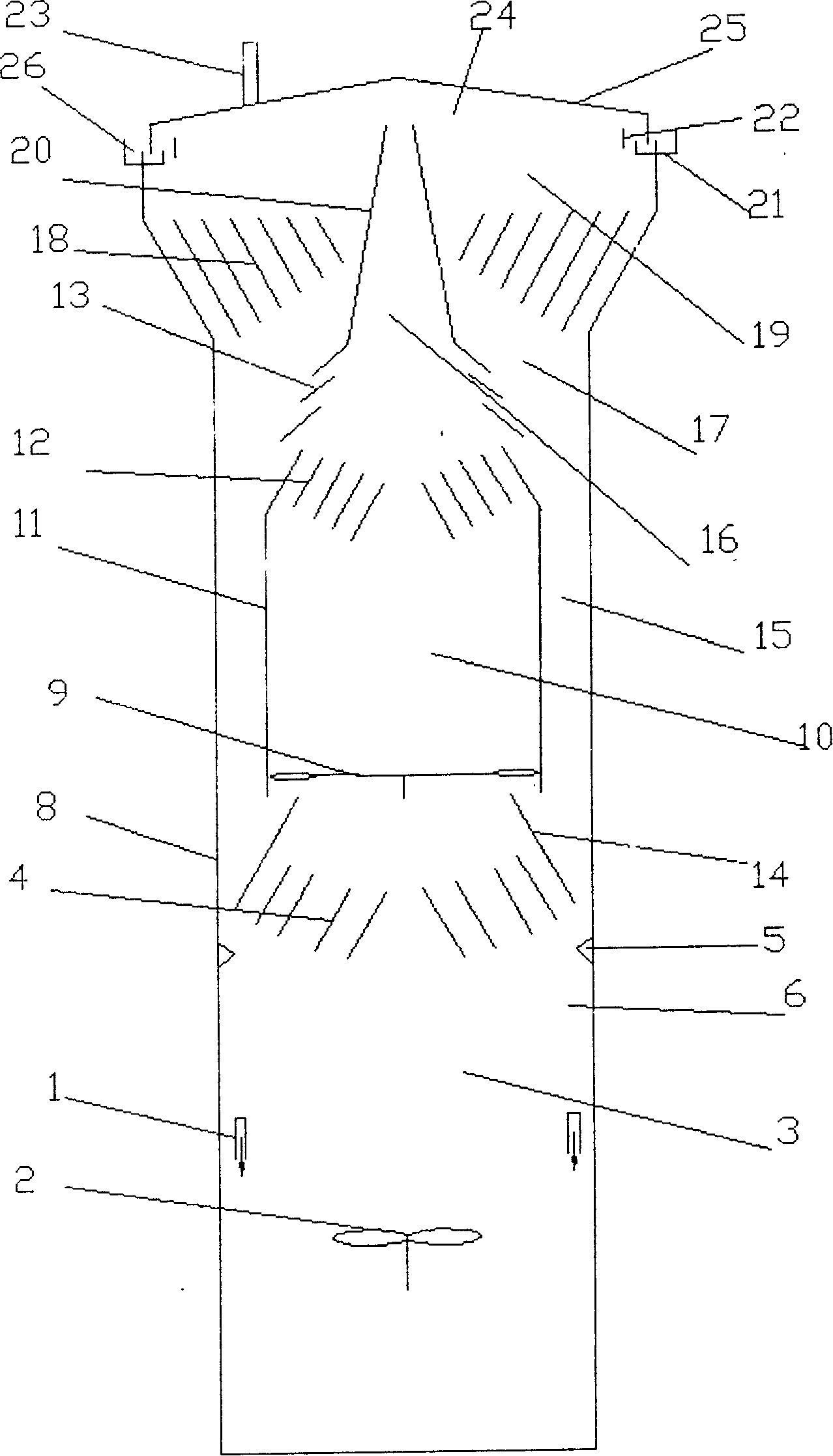

[0021] Two-phase integrated multi-level internal circulation anaerobic bioreactor of the present invention such as figure 1 shown. The reactor includes:

[0022] I, II bipolar reactor, precipitation area and outer casing 8, upper inner casing 20, middle inner casing 11, lower inner casing 7, primary gas-liquid separation reflection plate 4, secondary gas-liquid separation reflection plate 12, The two-phase integrated multi-phase structure of the first-level air separation deflector 14, the second-level air separation deflector 13, the upper stirring lifter 9, the lower stirring lifter 2, the liquid distributor 1, the gas seal 5, and the solid-liquid separator 18 Hierarchical internal circulation anaerobic bioreactor; said solid-liquid separator 18 is arranged between the outer shell 8 and the upper inner shell 20, and a gas phase zone 24 is arranged on it, and the cavity of the upper inner shell 20 is a gas-liquid Separation zone 16, middle inner housing 11 cavity is II reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com