Chemical raw material deposition-removing conveying device and method

A technology of conveying device and chemical raw material, applied in the field of chemical raw material de-deposition conveying device, can solve the problems of filter screen extrusion damage, crushing of large viscous impurities, inability to control the speed of raw materials entering the valve body, etc., to avoid problems such as Long-term deposition, avoiding the effect of excessive feeding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053]The technical solutions of the present invention will be further described below with reference to the accompanying drawings.

[0054]The drawings are for exemplary description, which is merely a schematic diagram, rather than the experiment, and is not to be understood to be in this patent; in order to better illustrate the embodiments of the invention, there will be omitted, Enlarge or shrink does not mean the size of the actual product.

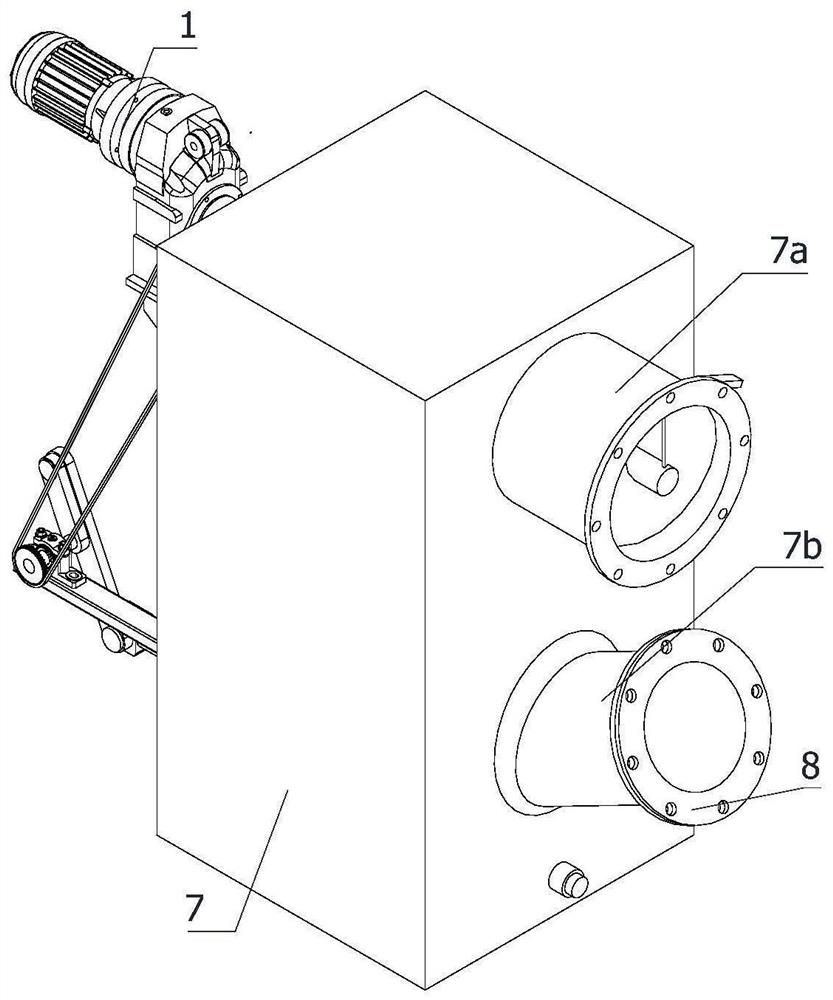

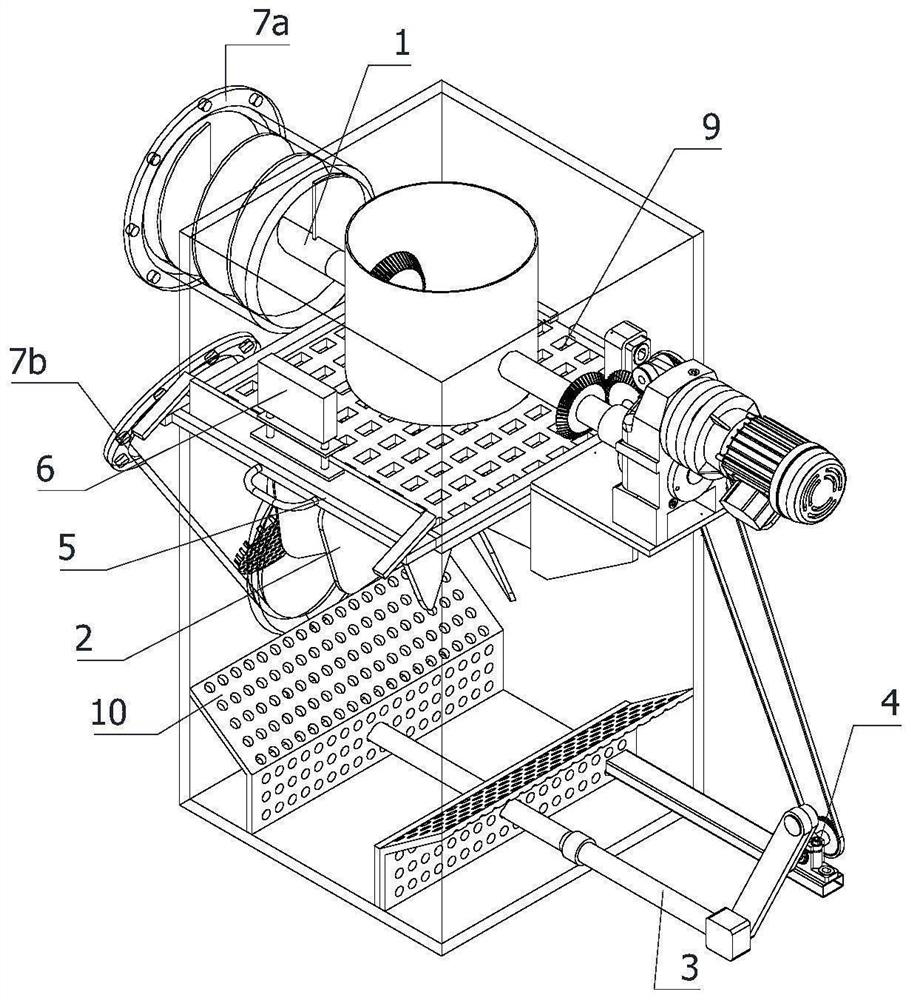

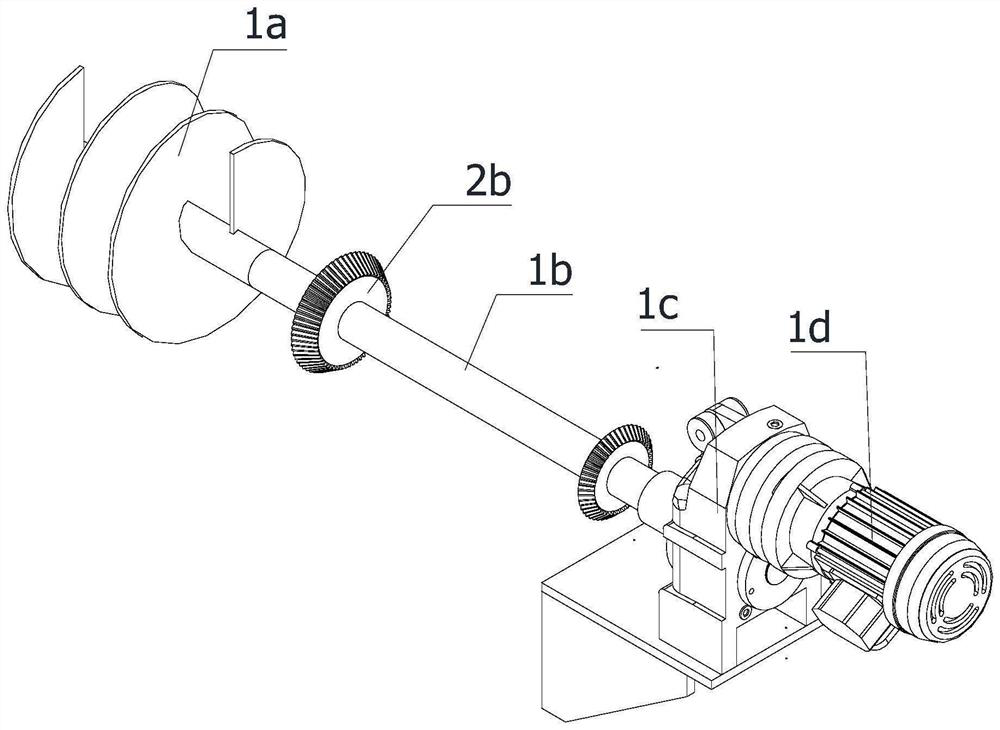

[0055]ReferFigure 1 to 9A chemical raw material deposited transport device, including a flow rate control mechanism 1, an axis push mechanism 2, a reciprocating pressing mechanism 3, a cleaning mechanism 5, a blocking gate 6, a valve body 7, a filter tub 8, a square filter plate 9 and The two bending plate 10, the valve body 7 is fixed to the installation conduit, and the feed tube 7a and the discharge tube 7b are provided on the valve body 7, and the feed tube 7a is fixedly connected to the pipe opening, the discharge tube 7b and The feed port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com