Continuous production method of insoluble sulfur

A production method and sulfur technology are applied in the field of insoluble sulfur preparation to achieve the effects of improving labor efficiency, avoiding pollution and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

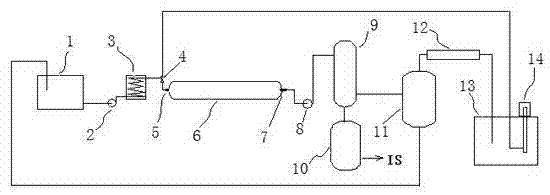

[0025] The specific embodiment of the present invention is as figure 1 shown.

[0026] (1) Sulfur melting and heating up: Add industrial sulfur into the high-level exposed sulfur melting pool 1 with a steam coil to melt, pump it into the heating coil 3 through the metering pump 2 and raise the temperature to 420-480°C, and stop the metering pump 2.

[0027] (2) Quenching: The carbon disulfide at a temperature of 10°C in the storage tank 13 is transported to the ejector 4 by the submerged pump 14, the metering pump 2 is started, and the high-temperature sulfur at 420-480°C and the low-temperature carbon disulfide are mixed in the ejector 4 to complete the quenching .

[0028] (3) Solidification: After quenching, the mixture of insoluble sulfur and carbon disulfide passes through the rotary joint 5 into the continuously rotating rotary kiln 6. The solid-phase insoluble sulfur in the mixture accounts for about 50% and has strong viscosity. Therefore, the rotary kiln To keep ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com