Method for preparing olivine type lithium iron phosphate positive electrode material

A technology of lithium iron phosphate and cathode material, applied in the directions of phosphate, phosphorus oxyacid, chemical instruments and methods, etc., can solve problems such as neglect, achieve the effect of simple method, guarantee batch stability and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The method for preparing an olivine-type lithium iron phosphate positive electrode material has the following specific steps:

[0016] Step 1. At room temperature, weigh lithium carbonate, anhydrous iron phosphate and carbon source by a certain molar ratio, add a certain amount of water ball mill and mix for 6h, wherein the solid content is 50%, and the molar ratio of Li / Fe / P is 1.02:1:1, anhydrous iron phosphate is trigonal iron phosphate, and the carbon source is sucrose;

[0017] Step 2: After the ball-milled material is dried, sintered at 700° C. for 16 hours in a nitrogen atmosphere, and the sintered product is cooled to below 60° C. to obtain an olivine-type lithium iron phosphate positive electrode material.

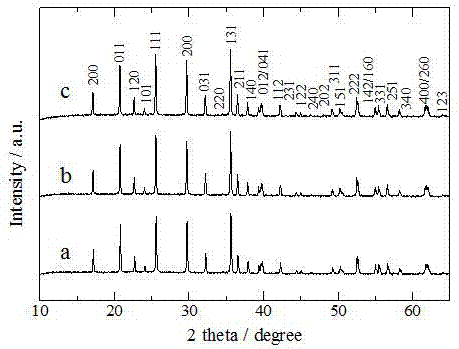

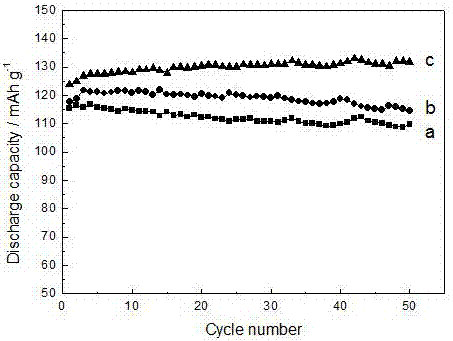

[0018] figure 1 a is the XRD pattern of the olivine-type lithium iron phosphate cathode material prepared in this example, indicating that the prepared material is a single olivine-type phase and has good crystallinity; figure 2 a is the 1C rate cycle di...

Embodiment 2

[0020] The method for preparing an olivine-type lithium iron phosphate positive electrode material has the following specific steps:

[0021] Step 1. At room temperature, weigh lithium carbonate, anhydrous iron phosphate and carbon source by a certain molar ratio, add a certain amount of water ball mill and mix for 6h, wherein the solid content is 50%, and the molar ratio of Li / Fe / P is 1.02:1:1, anhydrous iron phosphate is a mixed phase of monoclinic iron phosphate and trigonal iron phosphate with a molar ratio of 0.5:0.5, and the carbon source is sucrose;

[0022] Step 2: After the ball-milled material is dried, sintered at 700° C. for 16 hours in a nitrogen atmosphere, and the sintered product is cooled to below 60° C. to obtain an olivine-type lithium iron phosphate positive electrode material.

[0023] figure 1 b is the XRD pattern of the olivine-type lithium iron phosphate cathode material prepared in this example, indicating that the prepared material is a single olivin...

Embodiment 3

[0025] The method for preparing an olivine-type lithium iron phosphate positive electrode material has the following specific steps:

[0026] Step 1. At room temperature, weigh lithium carbonate, anhydrous iron phosphate and carbon source by a certain molar ratio, add a certain amount of water ball mill and mix for 6h, wherein the solid content is 50%, and the molar ratio of Li / Fe / P is 1.02:1:1, anhydrous iron phosphate is a mixed phase of hexagonal iron phosphate and trigonal iron phosphate with a molar ratio of 0.5:0.5, and the carbon source is sucrose;

[0027] Step 2: After the ball-milled material is dried, sintered at 700° C. for 16 hours in a nitrogen atmosphere, and the sintered product is cooled to below 60° C. to obtain an olivine-type lithium iron phosphate positive electrode material.

[0028] figure 1 c is the XRD pattern of the olivine-type lithium iron phosphate cathode material prepared in this example, indicating that the prepared material is a single olivine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com