Production method of novel tobacco sheet

A technology of tobacco flakes and production methods, applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of shortage of raw materials for tobacco flake production, environmental pollution, etc., and achieve the effects of solving the shortage of raw materials for production, small investment in production equipment, and improving health quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

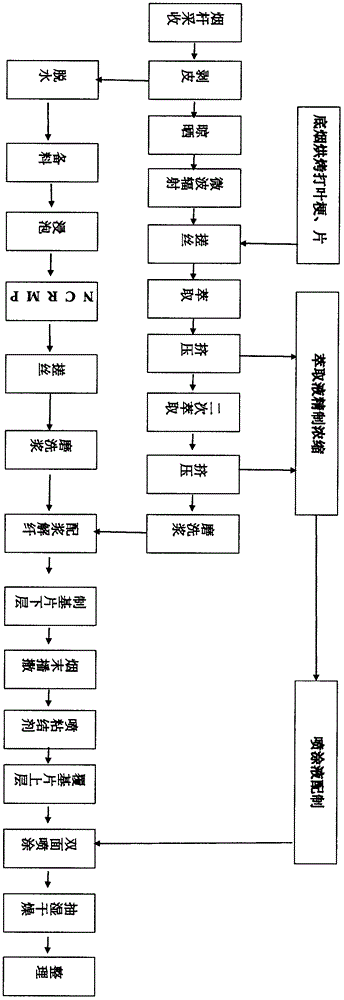

Method used

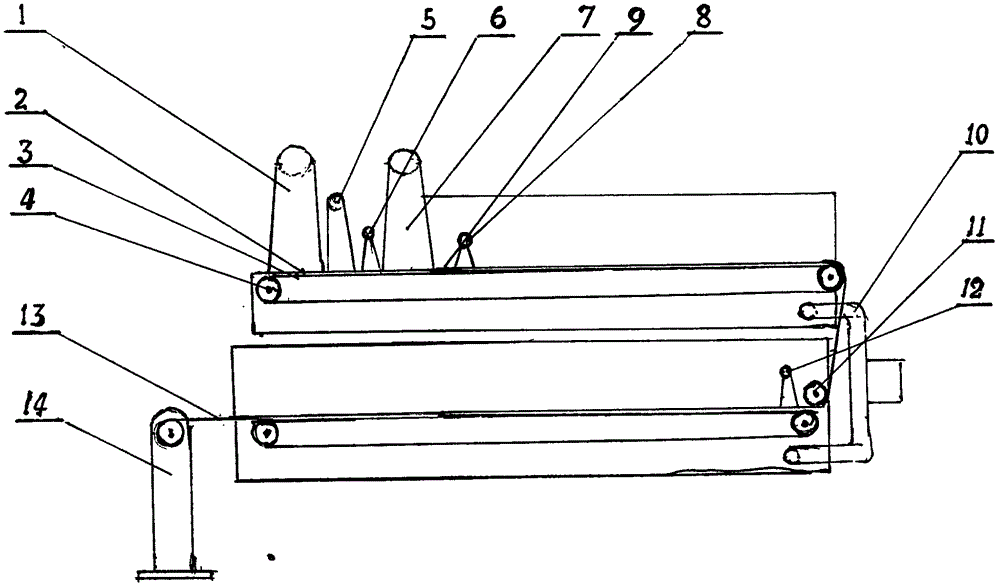

Image

Examples

Embodiment 1

[0041] 1. Tobacco stalk harvesting: Fresh tobacco stalks are harvested 10-30mm away from the ground;

[0042] 2. Peeling: fresh tobacco stalks are rotary cut and peeled to a thickness of 0.8-2mm, and the stems and skins are separated;

[0043] 3. Tobacco skins are dried: the tobacco skins are dried to a moisture content of 15%;

[0044] 4. Microwave radiation: Microwave treatment is carried out on the tobacco skin after drying, the microwave power is 10KW, and the radiation time is 20S;

[0045] 5. Rubbing: crush the tobacco skins to a length of 30-50 mm, the bottom tobacco stems to a length of 20-30 mm, wash and remove impurities, put them together with the wind-selected bottom tobacco slices into water with a liquid ratio of 1:3 and soak for 5 hours Send it to the wheat straw splitting and grinding machine for rubbing;

[0046] 6. Extraction: Put the rubbed tobacco skins, tobacco stems and slices directly into the extraction tank and heat water with a liquid ratio of 1:3. ...

Embodiment 2

[0064] In embodiment one, binder is changed into pullulan polysaccharide aqueous solution, and 5% flax pulp is changed into 3% flax pulp and adds 2% cotton pulp, and the upper and lower fiber layers of the substrate and the amount of soot powder are 15g / m 2 , both the front and back spraying quantity are 20g / m 2 , the basis weight of tobacco flakes is 85g / m 2 , and the rest of the steps and parameters are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com