Manufacturing method for rare earth alloy battery zinc powder

A technology of rare earth alloy and manufacturing method, which is applied in the field of manufacturing refractory metal alloy zinc powder, can solve the problems of excessive iron impurities and inaccurate addition of rare earth metals, etc., and achieve the effect of improving recovery rate and avoiding oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

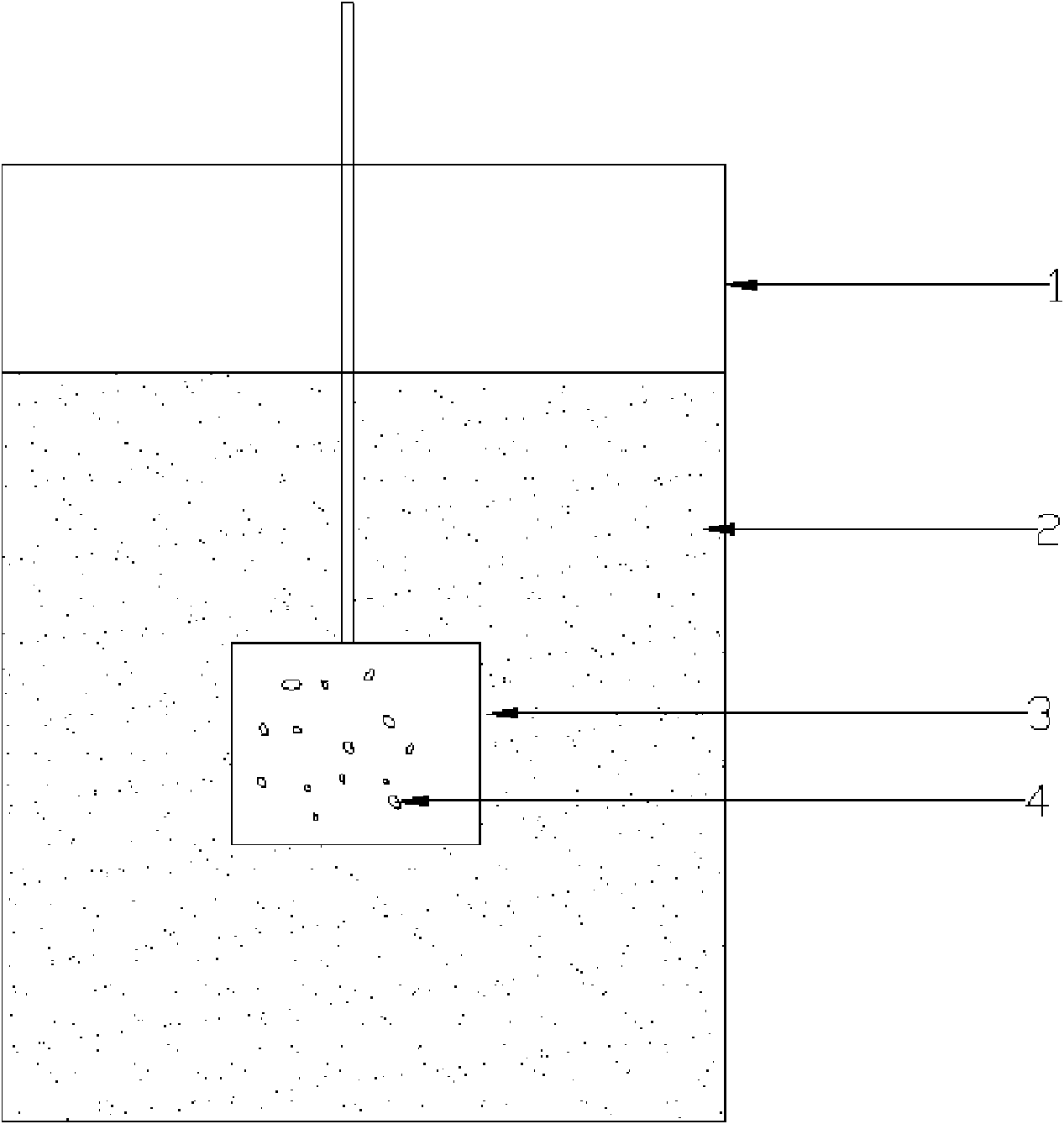

Image

Examples

Embodiment 1

[0021] Use a die-casting device made of high-purity graphite material with small holes on the wall (also known as "press melter", with 8 small holes per square centimeter), put 5g of tiny debris-like rare earth metal lanthanum, Yttrium and cerium are put into the pressure melter, wherein the mass ratio of lanthanum:yttrium:cerium is 1:1:1. In the molten state, the above rare earth metal is pressed into the zinc liquid to directly produce a zinc-rare earth master alloy, and the mass concentration of the rare earth metal is 8%; the prepared zinc-rare earth master alloy is melted in the zinc liquid to produce the required rare earth metal Concentration of zinc-rare earth alloy zinc solution, the total concentration of rare earth metals is 0.1%.

[0022] Compared with the prior art, the present invention adopts an alloy manufacturing method in which the rare earth metal is directly pressed into the zinc liquid in the first step of manufacture, and the rare earth metal is completel...

Embodiment 2

[0024] Use a die-casting device made of high-purity graphite material with small holes on the wall (also known as "press melter", with 6 small holes per square centimeter), put 8g of tiny debris-like rare earth metal lanthanum, Yttrium and cerium are put into the pressure melter, wherein the mass ratio of lanthanum:yttrium:cerium is 1:1:1. In the molten state, the above-mentioned rare earth metal is pressed into the zinc liquid to directly produce a zinc-rare earth master alloy, and the mass concentration of the rare earth metal is 12%; the prepared zinc-rare earth master alloy is melted in the zinc liquid to produce the required rare earth metal Concentration of zinc-rare earth alloy zinc solution, the total concentration of rare earth metals is 0.2%.

[0025] Compared with the prior art, the present invention adopts an alloy manufacturing method in which the rare earth metal is directly pressed into the zinc liquid in the first step of manufacture, and the rare earth metal i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com