Lateral mounting type full-color LED package and LED transparent screen

A technology of LED packaging and LED chips, applied in the direction of identification devices, instruments, electrical components, etc., can solve the problems of reduced production efficiency, easy bending and damage, occupying PCB board space, etc., and achieves small point spacing specifications and high permeability. , the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

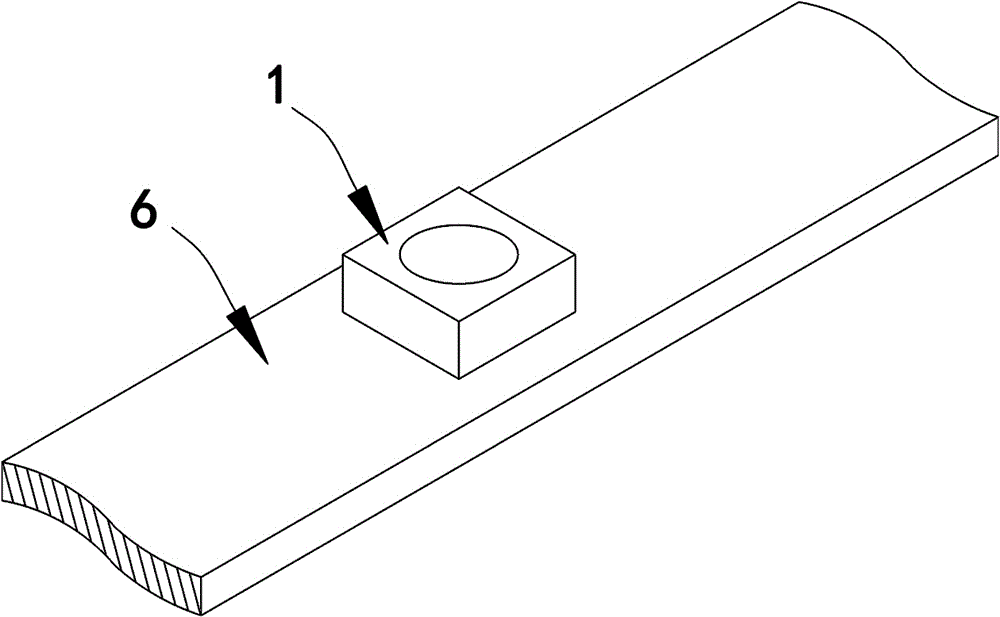

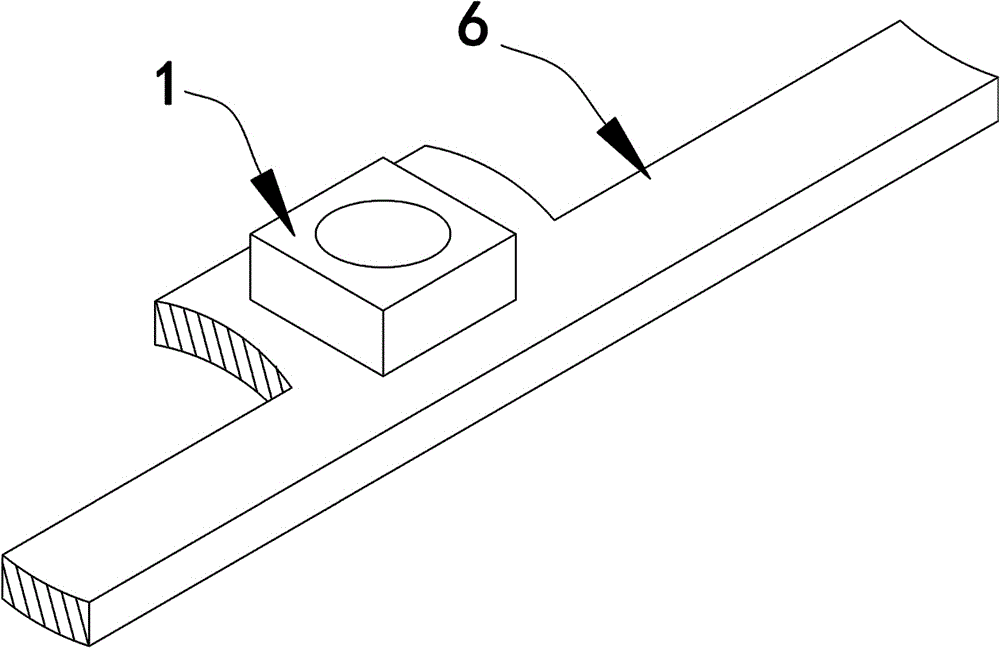

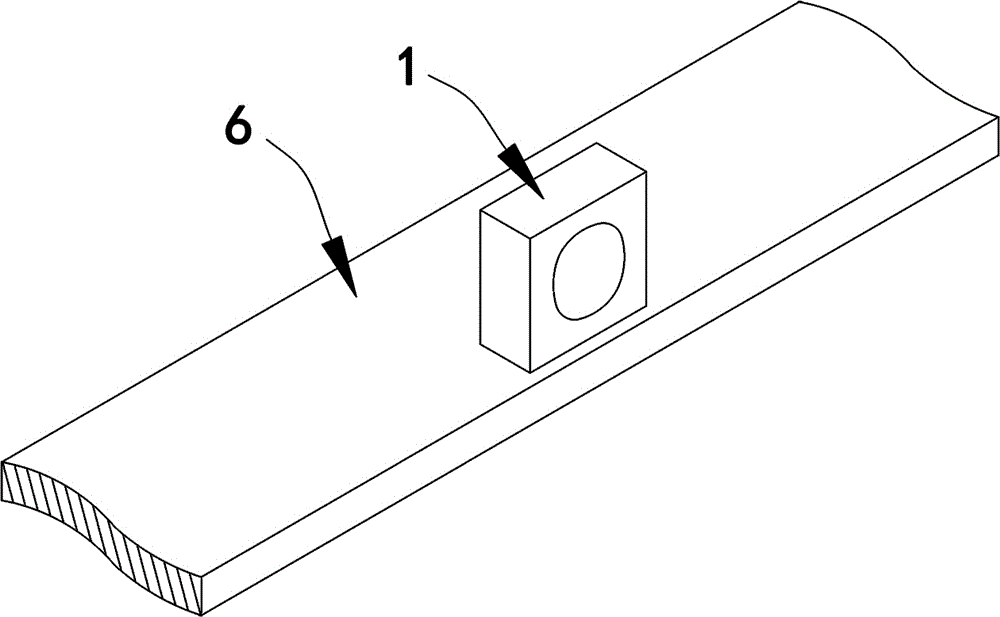

[0032] Below, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0033] refer to Figure 4-8 , this embodiment provides a side-mounted full-color LED packaged LED lamp bead 5, which includes an electrode metal sheet 3, a main body frame 2, a red LED chip 13, a green LED chip 12, a blue LED chip 11, a second A lead 41 , a second lead 42 , a third lead 43 , a fourth lead 44 , a fifth lead 45 and an encapsulant (not shown).

[0034] refer to Figure 4 1. The electrode metal sheet 3 has a rectangular frame 302, and the inside of the frame is punched and hollowed out to form four electrode areas 301 arranged in a line.

[0035] refer to Figure 5, the main body frame 2 is integrally formed by injection molding process, and is located in the rectangular frame 302 of the electrode metal sheet 3. It has a cuboid structure and wraps four electrode areas 301 arranged in a line. The main body base 21, and the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com