High performance insoluble sulfur production system and method

A production system and high-performance technology, applied in chemical instruments and methods, sulfur compounds, climate sustainability, etc., can solve the problems of poor thermal stability of insoluble sulfur, low yield, complicated operation process, etc., to avoid quenching agent The effect of drying process, uniform particle size and simplified process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The specific situation of the present invention will be further described below through specific examples, but not limited to the following examples.

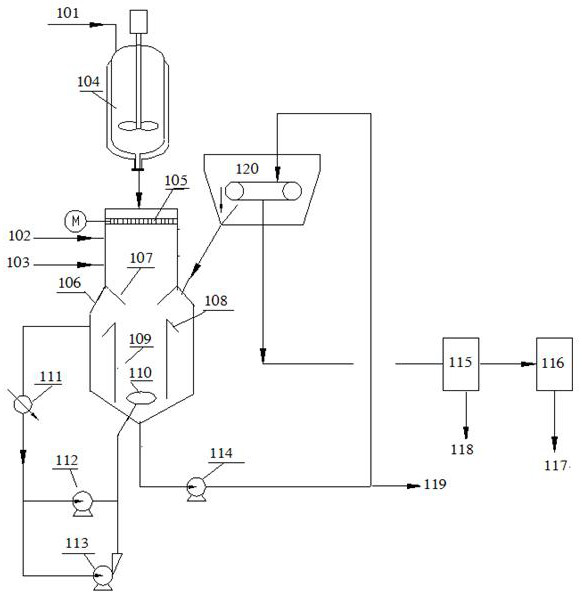

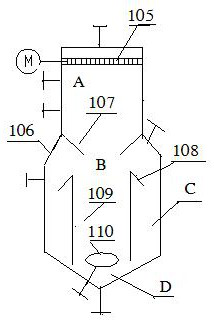

[0052] Such as figure 1 As shown, the present invention provides a kind of insoluble sulfur production system, and described production system comprises polymerizer 104, quick cooling tower 106, belt filter 120, washing filter 115 and drier 116; Described polymerizer 104 outlet The pipeline is connected with the feed port of the quenching tower 106, and the discharge port of the quenching tower 106 is connected with the feed port of the belt filter 120 through the discharge pump 114 through the pipeline, and the liquid outlet of the belt filter 120 is connected with the feed port of the washing filter 115 Connected, the solid outlet of the belt filter 120 is connected to the solid inlet of the quench tower 106, and the discharge of the washing filter 115 is connected to the feed port of the dryer 116 through a pipeline. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com