Patents

Literature

31results about How to "Granulation realization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

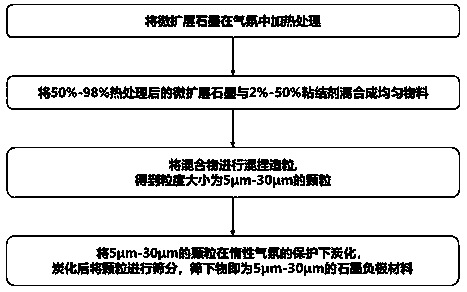

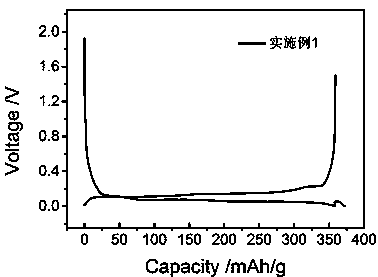

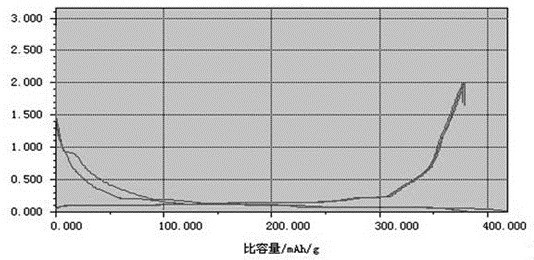

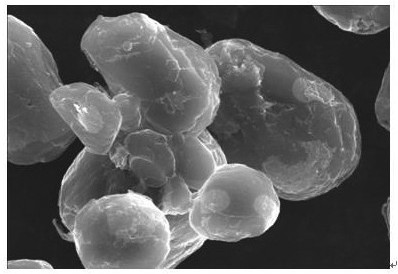

Preparation method of graphite anode material

InactiveCN109742356AIncrease spacingLow insertion resistanceCell electrodesSecondary cellsGraphite anodeHeat treating

The invention provides a preparation method of a graphite anode material. The preparation method comprises the following steps: firstly performing heat treatment on slightly layer-expanded natural graphite, then mixing the slightly layer-expanded natural graphite subjected to the heat treatment with a binder, performing kneading and pelletizing on mixture, and then carbonizing and screening in aninert atmosphere, so that the graphite anode material is obtained. The preparation method provided by the invention solves the problems that surface morphology of graphite becomes rough after layer expansion in the prior art, tap density is reduced and processing of anode slurry is not facilitated.

Owner:HUNAN SHINZOOM TECH

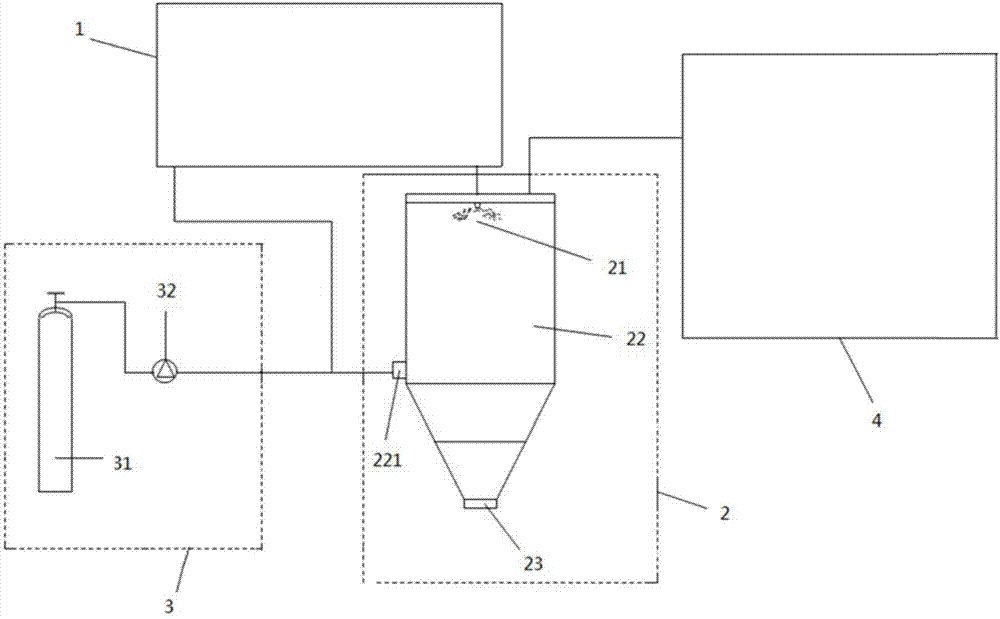

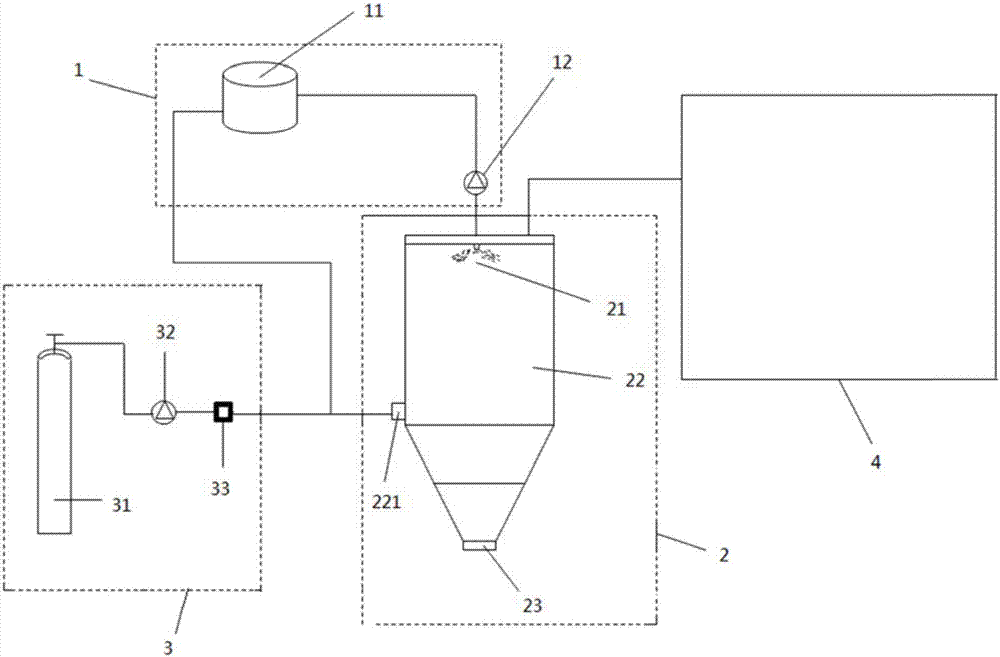

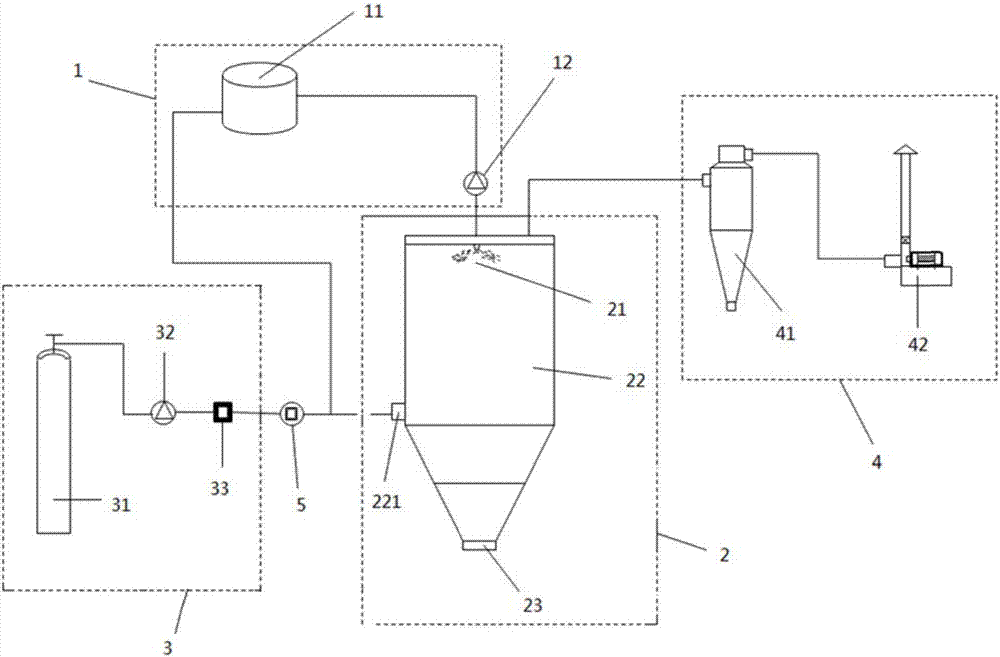

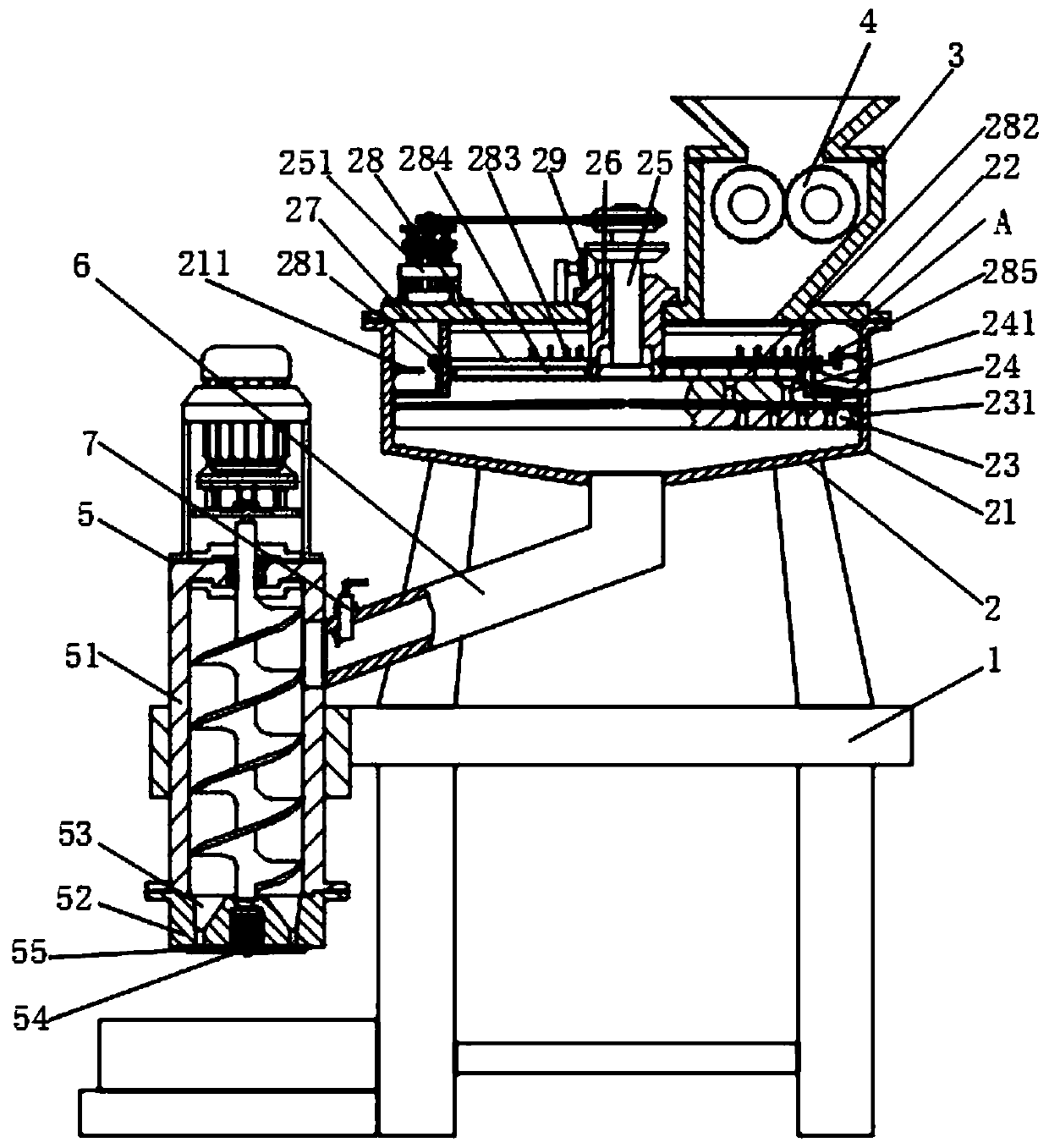

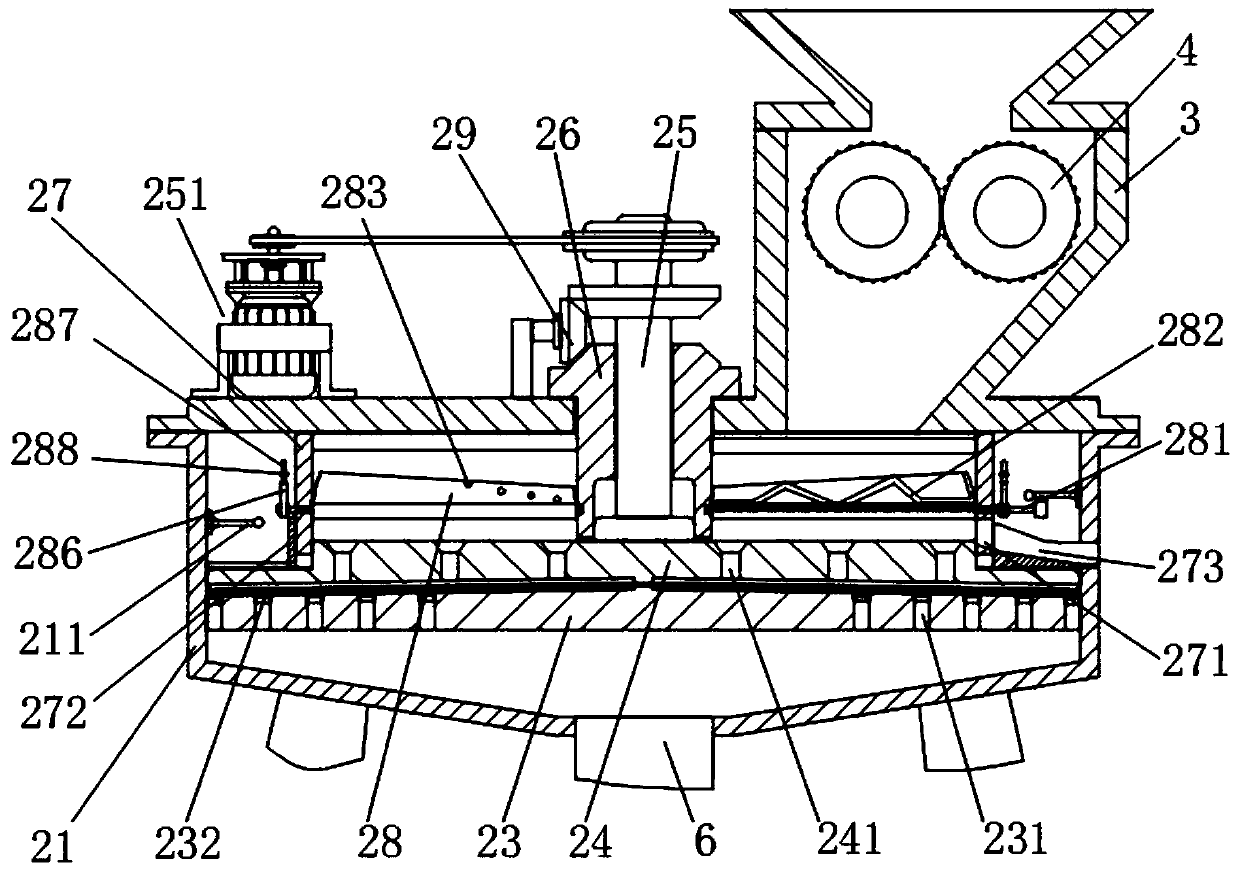

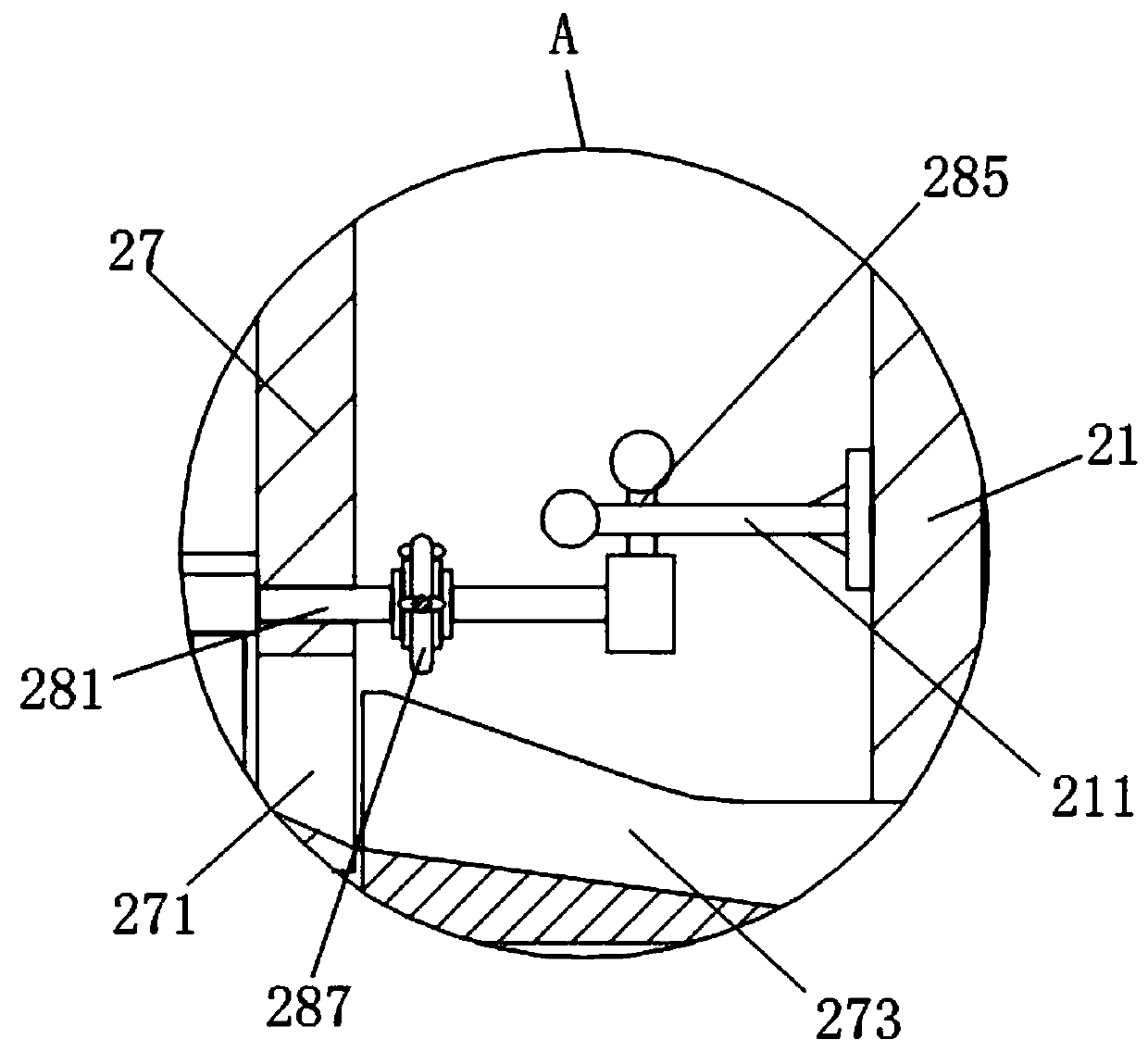

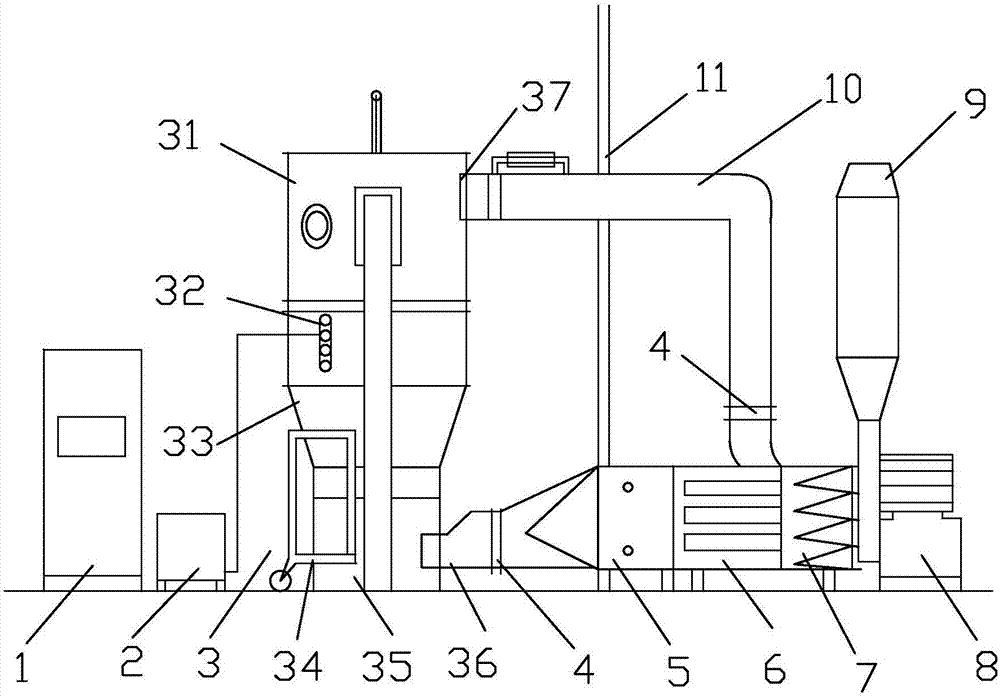

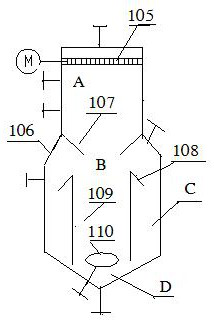

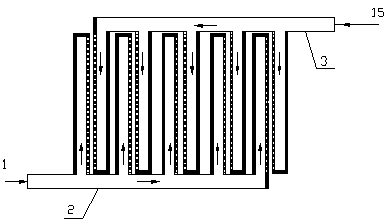

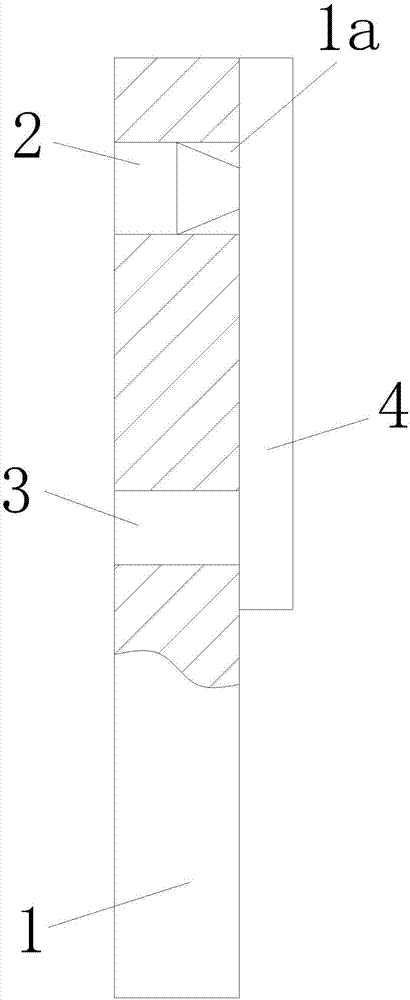

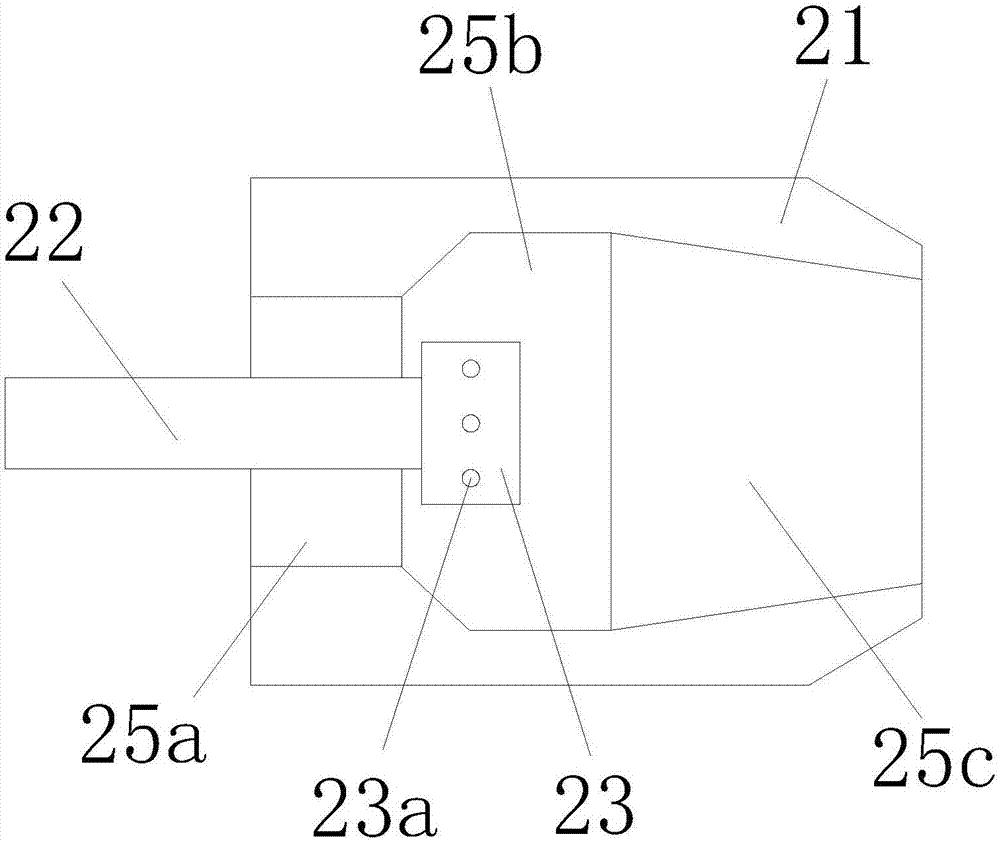

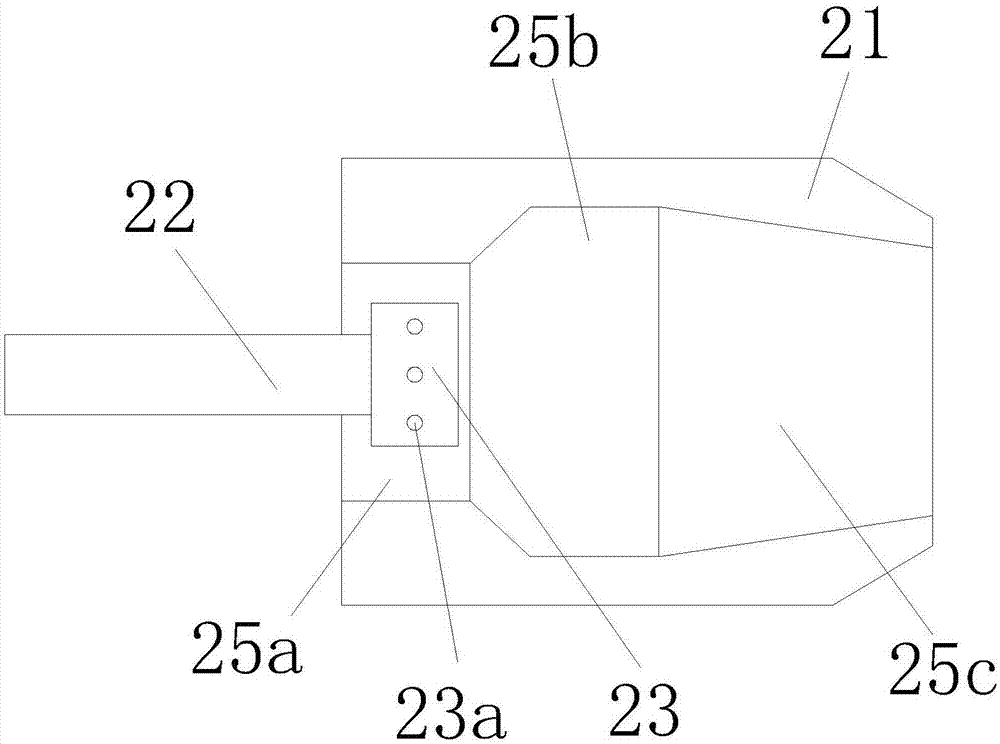

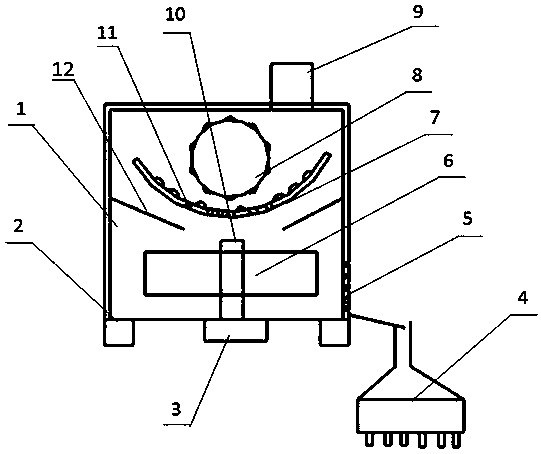

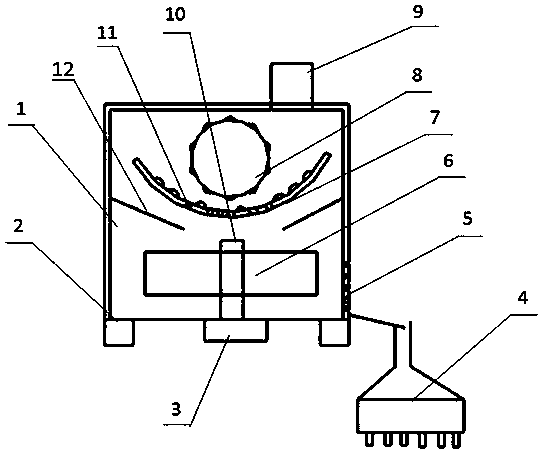

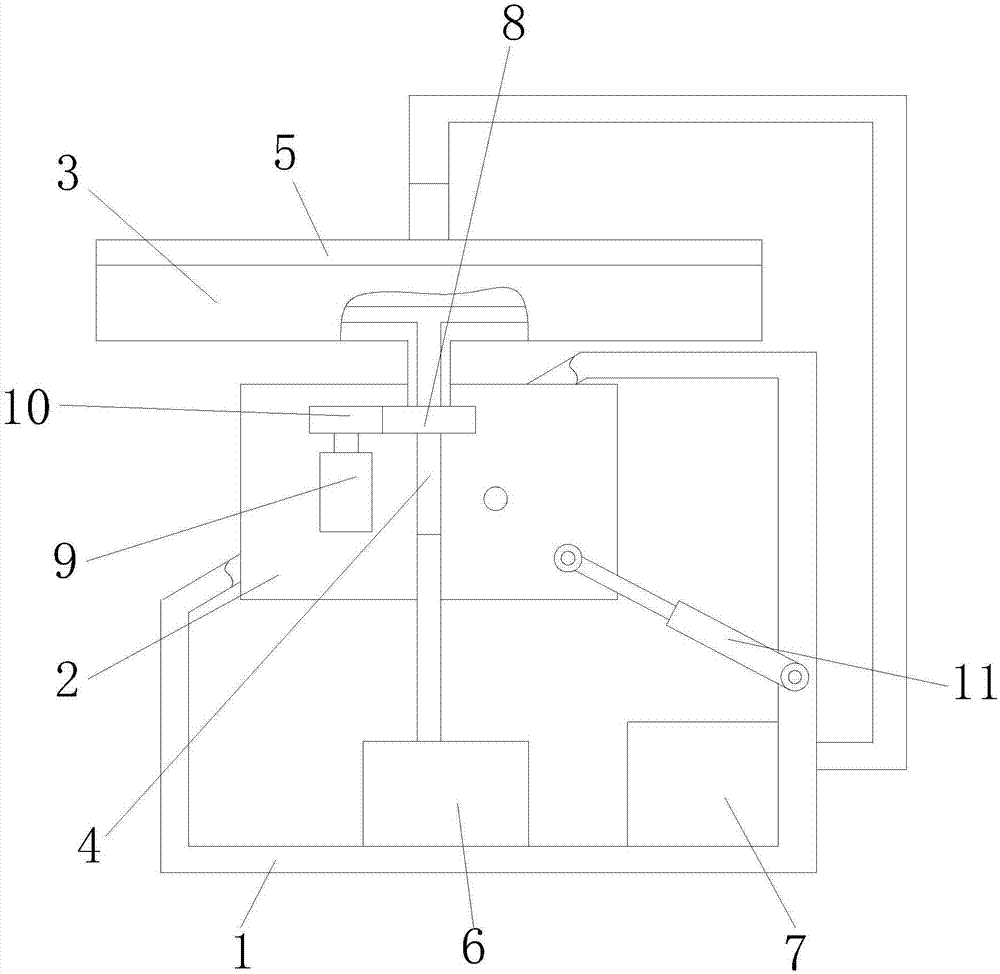

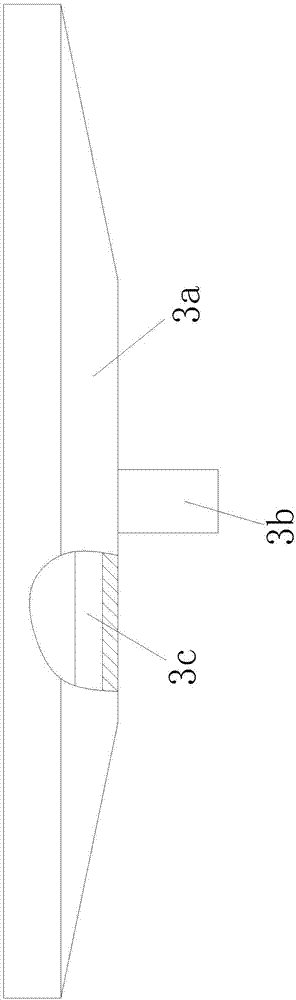

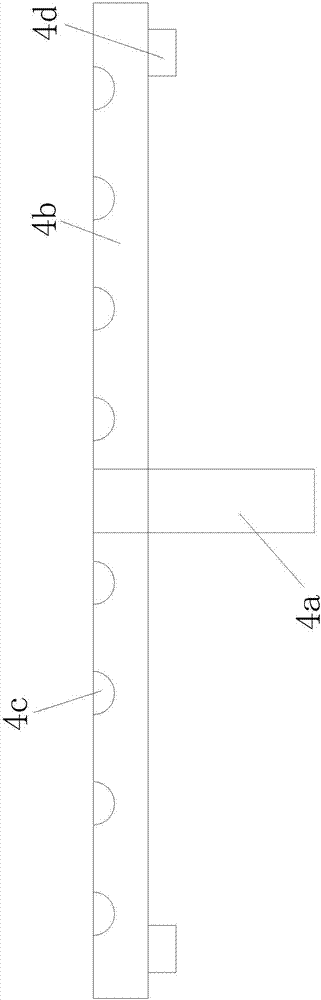

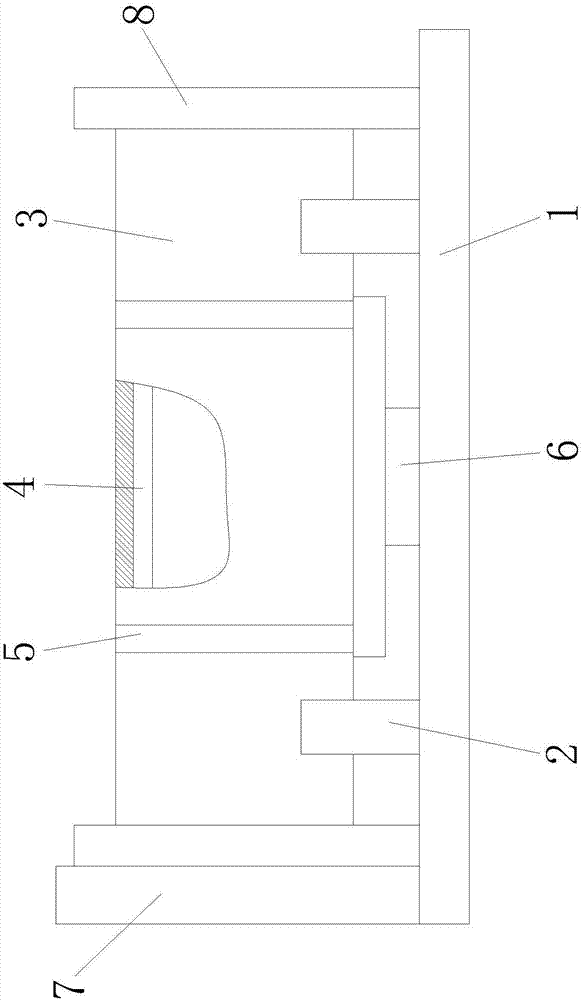

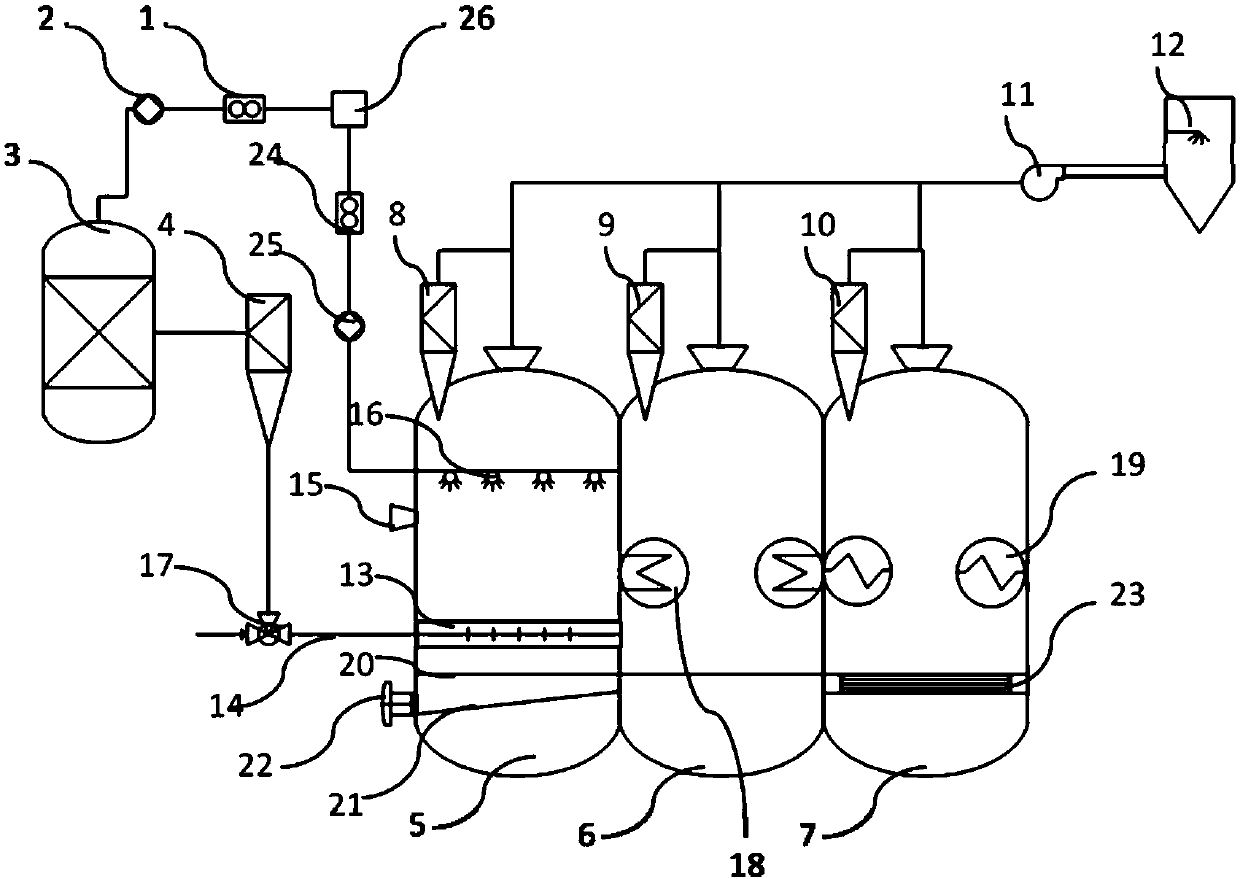

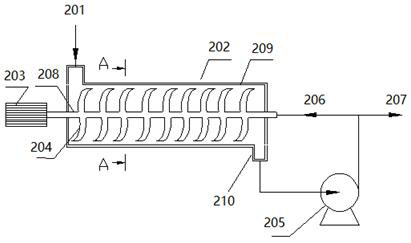

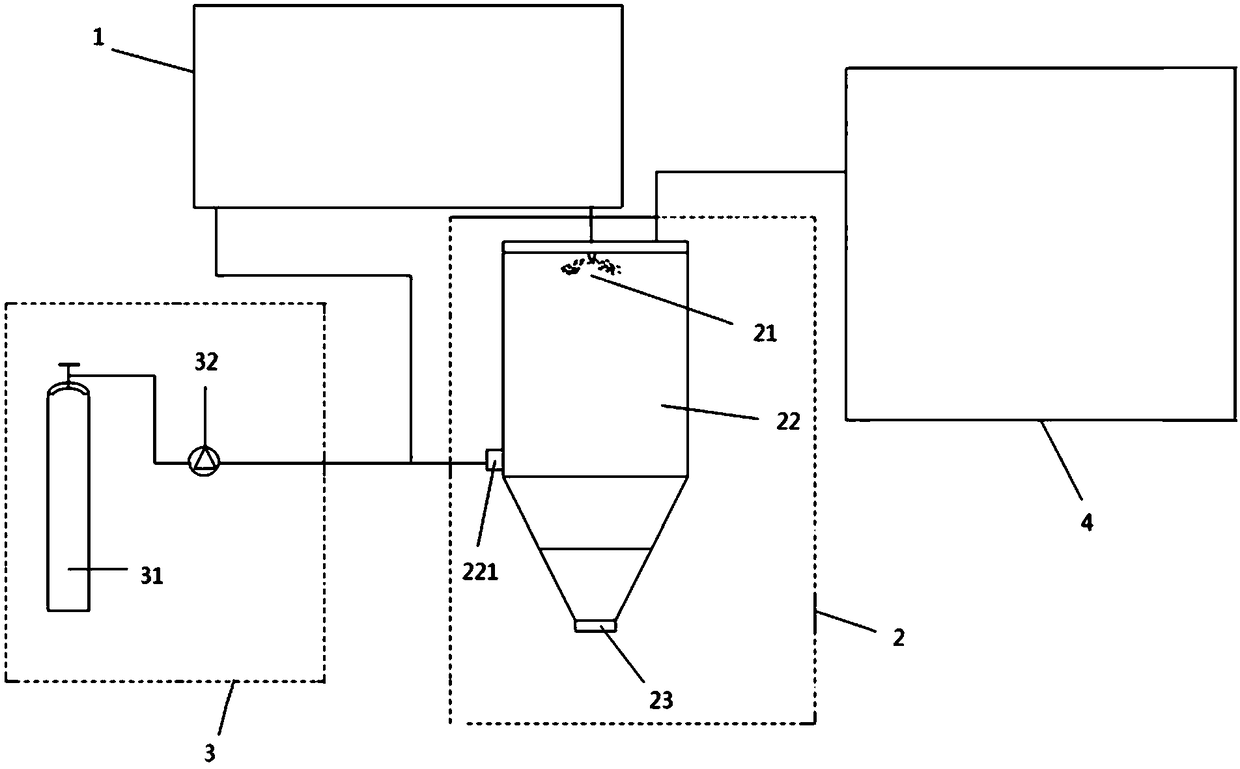

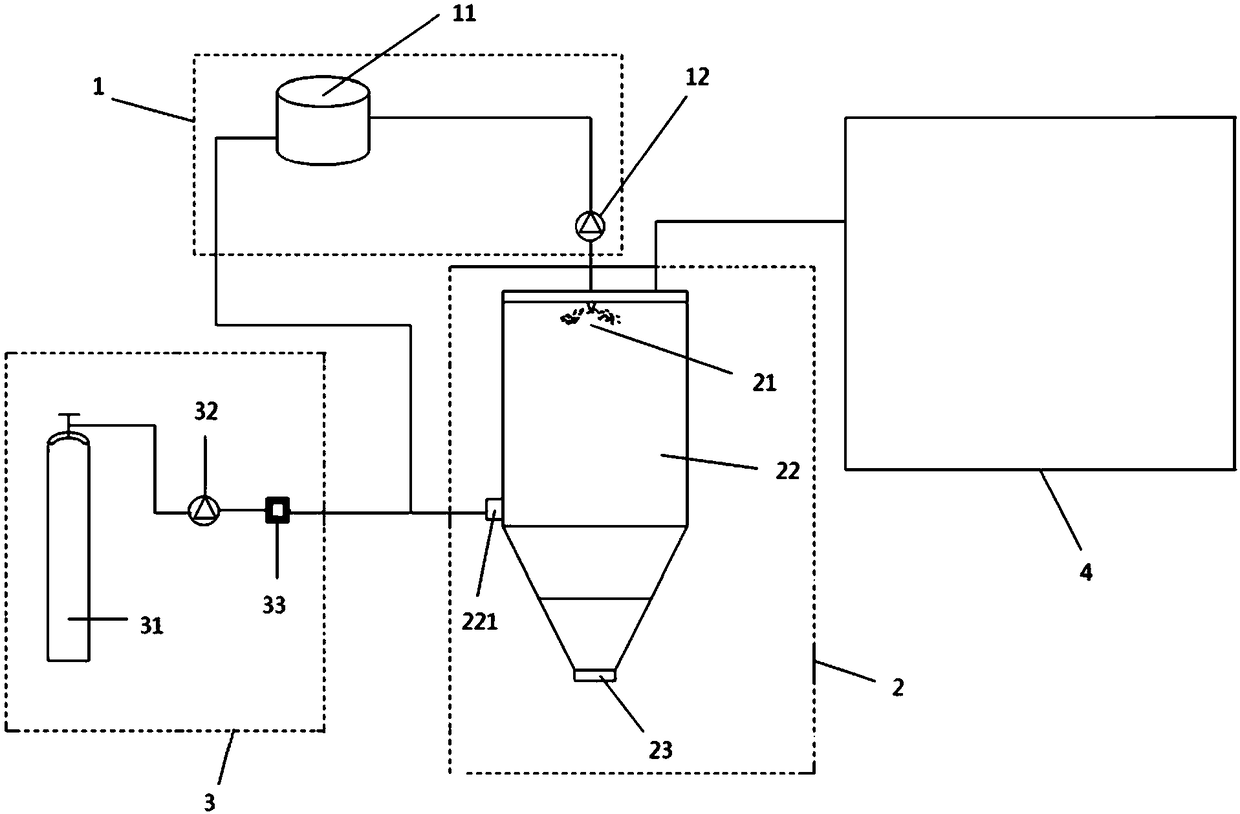

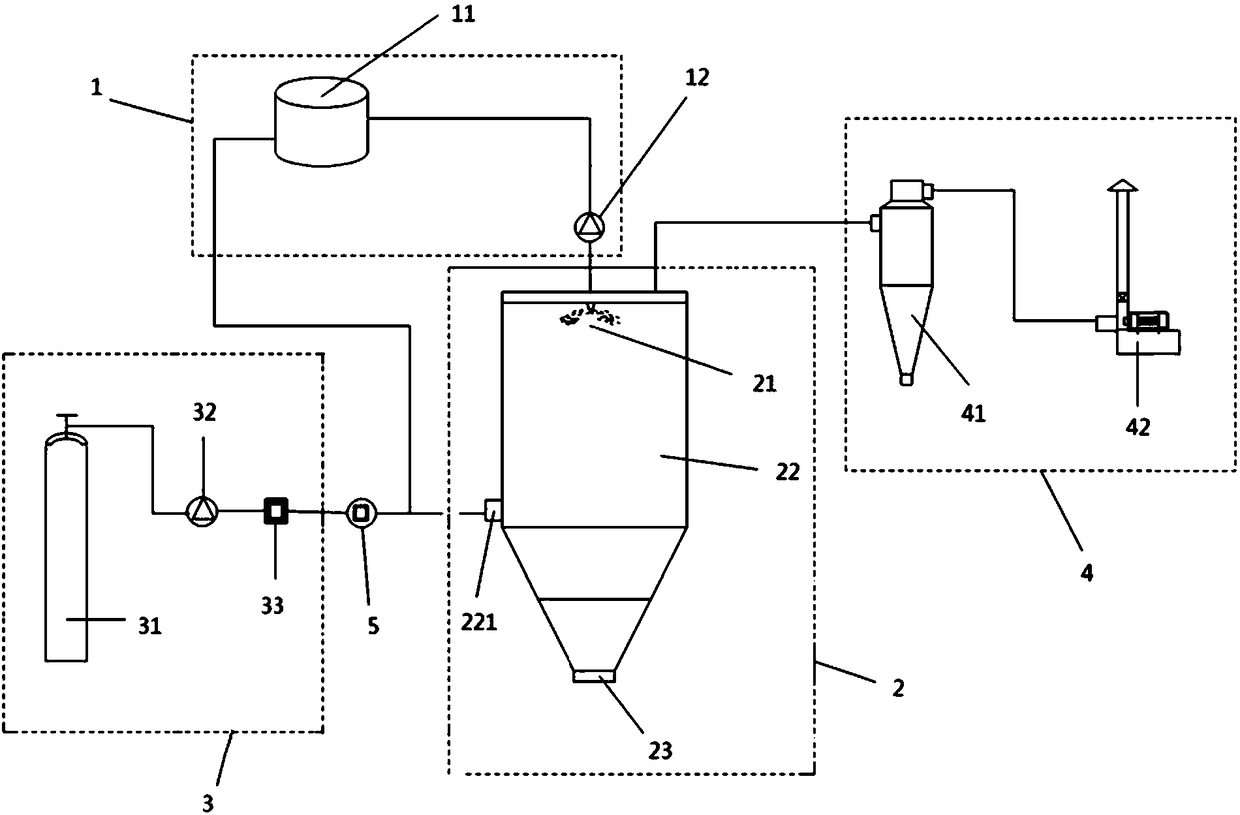

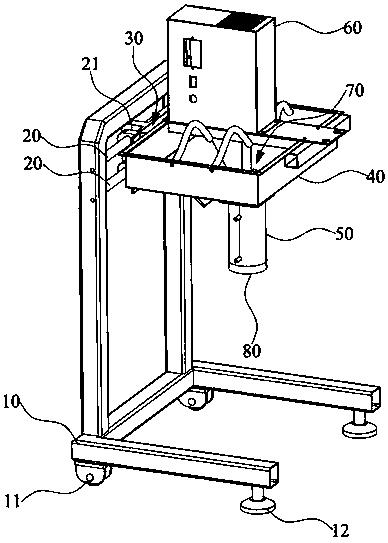

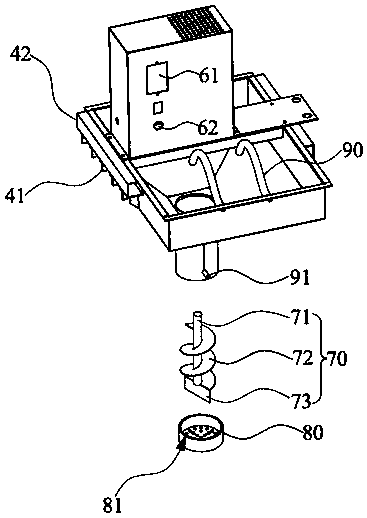

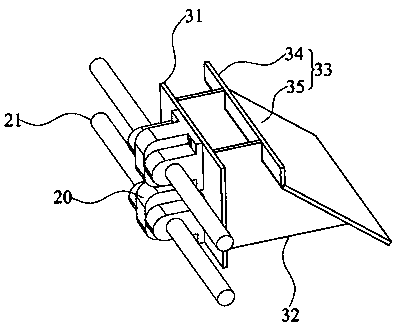

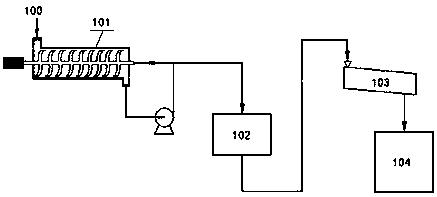

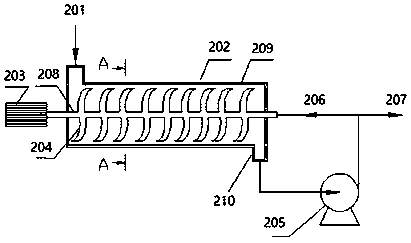

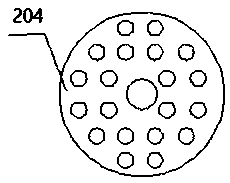

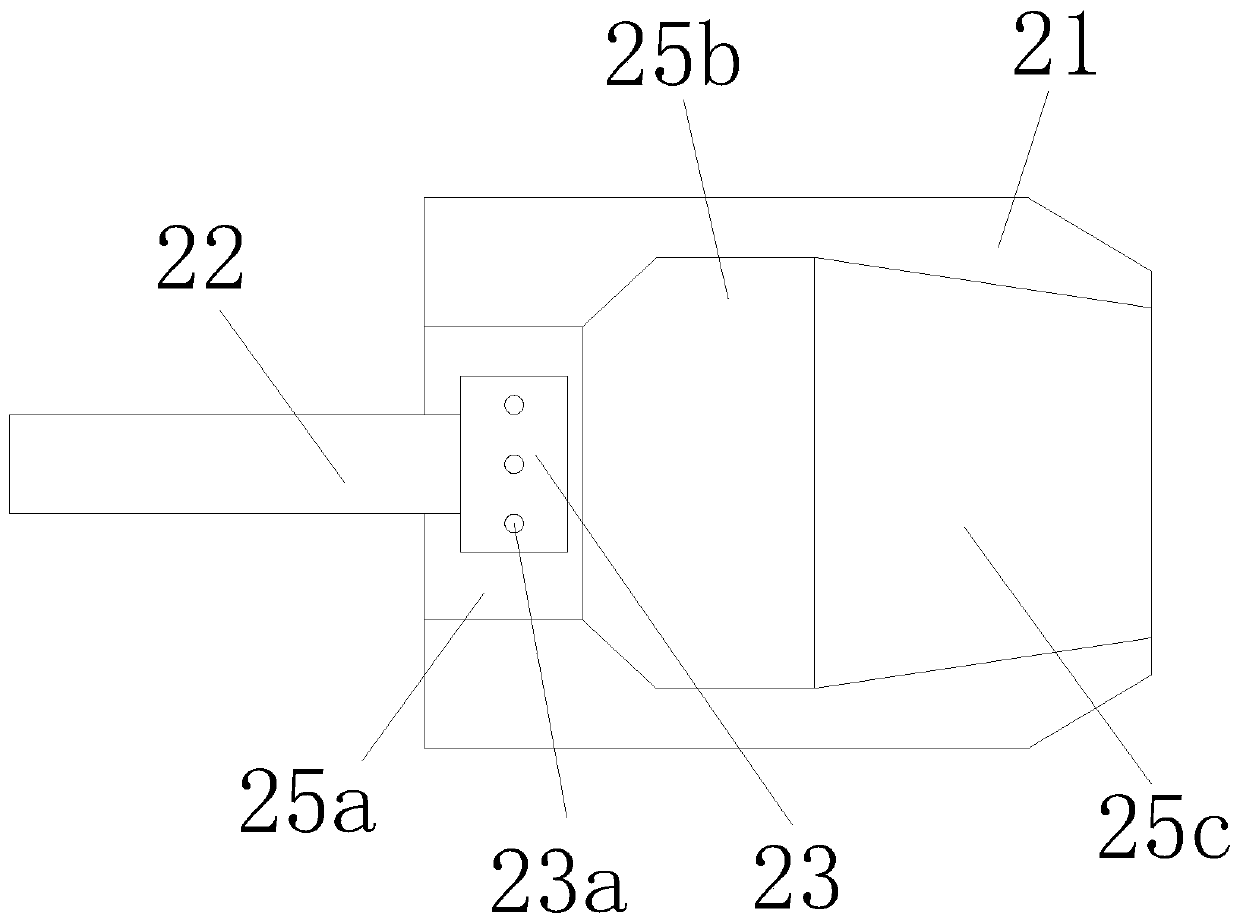

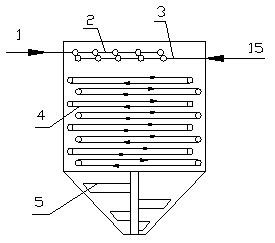

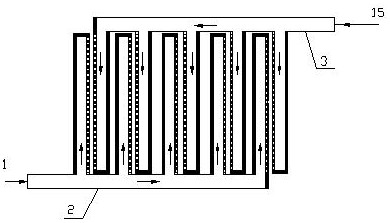

Inert atmosphere granulation system

ActiveCN107081112AGranulation realizationSolve the problem of high melting point substancesGranulation by liquid drop formationEngineeringProduct gas

The invention relates to the technical field of processing systems in the powdery material process and discloses an inert atmosphere granulation system. The inert atmosphere granulation system comprises a feeding device, a granulation device, an inert atmosphere device and an exhaust device, wherein the granulation device comprises a high-temperature spraying granulating machine, a condensing tower and a discharging hole, the high-temperature spraying granulating machine is distributed in the condensing tower, and the discharging hole is formed in the bottom of the condensing tower; the inert atmosphere device comprises an inert gas source and a wind supply pump; the feeding device is connected with the high-temperature spraying granulating machine and is used for conveying materials in the feeding device to the high-temperature spraying granulating machine, the high-temperature spraying granulating machine is used for spraying the materials into the condensing tower, and the inert gas source is in tight connection with an wind inlet of the condensing tower through the wind supply pump and is used for conveying inert gas into the condensing tower so as to granulate the materials sprayed into the condensing tower by the high-temperature spraying granulating machine in an inert gas environment; the exhaust device is used for exhausting waste gas in the condensing tower. By utilizing the inert atmosphere granulation system, the granulation of high-melting-point substances or water and oxygen sensitive powder is realized.

Owner:厦门中烁光电科技有限公司

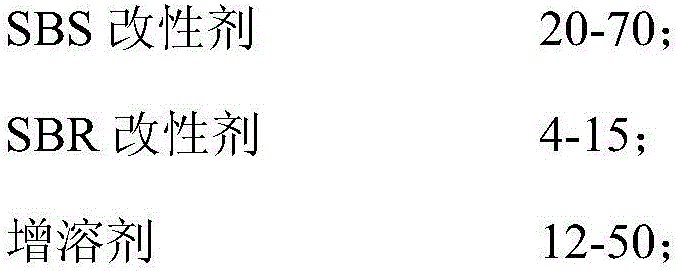

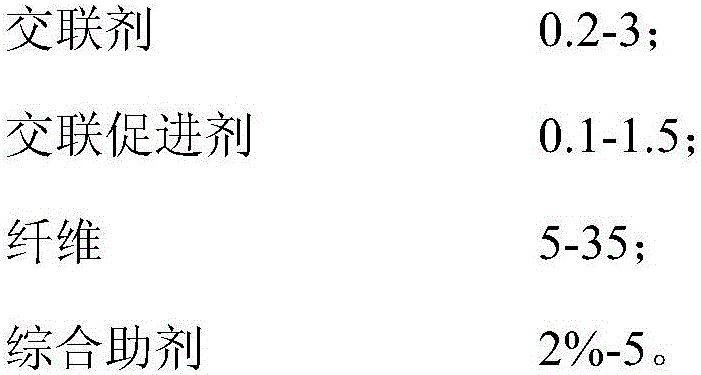

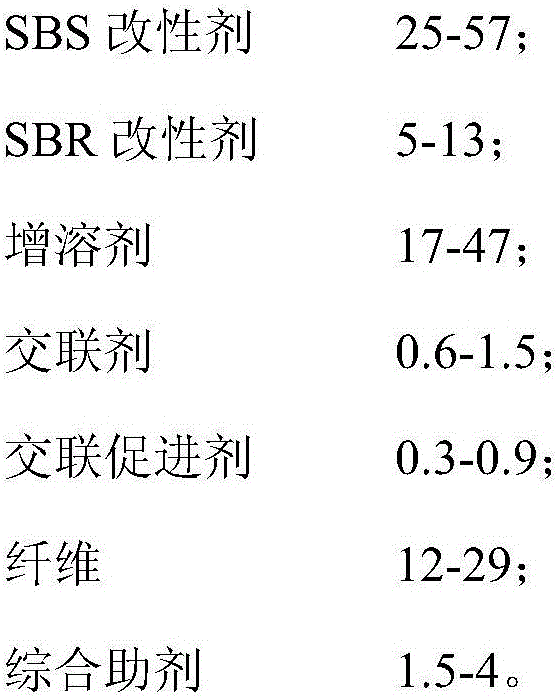

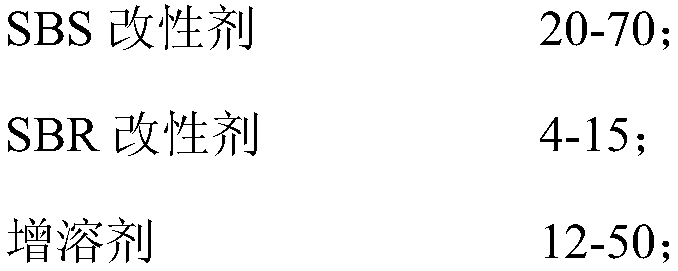

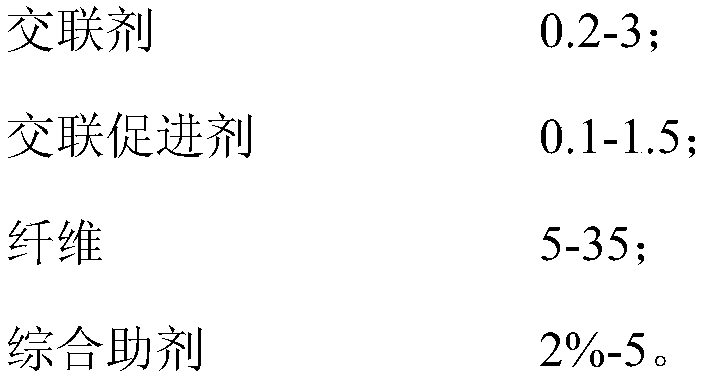

Composite modifier and high-scattering-resistance drainage asphalt concrete prepared through same

ActiveCN106630731AImprove adhesionImprove heat aging resistanceClimate change adaptationCeramicwareFiberCross-link

The invention discloses a composite modifier and a high-scattering-resistance drainage asphalt concrete prepared through the same and relates to the field of road engineering materials. The composite modifier is composed of base materials, fiber, comprehensive additives, cross-linking agent and cross-linking promoter, wherein the base materials are composed of SBS (styrene-butadiene-styrene) modifier, SBR (styrene butadiene rubber) modifier and solubilizer. The drainage asphalt concrete prepared through the composite modifier is high in scattering resistance. Through field deployment of conventional asphalt, aggregate, mineral powder and the composite modifier, a high-performance and stable-performance drainage mixture can obtained and meanwhile is more stable in properties compared with those applying modified asphalt, so that worries on storage segregation and performance degradation of the modified asphalt can be saved, and meanwhile construction deficiencies of dispersing non-uniformity of fiber deployment and grease spots can be completely avoided.

Owner:BEIJING ZHONGLU PAVING TECH +2

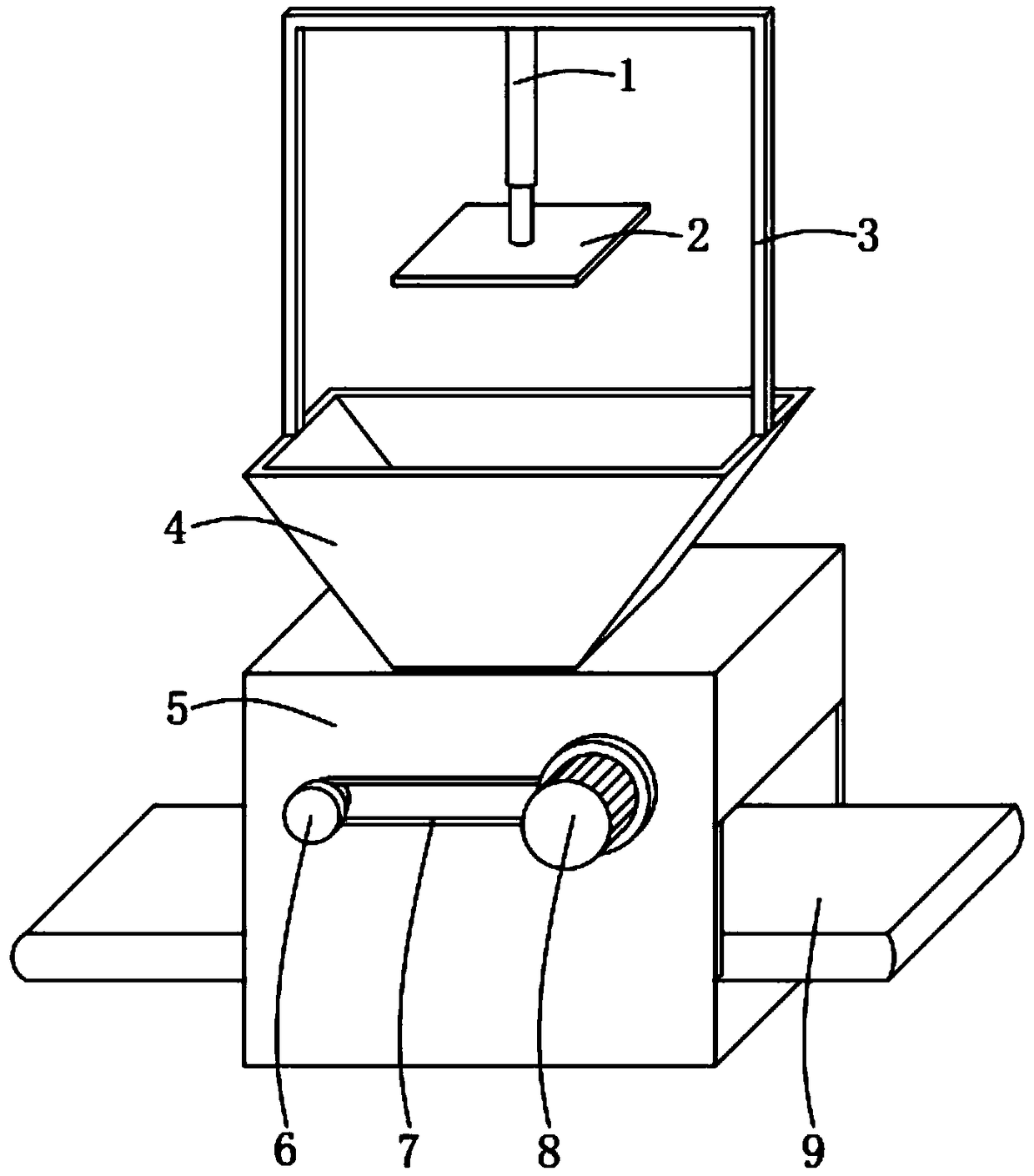

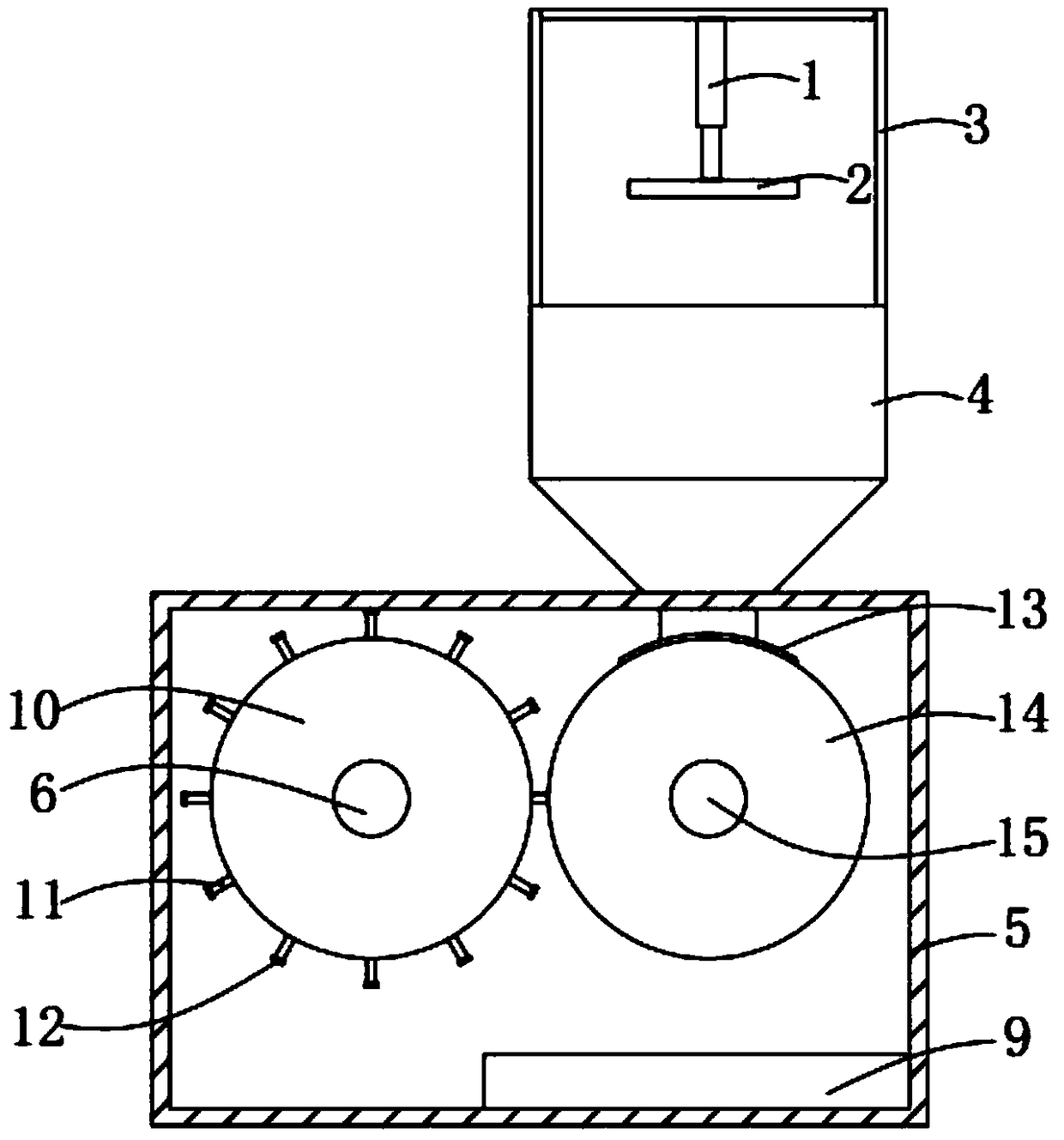

Energy-saving and environment-friendly blocky granulator

InactiveCN111530373AGranulation realizationIncrease profitCocoaGranulation by material expressionMechanical engineeringMaterials science

The invention discloses an energy-saving and environment-friendly blocky granulator. The energy-saving and environment-friendly blocky granulator includes a base, wherein a grinding mechanism is fixedly mounted at the top of the base; a feeding hopper is arranged at the top of the grinding mechanism; two crushing rollers are arranged in the feeding hopper; an extrusion granulating mechanism is fixedly mounted on one side of the base; the grinding mechanism comprises a grinding bin, the grinding bin is fixedly mounted at the top of the base, a bin cover is fixedly mounted at the top of the grinding bin, the feeding hopper is fixedly mounted on one side of the top of the bin cover, a bottom grinding disc is fixedly mounted in the grinding bin, and an upper grinding disc is rotatably connected to the top of the bottom grinding disc. The grinding mechanism and the feeding hopper are arranged at the top of the base, original blocky materials fall into the top of the upper grinding disc after being crushed by a crushing roller, enter the top of the bottom grinding disc through a feeding hole to be continuously ground into powder and are input into the extrusion granulating mechanism to be extruded and discharged, and therefore the utilization rate of the materials is greatly increased.

Owner:李良清

Boiling drying granulating device

PendingCN107096470AReduce flyingSimple structureGranular material dryingDispersed particle filtrationFluidized bedPulp and paper industry

The invention discloses a boiling drying granulating device. The boiling drying granulating device comprises a granulating machine; the granulating machine comprises an upper top cabin, a middle fluidized bed granulating cabin, and a lower bottom cabin; the top cabin, the fluidized bed granulating cabin, and the bottom cabin are communicated with each other, and are sealingly connected so as to form a complete cabin body; the side wall of the top cabin is provided with an induced air inlet; the side wall of the bottom cabin is provided with an air inlet; the air inlet is communicated with a steam heater via a pipeline; a wind regulating valve is arranged on the pipeline; an inlet of the steamer heater is connected with a sub-high-efficiency filter, and a primary middle efficiency filter successively; the induced air inlet is connected with a wind inlet of an induced draft fan via an exhaust duct; a wind regulating value is arranged on the exhaust duct; an wind outlet of the induced draft fan is provided with a silencer. The structure of the boiling drying granulating device is simple and reasonable; when the boiling drying granulating device is used for granulating, granulating fluidity is high, less dust is generated, and mixing, granulating, and drying can be completed in one step.

Owner:GUILIN RONGTONG TECH CO LTD

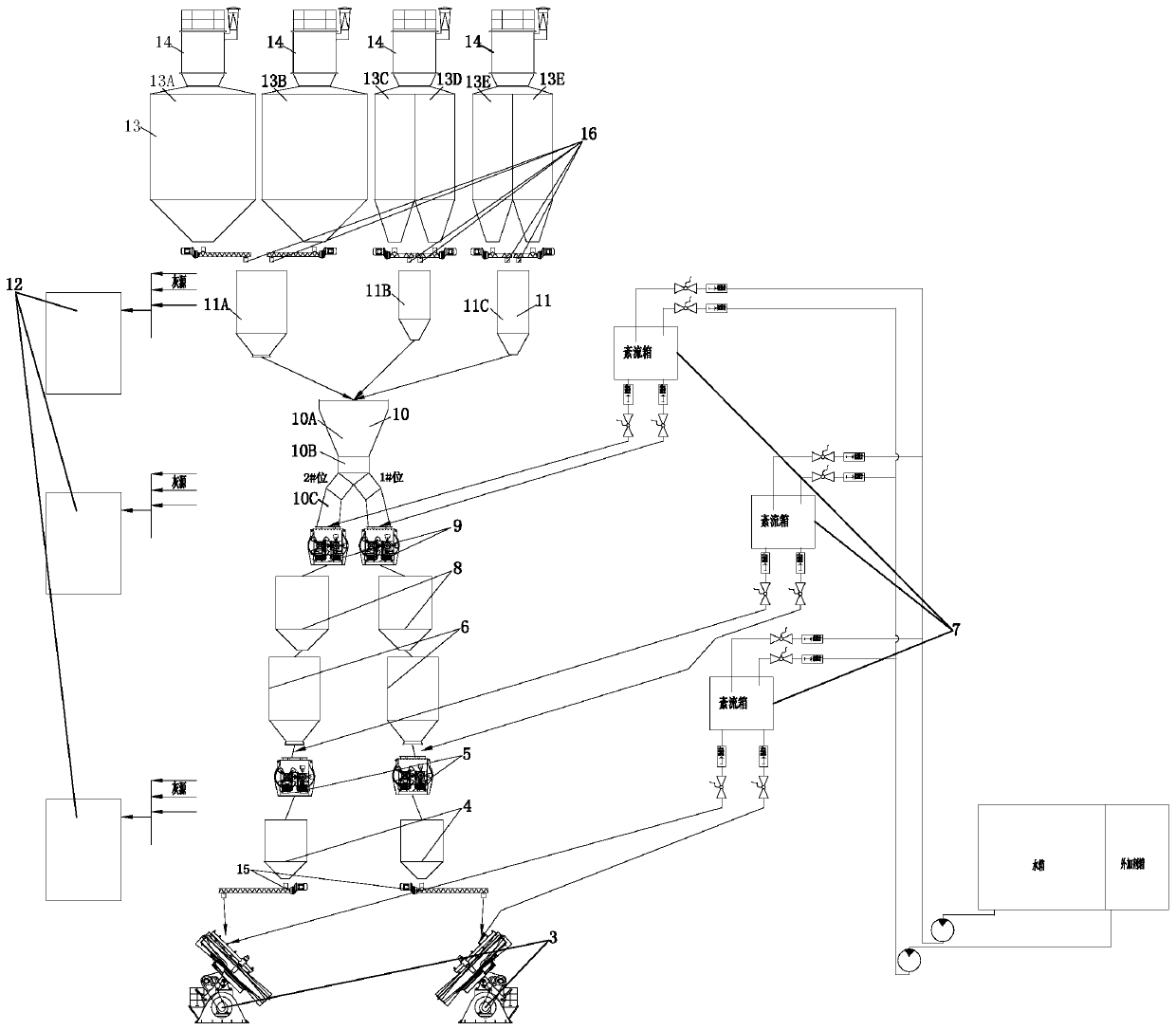

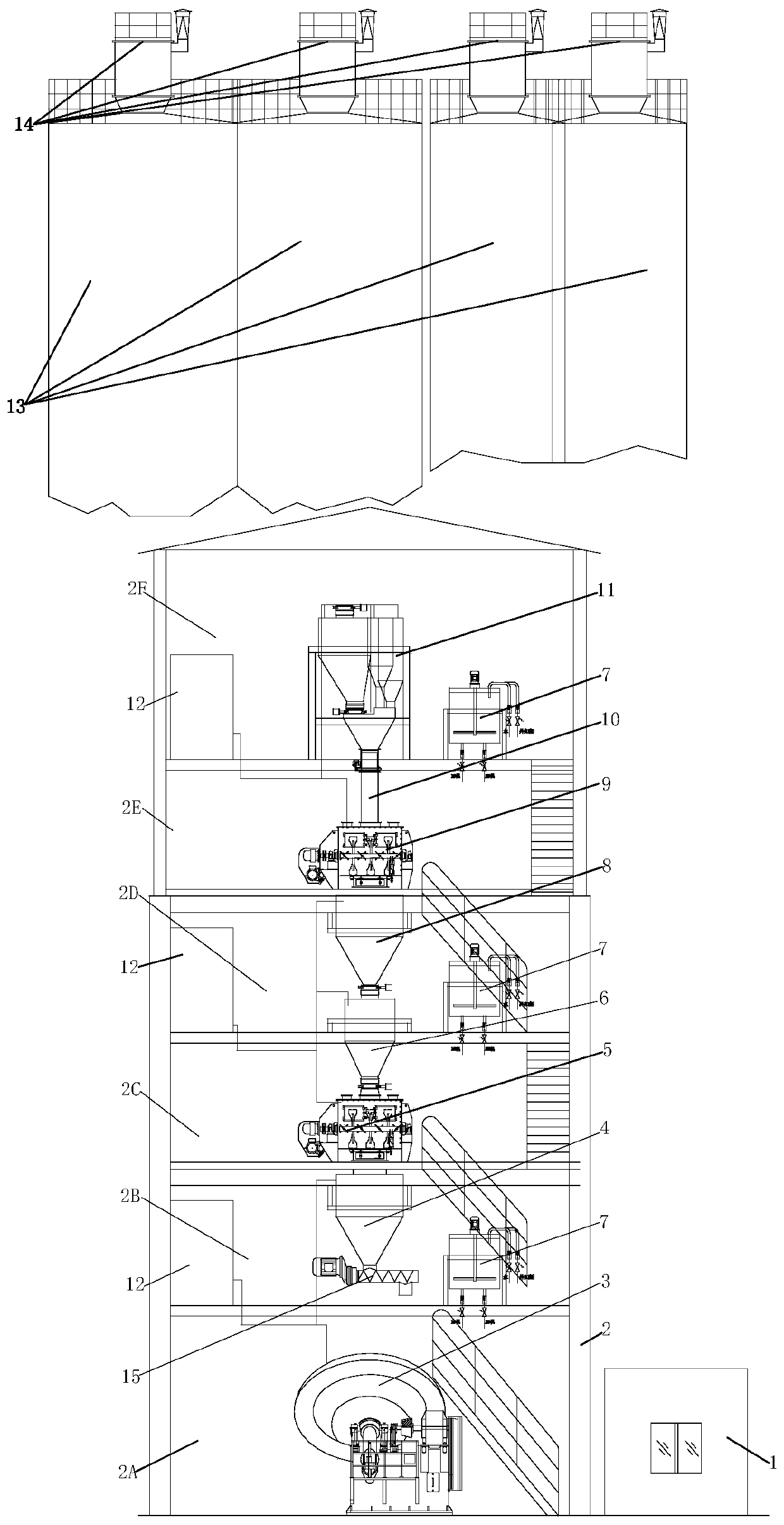

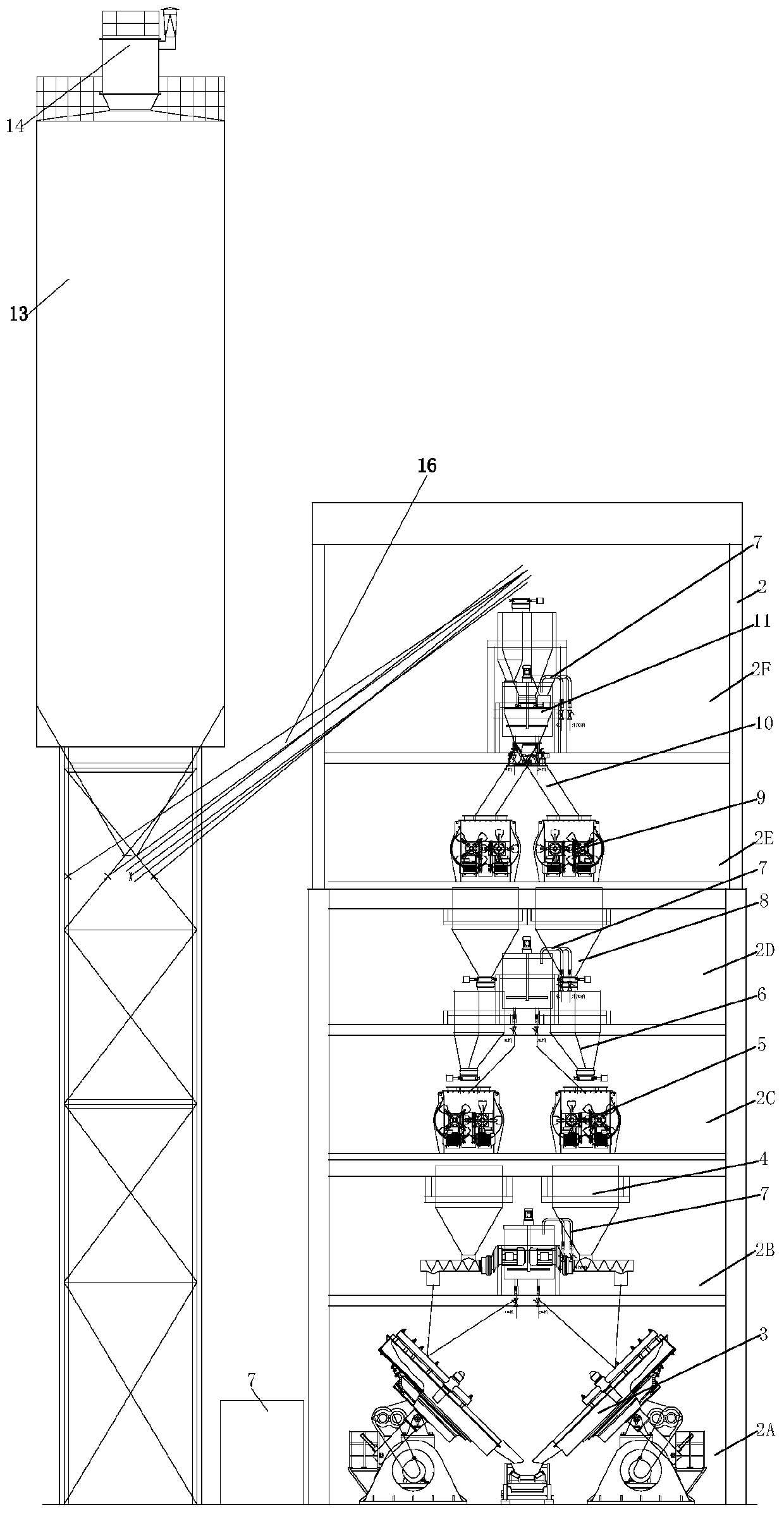

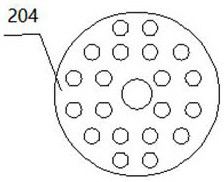

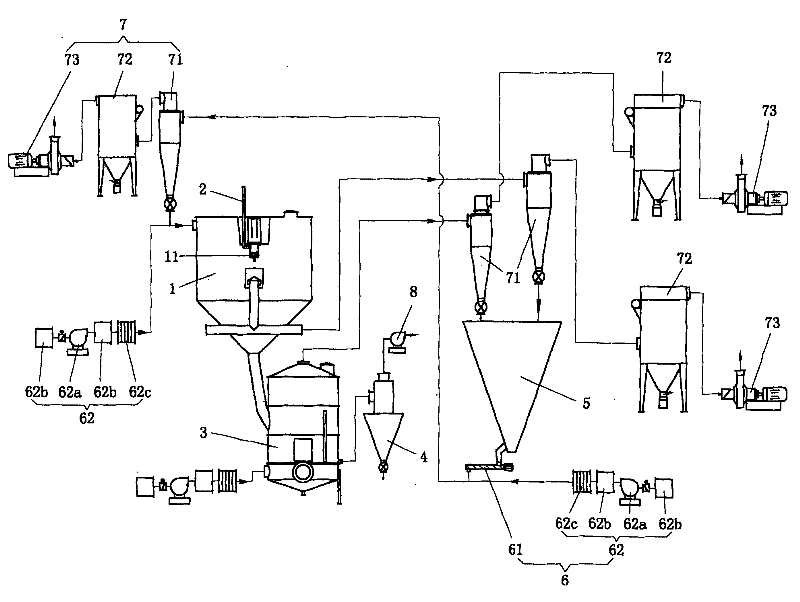

Pelletizing and granulating system and pelletizing and granulating method with large amount of fly ash

PendingCN109821476AIncrease productivityGranulation realizationGranulation in rotating dishes/pansEngineeringFly ash

The invention relates to a pelletizing and granulating system and pelletizing and granulating method with large amount of fly ash, and belongs to the technical field of powder pelletizing and granulating. A feeding screw machine is positioned above a disc type pelletizer, a secondary waiting hopper is positioned above the feeding screw machine, a secondary mixing machine is positioned above the secondary waiting hopper, a secondary batching scale is positioned above the secondary mixing machine, a primary waiting hopper is positioned above the secondary batching scale, a primary mixing machineis positioned above the primary waiting hopper, a powder material discharging device is positioned above the primary mixing machine, a primary batching scale is positioned above the powder material discharging device, a batching screw machine is positioned above the primary batching scale, a silo is positioned above the batching screw machine, a bin top dust remover is positioned above the silo,the disc type pelletizer, the secondary waiting hopper, the secondary mixing machine, the secondary batching scale, the primary waiting hopper, the primary mixing machine and the primary batching scale are connected with a dust remover in a building, the disc type pelletizer, the secondary mixing machine and the primary mixing machine are connected with a water admixture device.

Owner:杭州国电机械设计研究院有限公司

Granulation device for straw recycling

InactiveCN109012488AAvoid easy cloggingGranulation realizationBiofuelsSolid fuelsEngineeringMechanical engineering

The invention relates to the field of straw granulation equipment, in particular to a granulation device for straw recycling. The device includes a charging part, a pressing part and a blanking part.The charging part comprises a blanking hopper, a protective cover, a granulation roller and aggregate holes. The pressing part comprises a pressing wheel, connecting rods and pressing blocks. A firstrotating shaft is fixed inside the pressing blocks. The end of the first rotating shaft is connected to a second rotating shaft through a belt, and the second rotating shaft is connected to a motor. The blanking part includes piston plates, and second limiting rods are fixed at the sides of the piston plates. First limiting rods are fixed at the ends of the second limiting rods through check blocks, and both the second limiting rods and the first limiting rods are slidably connected inside sleeves. The sleeves and the check blocks are connected by springs. And a clump weight is placed inside the second rotating shaft. The granulation device provided by the invention realizes granulation, not only realizes cycle processing, but also has large granulation quantity and high efficiency. Moreover, the inside of the aggregate holes is not easily blocked.

Owner:安徽省兴源草业有限公司

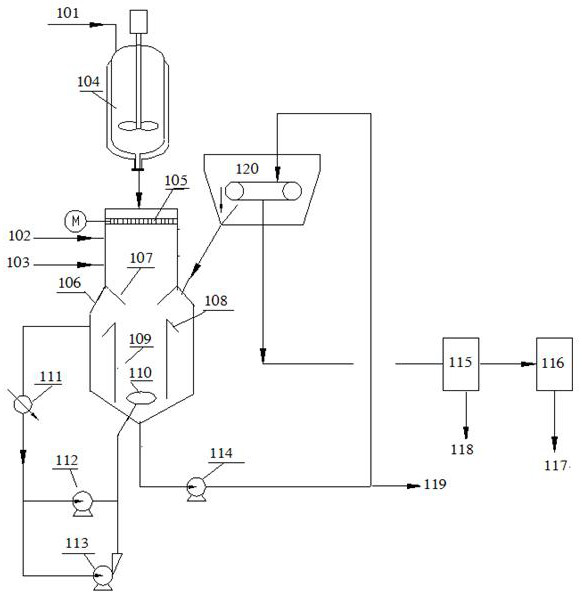

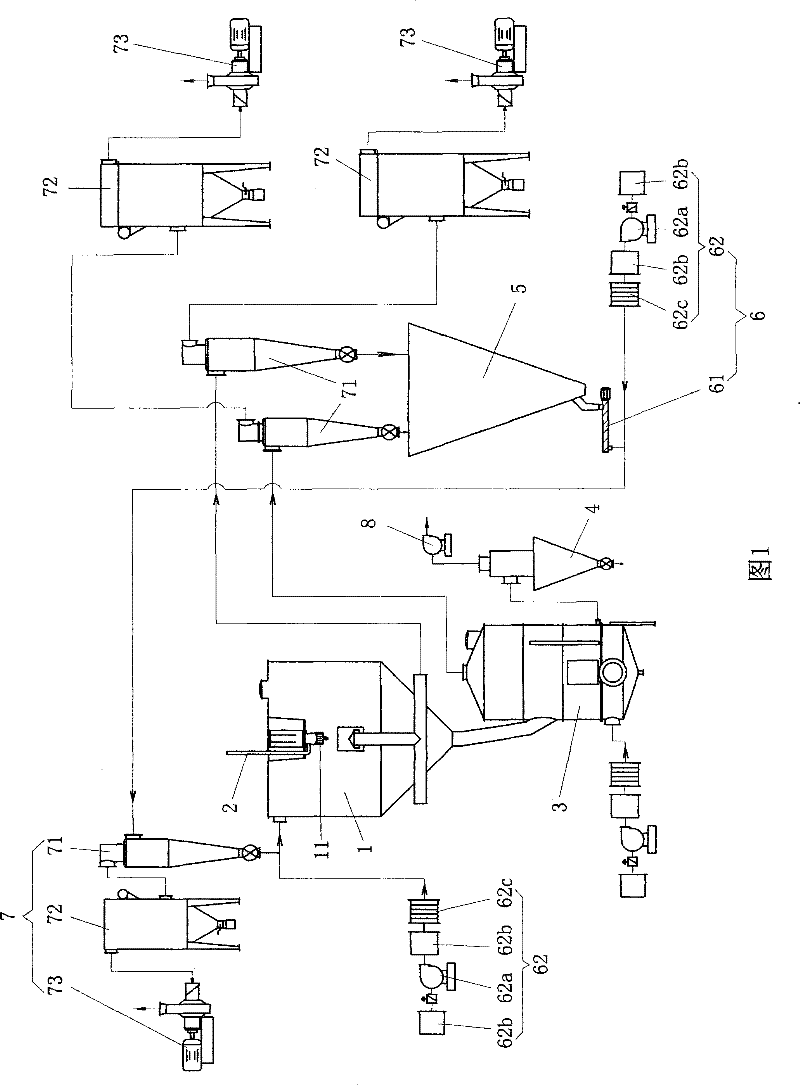

High performance insoluble sulfur production system and method

PendingCN113120870ASolve transportation difficultiesSolving Sulfur-Clogged PipelinesChemical industrySulfur preparation/purificationProcess engineeringSulphur granules

The invention discloses an insoluble sulfur production system and method. The production system comprises a polymerization kettle, a quench tower, a washing filter and a dryer, a discharge port of the polymerization kettle communicates with a feed port of the quench tower through a pipeline, a discharge port of the quench tower communicates with a feed port of the washing filter through a discharge pump through a pipeline, and a discharge port of the washing filter is connected with a feed port of the dryer through a pipeline. According to the production system disclosed by the invention, granulation, curing, extraction and crushing processes are integrated, continuous quenching, curing and the like of the polymerized sulfur are realized, and the technological process is simplified. According to the method, the operation process is shortened, the purity, thermal stability and yield of the product are ensured, the blockage of a sulfur particle system is avoided, and the production process has the characteristics of safety, reliability, simple equipment and operation, low operation cost, obvious energy-saving effect and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

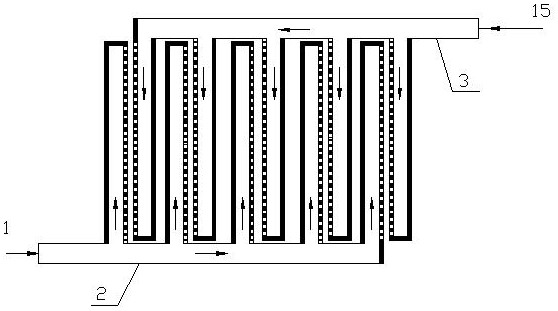

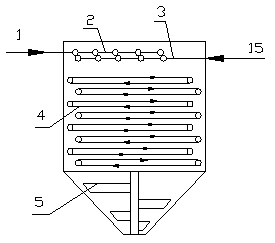

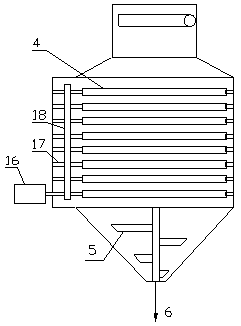

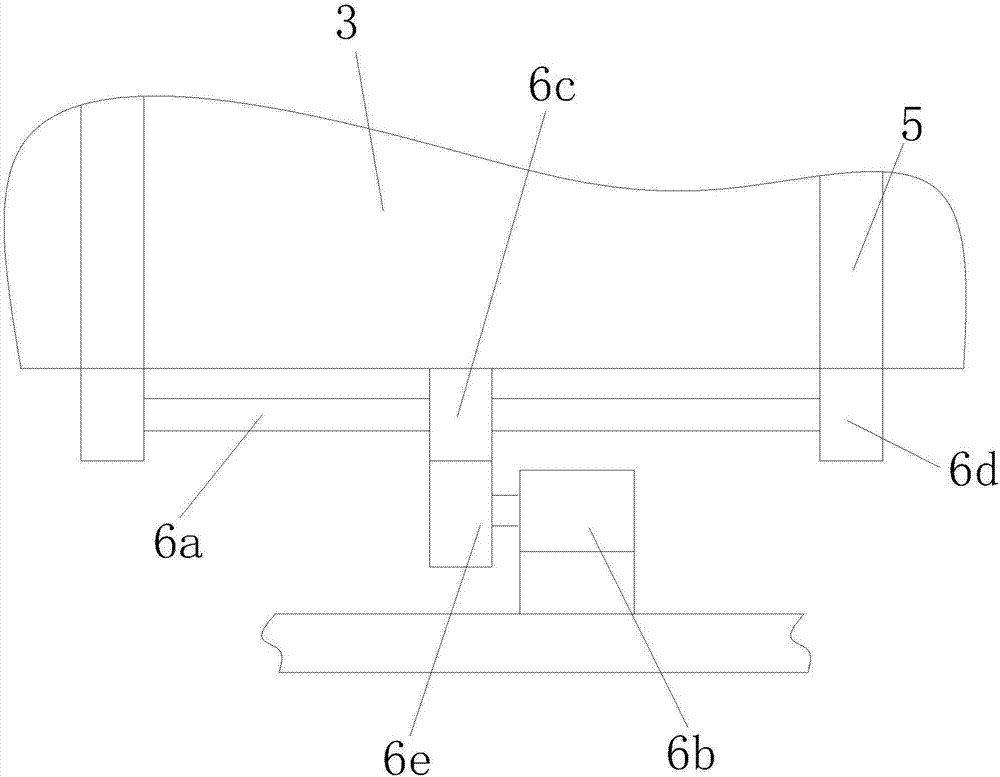

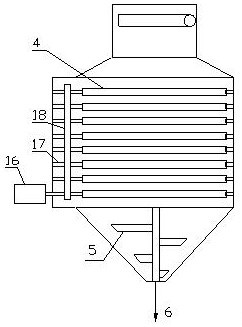

Insoluble sulfur continuous quenching device

ActiveCN111377412AHigh yieldGranulation realizationSulfur preparation/purificationPhysical chemistryThermal stability

The invention discloses an insoluble sulfur continuous quenching device which comprises a shell, and the interior of the shell comprises a feeding quenching section, a material conveying section and adischarging section in the material flowing direction; a feeding distributor and a quenching liquid distributor are arranged in the feeding quenching section, a plurality of layers of conveying beltsare arranged in the material conveying section, fixed rotating shafts are arranged at the two ends of each layer of conveying belt, and a discharging device is arranged in the discharging section. According to the continuous quenching device for insoluble sulfur, continuous quenching of polymerized sulfur can be achieved through continuous granulation and continuous conveying, so the consistencyof the quenching time of polymerized sulfur is achieved, and the yield and the thermal stability of quenched products are guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP +1

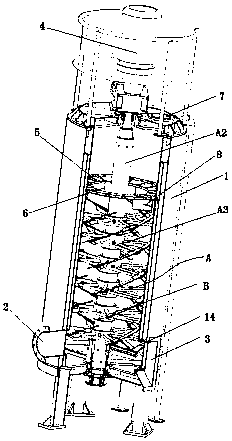

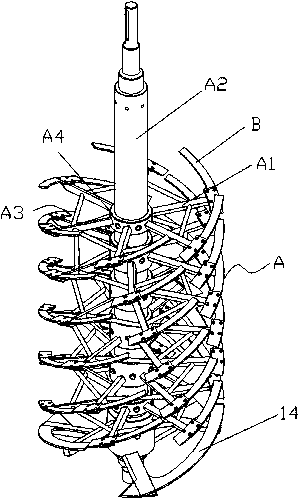

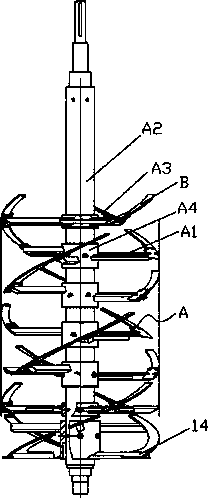

Vertical drying-and-granulating integrated equipment and working method thereof

PendingCN111253043ARealization of dry granulationImprove drying efficiencySludge treatment by de-watering/drying/thickeningGranulation in stationary drums/troughsSludgeProcess engineering

The invention relates to vertical drying-and-granulating integrated equipment and a working method thereof. The vertical drying-and-granulating integrated equipment comprises a vertical tank body anda cutter shaft assembly arranged in the vertical tank body, wherein interrupted spiral strip-shaped blades are distributed on the cutter shaft assembly, a cutting edge is arranged on the lower end edge of each blade, and each blade is connected to the cutter shaft assembly through a connecting rod. The equipment provided by the invention conducts circulated and repeated operations until sludge isdispersed into small-diameter particles and then gradually dries the sludge, so drying and granulating of the sludge are efficiently completed in one piece of equipment, and high efficiency is realized.

Owner:青绿智慧(福建省)环保能源科技有限公司

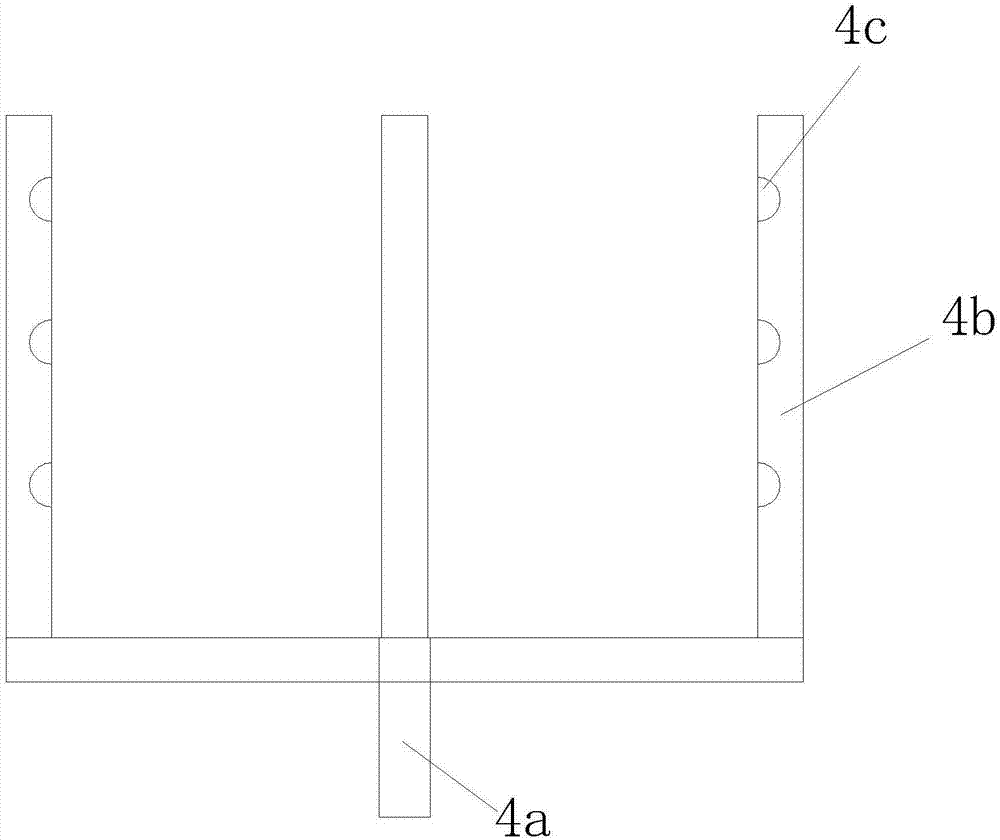

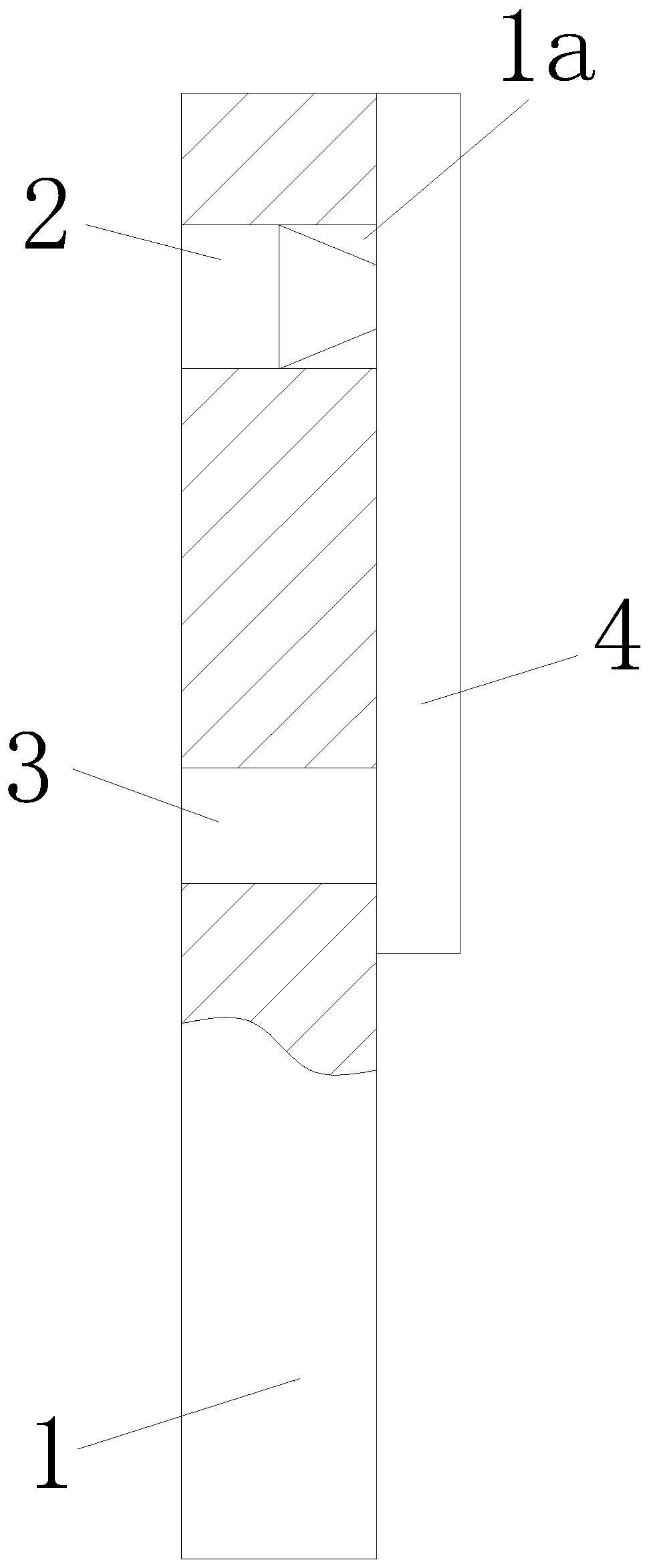

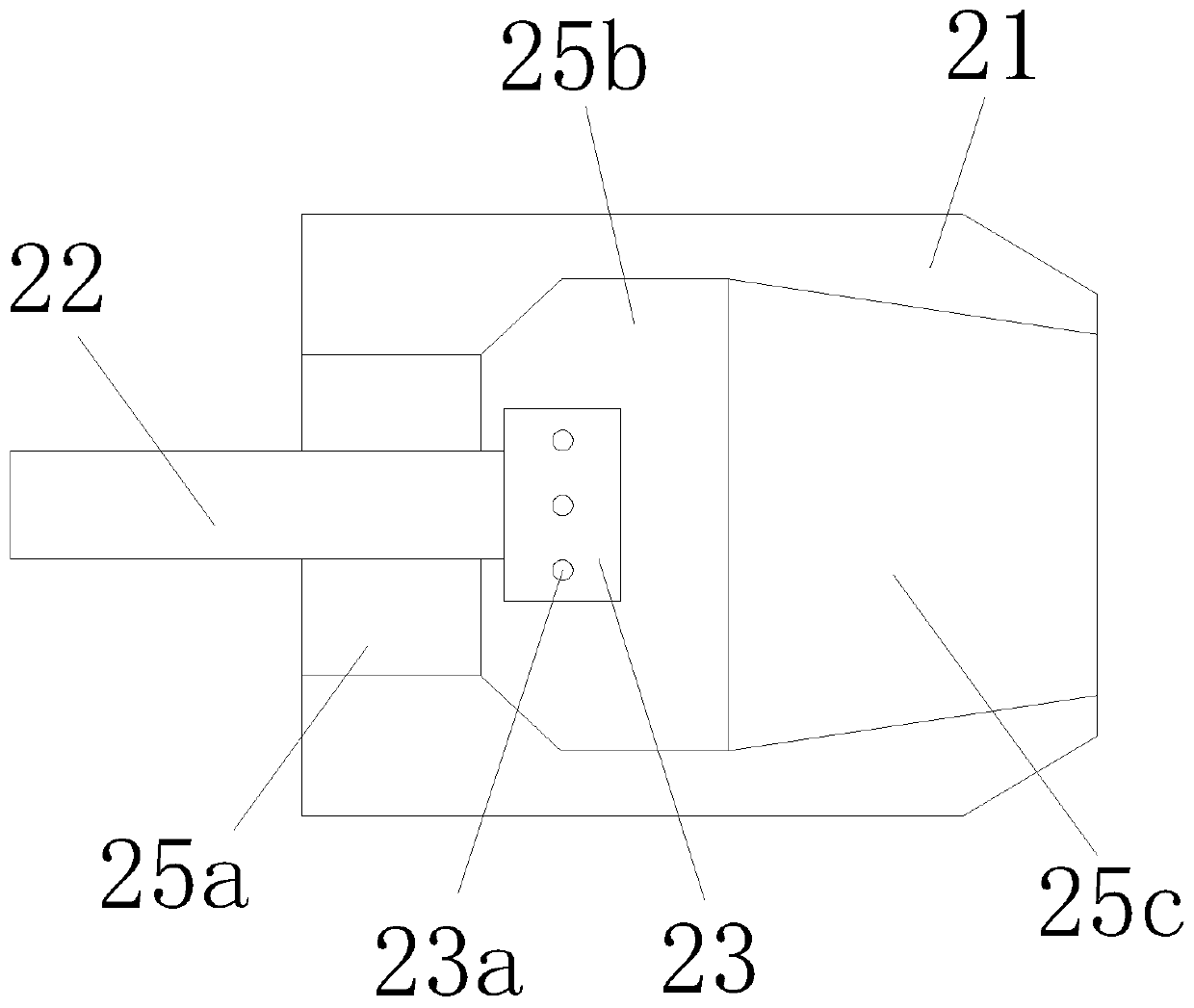

Extrusion die for biomass fuel

ActiveCN107875975AGranulation realizationImprove combustion efficiencyBiofuelsSolid fuelsCombustionMaterial resources

The invention discloses an extrusion die for biomass fuel. The extrusion die comprises a positioning head, wherein a plurality of through holes are formed in the positioning head; granulation units are arranged in the through holes in a detachable manner; a rotating shaft is arranged on the positioning head; a segmenting knife is arranged on the rotating shaft; and the rotating shaft is connectedwith a positioning shaft. According to the extrusion die disclosed by the invention, the granulation units are arranged in the detachable manner, so that granulation of different types of biomass fuelis realized, the application range of the device is widened, the maintenance is convenient, and the manpower and material resources are saved. Moreover, the produced biomass fuel has a hollow structure, and is large in contact area with oxygen and high in combustion efficiency.

Owner:利辛县逸安新能源有限公司

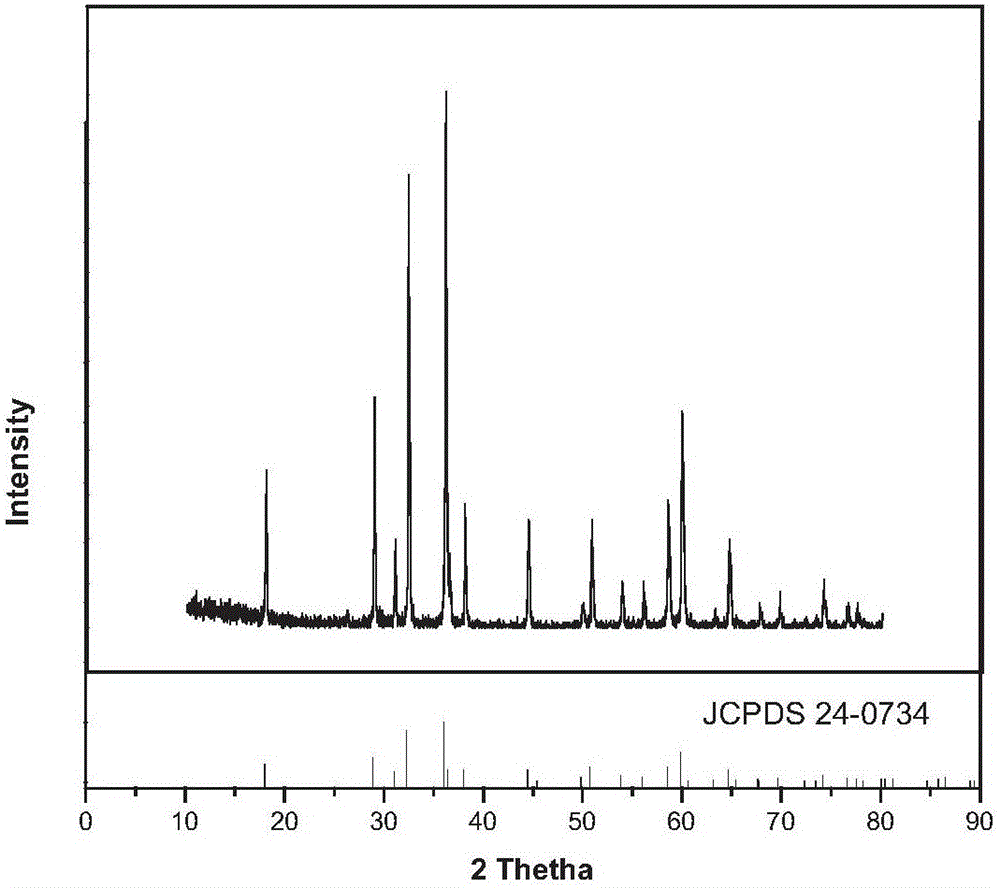

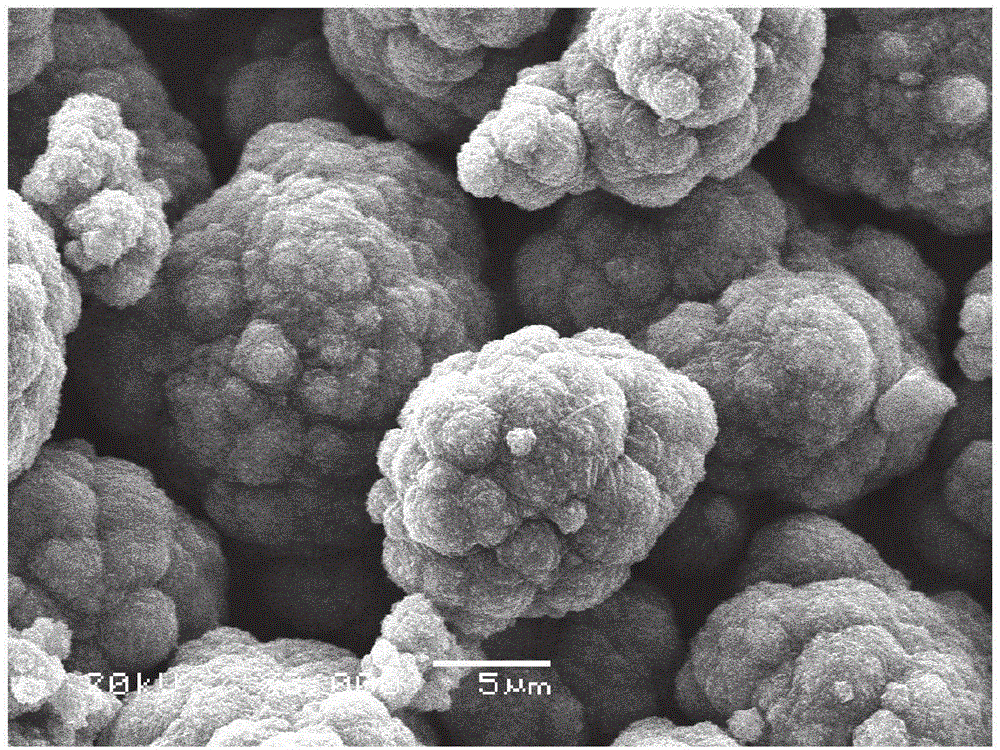

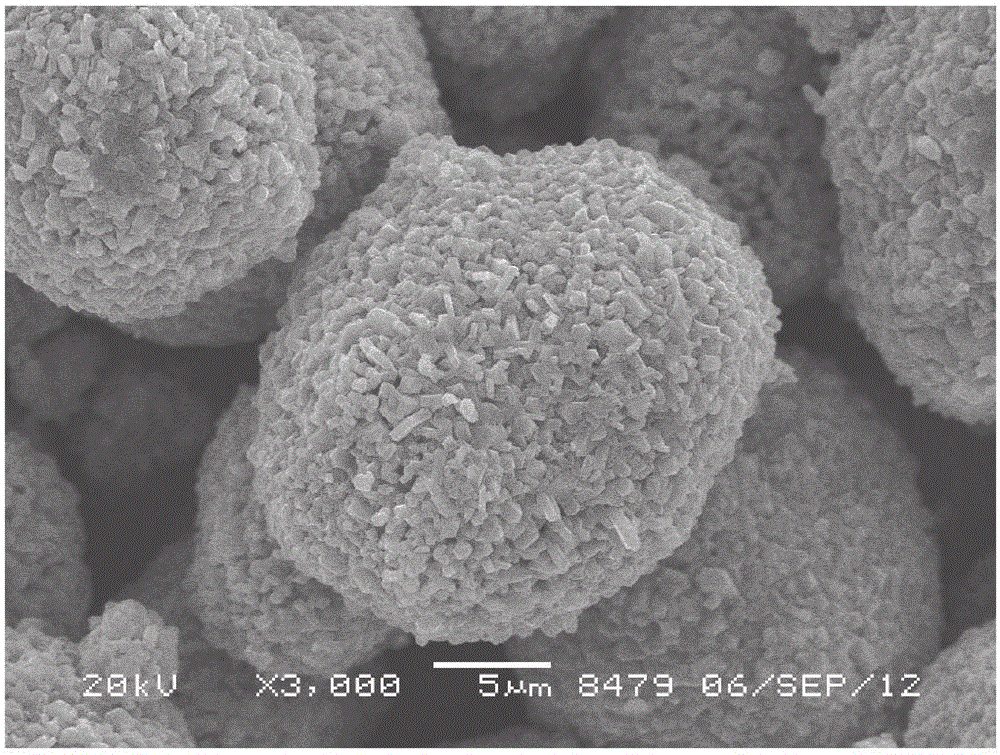

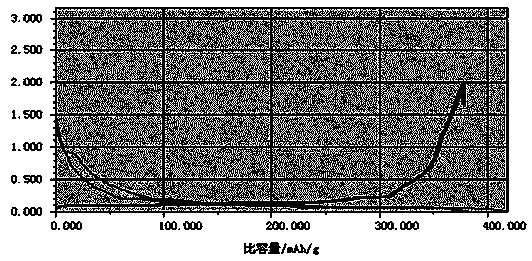

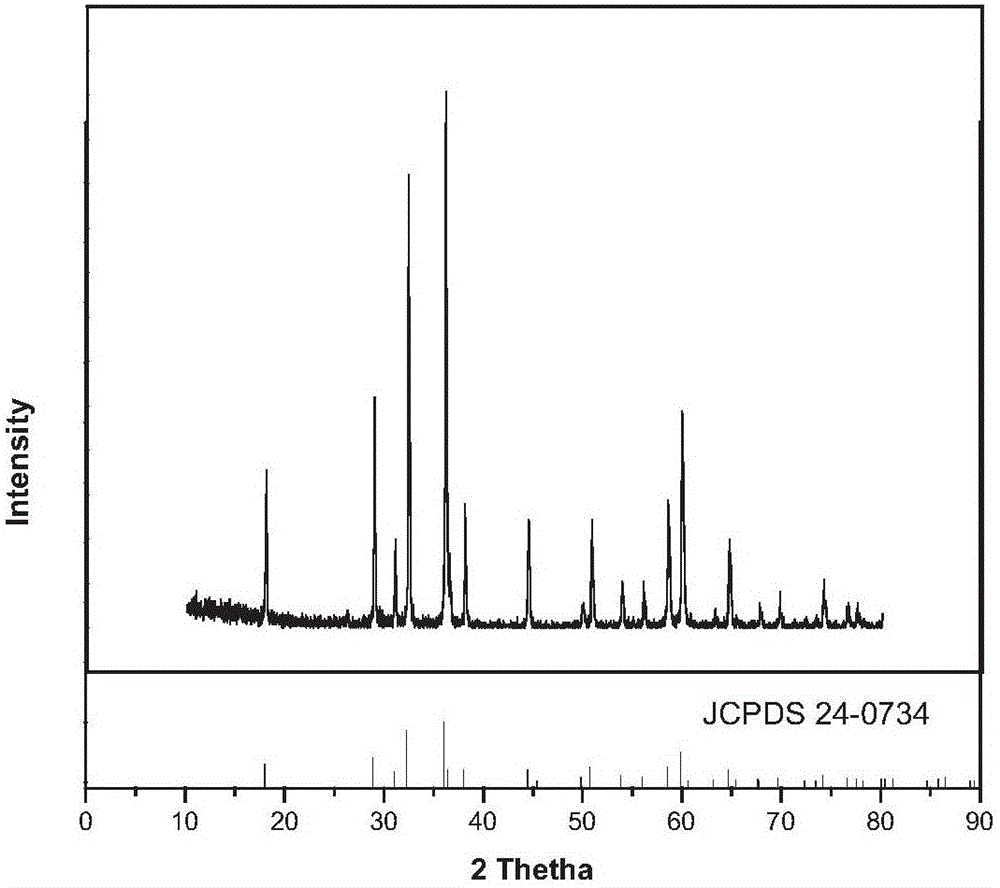

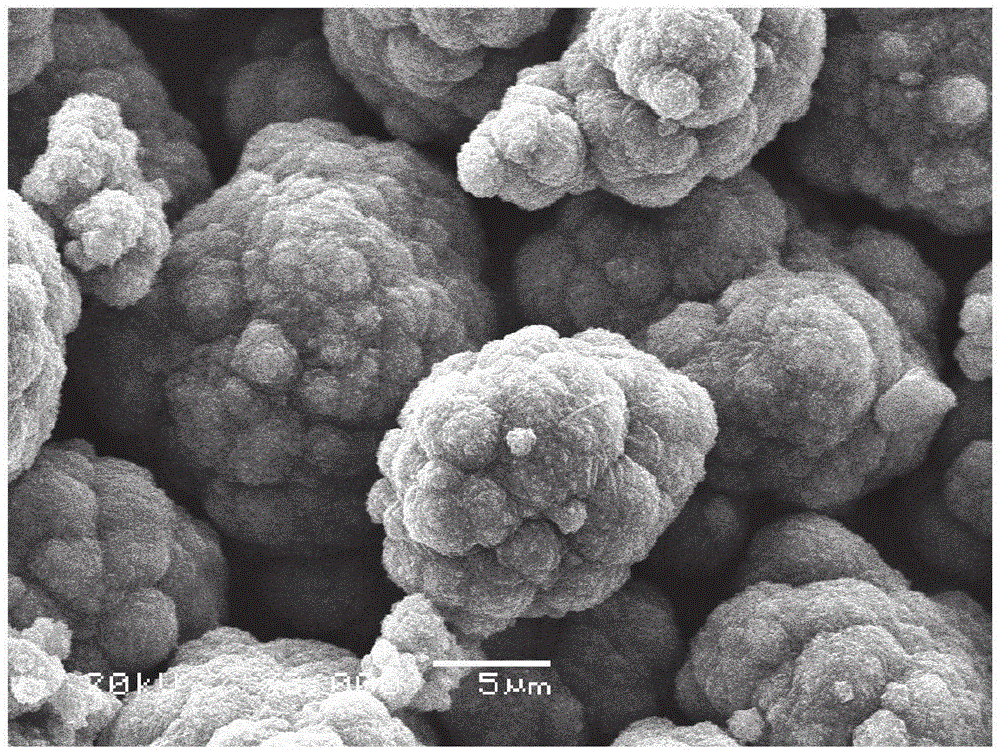

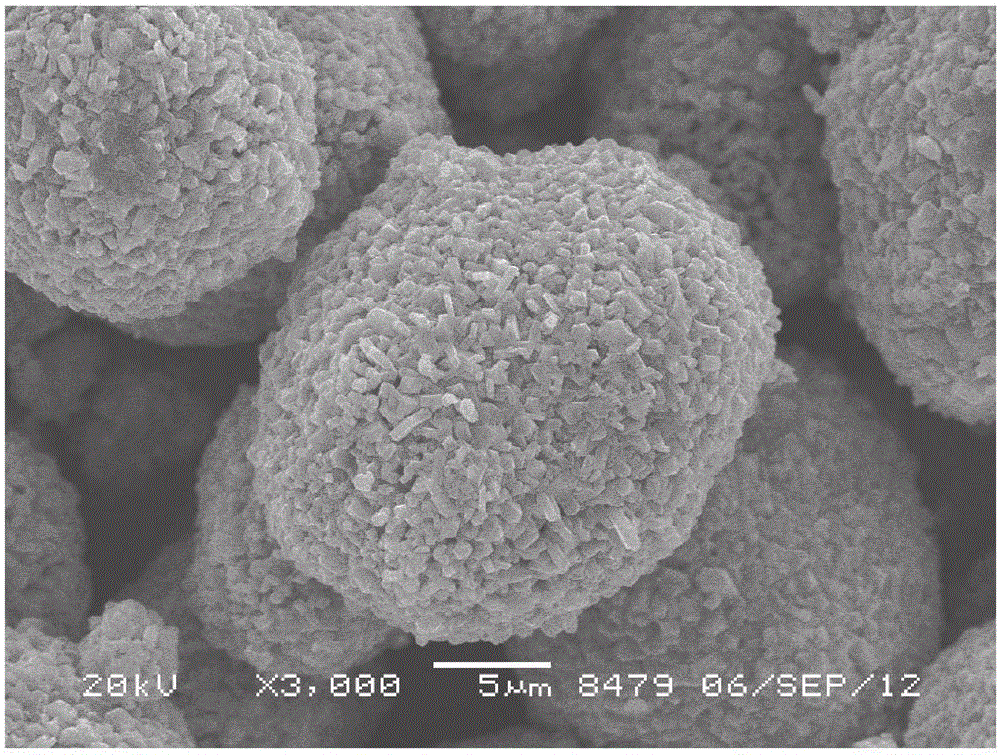

Trimanganese tetraoxide, as well as preparation method and application thereof

ActiveCN105948130AReduce contentParticle regularityCell electrodesSecondary cellsDecompositionParticle-size distribution

The invention discloses a preparation method for trimanganese tetraoxide. The preparation method comprises the following steps: pumping a manganese sulfate solution into a disc granulator, performing crystallization decomposition and rotary granulation under radiation of microwave irradiation, and washing and drying granules obtained by granulation to obtain the trimanganese tetraoxide, wherein the temperature of the microwave irradiation is 900 to 1,200 DEG C; the rotating speed of a disc of the disc granulator is 10 to 30r / min. In addition, the invention further discloses application of the trimanganese tetraoxide prepared by the preparation method to preparation of a cathode material. According to the preparation method and the application, crystallization and granulation are performed under the synergistic action of a rotating parameter of the disc granulator and the microwave radiation, so that preparation of the trimanganese tetraoxide with high purity, large specific gravity and uniform granularity distribution is facilitated, and problems about treatment of ammonium salt wastewater produced by an existing universal process of preparing trimanganese tetraoxide by virtue of a wet manganese sulfate oxidization method are solved; the method is short in process flow, easy to control and suitable for industrial production.

Owner:HUNAN MENGDA NEW ENERGY MATERIALS CO LTD

Granulating chicken-feeding device

The invention discloses a granulating chicken-feeding device. The granulating chicken-feeding device comprises a granulating box and a classifier; the granulating box is fixed on a frame; the top of the granulating box is provided with a feeding inlet; the feeding inlet is arranged at the right side of the granulating box; a motor is arranged at the bottom of the granulating box; the motor is disposed at an intermediate position of the bottom of the granulating box; the granulating box is provided with a grinding roller, a grinding wall, a guiding plate, a granulating shaft and a granulating knife; the grinding roller is provided with a grinding teeth; the grinding wall is disposed under the grinding roller; the grinding wall is provided with the same grinding teeth as the grinding roller;the guiding plate is disposed on the inner wall of the granulating box and placed under the grinding wall; the granulating shaft is connected to the granulating knife; the granulating shaft is connected to the motor; the inner wall of the granulating box is provided with a granulating wall; and the granulating box is connected to the classifier through the plate. The granulating chicken-feeding device can realize the grinding, stirring and granulation of a prepared feed, and has the advantages of simple structure and convenient operation.

Owner:广西北流森艺瓷业有限公司

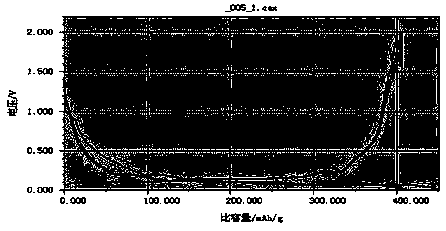

A kind of method for preparing tin-carbon lithium ion negative electrode material

ActiveCN108493437BLow expansion propertiesGranulation realizationCell electrodesTin dioxideCopper oxide

The invention discloses a method for preparing a cathode material of tin-carbon lithium ion cathode material. The method comprises the following steps: (1) performing doping modification on tin dioxide, namely weighing certain amounts of nano tin dioxide and red copper oxide in a ratio of 100:(10-50), performing dry-method ball milling for 1 hour; and performing carbon heat reduction in an atmosphere furnace; (2) performing composite pelletizing on a tin dioxide modification product with graphite; (3) performing secondary wrapping modification. According to the method, as the tin dioxide is subjected to doping modification with the red copper oxide, the expansion property of a tin-carbon compound can be degraded, and the circulation property can be improved; due to two times of pelletization with processes of molding, roasting and dispersion formation, the method is short in time, simple in process and easy in industrial large-scale production; meanwhile, advantages of pelletization oftin dioxide and graphite and graphite and graphite can be achieved, and a function of surface modification upon the graphite with the tin dioxide can be also achieved; due to two times of coating, surface defects caused in the two times of pelletization process can be remarkably alleviated, and the first efficiency and the circulation property of a product can be improved.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

Compound fertilizer granulator

InactiveCN107511113AGranulation realizationWell mixedDispersed particle filtrationGranulation in rotating dishes/pansWorking environmentEngineering

The invention discloses a compound fertilizer granulator. The granulator comprises a rack, a turret is mounted on the rack, a granulation tray and a power device for rotating the granulation tray are mounted on the turret, a spray tube for adding medicaments is arranged in the granulation tray, an end cap is arranged on the end of the granulation tray via a bearing connection manner, the rack is provided with a driving device for controlling the rotation of the turret, a mixing device for supplying raw materials to the spray tube, and a filtering device for filtering the air inside the granulation tray. The compound fertilizer granulator has the advantages of small floor space, convenient use and the like, and the granulation of the fertilizer is realized through the cooperation of the granulation tray, the spray tube and the mixing device, the artificial spraying is replaced, the fertilizer is guaranteed to be uniformly mixed and granulation efficiency of the fertilizer is improved, and the exhaust gas is filtered through the filtering device, the pollution of the fertilizer to the surrounding environment in the manufacturing process is reduced, and the working environment of an operator is improved.

Owner:ANHUI RUIHU BIO FERTILIZER

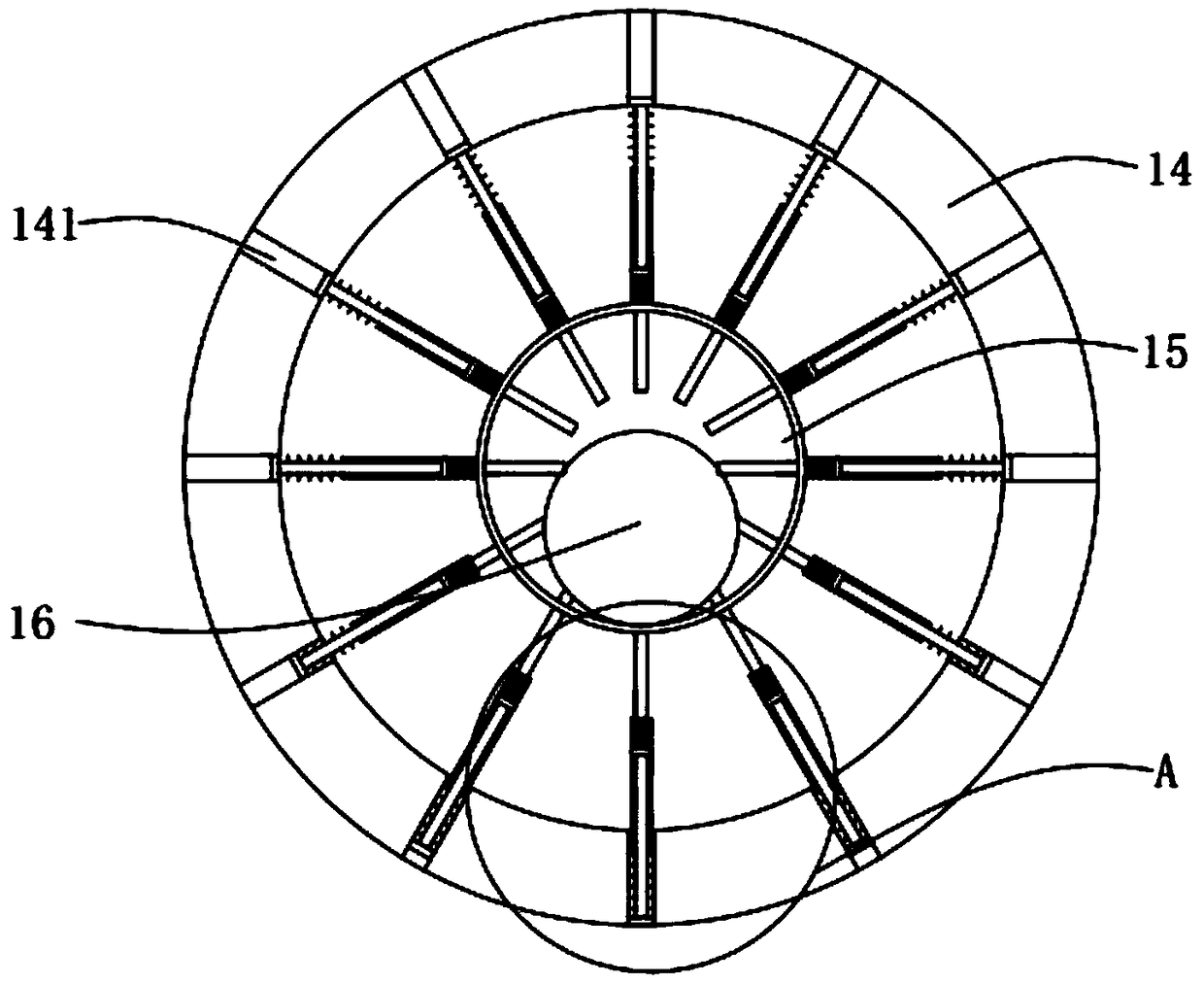

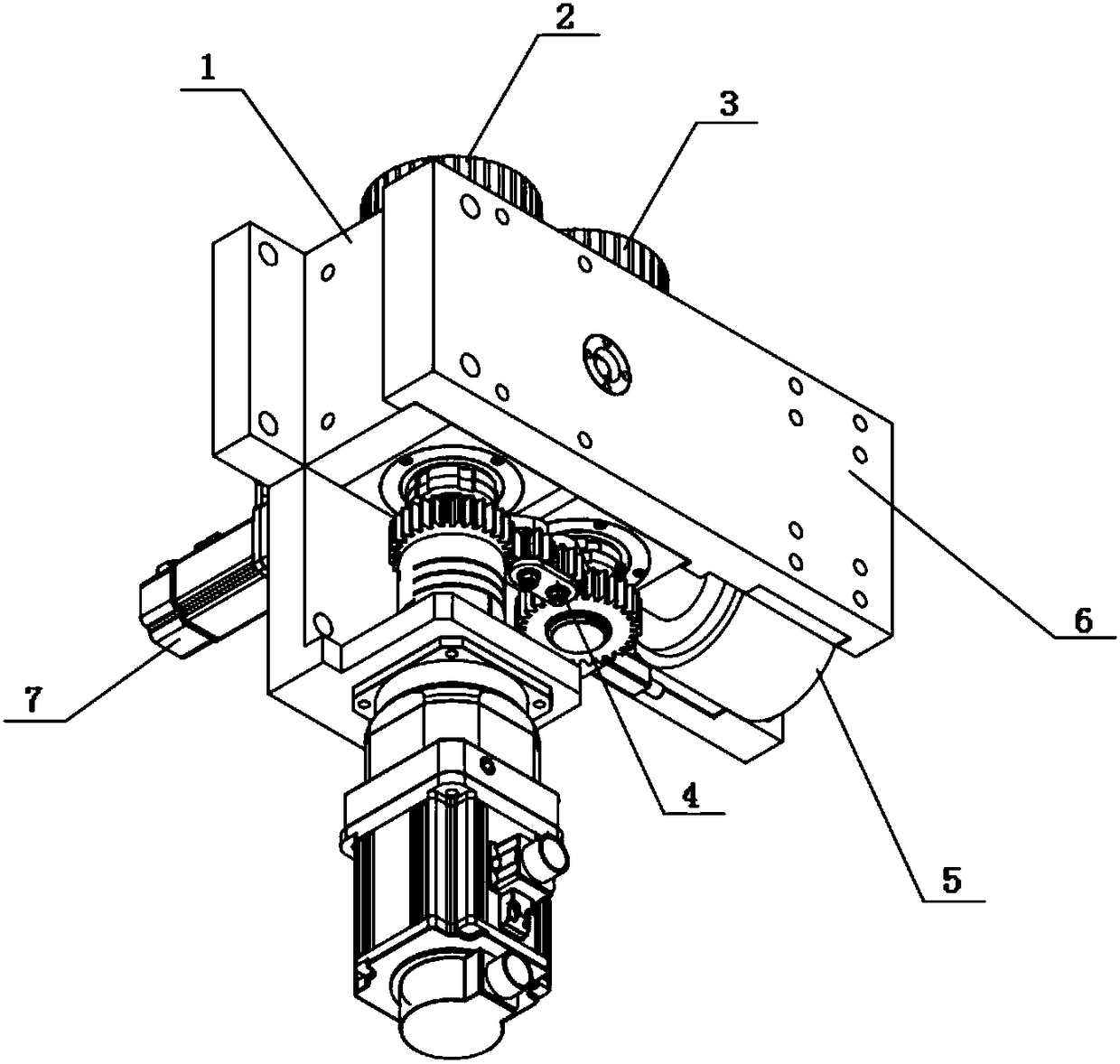

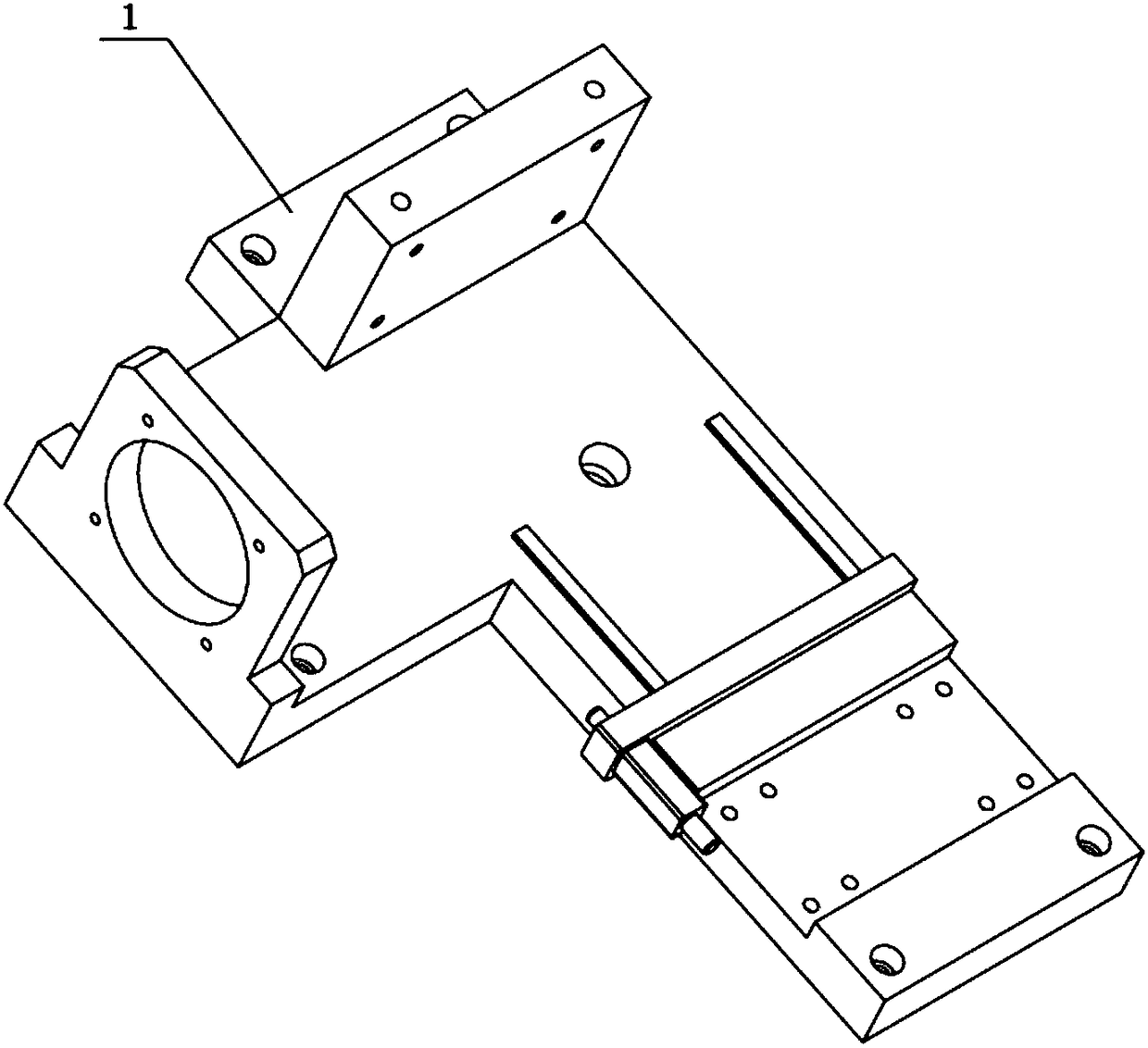

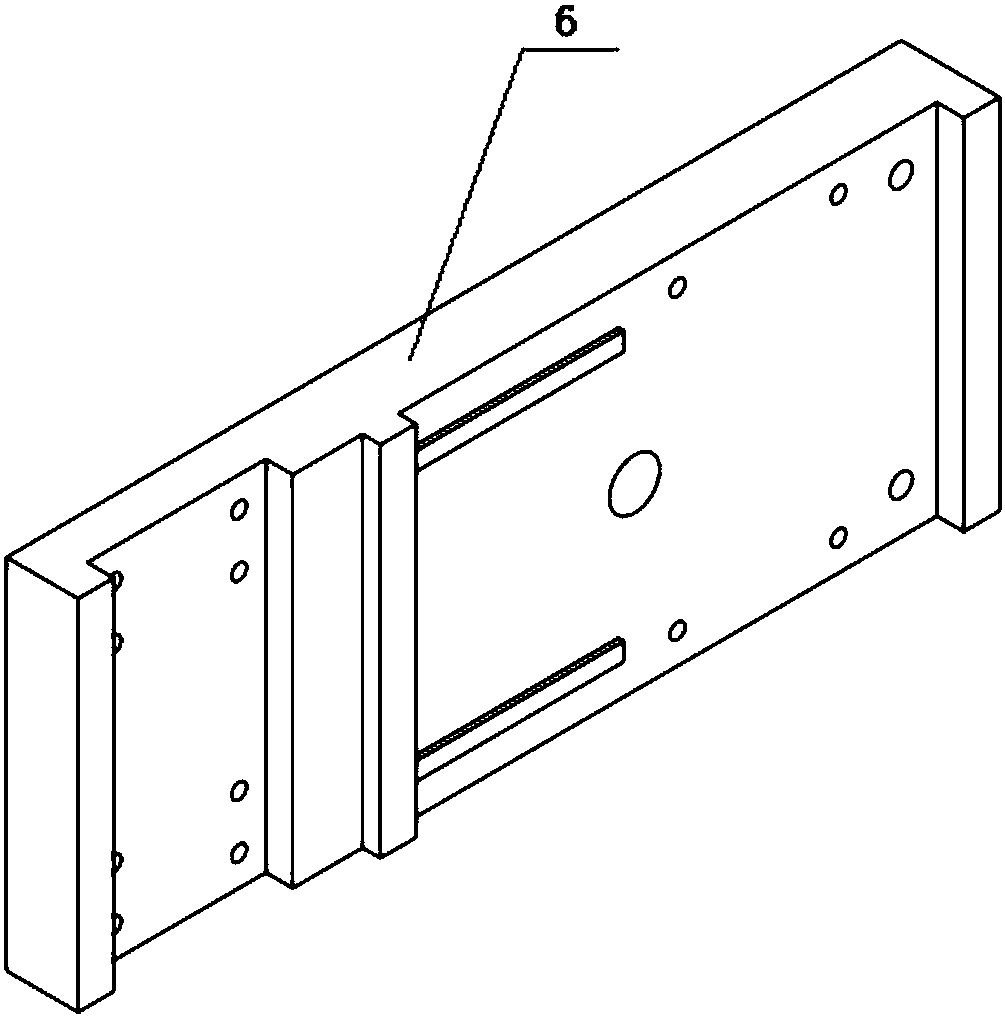

Squeezing roller device for dry granulator

ActiveCN108339495AAccurate and controllable speedWide speed rangeGranulation by pressingHydraulic cylinderMotor drive

The invention discloses a squeeze roller device for a dry granulator. The device comprises a base frame with an upper cover plate, a driving roller device and a driven roller device, wherein the driving roller device and the driven roller device are mounted on the base frame and provided with squeeze rollers. An automatic gap adjusting device for adjusting the spacing between the driving roller device and the driven roller device is mounted at the bottom of the base frame; the driving roller device and the driven roller device are provided with a driving bearing base and a driven bearing baserespectively, the face, is opposite to the driving bearing base, of the driven bearing base is provided with a double-sided slope which tends to be parallel to the automatic gap adjusting device, andthe back face of the double-sided slope on the driven bearing base abuts against a hydraulic cylinder pushing device; the automatic gap adjusting device includes a left rotary screw rod, a right rotary screw rod and a servo motor driving the left and right rotary screw rods to rotate, wherein the two ends of the left rotary screw rod and the two ends of the right rotary screw rod are provided withsliding blocks. By using the device, high-precision automatic gap adjustment can be conducted on the driving roller device and the driven roller device, the device is simple in structure and convenient to operate, and the production efficiency is improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for preparing cathode material of tin-carbon lithium ion cathode material

ActiveCN108493437ALow expansion propertiesImprove cycle performanceCell electrodesPelletizingSurface modification

The invention discloses a method for preparing a cathode material of tin-carbon lithium ion cathode material. The method comprises the following steps: (1) performing doping modification on tin dioxide, namely weighing certain amounts of nano tin dioxide and red copper oxide in a ratio of 100:(10-50), performing dry-method ball milling for 1 hour; and performing carbon heat reduction in an atmosphere furnace; (2) performing composite pelletizing on a tin dioxide modification product with graphite; (3) performing secondary wrapping modification. According to the method, as the tin dioxide is subjected to doping modification with the red copper oxide, the expansion property of a tin-carbon compound can be degraded, and the circulation property can be improved; due to two times of pelletization with processes of molding, roasting and dispersion formation, the method is short in time, simple in process and easy in industrial large-scale production; meanwhile, advantages of pelletization oftin dioxide and graphite and graphite and graphite can be achieved, and a function of surface modification upon the graphite with the tin dioxide can be also achieved; due to two times of coating, surface defects caused in the two times of pelletization process can be remarkably alleviated, and the first efficiency and the circulation property of a product can be improved.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

A kind of trimanganese tetraoxide, preparation method and application thereof

ActiveCN105948130BReduce contentParticle regularityCell electrodesSecondary cellsDecompositionMicrowave irradiation

The invention discloses a preparation method for trimanganese tetraoxide. The preparation method comprises the following steps: pumping a manganese sulfate solution into a disc granulator, performing crystallization decomposition and rotary granulation under radiation of microwave irradiation, and washing and drying granules obtained by granulation to obtain the trimanganese tetraoxide, wherein the temperature of the microwave irradiation is 900 to 1,200 DEG C; the rotating speed of a disc of the disc granulator is 10 to 30r / min. In addition, the invention further discloses application of the trimanganese tetraoxide prepared by the preparation method to preparation of a cathode material. According to the preparation method and the application, crystallization and granulation are performed under the synergistic action of a rotating parameter of the disc granulator and the microwave radiation, so that preparation of the trimanganese tetraoxide with high purity, large specific gravity and uniform granularity distribution is facilitated, and problems about treatment of ammonium salt wastewater produced by an existing universal process of preparing trimanganese tetraoxide by virtue of a wet manganese sulfate oxidization method are solved; the method is short in process flow, easy to control and suitable for industrial production.

Owner:HUNAN MENGDA NEW ENERGY MATERIALS CO LTD

Method for preparing copper-antimony-doped tin-carbon-lithium ion cathode material

ActiveCN108807873ALow expansion propertiesGranulation realizationCell electrodesSecondary cellsTin dioxideGraphite

The invention discloses a method for preparing a copper-antimony-doped tin-carbon-lithium ion cathode material. The method comprises the following steps: (1) carrying out doping modification on tin dioxide, namely weighing certain amounts of tin dioxide, copper and antimony, and carrying out dry-method ball-milling mixing for 0.5-1.5 hours in a ratio of 100:(5-20):(5-20); (2) carrying out composite pelletizing on a tin dioxide modified product and graphite; (3) carrying out secondary coating modification. By adopting the method, copper and antimony are adopted to carry out doping modificationon the tin dioxide, so that the expansion properties of a tin-carbon compound can be degraded, and circulation properties can be improved; secondary pelletizing is carried out through isostatic compaction, roasting and dispersion shaping processes, and the method is short in time, simple in process and easy in industrial large-scale production; meanwhile, the advantage of pelletizing of tin dioxide and graphite and graphite and graphite can be taken into play, and a function that surface modification of the graphite with the tin dioxide can be also achieved; due to two times of coating, surface defects caused in a secondary pelletizing process can be remarkably alleviated, and the first-time frequency and the circulation properties of a product can be improved.

Owner:SHENZHEN XIANGFENGHUA TECH CO LTD +1

Granulating machine for controlled-release fertilizer

PendingCN107497367AReasonable structural designEasy to useGranulation in rotating drumsFertilizerAgricultural engineering

The invention discloses a granulating machine for controlled-release fertilizer. The granulating machine comprises a machine frame, wherein a support wheel group is arranged on the machine frame; a granulating bucket is arranged on the support wheel group; a medicine liquid pipe is arranged in the granulating bucket and is used for humidifying and stirring raw material; toothed rings are respectively arranged at the left part and right part of the granulating bucket; a driving device, a filtering device and a sealing device are arranged on the machine frame 1, the driving device is used for providing power for the rotation of the toothed rings, the filtering device is used for filtering the gas in the granulating bucket, and the sealing device is used for sealing the end part of the granulating bucket. The granulating machine has the advantages that the structural design is reasonable, and the convenience in use is realized; by matching the granulating bucket and the driving device, the granulating of the controlled-release fertilizer is realized, the artificial spraying of medicine agent is replaced, the fertilizer can be uniformly mixed, and the production quality of the controlled-release fertilizer is improved; by matching the sealing device and the filtering device, the pollution to surrounding air in the granulating process is decreased, the pollution to surrounding environment in the production process of the controlled-release fertilizer is decreased, and the working environment of an operator is improved.

Owner:ANHUI RUIHU BIO FERTILIZER

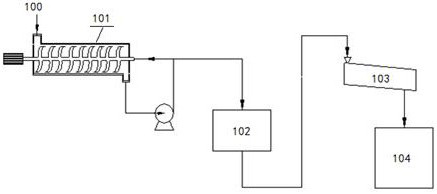

Low-polyfructose granulation device and application thereof

InactiveCN107649071AGranulation realizationRealize continuous granulationEvaporator accessoriesGranulation by powder suspensionPolyfructoseSprayer

The invention discloses a low-polyfructose granulation device which comprises a spray drying system and a granulation system. The low-polyfructose granulation device further comprises a distribution device which divides slurry into two paths, one flows into the spray drying system via a first flowmeter and a first feed pump while the other flows to the a slurry sprayer in a granulation fluidization chamber via a second flowmeter and a second feed pump. Continuous low-polyfructose granulation in the absence of any adhesives can be realized, and low-polyfructose granules obtained are even in diameter, good in compressive property and less prone to crispness.

Owner:南京疏理健康管理有限公司

A kind of preparation method and preparation system of insoluble sulfur

ActiveCN111377413BIncrease productivityGuaranteed yieldSulfur preparation/purificationPhysical chemistryEngineering

The invention discloses a preparation method and a preparation system for insoluble sulfur. The preparation system includes a polymerization kettle, a quenching device, a drying and curing unit; The outlet of the cooling device is connected to the inlet of the drying unit through a pipeline; the quenching device includes a shell, and the inside of the shell includes a feed quenching section, a material conveying section and a discharge section according to the flow direction of the material; the feed The quenching section is equipped with a feed distributor and a quenching liquid distributor. The material conveying section includes several layers of conveyor belts. Both ends of each layer of conveyor belts are equipped with fixed shafts, and a discharger is installed in the discharge section. At the same time, a method for preparing insoluble sulfur using the above preparation system is also provided. The insoluble sulfur preparation method and preparation system of the present invention can realize continuous quenching and continuous extraction of polymerized sulfur through continuous granulation, continuous transportation, and continuous cycle extraction of the extractant, so as to ensure the purity, thermal stability and yield of the product, and are suitable for large-scale continuous chemical production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Microcapsule granulation device

ActiveCN101391200BGranulation realizationSmooth feedingMicroballoon preparationMicrocapsule preparationFluidized bedSlurry

Owner:CHANGZHOU YISITE DRYING EQUIP

An inert atmosphere granulation system

The invention relates to the technical field of processing systems in the powdery material process and discloses an inert atmosphere granulation system. The inert atmosphere granulation system comprises a feeding device, a granulation device, an inert atmosphere device and an exhaust device, wherein the granulation device comprises a high-temperature spraying granulating machine, a condensing tower and a discharging hole, the high-temperature spraying granulating machine is distributed in the condensing tower, and the discharging hole is formed in the bottom of the condensing tower; the inert atmosphere device comprises an inert gas source and a wind supply pump; the feeding device is connected with the high-temperature spraying granulating machine and is used for conveying materials in the feeding device to the high-temperature spraying granulating machine, the high-temperature spraying granulating machine is used for spraying the materials into the condensing tower, and the inert gas source is in tight connection with an wind inlet of the condensing tower through the wind supply pump and is used for conveying inert gas into the condensing tower so as to granulate the materials sprayed into the condensing tower by the high-temperature spraying granulating machine in an inert gas environment; the exhaust device is used for exhausting waste gas in the condensing tower. By utilizing the inert atmosphere granulation system, the granulation of high-melting-point substances or water and oxygen sensitive powder is realized.

Owner:厦门中烁光电科技有限公司

Eccentric colorful medium-sized granulator

InactiveCN108393038AEasy to collectGranulation realizationGranulation in stationary drums/troughsGranulation by material expressionMechanical engineeringCoating

The application discloses an eccentric colorful medium-sized granulator. The eccentric colorful medium-sized granulator comprises a rack, sliding blocks, a material supporting rack, a feeding bin, a discharging pipe, an equipment cabinet, a spiral conveying and granulating assembly and a discharging mesh sheet, wherein two guide rods are arranged on the rack at intervals; the sliding blocks are respectively sleeved and arranged on the corresponding guide rods; the material supporting rack is fixed on the sliding blocks; the feeding bin is buckled on the material supporting rack; the discharging pipe is arranged below the feeding bin and is communicated with the discharging pipe of the feeding bin; the equipment cabinet is erected on the feeding bin; the spiral conveying and granulating assembly is driven by the equipment cabinet and is oriented to the discharging pipe; the discharging mesh sheet is sleeved and arranged on the discharging pipe. According to the eccentric colorful medium-sized granulator disclosed by the invention, the spiral conveying and granulating assembly is supported by the rack; the sliding blocks are matched with the offset feeding bin, a material barrel is conveniently changed for collecting, medium-batch coating granulation is realized, and the trouble of low manual efficiency is avoided.

Owner:江苏恒兆新材料科技有限公司

Preparation method and preparation system of insoluble sulfur

ActiveCN111377413AIncrease productivityGuaranteed yieldSulfur preparation/purificationPhysical chemistryPolymer chemistry

The invention discloses a preparation method and a preparation system of insoluble sulfur. The preparation system comprises a polymerization kettle, a quenching device and a drying and curing unit; adischarge port of the polymerization kettle is communicated with a feed port of the quenching device through a pipeline, and a discharge port of the quenching device is communicated with an inlet of the drying unit through a pipeline; the quenching device comprises a shell, and the interior of the shell comprises a feeding quenching section, a material conveying section and a discharging section in the material flowing direction; a feeding distributor and a quenching liquid distributor are arranged in the feeding quenching section, a plurality of layers of conveying belts are arranged in the material conveying section, fixed rotating shafts are arranged at the two ends of each layer of conveying belt, and a discharging device is arranged in the discharging section. The invention also provides an insoluble sulfur preparation method adopting the preparation system. According to the preparation method and the preparation system of the insoluble sulfur, continuous quenching and continuousextraction of the polymerized sulfur can be realized through continuous granulation, continuous conveying and continuous cyclic extraction of the extracting agent, such that the purity, the thermal stability and the yield of the product are ensured, and the preparation method and the preparation system are suitable for large-scale continuous production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Extrusion die for biomass fuel

ActiveCN107875975BGranulation realizationImprove combustion efficiencyBiofuelsSolid fuelsProcess engineeringMaterial resources

The invention discloses an extrusion die for biomass fuel. The extrusion die comprises a positioning head, wherein a plurality of through holes are formed in the positioning head; granulation units are arranged in the through holes in a detachable manner; a rotating shaft is arranged on the positioning head; a segmenting knife is arranged on the rotating shaft; and the rotating shaft is connectedwith a positioning shaft. According to the extrusion die disclosed by the invention, the granulation units are arranged in the detachable manner, so that granulation of different types of biomass fuelis realized, the application range of the device is widened, the maintenance is convenient, and the manpower and material resources are saved. Moreover, the produced biomass fuel has a hollow structure, and is large in contact area with oxygen and high in combustion efficiency.

Owner:利辛县逸安新能源有限公司

MOX mixed powder pelleting method

InactiveCN111014698AImprove pass rateSolve the problem of hard particlesPellet ProductMicrostructure

The invention relates to the technical field of preparation of fuel pellets and particularly discloses an MOX mixed powder pelleting method. The method comprises the following steps that firstly, pelleting parameters are adjusted; secondly, pelleting is performed; and thirdly, the pellet sizes are detected. By means of the MOX mixed powder pelleting method provided by the invention, the problem oflocal hard pellets in a pellet metallographic microstructure is solved, the MOX mixed powder pelleting method is improved, and the MOX pellet product percent of pass is increased.

Owner:THE 404 COMPANY LIMITED CHINA NAT NUCLEAR

A kind of compound modifier and the drainage asphalt concrete with high anti-scattering performance prepared by it

ActiveCN106630731BOutstanding anti-scattering functionImprove water stabilityClimate change adaptationCeramicwareCross-linkFiber

The invention discloses a composite modifier and a high-scattering-resistance drainage asphalt concrete prepared through the same and relates to the field of road engineering materials. The composite modifier is composed of base materials, fiber, comprehensive additives, cross-linking agent and cross-linking promoter, wherein the base materials are composed of SBS (styrene-butadiene-styrene) modifier, SBR (styrene butadiene rubber) modifier and solubilizer. The drainage asphalt concrete prepared through the composite modifier is high in scattering resistance. Through field deployment of conventional asphalt, aggregate, mineral powder and the composite modifier, a high-performance and stable-performance drainage mixture can obtained and meanwhile is more stable in properties compared with those applying modified asphalt, so that worries on storage segregation and performance degradation of the modified asphalt can be saved, and meanwhile construction deficiencies of dispersing non-uniformity of fiber deployment and grease spots can be completely avoided.

Owner:BEIJING ZHONGLU PAVING TECH +2

A continuous quenching device for insoluble sulfur

ActiveCN111377412BHigh yieldGranulation realizationSulfur preparation/purificationThermal stabilityConveyor belt

The invention discloses a continuous quenching device for insoluble sulfur. The quenching device includes a shell, and the inside of the shell includes a feeding quenching section, a material conveying section and a discharging section according to the flow direction of the material; the feeding The quenching section is equipped with a feed distributor and a quenching liquid distributor. The material conveying section includes several layers of conveyor belts. Both ends of each layer of conveyor belts are equipped with fixed rotating shafts, and a discharge device is installed in the discharge section. The insoluble sulfur continuous quenching device can realize continuous quenching of polymerized sulfur through continuous granulation and continuous transportation, achieve the consistency of quenching time of polymerized sulfur, and ensure the yield and thermal stability of quenched products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com