Insoluble sulfur continuous quenching device

A technology of quenching and sulfur, which is applied in the direction of sulfur compounds, sulfur preparation/purification, inorganic chemistry, etc., and can solve the problems of high operating temperature and pressure of sulfur polymerization and high requirements for reaction equipment

Active Publication Date: 2020-07-07

CHINA PETROLEUM & CHEM CORP +1

View PDF15 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Patent CN102070127A discloses a production method of insoluble sulfur, the steps include: (1) melt polymerization; (2) atomization cold extraction; (3) solidification; (4) centrifugal separation; (5) continuous drying; (6) pulverization , screening and oil filling, and finally get the finished product; this method is a continuous production method, but the sulfur polymerization operation temperature and pressure of this method are high, the operating temperature is 580-690 °C, and the operating pressure is 0.8-1.2 MPa. Higher requirements for reaction equipment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0028] The specific situation of the present invention will be further described below through specific examples, but not limited to the following examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

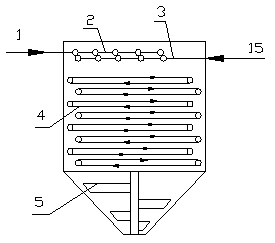

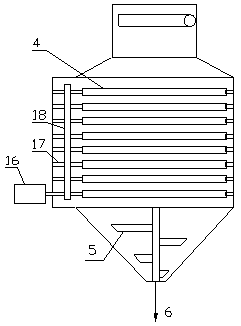

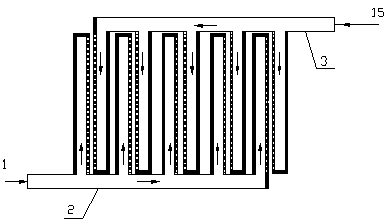

The invention discloses an insoluble sulfur continuous quenching device which comprises a shell, and the interior of the shell comprises a feeding quenching section, a material conveying section and adischarging section in the material flowing direction; a feeding distributor and a quenching liquid distributor are arranged in the feeding quenching section, a plurality of layers of conveying beltsare arranged in the material conveying section, fixed rotating shafts are arranged at the two ends of each layer of conveying belt, and a discharging device is arranged in the discharging section. According to the continuous quenching device for insoluble sulfur, continuous quenching of polymerized sulfur can be achieved through continuous granulation and continuous conveying, so the consistencyof the quenching time of polymerized sulfur is achieved, and the yield and the thermal stability of quenched products are guaranteed.

Description

technical field [0001] The invention relates to the technical field of chemical equipment, in particular to a continuous quenching device for insoluble sulfur. Background technique [0002] With the sharp increase in oil consumption, global oil resources are increasingly scarce, and the quality and inferiority of refinery raw materials are becoming more and more serious. At the same time, environmental protection regulations in various countries are becoming stricter, and the control of total sulfur content in petroleum products and natural gas is becoming more stringent. Therefore, the capacity of sulfur recovery units in major refineries and natural gas purification plants has increased rapidly. The domestic and foreign markets of this common sulfur have become saturated, so the price is low. How to provide high value-added sulfur products that are in short supply in the market has become the focus of relevant enterprises. [0003] Insoluble sulfur is a high-efficiency r...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C01B17/12

CPCC01B17/12C01B17/0237

Inventor 方向晨廖昌建王海波孟凡飞朴勇

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com