Patents

Literature

71results about How to "Convenient Quenching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

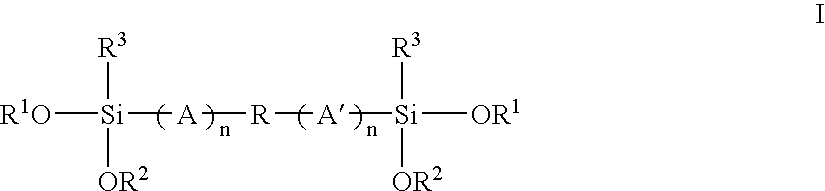

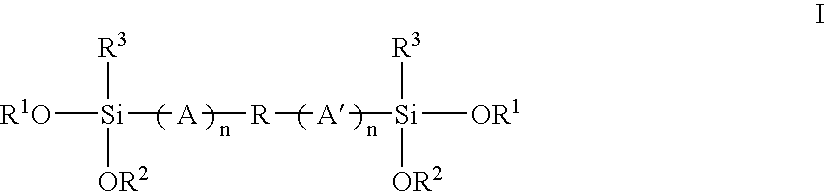

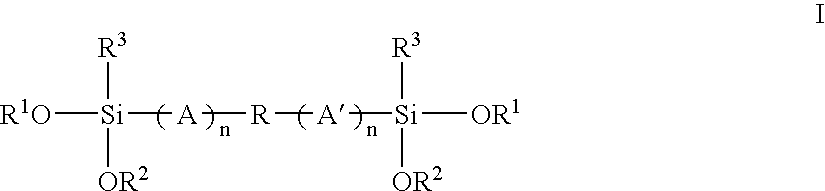

Mixed alkoxysilyl functional polymers

This invention relates to silylated polymers having mixed alkoxy groups on the silyl portion thereof, methods of their preparation, and compositions and reaction products formed therefrom. These alkoxysilylated polymers can be crosslinked when exposed to atmospheric moisture to become useful elastomers, sealants or adhesives. The presence of different alkoxy groups on the silicon atoms can control or otherwise moderate the cure speeds of these silylated polymers.

Owner:HENKEL KGAA

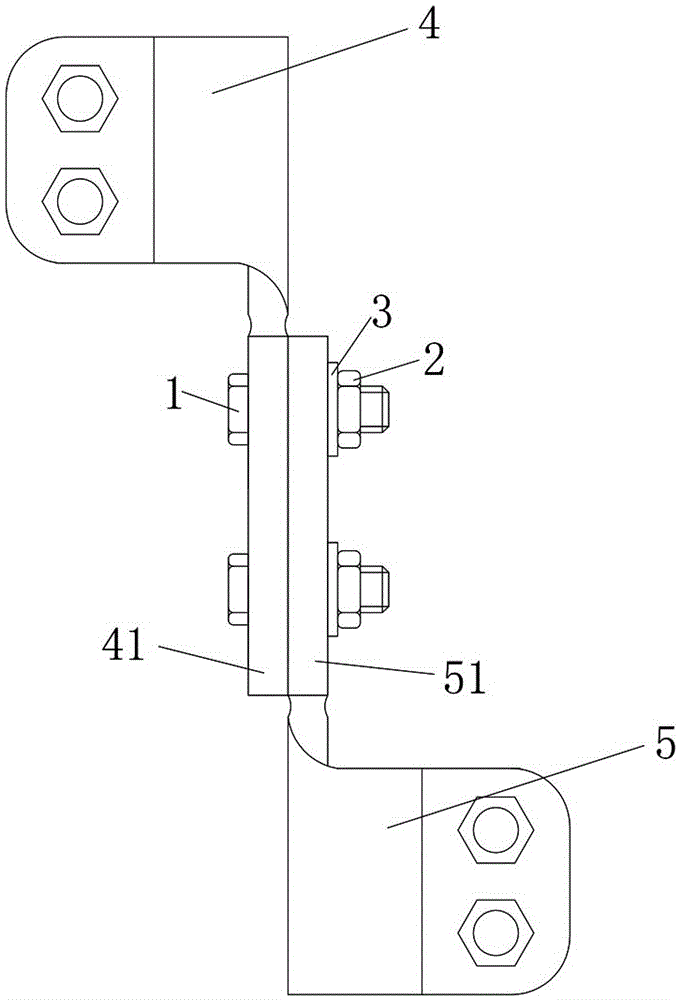

Bolt assembly of shape memory alloy cable clamp

The invention discloses a bolt assembly of a shape memory alloy cable clamp. The bolt assembly comprises bolts connecting flow guiding parts of a plurality of cable clamps, nuts in threaded match with the bolts and disc washers arranged between the nuts and one of the flow guiding pieces. The mounted washers are in a pressed state. The bolt assembly is characterized in that the washers are made from a shape memory alloy material. When the heating temperature of the cable clamp is equal to or greater than austenite initial phase change temperature of the shape memory alloy material, the washers start to restore and compress drainage plates of the two cable clamps. The bolt assembly of the shape memory alloy cable clamp has the advantages of being capable of spontaneously inhibiting heating effect, improving the economic benefit and safety of operation of a power grid and the like.

Owner:STATE GRID CORP OF CHINA +2

Gold recovery

ActiveUS20150114182A1Increase in sizeReduce the amount of waterElectrolysis componentsProcess efficiency improvementMaterials scienceGold leaching

The cost of precious metals, such as gold, makes recovery or recycling of these materials economically viable and desirable. Disclosed herein is a method of recovering gold from waste sources thereof, in particular waste electrical goods. Also disclosed herein is an apparatus for recovering gold from said waste sources. In particular, disclosed herein is a method and apparatus in which gold leaching chlorine gas is generated externally to a reactor vessel and subsequently pumped into the reactor vessel comprising the waste gold materials.

Owner:HIGH VALUE METALS RECOVERY

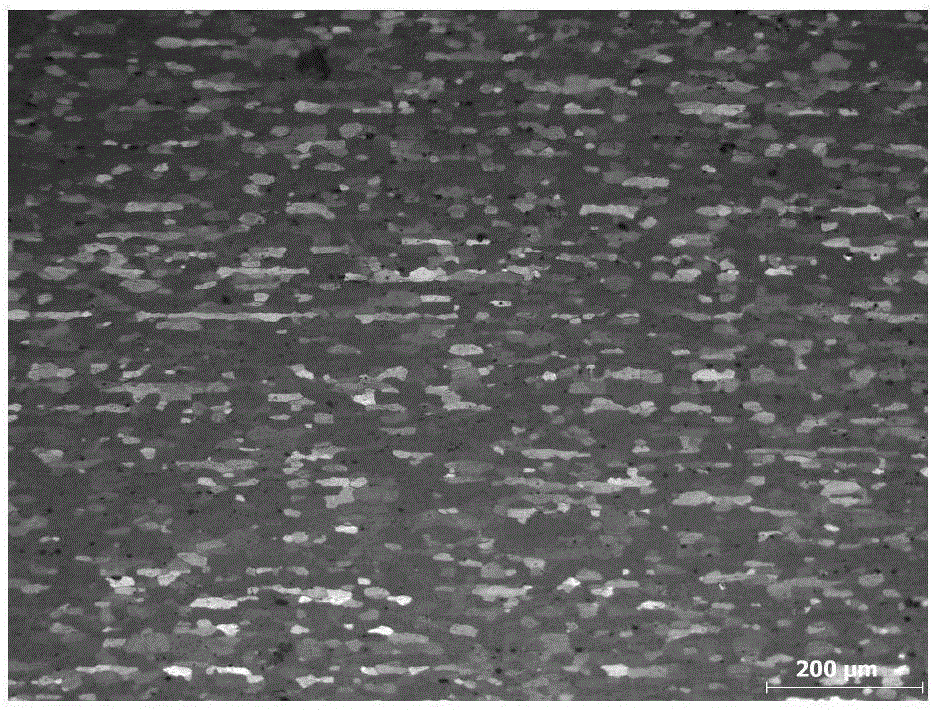

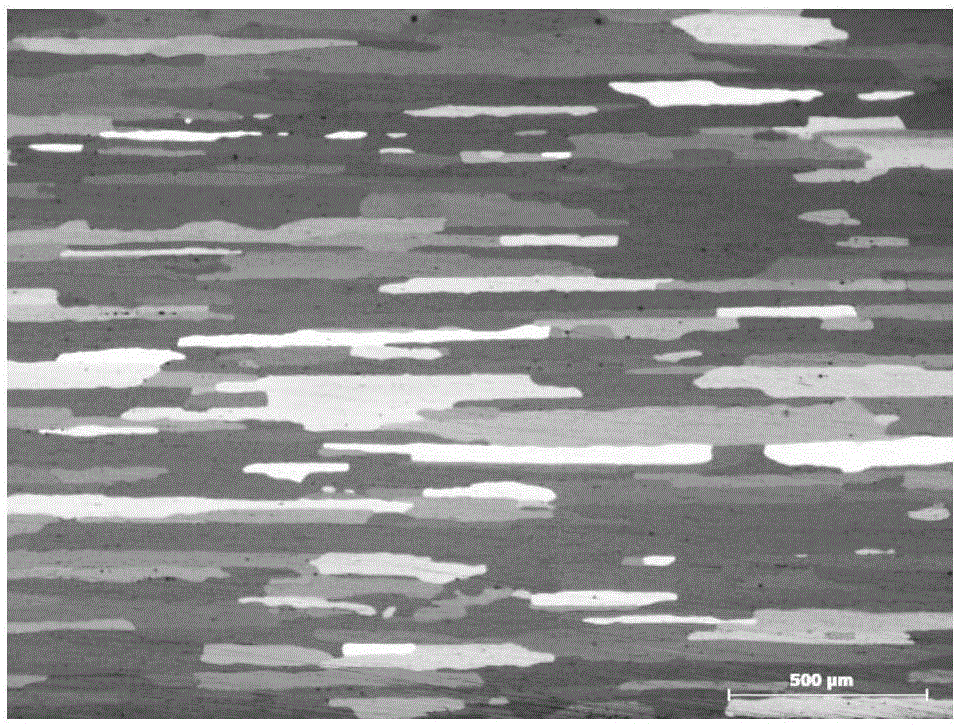

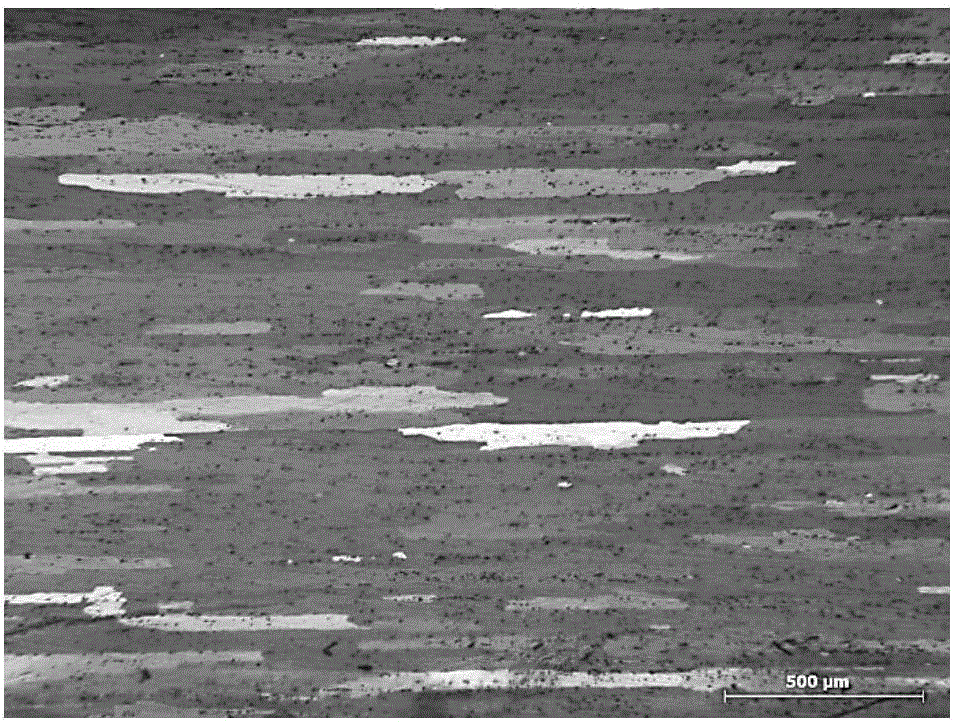

Solid-solution pre-treatment method for improving strength and plasticity and toughness of aluminum lithium alloy thin sheet and heat treatment method thereof

The invention provides a solid-solution pre-treatment method for improving strength and plasticity and toughness of an aluminum lithium alloy thin sheet. The method is characterized in that the solid-solution pretreatment is carried out on the aluminum lithium alloy in a temperature increase rate controlling manner, wherein the temperature increase rate of the solid-solution pre-treatment is 2 to 15 DEG C per minute; the initial temperature in temperature increase of the solid-solution pre-treatment is 20 to 25 DEG C, and the end temperature in the temperature increase of the solid-solution pre-treatment is 500 to 510 DEG C. According to the solid-solution treatment method, the aluminum lithium alloy is treated by temperature increase at the rate of 2 to 15 DEG C per minute, thus influencing the form and distribution of recrystallized grain to generate a textured structure form. Therefore, the comprehensive mechanical property of the aluminum lithium alloy thin sheet can be improved, and the strength and the plasticity and toughness can be improved.

Owner:CENT SOUTH UNIV +1

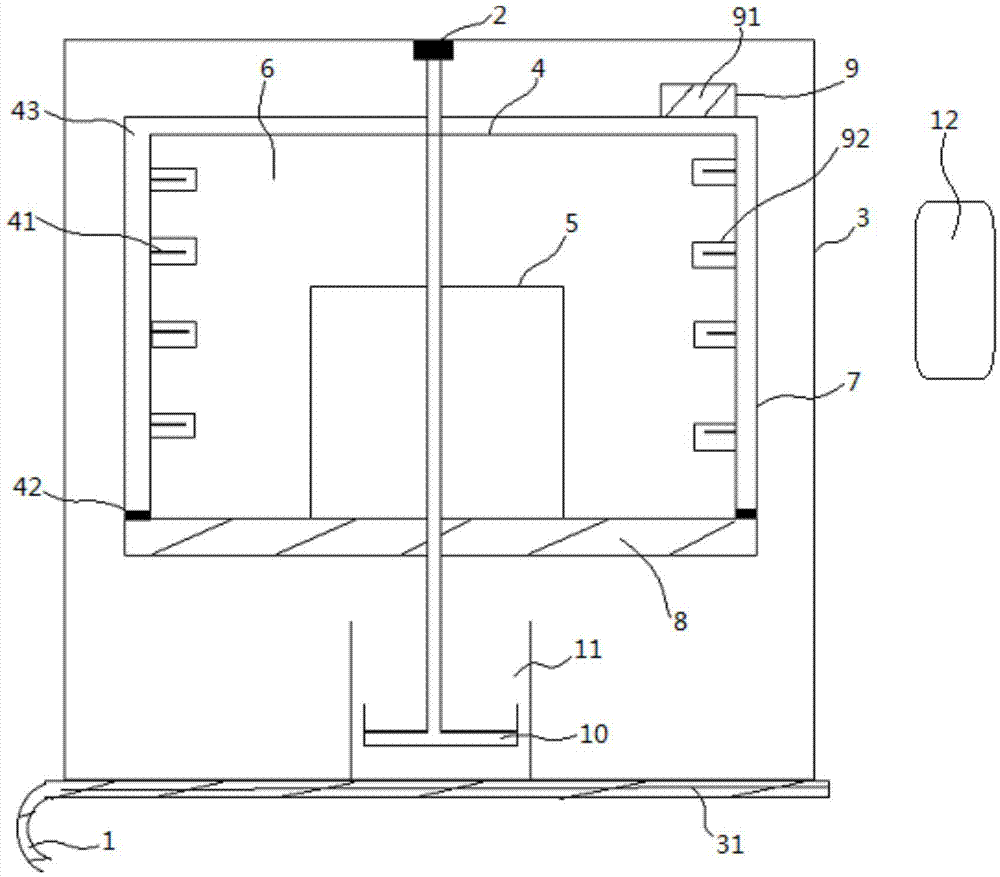

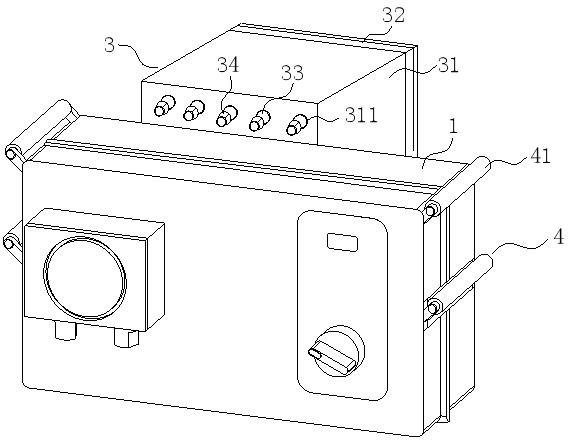

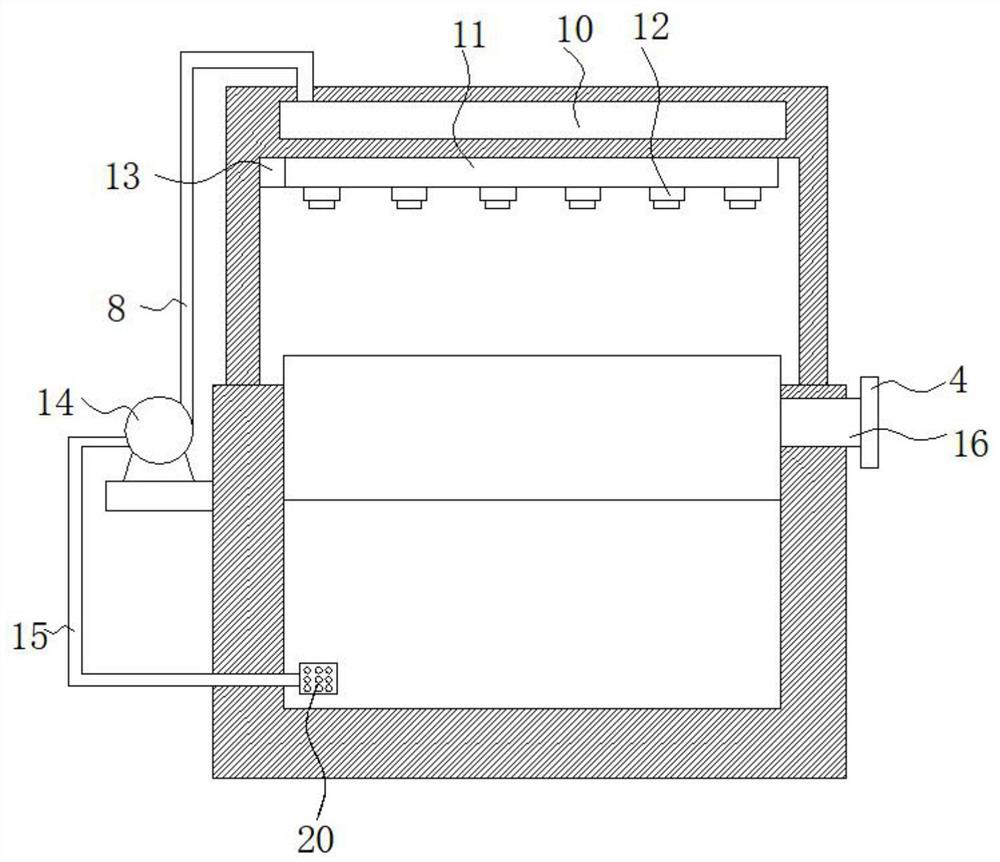

Quenching furnace

The invention provides a quenching furnace comprising a push-pull mechanism, a lifting mechanism, a bracket, a furnace body, a furnace cover, a hearth, a furnace shell, a furnace door, a thermal cycling system, a charging basket and a quenching tank, wherein the main body of the quenching furnace is the furnace body, the main body of the furnace body is a heating furnace, the furnace shell, the hearth and the furnace cover are arranged in the heating furnace, and a heating element and the furnace cover are arranged in the hearth; the thermal cycling system is arranged at the upper end of the furnace body; a furnace opening is formed in the lower end of the furnace body, and a refractory fiber cotton sand sealing cutter is arranged at the connection part between the furnace door and the furnace body; the bracket is arranged at the two sides of the furnace body, and a control cabinet is arranged at one side of the bracket; a layer of rubber asbestos plate is attached to the inner surface of the furnace shell and can achieve an effect of heat insulation, thereby reducing the loss of heat, saving energy sources, protecting the surface of the furnace shell from being corroded, and prolonging the service life of equipment; and a self-locking device is arranged in each of a reduction box I and a reduction box II in the lifting mechanism, so that the charging basket can be stopped or slowed down at any position, the accuracy for positioning the charging basket is improved, and the charging basket is prevented from rapidly impacting the quenching tank and damaging the equipment when coming down.

Owner:JIASHAN THREE STAR BEARING

Steel powder and die using same

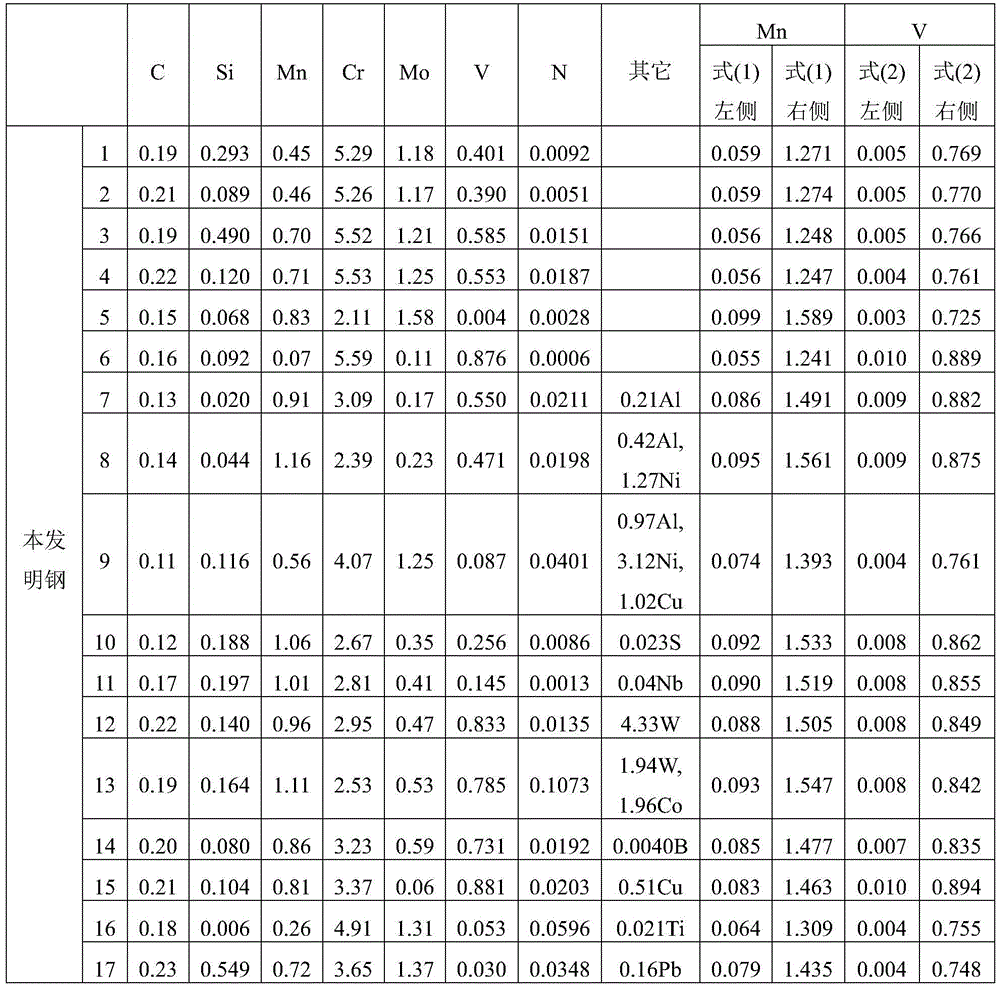

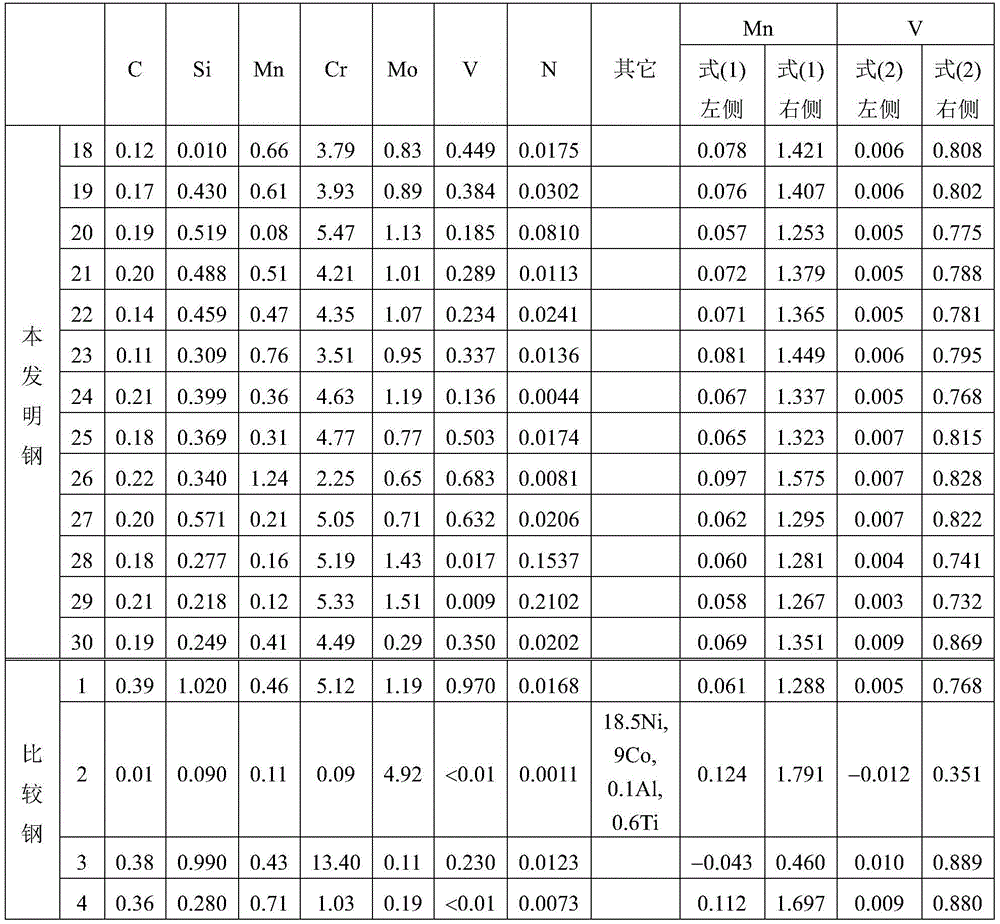

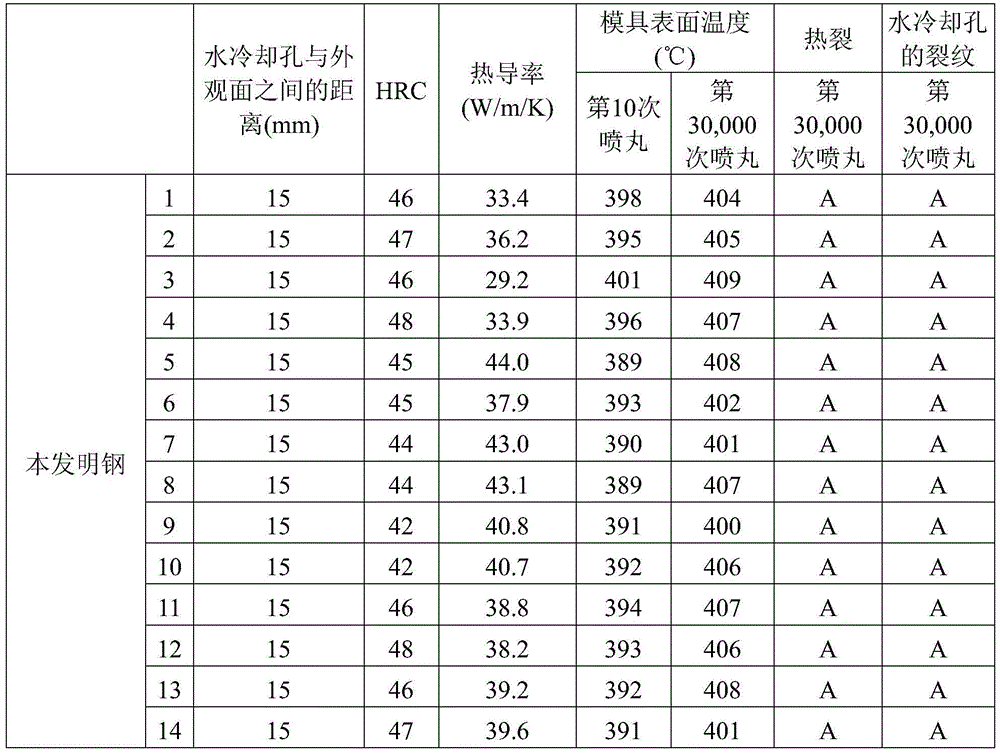

ActiveCN105821327AConvenient QuenchingCrack suppressionShaping toolsQuenching devicesMetallurgyImpurity

The invention relates to steel powder and a die using the same. The steel powder comprises has a composition containing, by mass percentage, 0.10<=C<0.25, 0.005<=Si<=0.600, 2.00<=Cr<=6.00, -0.0125x[Cr]+0.125<=Mn<= -0.100x [Cr]+1.800, wherein [Cr] represents the value of Cr content by mass percentage, 0.01<=Mo<=1.80, -0.00447 * [Mo]+0.010<=V<=-0.1117 * [Mo]+0.901 , wherein the [Mo] represents the value of Mo content by mass percentage, 0.0002<=N<=0.3000, and the balance being Fe and unavoidable impurities.

Owner:DAIDO STEEL CO LTD

Oxidation resistant coating for hot stamping parts of ultrahigh strength sheet steel at high-temperature

InactiveCN101624500ALow volatilityImprove thermal stabilityAnti-corrosive paintsBulk chemical productionIonOxidation resistant

The invention relates to an oxidation resistant coating for hot stamping parts of ultrahigh strength sheet steel at high-temperature, comprising the following main components: boron modified organic silicon resin, polymethylsiloxane resin, tetraborate nitride powder, ionic liquid, aluminum powder, and polydimethylsiloxane. The coating has the advantages that the ionic liquid is used as organic solvent, therefore, the volatility is low and the thermal stability is high, in addition, solid lubricant is added, which can effectively prevent sheet materials from being oxidized, improves the frictional behaviour and the shaping property of the sheet materials; the thermal conduction of the coating is improved by adding metal particles, thus being beneficial to quenching. The coating can be directly applied to direct hot stamping forming process and indirect hot stamping forming process.

Owner:JILIN UNIV

Quenching oil for reduced pressure quenching and method for quenching

A quenching oil for reduced pressure quenching which comprises a base oil having a kinematic viscosity at 40° C. of 40 mm2 / s or more and a vapor blanket breaking agent; and a method for quenching wherein the quenching oil is used and quenching is carried out while adjusting the pressure on the surface of the oil. The method allows the achievement of cooling characteristics over a wide range from those conventionally achieved by a cold oil to those by a hot oil, by the use of a single quenching oil.

Owner:IDEMITSU KOSAN CO LTD

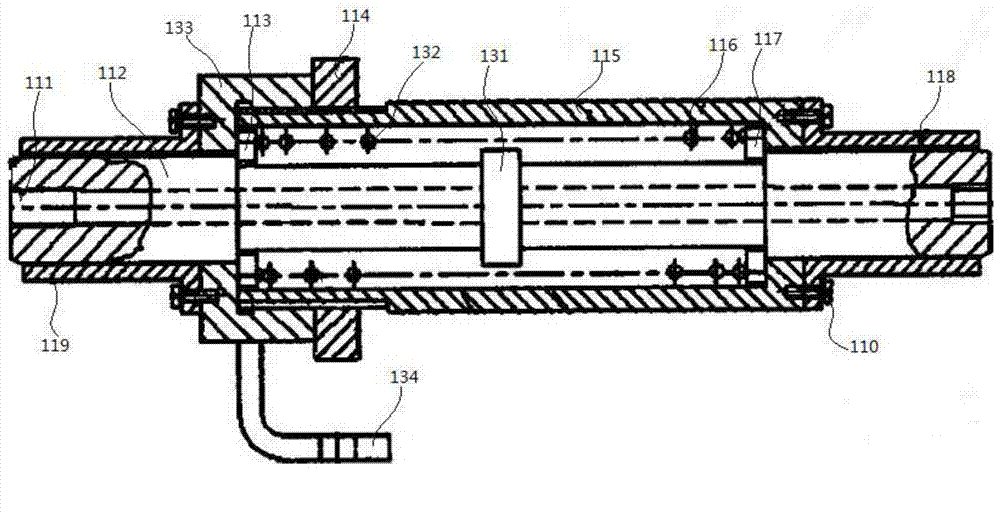

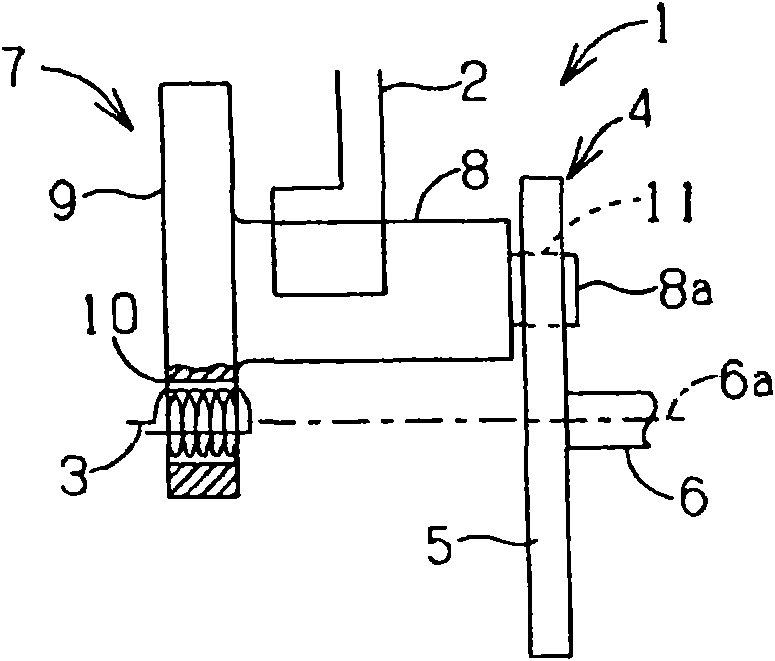

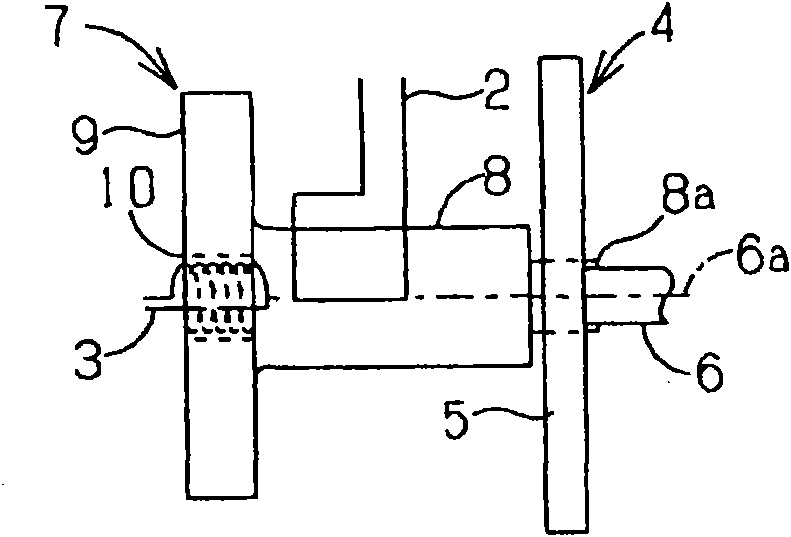

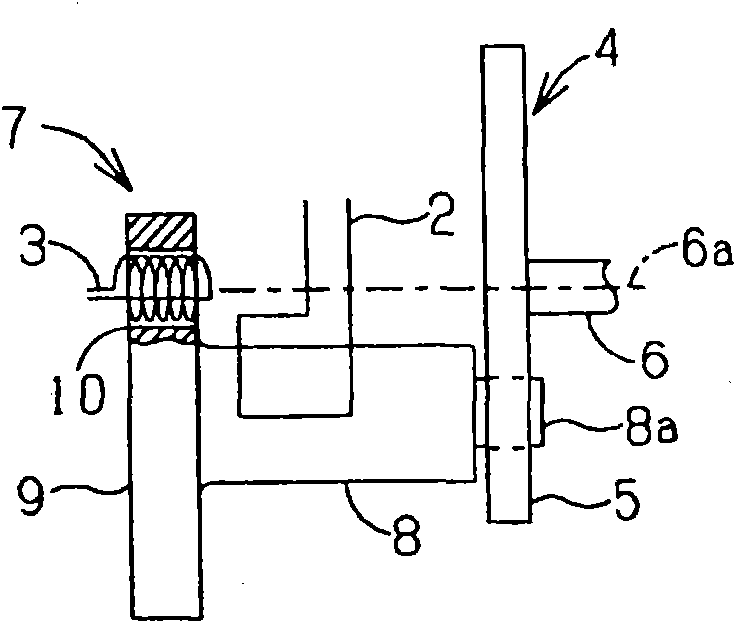

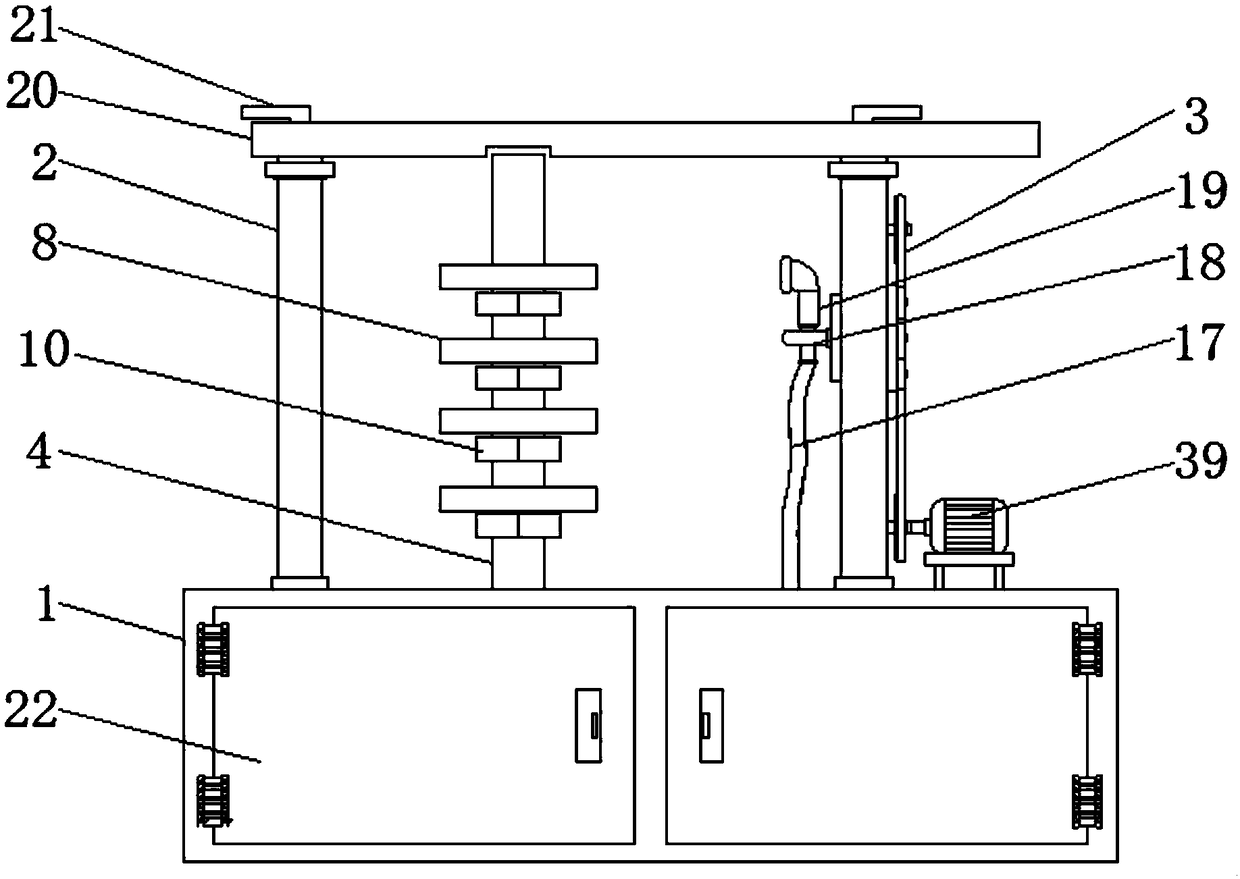

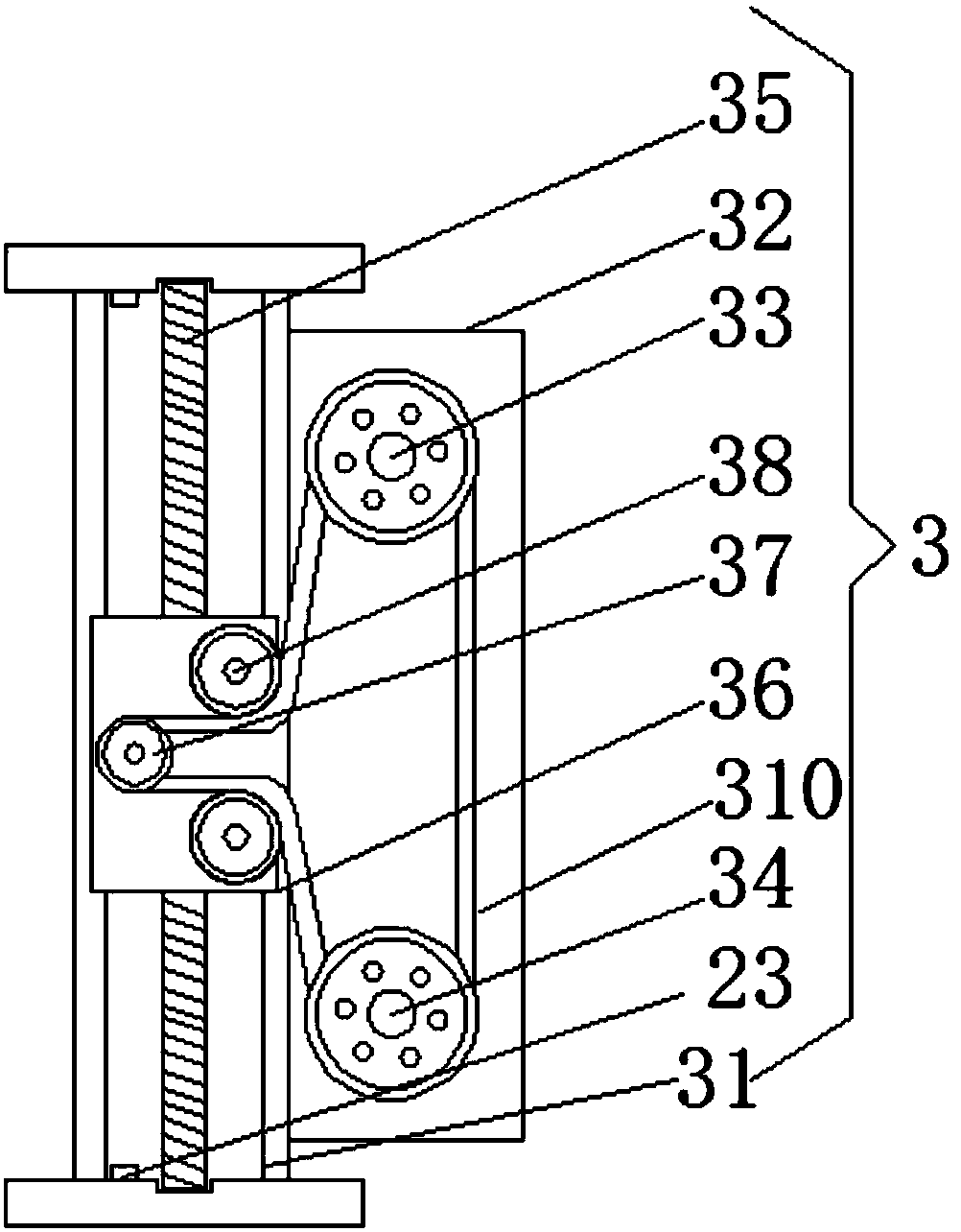

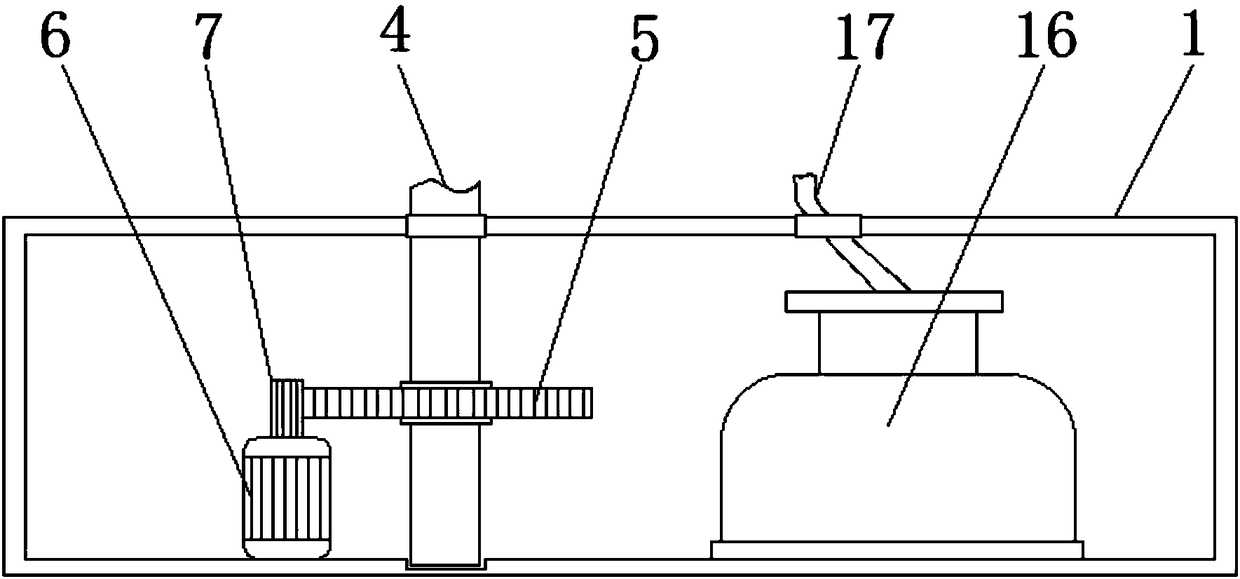

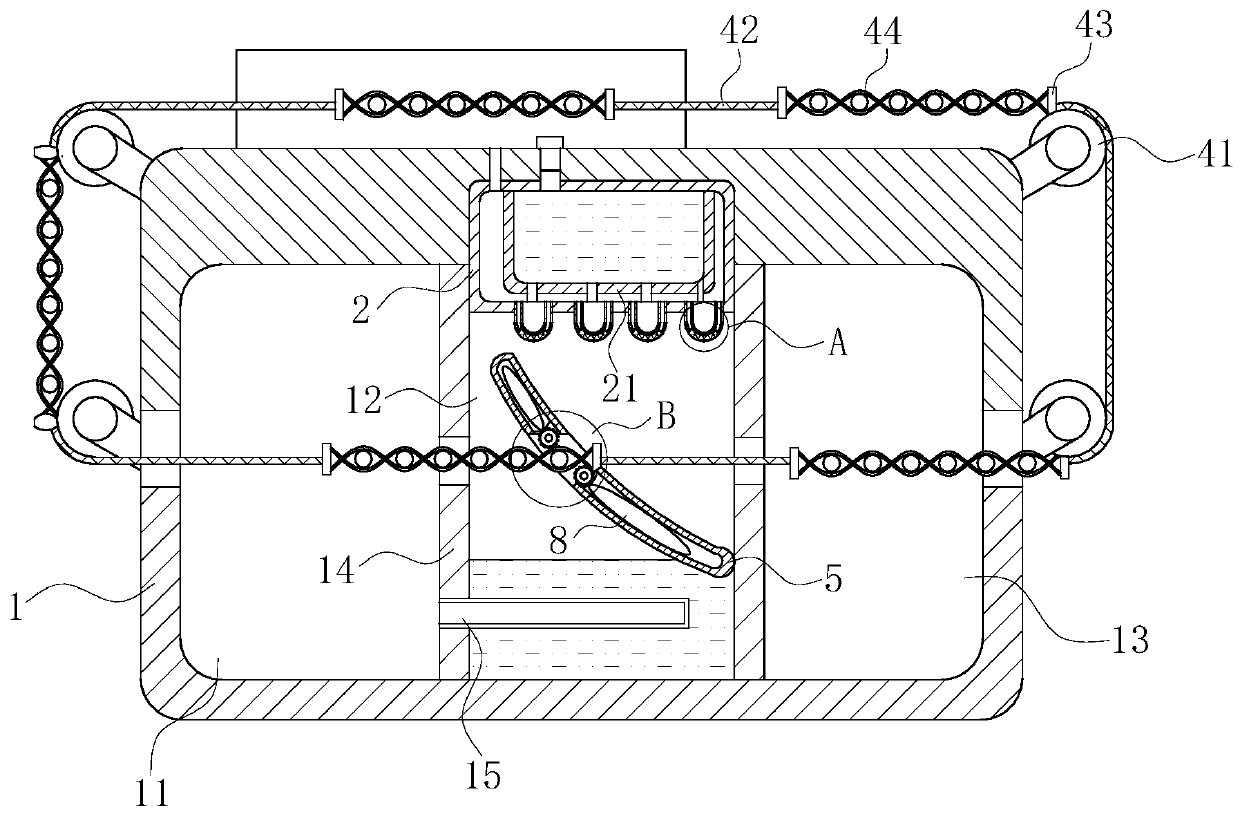

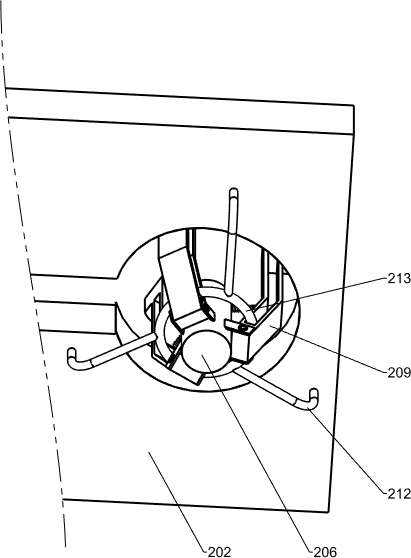

Hardening method and hardening device

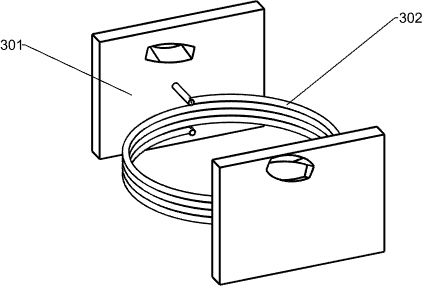

ActiveCN101787415AConvenient QuenchingGood induction heatingCoil arrangementsIncreasing energy efficiencyElectrical conductorMetallurgy

An object of the present invention is to provide a hardening method and a hardening device capable of successfully hardening a shaft and an inner wall of a hole of a work in which the hole is formed close to the shaft on a flat plate. A hardening device for hardening a shaft and an inner wall of a hole, the shaft 8 extending vertically from a flat plate 9 and the hole 10 being formed adjacent to the shaft 8, includes a first heating coil 2 that is a conductive body facing the shaft 8 and a second heating coil 3 that is a helical conductive body having at least a portion inserted into the hole, so that the first heating coil 2 and the second heating coil 3 heat the shaft 8 and the inner wall of the hole 10 respectively and simultaneously.

Owner:FUJI ELECTRONICS IND

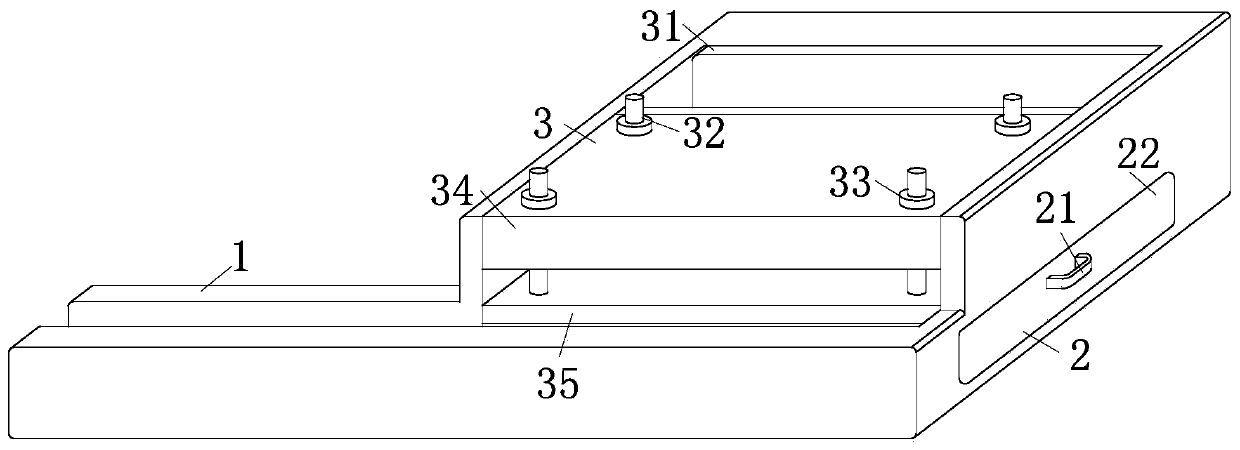

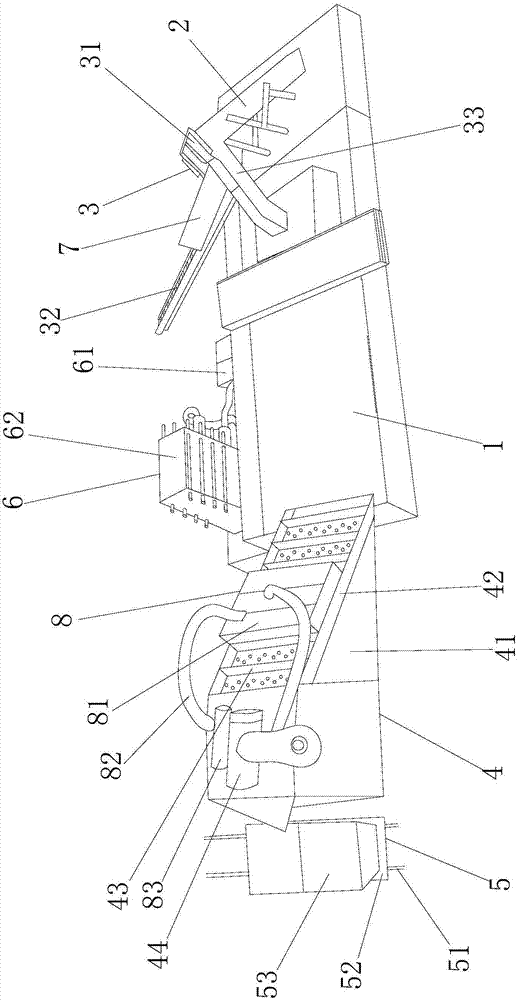

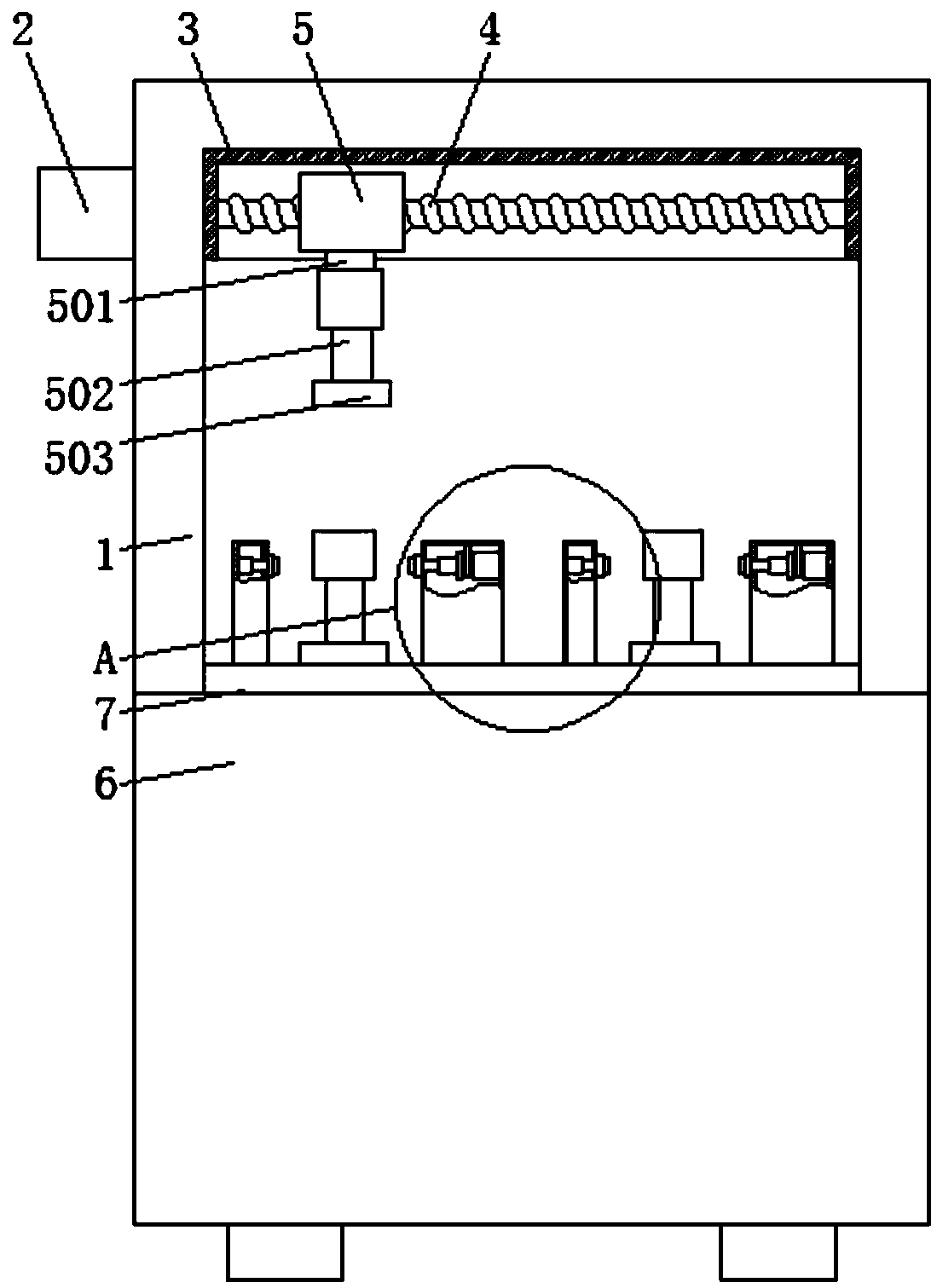

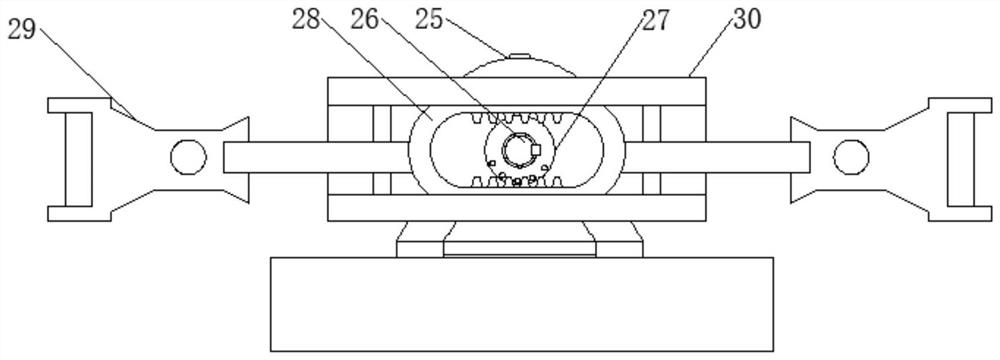

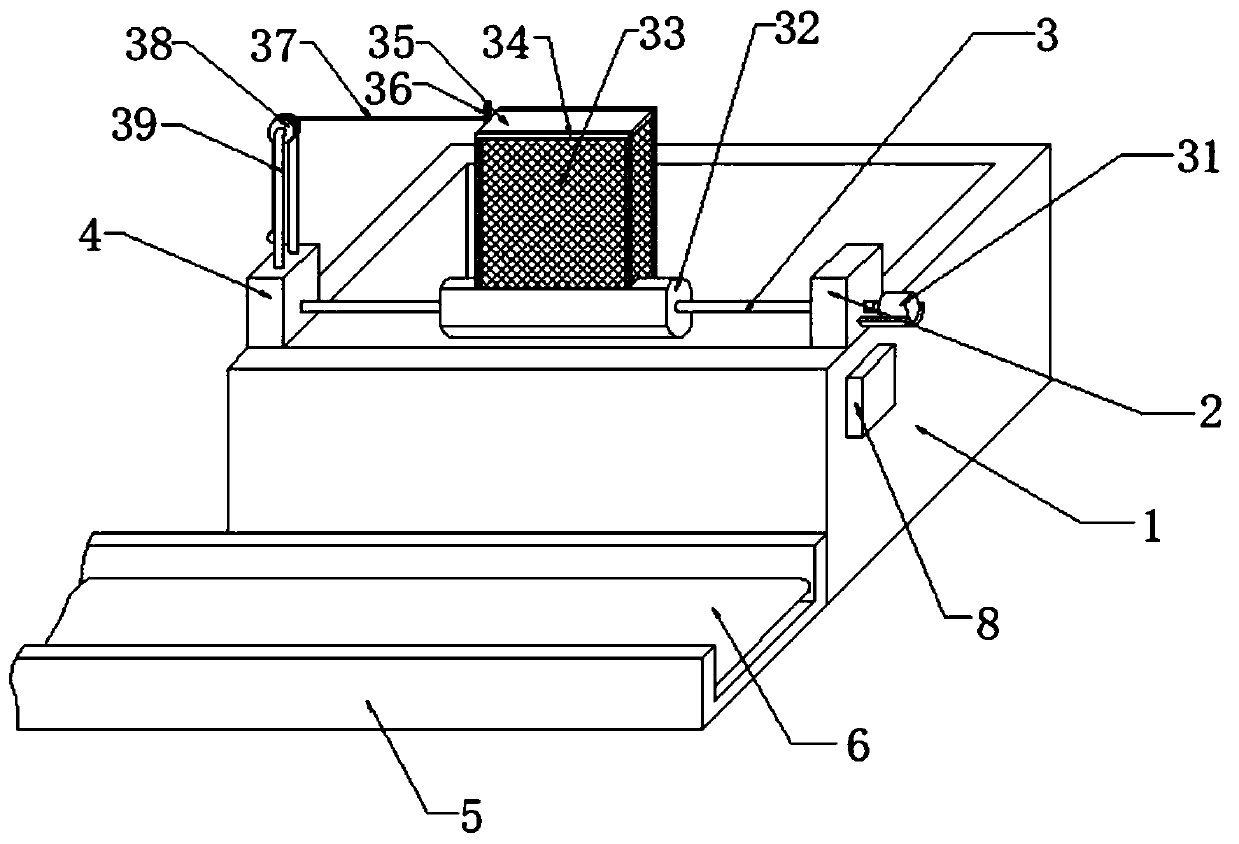

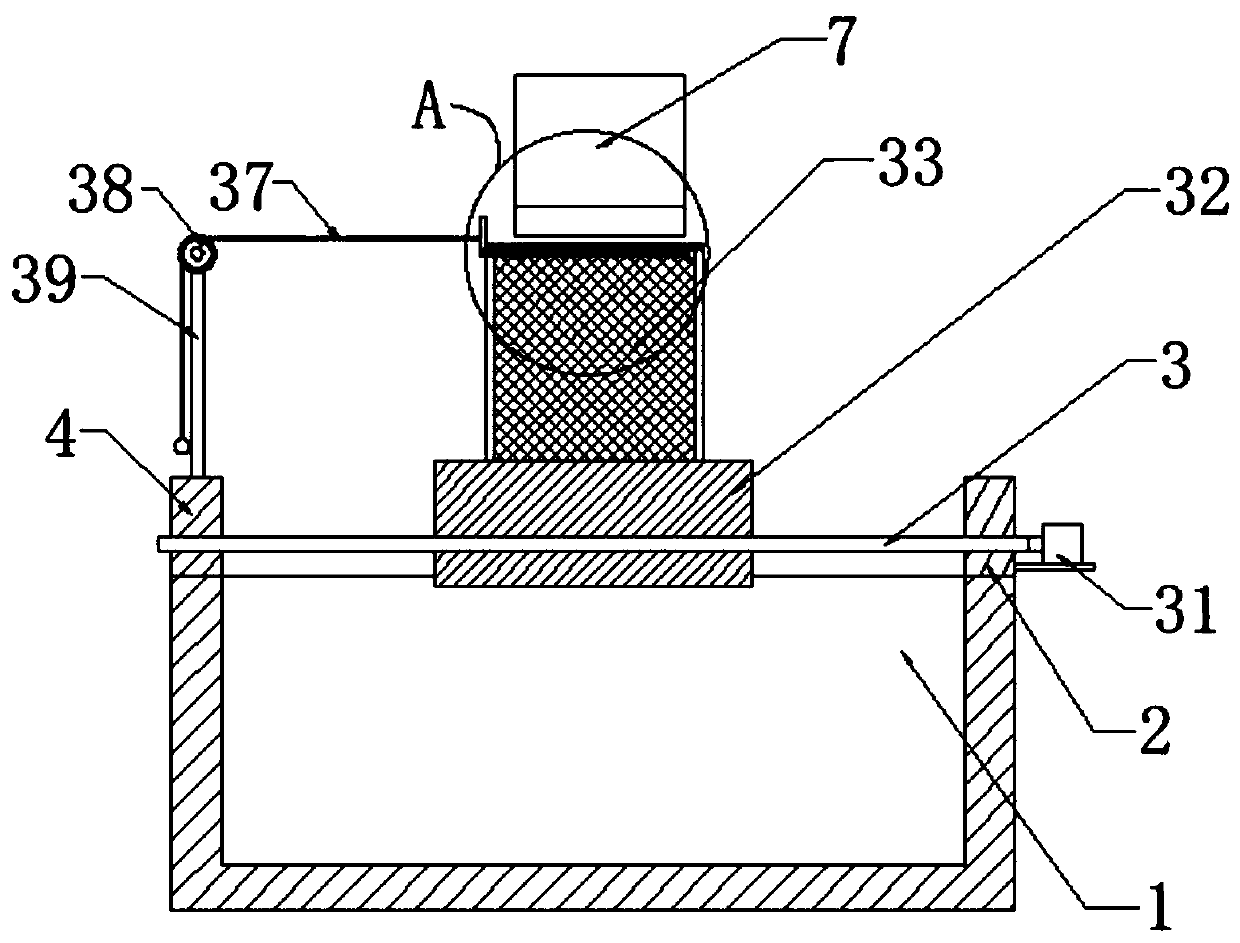

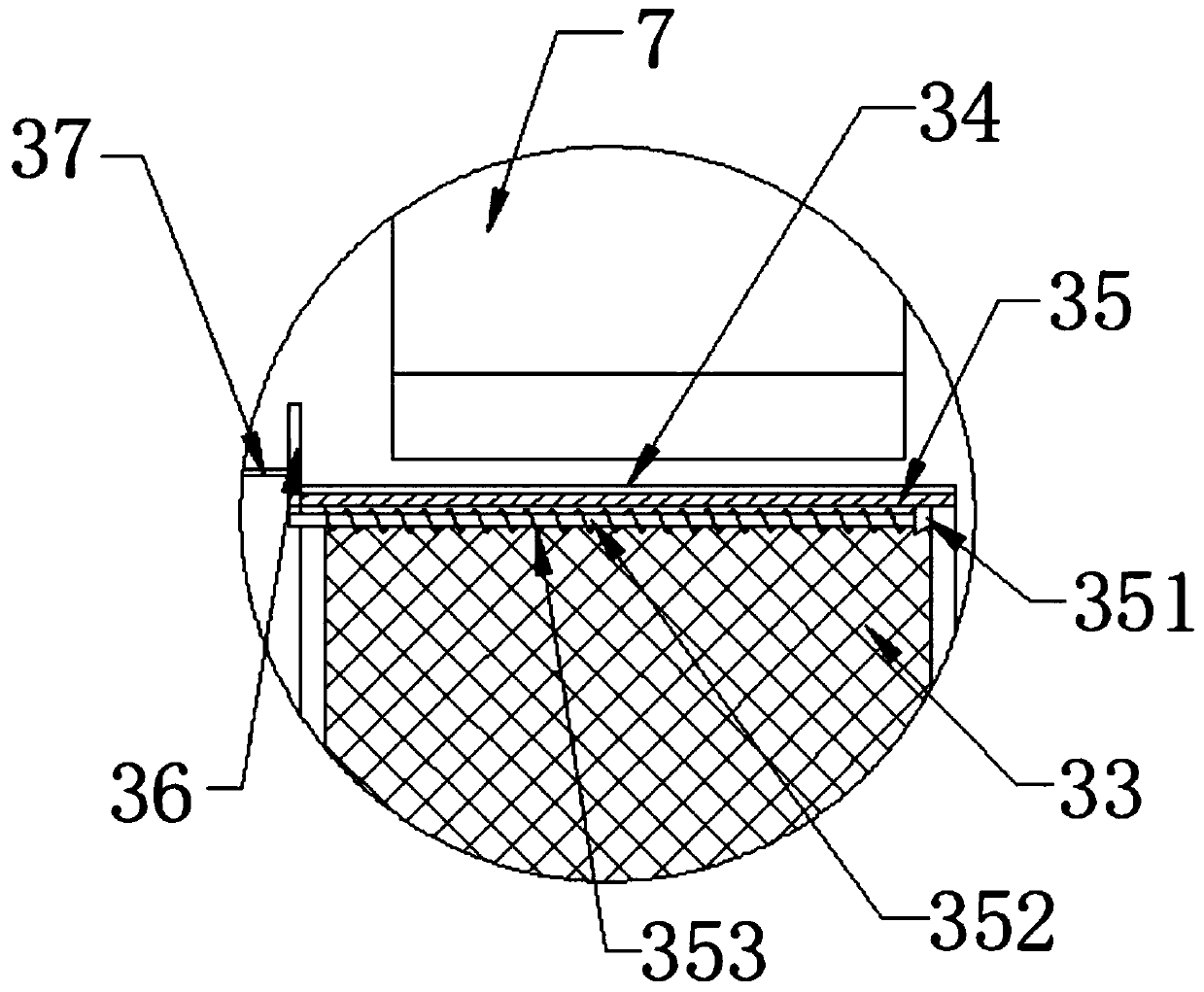

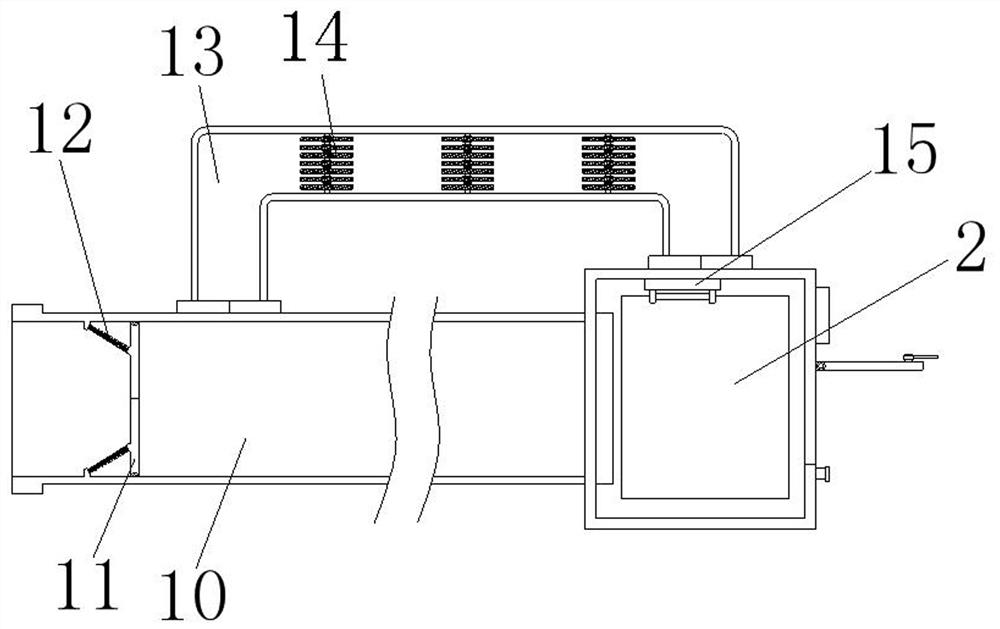

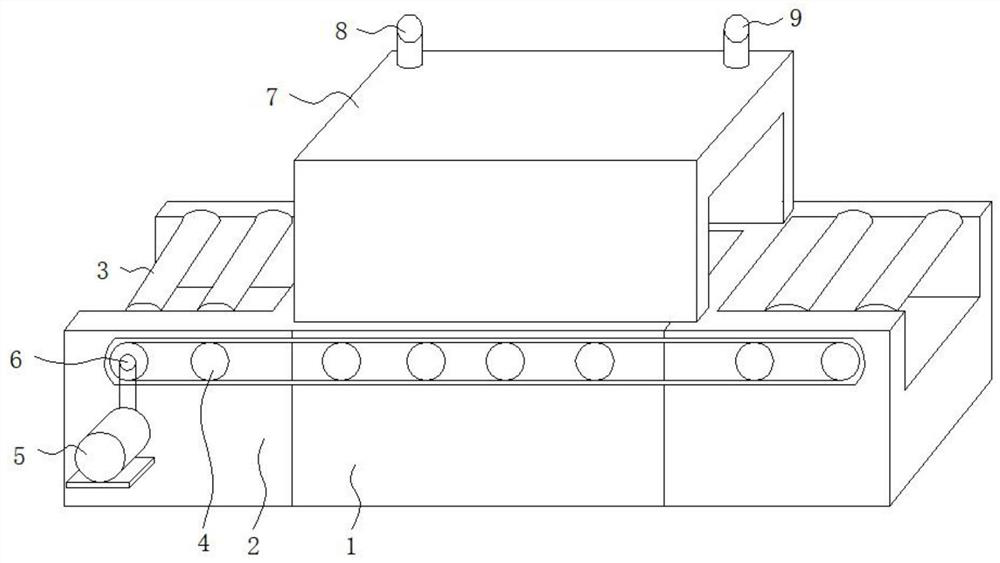

Feeding device of deformed steel bar quenching device with uniform quenching function

ActiveCN111020168ALess work for workersEasy to moveFurnace typesCleaning using toolsSteel barMechanical engineering

The invention relates to the field of deformed steel bar production, in particular to a feeding device of a deformed steel bar quenching device with a uniform quenching function. The feeding device comprises a base, a collecting mechanism, a pushing mechanism, a first conveying mechanism, a second conveying mechanism and a cleaning mechanism. The pushing mechanism is fixedly mounted on the base; and the pushing mechanism pushes deformed steel bars, and the pushing mechanism facilitates separation of the deformed steel bars with different diameters, so that multiple deformed steel bars are conveniently added at a time, and the deformed steel bars are pushed one by one through the pushing mechanism, the work of workers is reduced, trouble and labor are saved, continuous movement of the deformed steel bars is facilitated, feeding coherence is facilitated, and utilization of heat resources is facilitated. The first conveying mechanism is installed on the base, and the second conveying mechanism is installed on the base, so that the first conveying mechanism and the second conveying mechanism are conveniently used for conveying the deformed steel bars, the deformed steel bars can be continuously conveyed one by one, continuous and uniform quenching of the deformed steel bars is facilitated, trouble and labor are saved, and the efficiency is improved.

Owner:湖北立晋钢铁集团有限公司

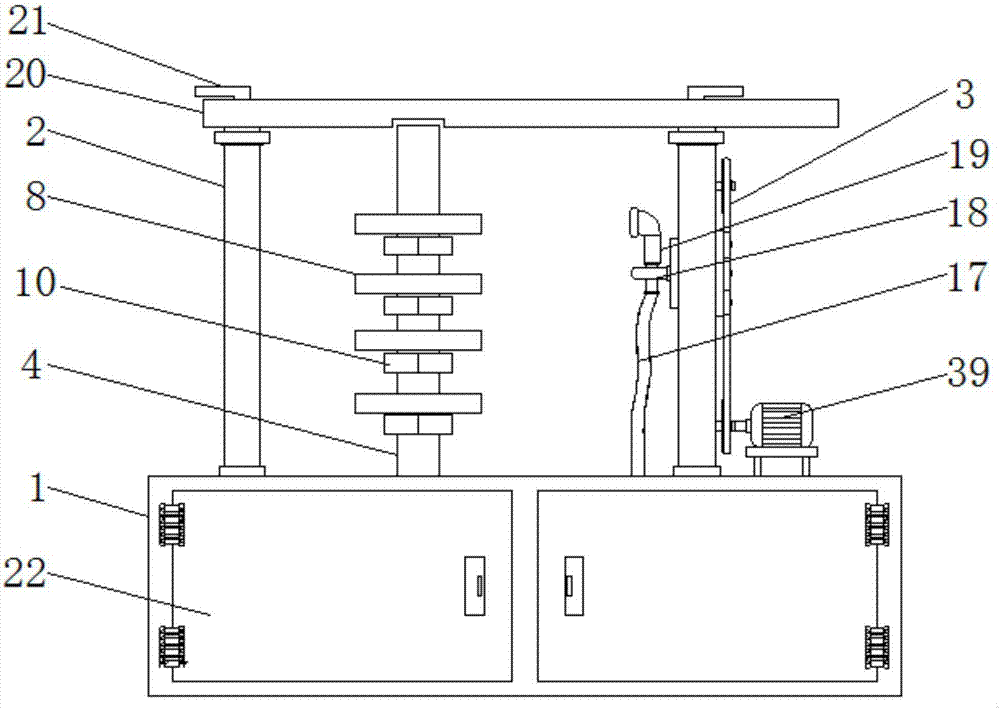

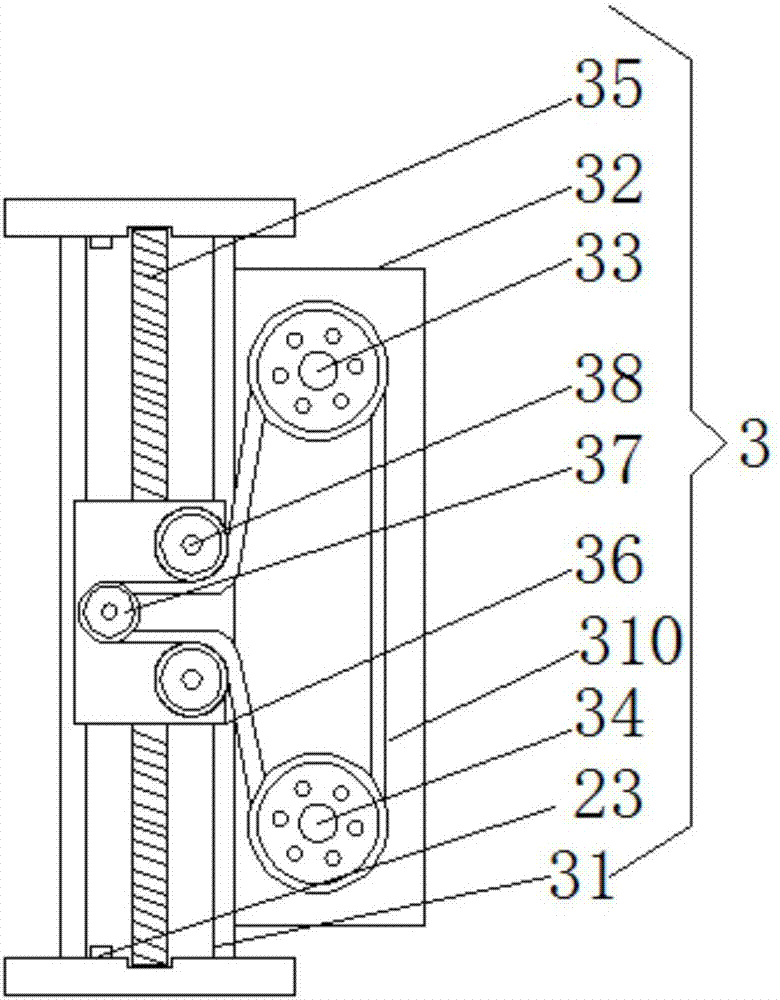

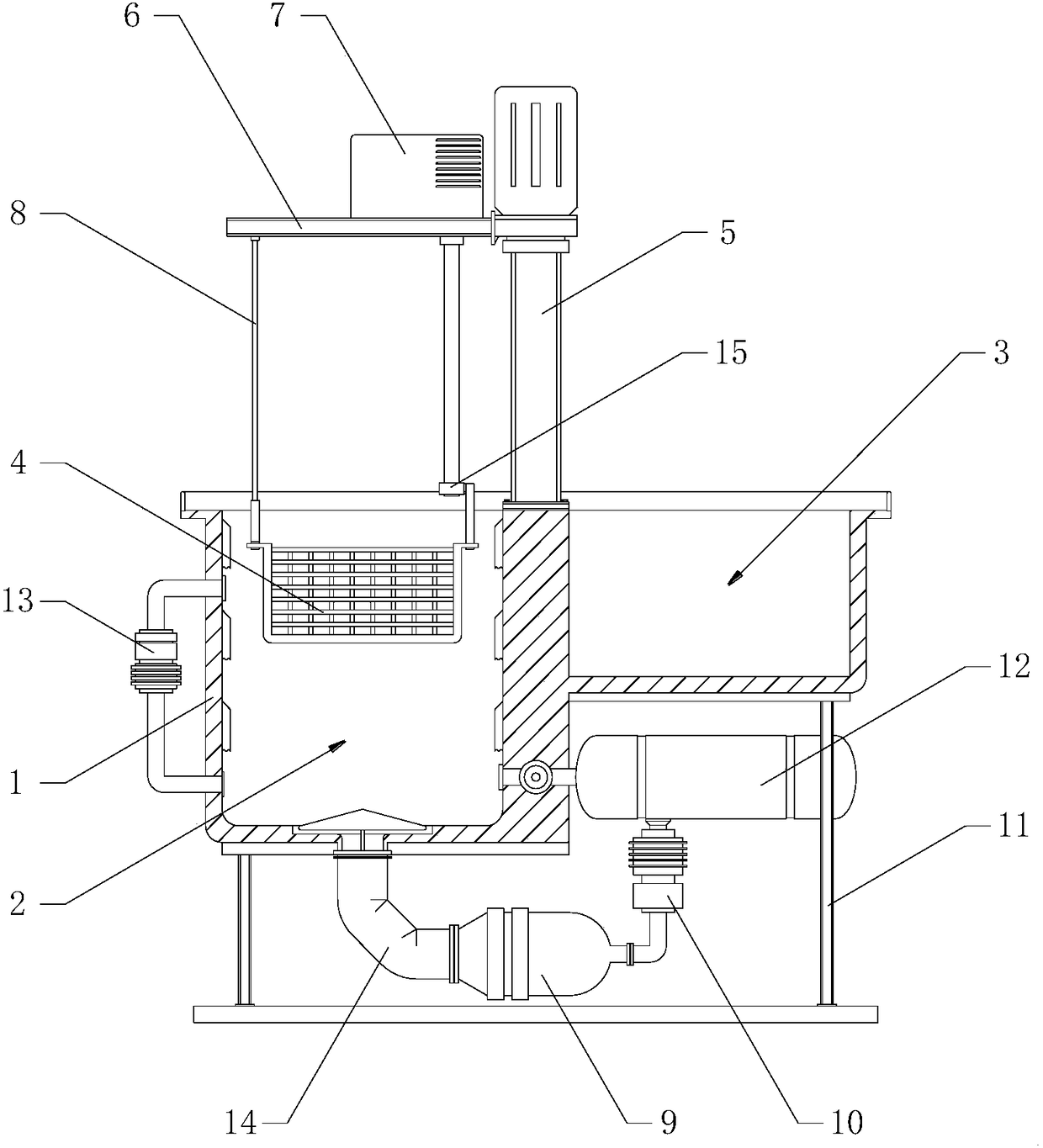

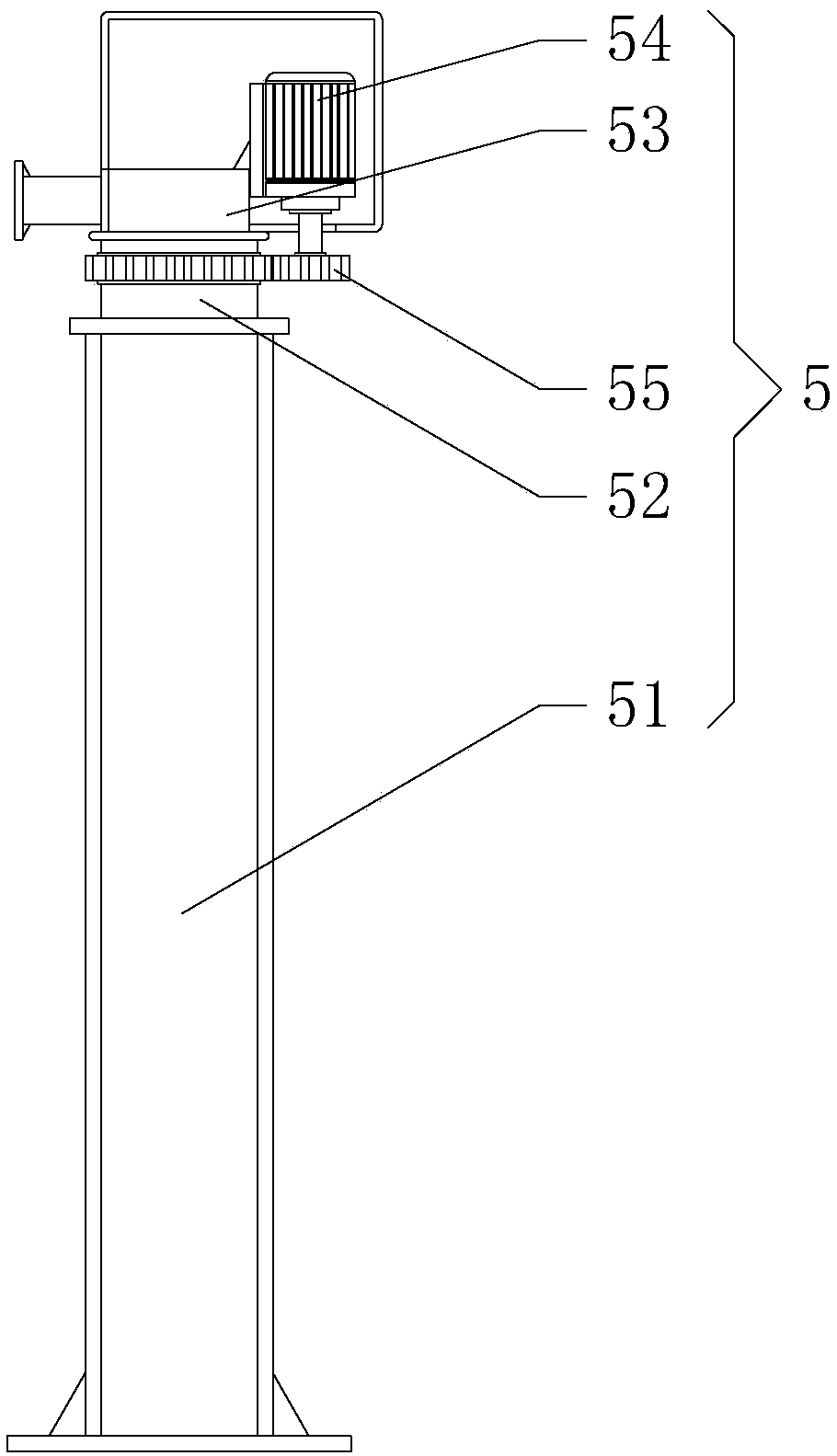

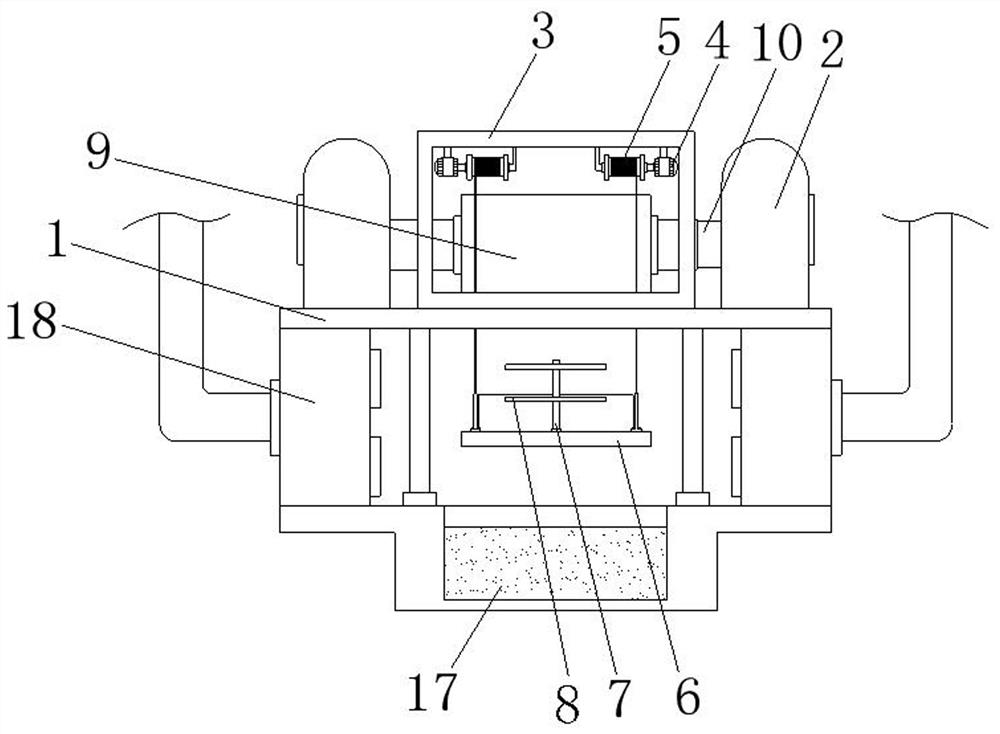

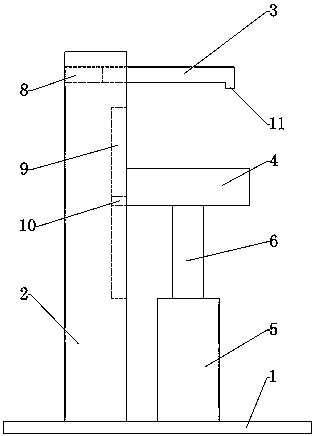

Quenching device for bearing support production

ActiveCN108531696AConvenient QuenchingImprove heating efficiencyFurnace typesHeat treatment furnacesFixed bearingEngineering

Owner:徐州金马回转支承制造有限公司

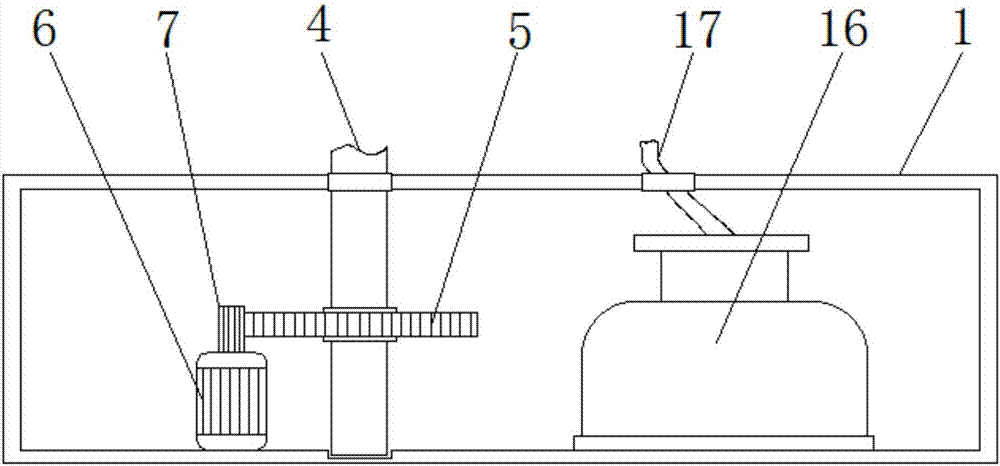

Quenching device for bearing support production

ActiveCN107400770AConvenient QuenchingImprove heating efficiencyFurnace typesHeat treatment furnacesFixed bearingCombustion

The invention discloses a quenching device for bearing support production. The device includes a box, one side at the top of the box is fixedly connected to a support column, and the other side at the top of the box is fixedly connected to a mobile device, and the mobile device is equipped with a fire-jet head. A rotating column for fixing bearing supports runs through the top of the box, and one rotating column end extending into the box is in flexible connection with the bottom of the box inner wall. One side at the bottom of the box inner wall is fixedly connected to a combustion gas tank, the top of the combustion gas tank is communicated with a communicating pipe, and one end of the communicating pipe far from the combustion gas tank runs through the inner wall of the box and is in connection with the fire-jet head. The quenching device for bearing support production can quench a plurality of bearing supports simultaneously, also the bearing supports rotate incessantly in the heating process, and during heating the fire-jet head keeps moving, thus improving the quenching and heating efficiency.

Owner:五河县纬立农业科技有限公司

Glass plate

The invention provides a glass plate, which has the following composition: 66.0-74.0% by mass SiO2, 2.0-4.0% by mass Al2O3, 7.0-10.0% by mass CaO, 3.8-6.0% by mass MgO, 12.6-14.6% by mass Na2O and 0.4- 2.0% by mass K2O, the total amount of the above components is at least 96% by mass, and the total amount of SiO2+Al2O3 is 70.0-74.4% by mass, the total amount of CaO+MgO is 12.0-14.5% by mass, the total amount of Na2O+K2O 13.5-15.5% by mass, CaO / MgO mass ratio is 1.7-2.2. The above-mentioned glass sheet is easy to quench, has a high softening point, and does not substantially impair stability during float manufacturing.

Owner:AGC INC

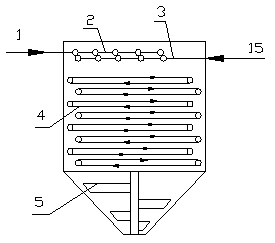

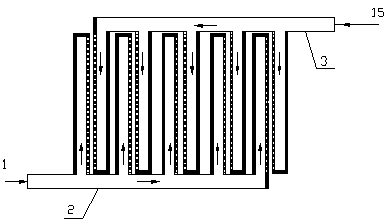

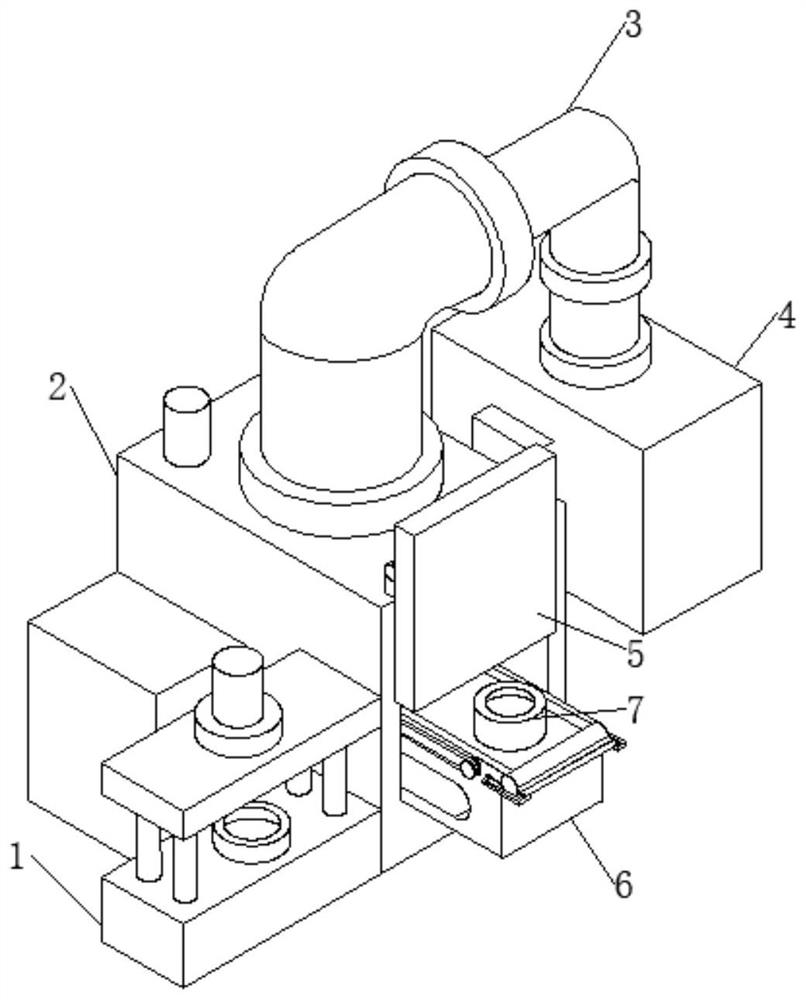

Oil pool quenching equipment

InactiveCN103572017AConvenient QuenchingReasonable designQuenching devicesQuenchingEnergy conservation

The invention provides oil pool quenching equipment which comprises an oil pool, a feeding pipeline arranged at one end of the oil pool, a distribution mechanism connected to the feeding pipeline, a discharging mechanism arranged at the other end of the oil pool, a material receipt mechanism arranged on one side of the discharging mechanism, and an oil liquid heat exchange mechanism arranged on one side of the oil pool. The oil pool quenching equipment has the advantages of reasonable design, simple structure, simplicity and convenience in manufacture, convenience in quenching, high working efficiency, energy conservation and the like.

Owner:HAIYAN SANMA STANDARD HARDWARE

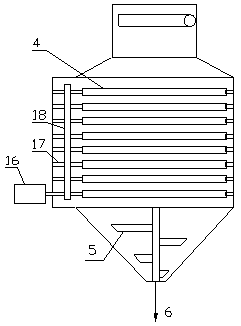

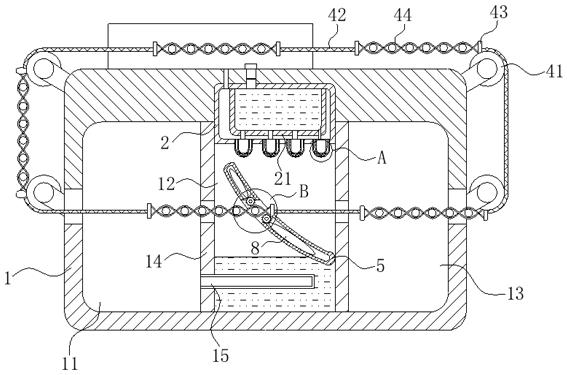

Insoluble sulfur continuous quenching device

ActiveCN111377412AHigh yieldGranulation realizationSulfur preparation/purificationPhysical chemistryThermal stability

The invention discloses an insoluble sulfur continuous quenching device which comprises a shell, and the interior of the shell comprises a feeding quenching section, a material conveying section and adischarging section in the material flowing direction; a feeding distributor and a quenching liquid distributor are arranged in the feeding quenching section, a plurality of layers of conveying beltsare arranged in the material conveying section, fixed rotating shafts are arranged at the two ends of each layer of conveying belt, and a discharging device is arranged in the discharging section. According to the continuous quenching device for insoluble sulfur, continuous quenching of polymerized sulfur can be achieved through continuous granulation and continuous conveying, so the consistencyof the quenching time of polymerized sulfur is achieved, and the yield and the thermal stability of quenched products are guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Induction quenching machine tool with double-frequency heating power source

InactiveCN109609741AImprove the heating effectConvenient QuenchingFurnace typesIncreasing energy efficiencyQuenchingFlue

The invention relates to the technical field of quenching machine tools, and discloses an induction quenching machine tool with a double-frequency heating power source. The induction quenching machinetool comprises a workbox. A first motor is fixedly mounted on the top of the side face of the workbox, a fixing box is arranged on the top of an inner cavity of the workbox, and an output shaft of the first motor is fixedly sleeved with a lead screw located in the fixing box. According to the induction quenching machine tool with the double-frequency heating power source, two sets of draught fansare started, smoke dust generated when a workpiece is heated and quenched is absorbed through an air flue, the smoke dust generated during quenching is purified through a smoke dust purification device connected with air outflow pipes of the two sets of draught fans, meanwhile, one set of draught fan can be driven to extract cold air from the external environment, the cold air is conveyed into the workbox through the air flue, the other set of draught fan is used for extracting heat generated in the workbox in the heating and quenching processes, thus, the workbox is cooled, the situation that operation of equipment is affected as the working temperature in the workbox is too high is avoided, and the service life of the equipment is prolonged.

Owner:XIAN TECHNOLOGICAL UNIV

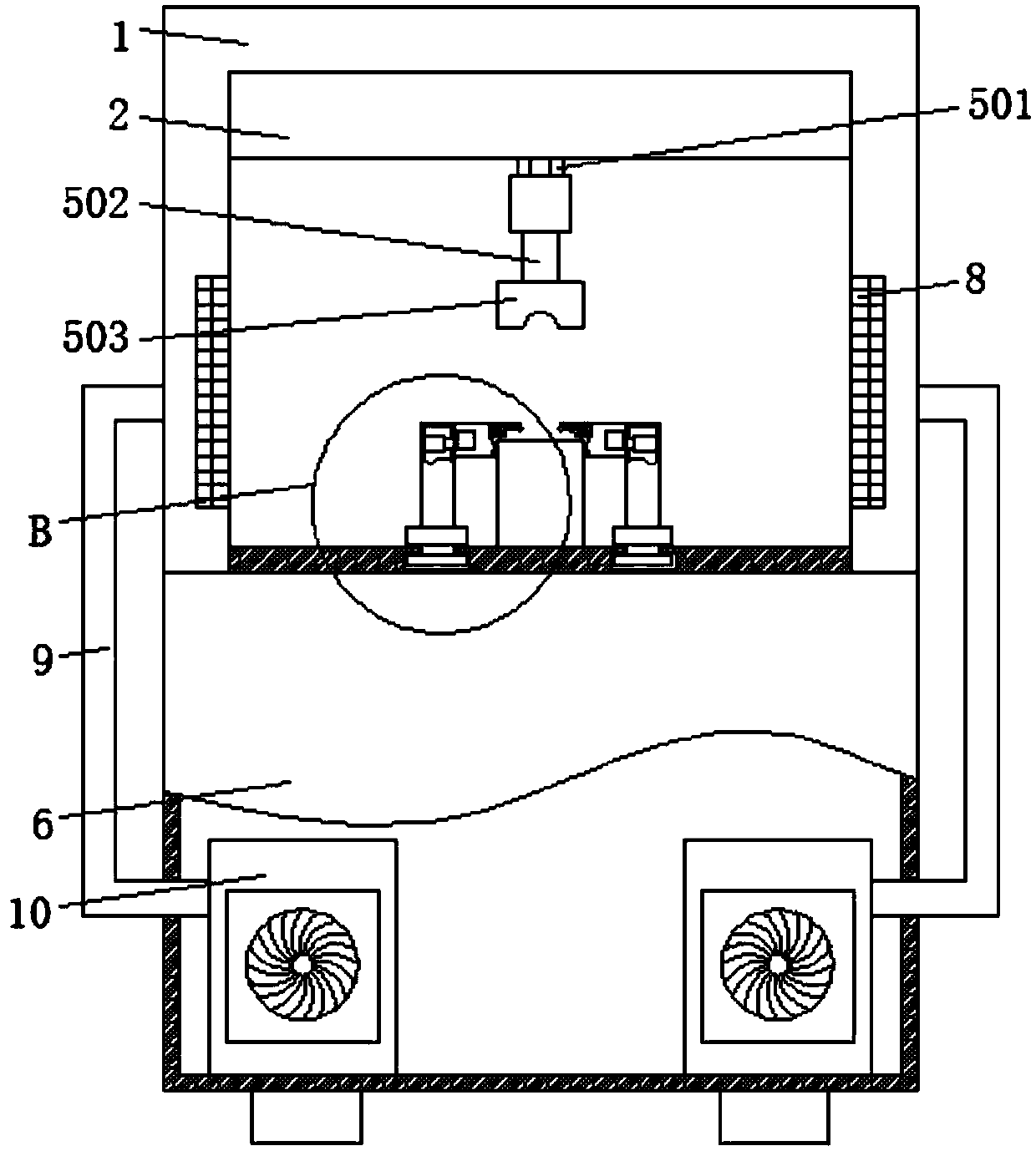

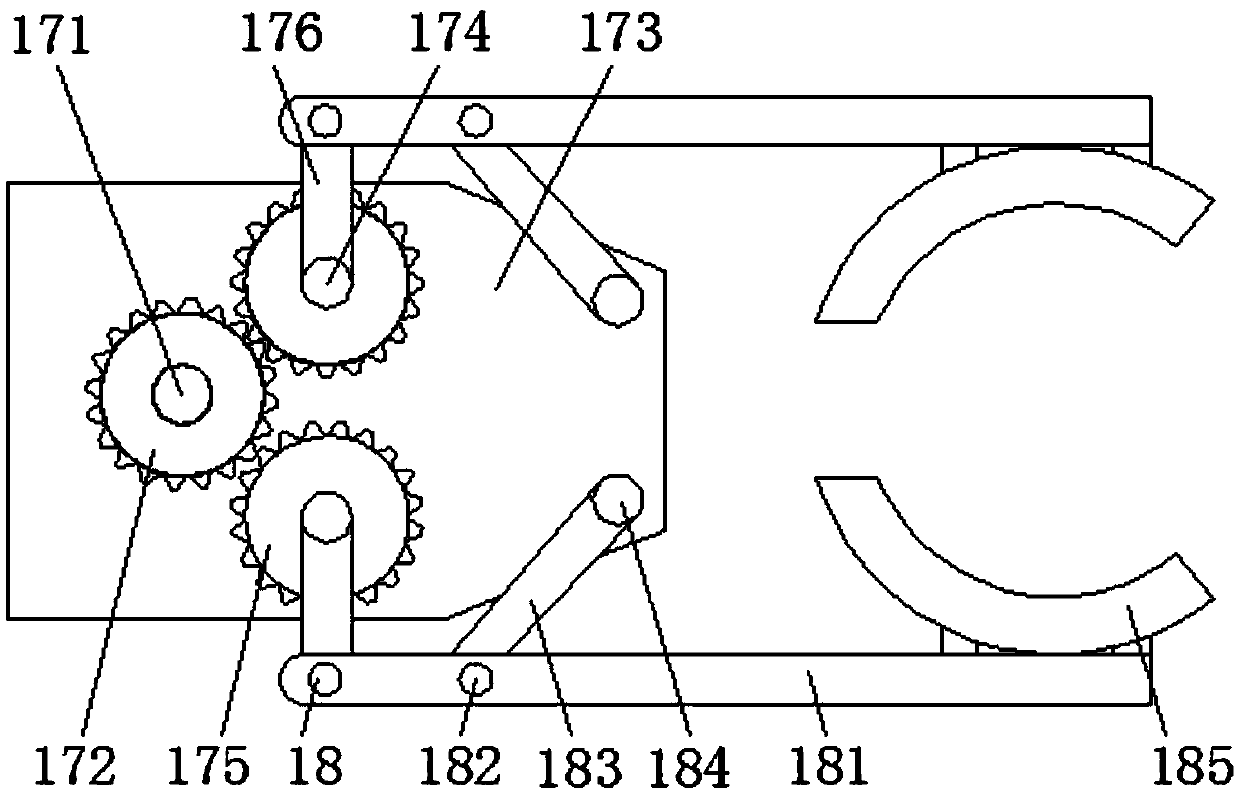

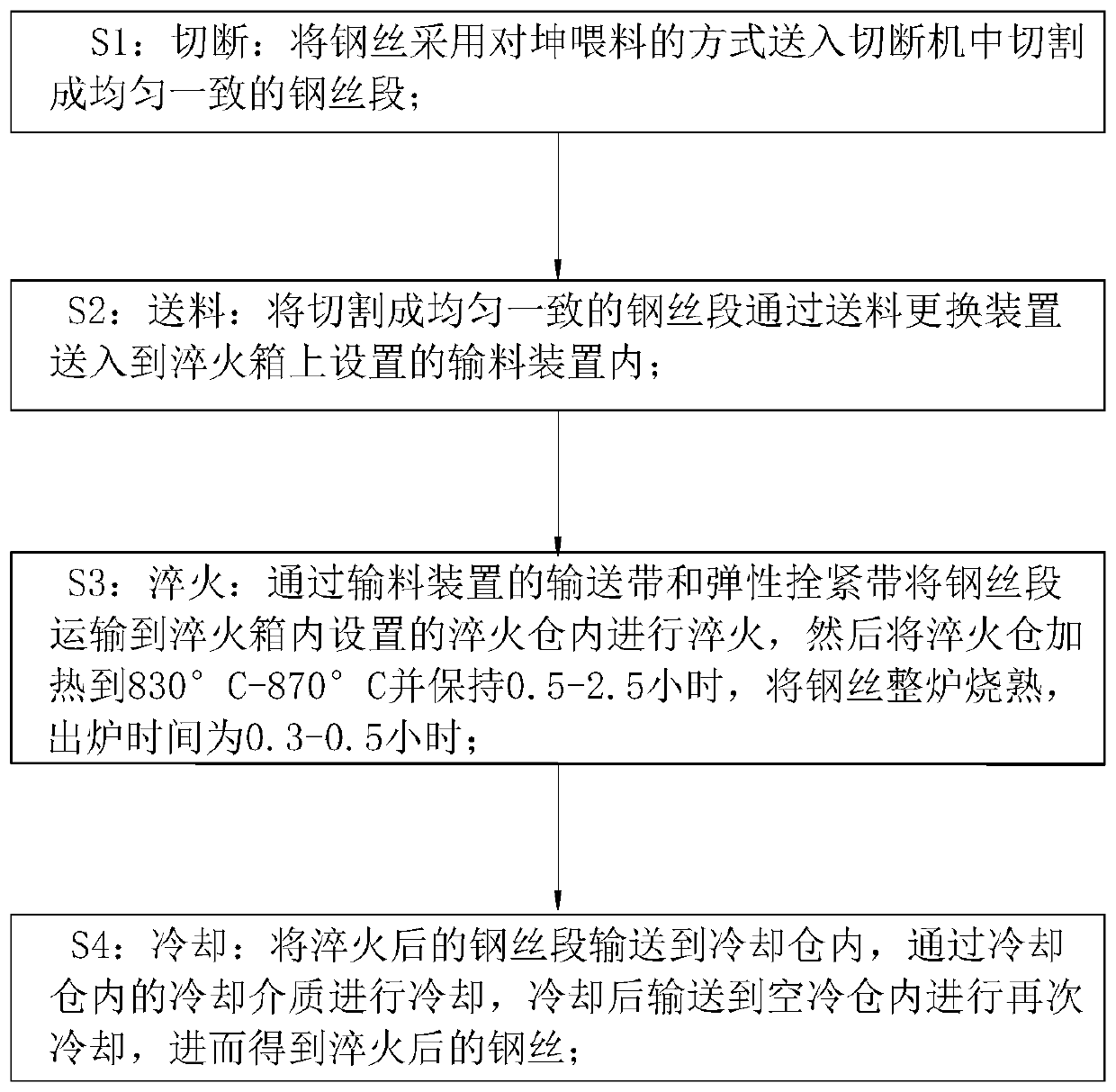

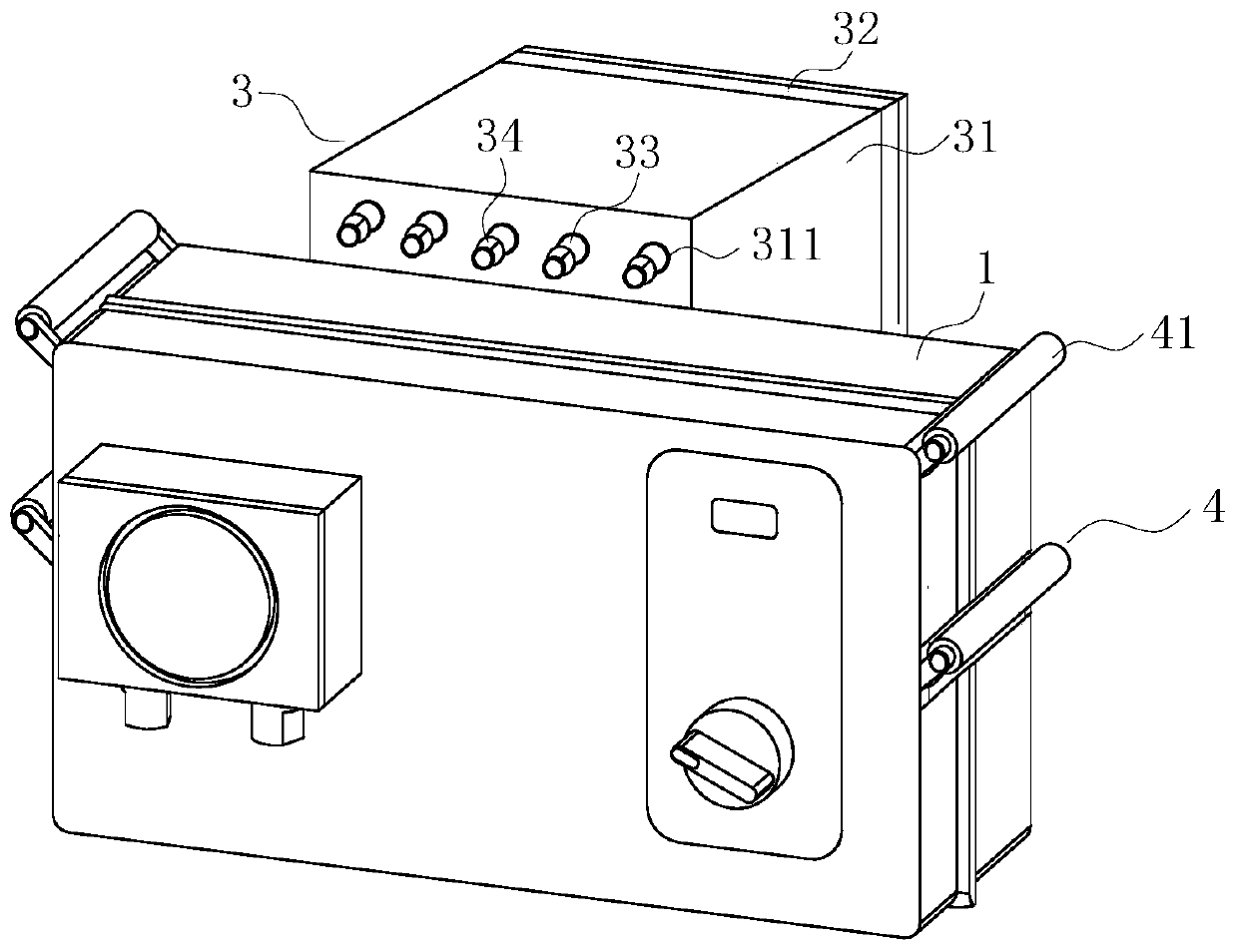

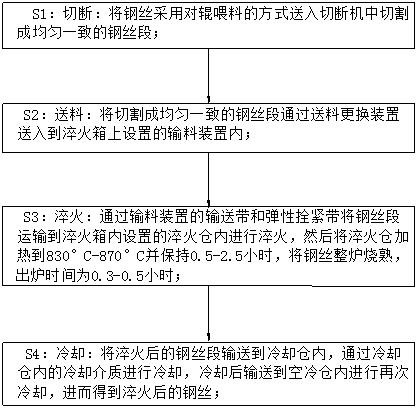

Steel wire quenching process

ActiveCN110343842AImprove quenching efficiencyIncrease the quenching areaFurnace typesHeat treatment furnacesQuenchingWire segment

The invention belongs to the technical field of steel wire quenching, in particular to a steel wire quenching process. A quenching bin is arranged inside a quenching box; a cooling medium is filled into a cooling bin, and the bottom end of the cooling bin communicates with the quenching bin through a heating pipe; a condensing tank is arranged above the cooling bin and is filled with condensed gas; the inside of a pushing box is slidably provided with a sliding guide plate through a telescopic rod, and the sliding guide plate is provided with a hollow guiding rod; the end of the hollow guidingrod is slidably arranged in a guiding sliding hole, and the end of the hollow guiding rod is provided with a guiding push head; conveying rollers are evenly arranged on the outer wall of the quenching box through supporting frames; a conveying belt is arranged on the outer walls of the conveying rollers in a rotating manner, and the conveying belt is evenly connected with a plurality of elastic fastening bands through elastic connecting blocks; and steel wire segments can be shaken in the quenching box, so that the effect of changing the steel wire segments from the static state to the dynamic state in the quenching process is increased, and the quenching effect of the steel wire segments is further increased.

Owner:安徽普力森特钢股份有限公司

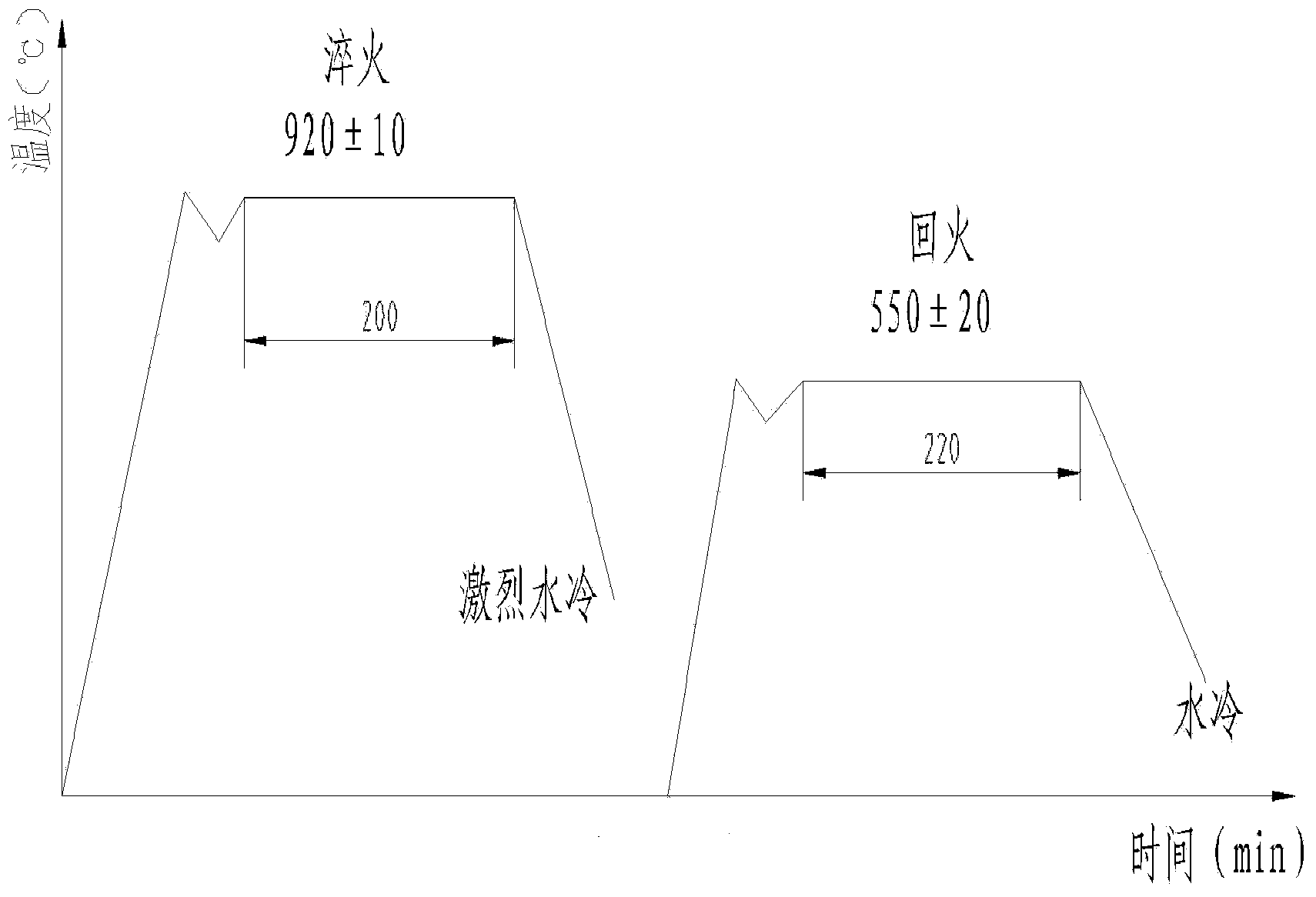

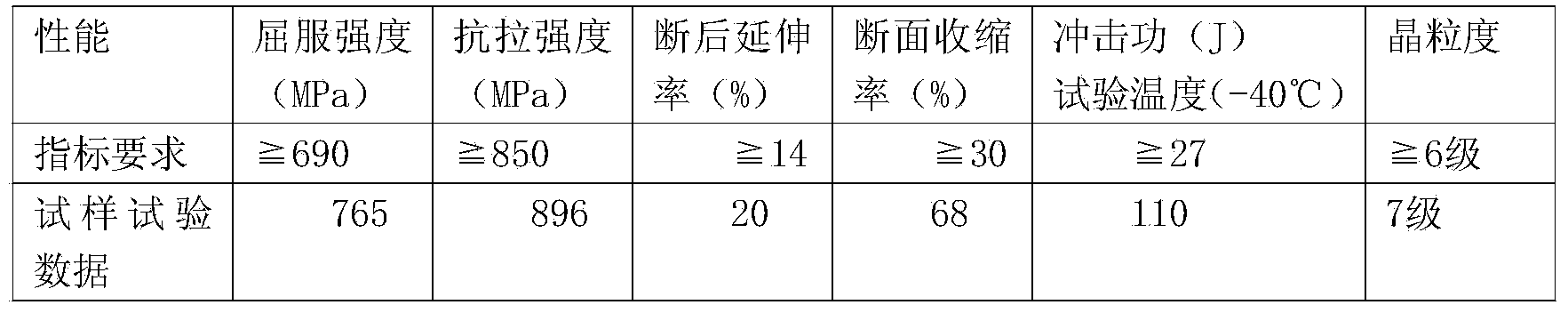

Heat treatment technology for forging coupler yoke

InactiveCN103710498AReduce heat treatment energy consumptionStable mechanical propertiesFurnace typesHeat treatment furnacesPerformance indexHeating furnace

The invention discloses a heat treatment technology for forging a coupler yoke. Coupler yoke forging steel is 25MnCrNiMoA low-alloy steel. The heat treatment technology comprises the following steps: (1) quenching, to be specific, putting the machined coupler yoke forging steel in a heating furnace, heating to 910-930 DEG C, carrying out heat preservation for 200 minutes, and then directly carrying out intense water cooling; and (2) tempering, to be specific, putting the quenched coupler yoke forging steel in a tempering furnace, heating to 530-570 DEG C, carrying out heat preservation for 220 minutes, and then carrying out water cooling. The heat treatment technology for forging the coupler yoke, provided by the invention, is reasonable in technological design and can be used for obtaining the coupler yoke which has a relatively stable microstructure and is balanced and stable in mechanical performance indexes.

Owner:HEBEI LUYOU RAILWAY LOCOMOTIVE & ROLLING STOCK PARTS

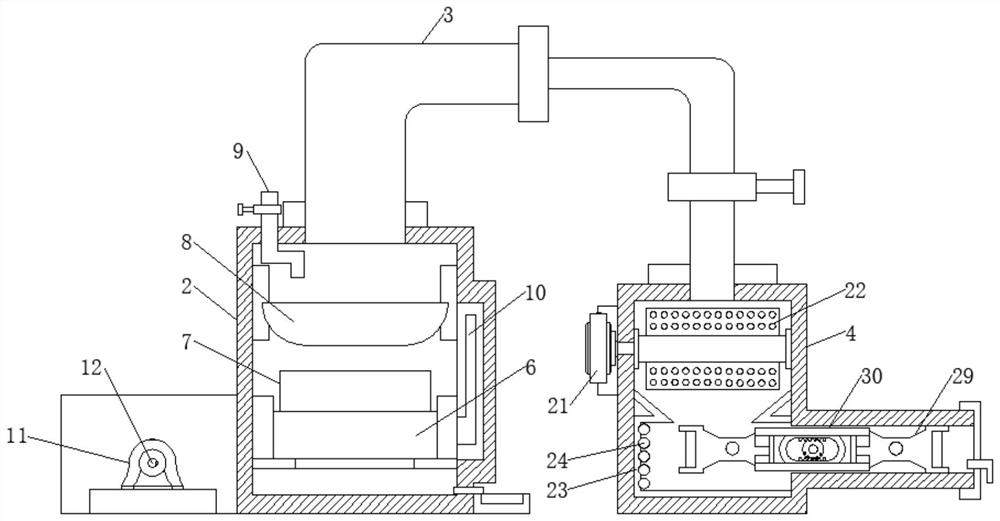

Agricultural machine casting quenching unit

InactiveCN108277332AUniform temperatureLow water consumptionFurnace typesHeat treatment furnacesQuenchingWater pipe

The invention discloses an agricultural machine casting quenching unit which comprises a water tank and a filter. A quenching chamber is arranged on one side of the interior of the water tank, an airdrying chamber is arranged on the other side of the interior of the water tank, an adjusting mechanism is vertically installed at the middle portion of the upper portion of the water tank, a top support is horizontally installed on one side of the upper portion of the adjusting mechanism, a lifting mechanism is installed on one side of the upper portion of the top support, one side of a straight rod is sleeved with an object containing basket in a sleeving manner, a circulation pump is arranged outside the side, close to the quenching chamber, of the water tank, a water inlet of the filter isconnected to the other end of a guide rail pipe, and a water outlet of the pressure water tank communicates with the quenching chamber through a guide pipe. According to the agricultural machine casting quenching unit, water is guided to the interior of the filter through a water guide pipe to be filtered and then conveyed into the pressure water tank for temporary storage, then the water is appropriately conveyed back to the interior of the quenching chamber for supplementing for internal water amount, water consumption is reduced, the water using efficiency is improved, and the environment is protected.

Owner:郑伟杰

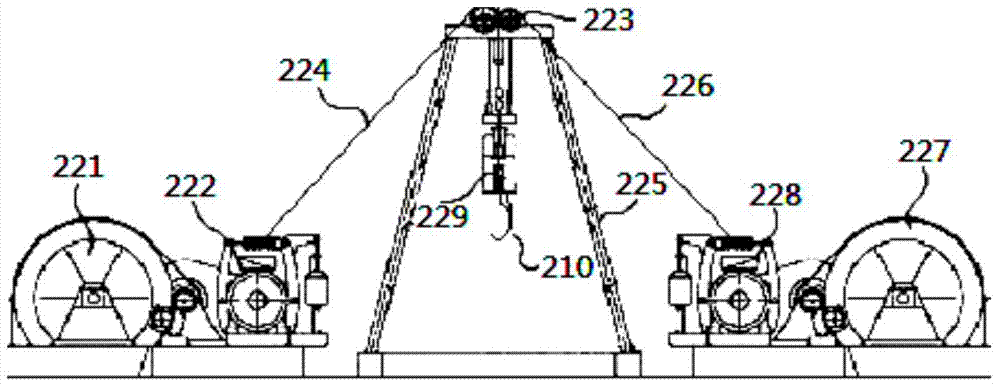

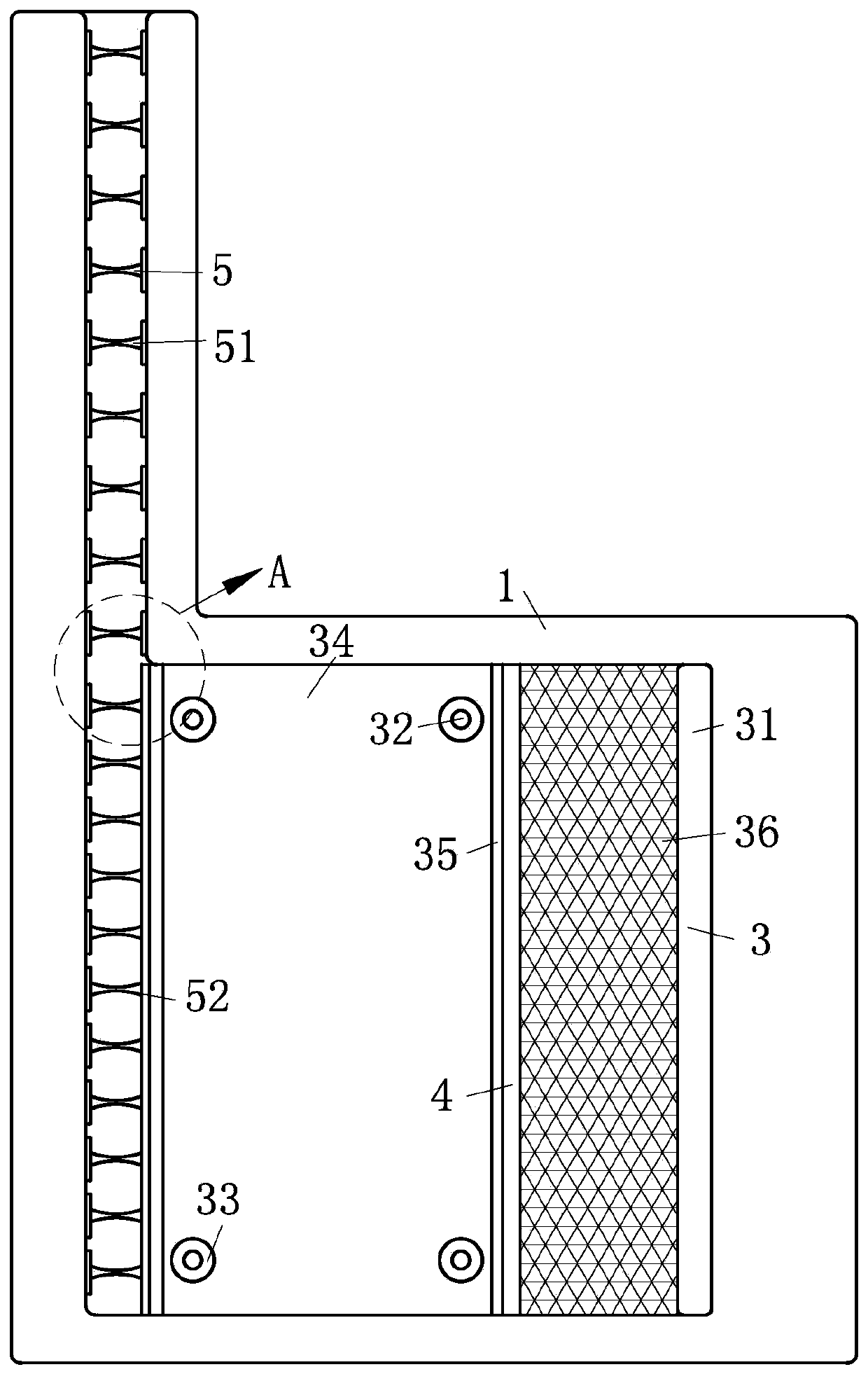

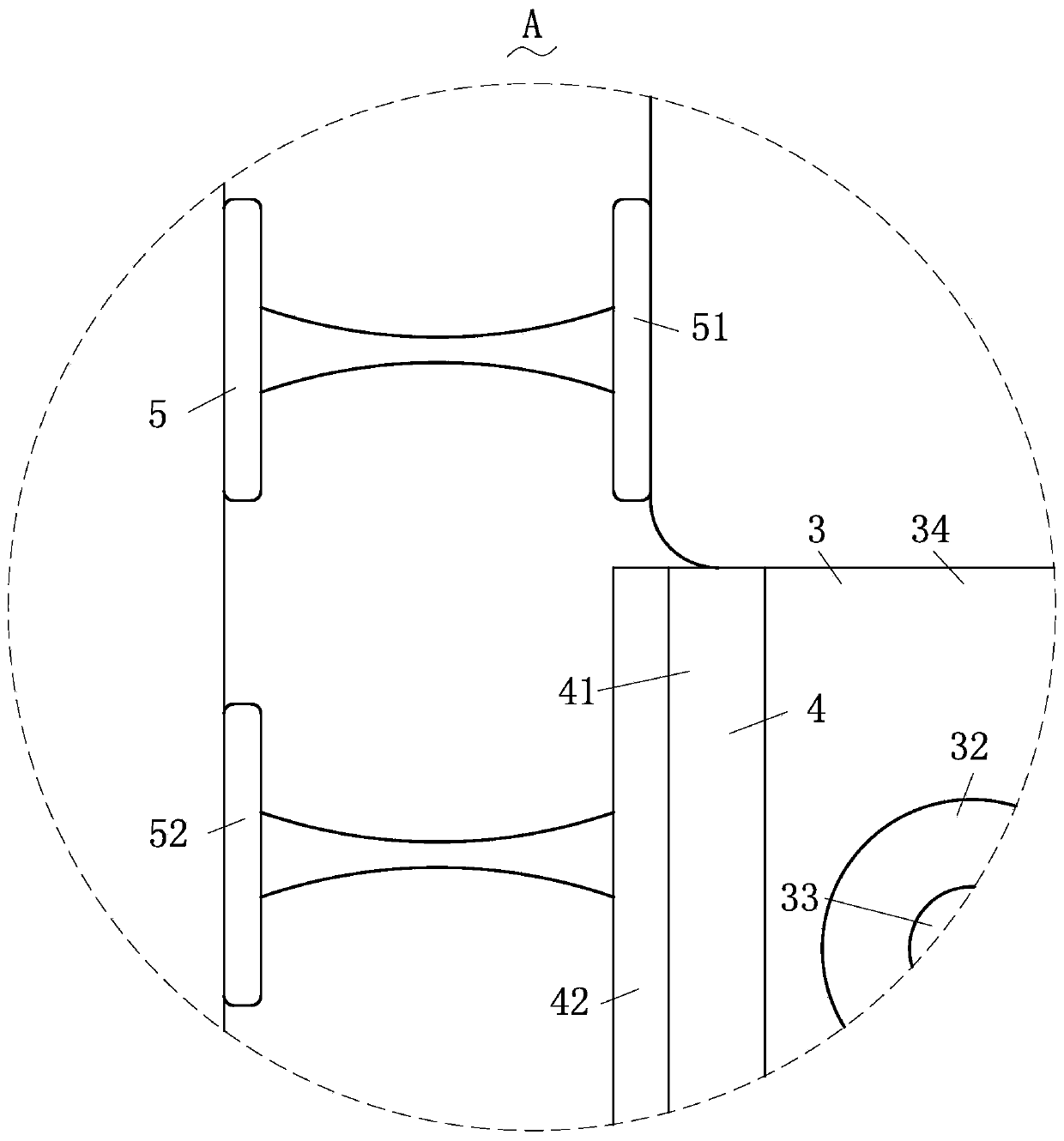

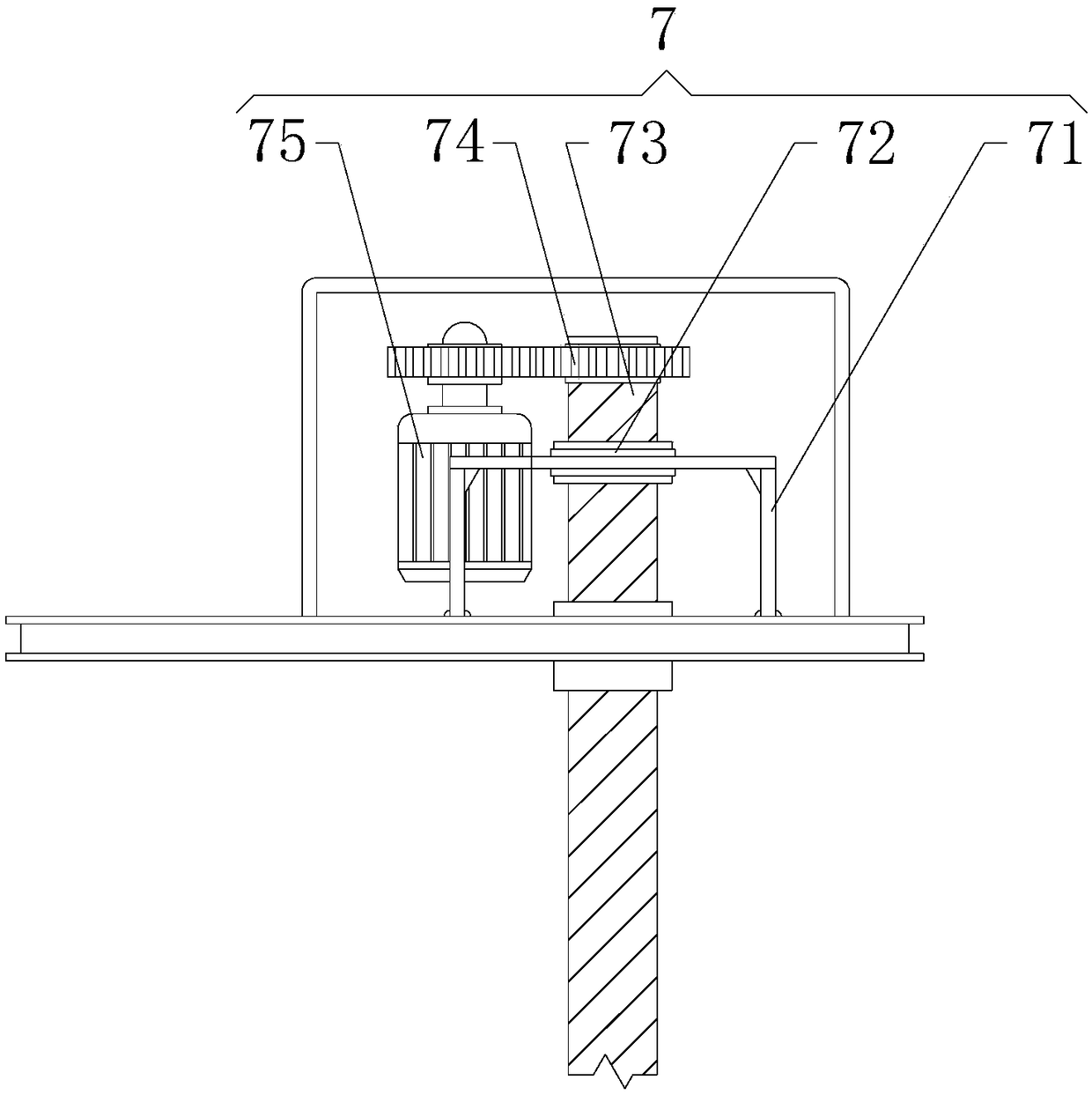

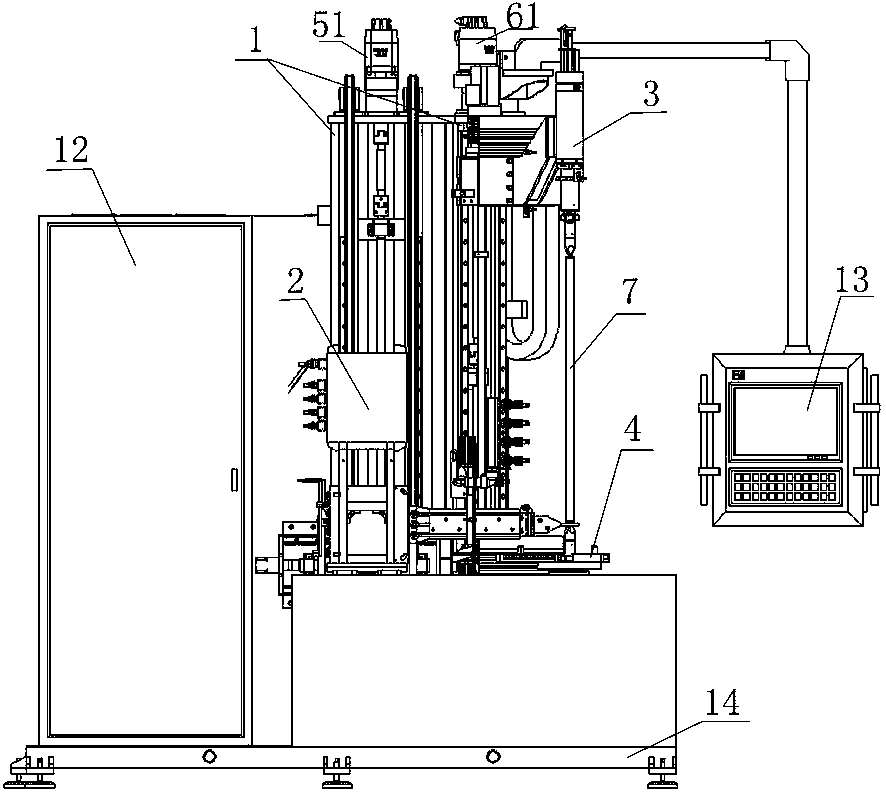

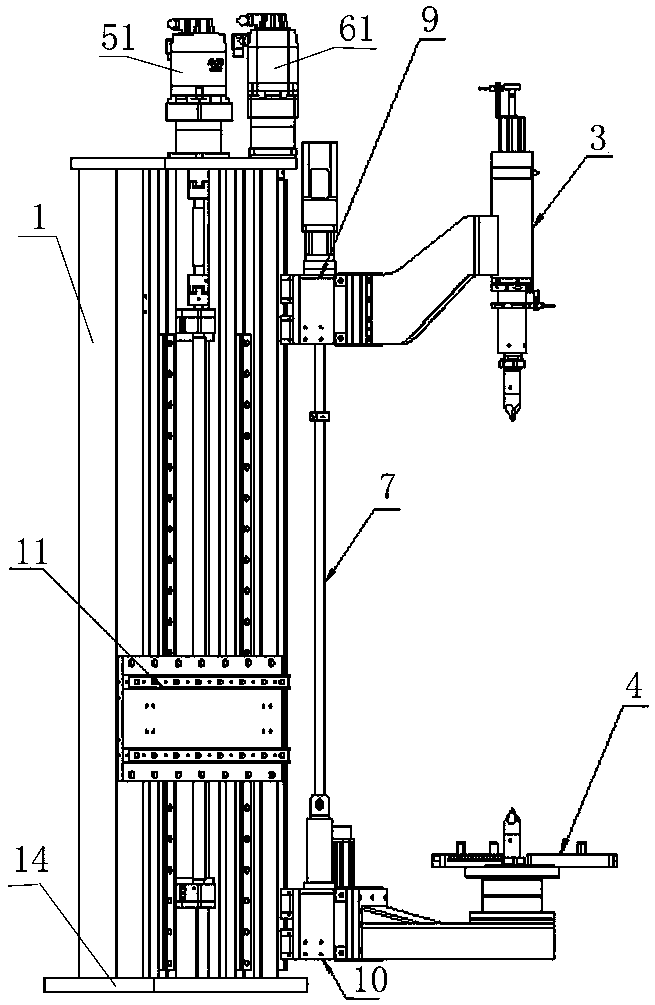

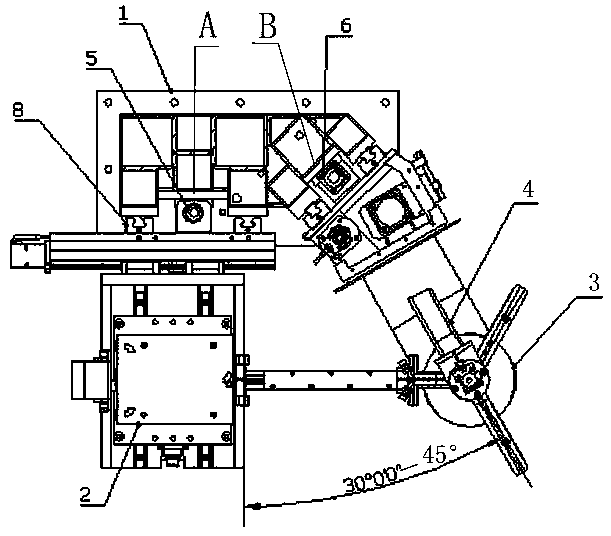

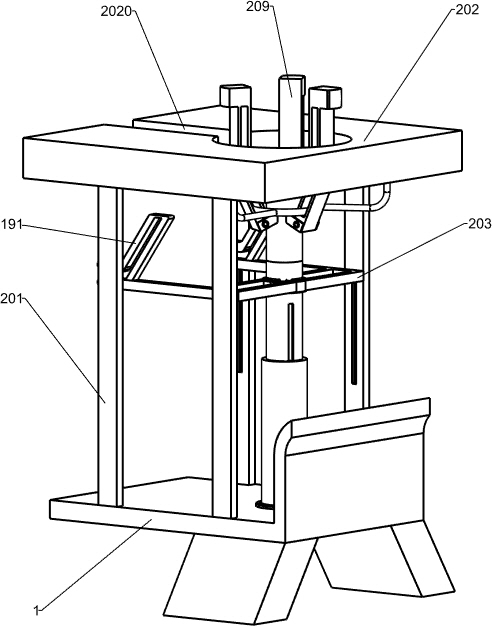

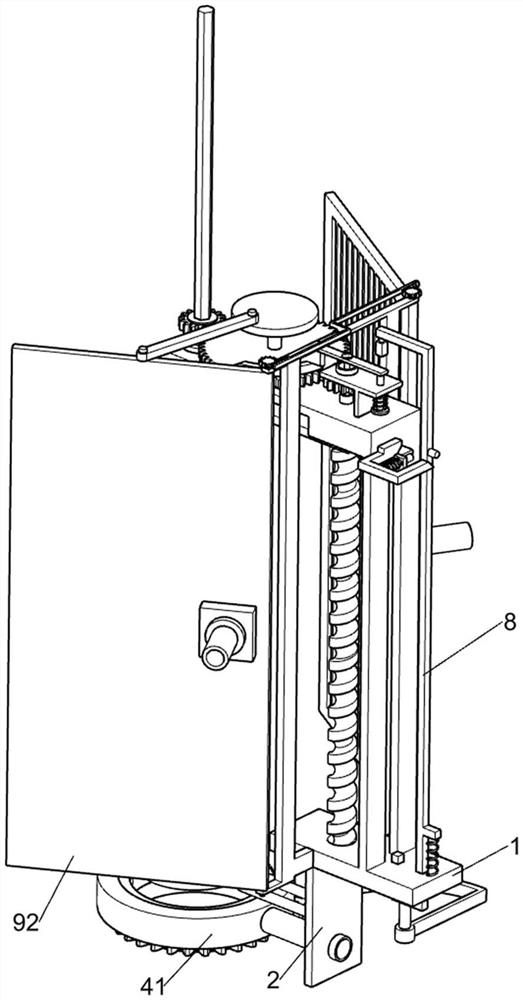

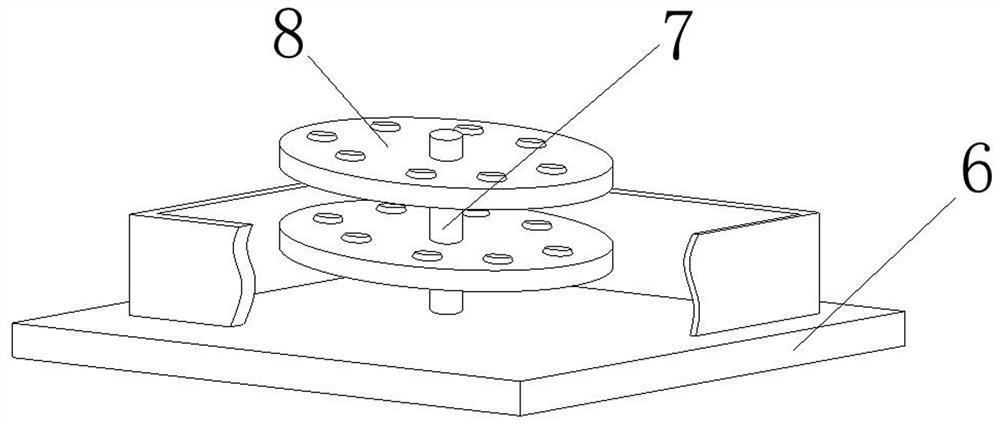

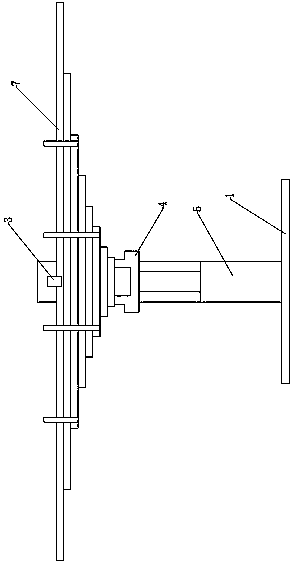

General induction quenching device for shafts and discs

PendingCN109868353AConvenient QuenchingEasy clampingIncreasing energy efficiencyFurnace typesQuenchingColumn structure

The invention discloses a general induction quenching device for shafts and discs. The two side faces are designed on the positions, facing the direction of the work station, of a standing column structure body, the two side faces are arranged in an included angle structure, a first guiding rail body and a first ball screw are used to drive a loading sliding table so that the quenching load movesup and down, and a second guiding rail body and a second ball screw are used to drive top and lower tips to move relatively. The upper and lower tips can achieve the clamping of the shaft-like workpieces of different lengths, meanwhile, the up and down movement of the quenching load can achieve the non movement of the shaft-like components, and the quenching of the long-shaft-like components is simple and easy to operate accordingly; and the manner that the quenching load shares the same standing column with the upper and lower tips is adopted, the difficulty of the manufacturing and installation is reduced, the accuracy of the equipment is improved, and the appearance size of the machine tool is reduced, so that the machine tool is more exquisite and beautiful.

Owner:SHIYAN HENGJIN INDUCTION TECH CO LTD

A steel wire quenching process

ActiveCN110343842BImprove quenching efficiencyIncrease the areaFurnace typesHeat treatment furnacesEngineeringConveyor belt

The invention belongs to the technical field of steel wire quenching, specifically a steel wire quenching process; a quenching chamber is provided inside the quenching box; the cooling chamber is filled with cooling medium, and the bottom of the cooling chamber is connected with the quenching chamber through a heating tube; A condensate pool is set above the condensate pool, and the interior of the condensate pool is filled with condensed gas; the inside of the push box is slid with a sliding material guide plate through a telescopic rod, and a hollow guide rod is set on the sliding material guide plate; the end of the hollow guide rod slides It is arranged in the guide slide hole, and the end of the hollow guide rod is provided with a guide push head; the feeding roller is evenly arranged on the outer wall of the quenching box through the support frame; the conveyor belt is rotated and arranged on the outer wall of the feeding roller, and the conveyor belt There are multiple elastic fastening belts evenly connected by elastic connecting blocks; it can make the steel wire section shake in the quenching box, thereby increasing the effect that the steel wire section changes from static to dynamic during the quenching process, and further increases the quenching of the steel wire section. Effect.

Owner:安徽普力森特钢股份有限公司

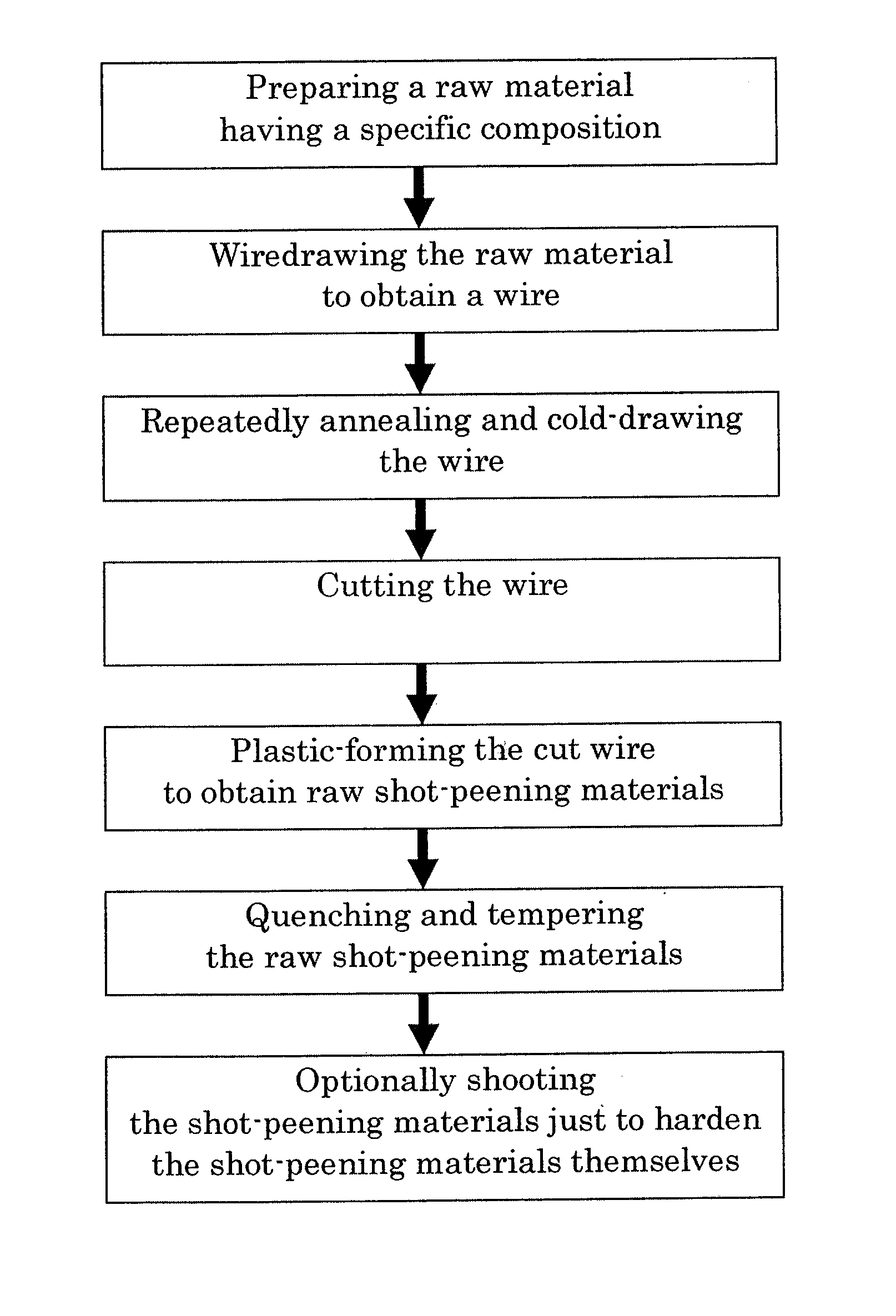

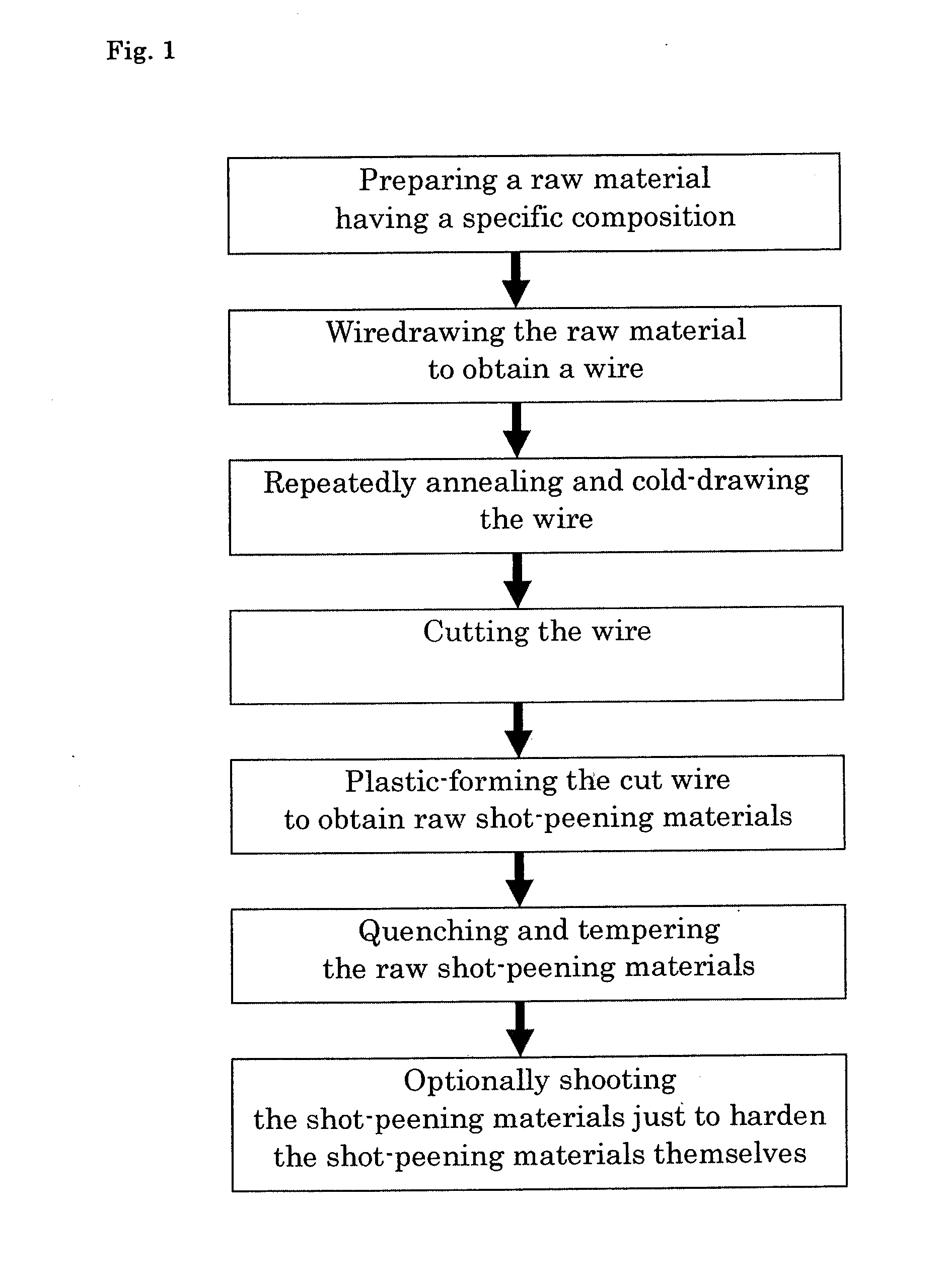

Raw material for shot-peening materials, finished wire, method of manufacturing shot-peening materials, and shot-peening materials

InactiveUS20100322816A1Efficient preparationQuality improvementAbrasion apparatusFurnace typesProduction rateSulfur

The purposes of the present inventions are to provide a raw material for shot-peening materials wherein breaking a wire is prevented in obtaining a finished wire to improve the productivity, to provide a finished wire and a method of manufacturing shot-peening materials by which productivity is improved, and to provide shot-peening materials that are manufactured by that method. The finished wire, of which the area of carbides with a particle size of 2 μm or less is 80% or more of the total area, is manufactured by the steps of wiredrawing a raw material to obtain a wire, and repeatedly annealing and cold-drawing the wire. The raw material for the shot-peening materials comprises, by mass %, 0.95-1.10% carbon, 0.15-0.30% silicon, 0.40% or less manganese, 0.020% or less phosphorus, 0.010% or less sulfur, 1.40-1.60% chromium, 0.0015% or less oxygen, and the remaining materials of iron and unavoidable impurities. The method of manufacturing the shot-peening materials uses that raw material. The shot-peening materials are manufactured by that method.

Owner:SINTOKOGIO LTD

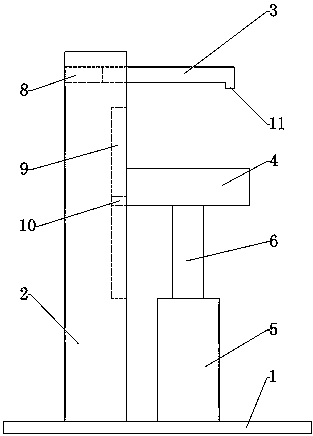

Anti-scald pollution-free quenching machine

ActiveCN112522483AEasy to processImprove quenching efficiencyDirt cleaningFurnace typesEngineeringSmoke Emission

The invention relates to a quenching machine, in particular to an anti-scald pollution-free quenching machine. The invention aims to overcome the defects that the workload of workers is large and thequenching efficiency of bearing rings is low due to the fact that existing quenching equipment needs the workers to take and place the bearing rings and put the bearing rings into water for cooling. The anti-scald pollution-free quenching machine comprises a bottom frame and a quenching mechanism. A lifting mechanism is mounted on the bottom frame, the quenching mechanism is arranged on the lifting mechanism, and the lifting mechanism is matched with the quenching mechanism. According to the anti-scald pollution-free quenching machine, a bearing ring can be conveniently machined through the lifting mechanism and the quenching mechanism, so that the bearing ring can be quenched; the bearing ring can be pushed to be fed through rightward movement of a push plate, and meanwhile, the quenchedbearing ring can be pushed rightward, so that the labor intensity can be reduced, and the quenching efficiency of the bearing ring can be improved; and smoke generated during quenching of the bearinginner ring can be sucked through work of an exhaust fan, and therefore the bearing ring can be conveniently quenched.

Owner:上海程运模具科技有限公司

Intelligent forging production device for automobile parts

InactiveCN112501399ASolve the problem of slow transfer quenching efficiencyConvenient QuenchingFurnace typesProcess efficiency improvementRotational axisWater vapor

The invention discloses an intelligent forging production device for automobile parts, and relates to the technical field of intelligent machining equipment. The intelligent forging production devicecomprises a forging table, a quenching box is arranged at one end of the forging table, a vent pipe is connected to the top end of the quenching box, a recycling box is connected to the end, away fromthe quenching box, of the vent pipe, and a lifting door is mounted at one end of the quenching box. A second motor is rotationally connected with a fan blade shaft through a rotating shaft, the second motor drives the fan blade shaft to rotate to attract water vapor in the quenching box into a recycling box, a third motor drives a rotating disc to rotate through a third rotating shaft, the rotating disc drives a rack disc to rotate through a convex edge on the surface of the rotating disc, then the rack disc drives a piston rod to reciprocate, the flowing of water vapor is accelerated, so that the water vapor makes full contact with a steel pipe, the water vapor is accelerated to be condensed into water, then the water flows out through a water outlet pipe at one end of the recycling box,therefore, the recycling of water resources is facilitated, and the problem of water resource waste is solved.

Owner:广州承光电子科技有限公司

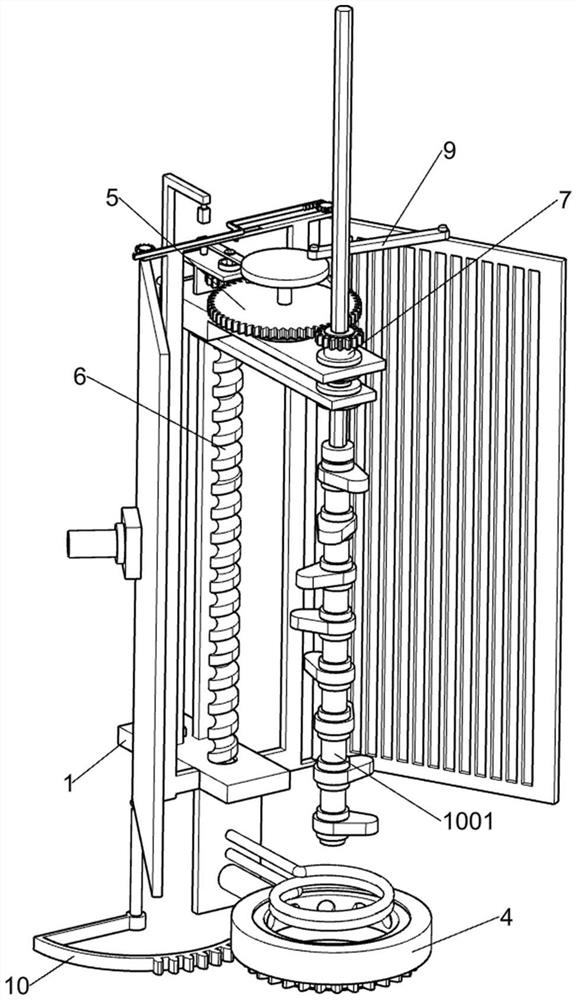

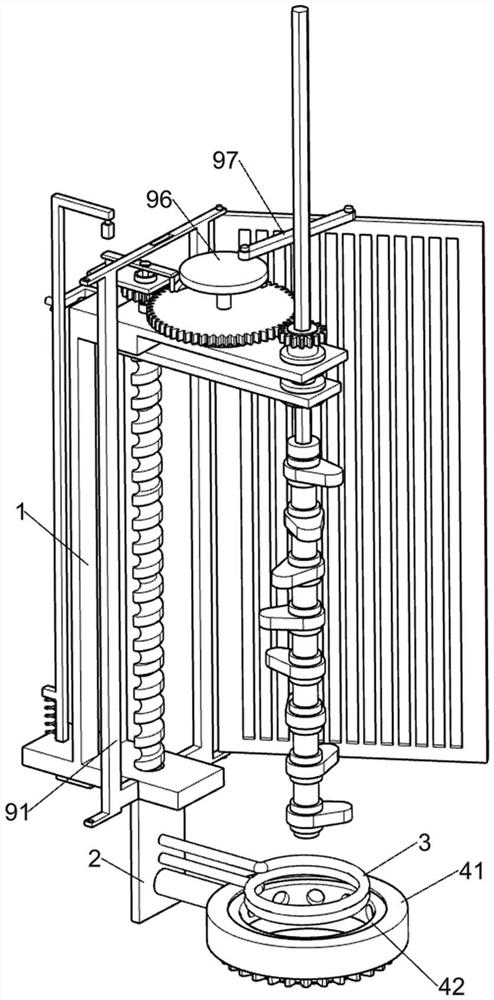

Camshaft high-frequency quenching device capable of effectively absorbing and removing water vapor

PendingCN114645120AConvenient QuenchingQuick resetDispersed particle separationFurnace typesPhysicsEngineering

The invention relates to the technical field of camshaft repair, in particular to a camshaft high-frequency quenching device capable of effectively absorbing and removing water vapor, which comprises a slotted guide plate frame, a vertical plate, an induction heating hollow copper pipe, a heat dissipation part and the like, a vertical plate is fixedly connected to the bottom of the grooving guide plate frame, an induction heating hollow copper pipe is fixedly connected to the front side of the vertical plate, and a heat dissipation component is arranged on the vertical plate. Through cooperation of internal parts of the device, the conveying part can intermittently convey the cam shaft downwards, the high-frequency quenching process of the whole cam shaft can be conveniently completed, after quenching is completed, the conveying part can rapidly convey the cam shaft upwards to reset, the next cam shaft can be conveniently quenched, and the production efficiency is improved. Water vapor around the camshaft in the quenching process is adsorbed by swinging the adsorption plate, so that the humidity in the air can be prevented from being too high, a large amount of water vapor can be prevented from being attached to the surfaces of other parts of the device, and normal operation of the device is guaranteed.

Owner:熊建

Metal quenching device for metal heat treatment

InactiveCN111471843AConvenient QuenchingImprove work efficiencyFurnace typesHeat treatment furnacesEngineeringLiquid tank

Disclosed is a metal quenching device for metal heat treatment. The metal quenching device for metal heat treatment comprises a cooling liquid tank, a first supporting table, a rotating shaft, a second supporting table, a roller, a mesh box, a mounting frame, a sealing plate, a protruding bar, a pull rope, a guide pulley and a round rod; the first supporting table is fixed to the corner of one side of the upper surface of the cooling liquid tank; the second supporting table is fixed to the side, away from the first supporting table, of the upper side face of the cooling liquid tank; the two ends of the rotating shaft are installed at the upper ends of the first supporting table and the second supporting table in a penetrating manner respectively; the middle of the rotating shaft is sleevedwith the roller, and the mesh box is fixed to the annular side face of the roller; the mounting frame is fixed to the end, away from the roller, of the mesh box, and the sealing plate is mounted in the mounting frame; the protruding bar is fixed to the middle of the side, close to the second supporting table, of the outer surface of the sealing plate, and the side, close to the first supporting table, of the outer surface of the protruding bar is connected with the pull rope; and the end, away from the protruding bar, of the pull rope is wound around the guide pulley, and the guide pulley sleeves the upper end of the round rod. The metal quenching device for metal heat treatment facilitates the one-time mass movement of small-size metal in the quenching process and effectively improves the working efficiency.

Owner:南通祥博热处理科技有限公司

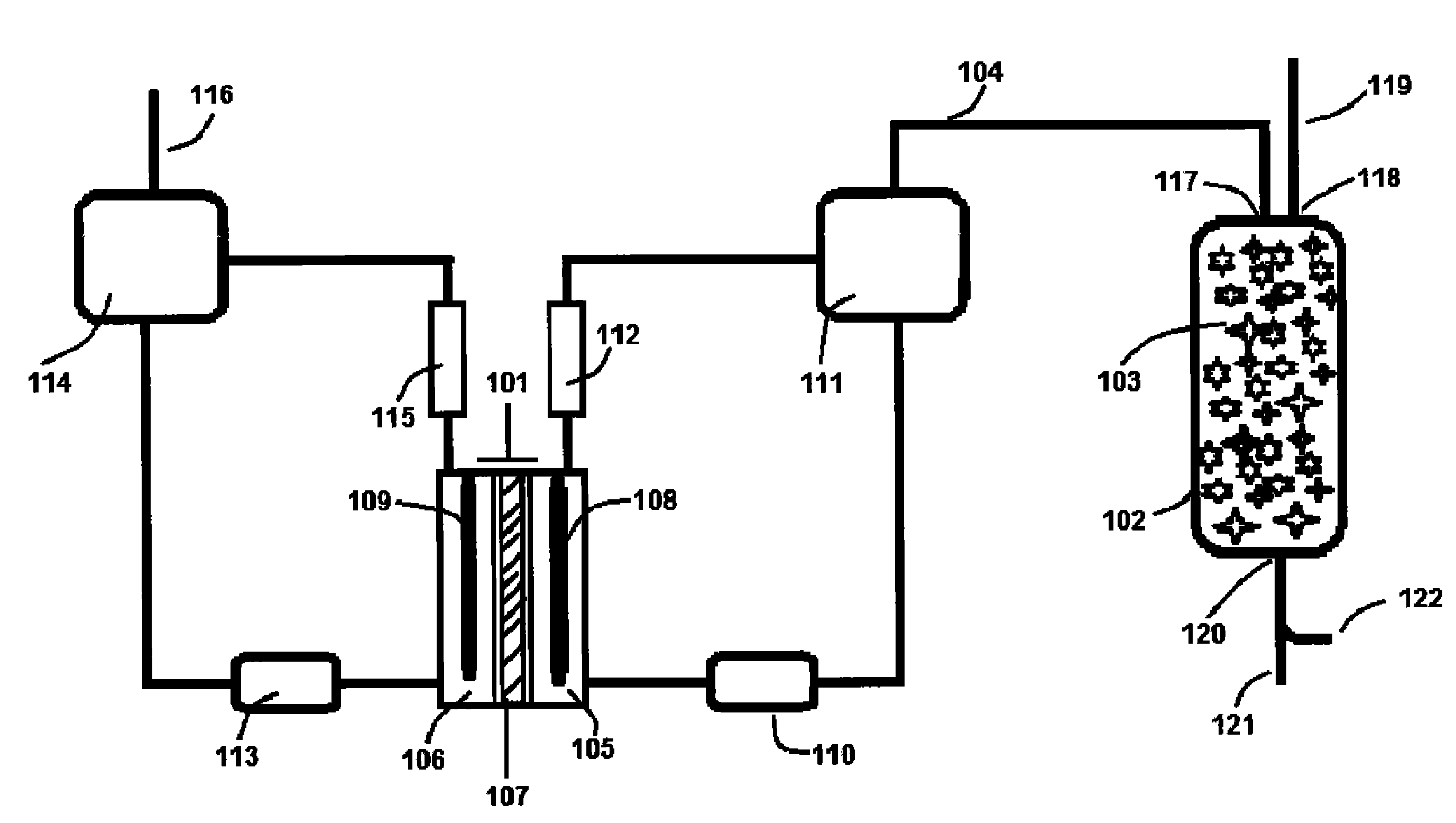

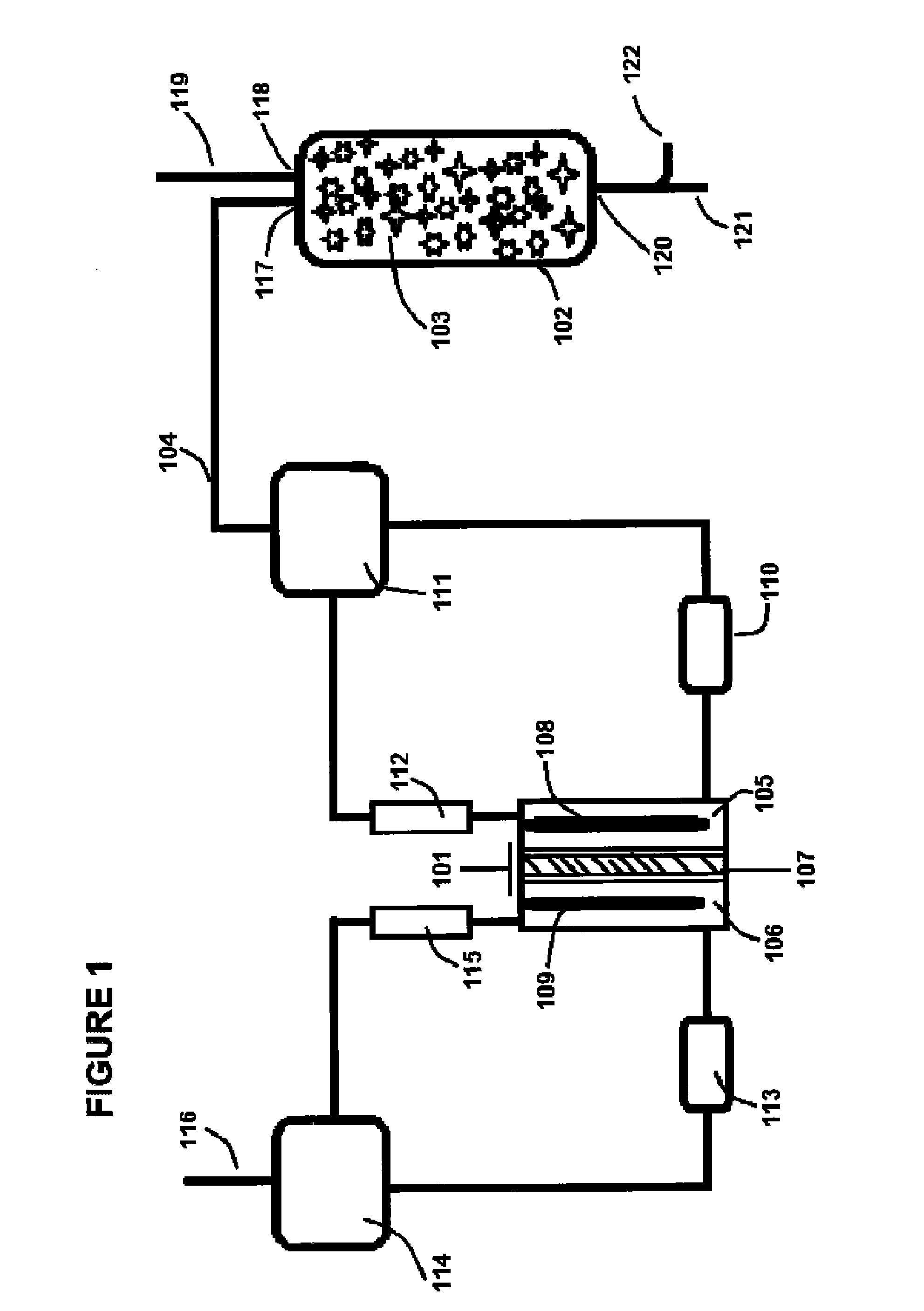

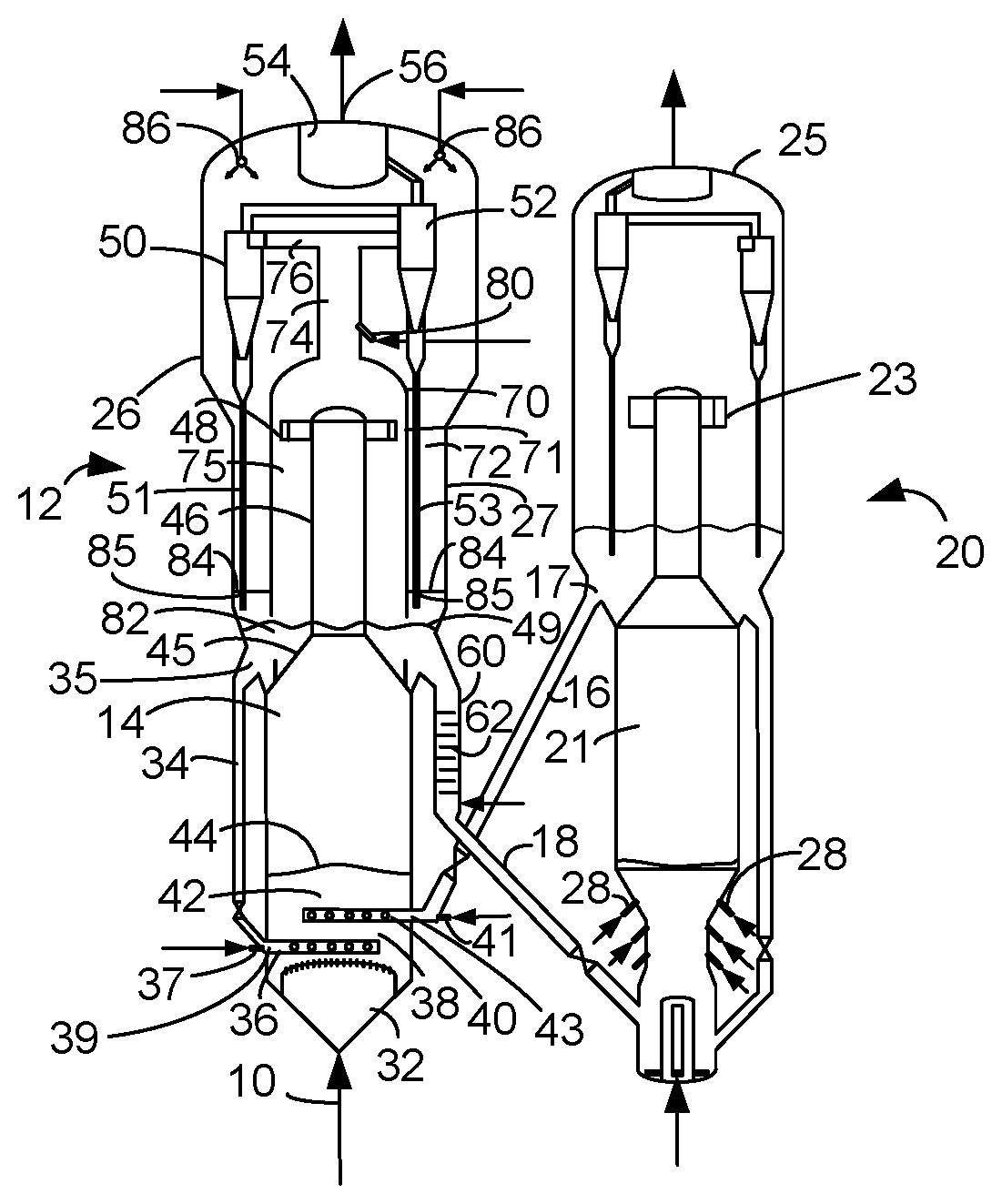

Process and apparatus for reacting feed with fluidized catalyst and confined quench

ActiveUS20220033326A1Convenient QuenchingHigh selectivityHydrocarbonsChemical/physical processesAlkanePtru catalyst

A dehydrogenation process and apparatus contact a paraffinic stream with dehydrogenation catalyst to product olefinic product gases. The olefinic product gases are separated from spent dehydrogenation catalyst and contained in a confined space that has a smaller volume than the reactor particularly at the same elevation. The containment of the olefinic product gases facilitates quenching the olefinic product gases to terminate reaction and improve selectivity to propylene.

Owner:UOP LLC

Automatic quenching device for demolded motorcycle aluminum alloy hub

ActiveCN112195324AConvenient QuenchingIncrease profitFurnace typesHeat treatment furnacesCircular discElectric machine

The invention discloses an automatic quenching device for a demolded motorcycle aluminum alloy hub. The automatic quenching device comprises a base, wherein a furnace is fixedly installed at the top of the base, a heating chamber is fixedly installed on one side of the furnace, a motor is fixedly installed at the top of an inner cavity of the heating chamber, and wire rollers are fixedly installedat the output end of the motor; a supporting plate is installed on the wire rollers through steel cables in a transmission manner, a supporting column is fixedly installed in the supporting plate, and discs are fixedly installed on the outer surface of the supporting column. According to the automatic quenching device, resistance is provided by arranging baffles and elastic force of springs, whenthe temperature in the furnace reaches a certain degree, the baffles can be burst through, it is ensured that fire power during quenching meets the process requirement, meanwhile, a heat return pipeline is connected between the furnace and a heating pipeline, hot air can flow back into the furnace, the temperature in the furnace can be stabilized, then the fuel consumption is effectively reduced,steam generated during cooling is fed in through ventilation equipment and used in cooperation with external equipment, and the energy utilization rate is increased.

Owner:临海市巨丰机械有限公司

Vehicle leaf spring unit gap detecting system

The invention discloses a vehicle leaf spring unit gap detecting system, which is characterized by comprising a base; a vertical column is arranged vertically on the base; the top of the vertical column is provided with an upper fixed block; a movable block is arranged right below the fixed block; the bottom of the movable block is connected with the piston rod of a cylinder mounted on the base and reciprocally moved in a vertical direction under the push of the cylinder; the cylinder is connected with an air supply device; and a leaf spring is clamped between the fixed block and the movable block. According to the vehicle leaf spring unit gap detecting system, the clamp adopts a pneumatic mode, the degree of automation is high, the labor intensity of a worker is reduced, random leaf spring matching state detection after quenching, tempering or shot blasting of the leaf spring is facilitated, and stress is relieved for a later assembly process.

Owner:SICHUAN HUAYU VEHICLE LEAF SPRING

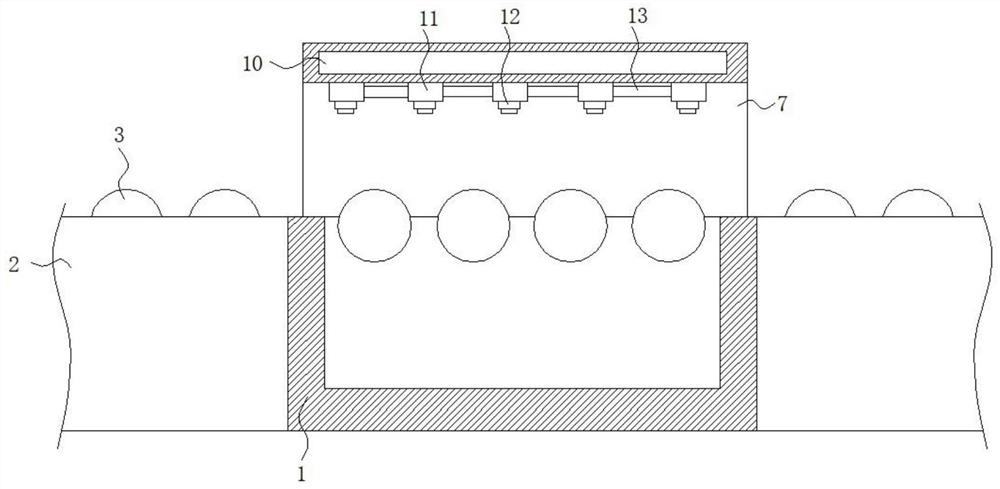

Surface quenching device and process for smelting and calendering stainless steel plate

InactiveCN112176163AConvenient QuenchingAvoid transitional wasteFurnace typesHeat treatment furnacesWater resourcesEngineering

The invention relates to the technical field of quenching devices, in particular to a surface quenching device and process for smelting and calendering a stainless steel plate. In order to solve the problem that the surface quenching device for smelting and calendering the stainless steel plate in the prior art is low in production efficiency, the invention provides a scheme as follows: the devicecomprises a quenching pond, transmission tables mounted at two ends of the quenching pond and a protecting hood mounted on the top of the quenching pond. The device is characterized in that a first water pump and a second water pump are mounted on the outer wall of one side of the quenching pond, and water suction pipes, one ends of which extend into the quenching pond, are fixed to water inletsof the first and second water pumps; and grooves are formed in the tops of the two transmission tables, and a plurality of transmission rollers are rotatably mounted in the grooves and on the inner side of the quenching pond. The surface quenching device is reasonable in structure and easy to operate, and can quench the surface of the calendered stainless steel plate conveniently and quickly, so that the production efficiency is improved greatly. Moreover, waste of water resources is avoided effectively, too, and the surface quenching device is easy to popularize and use.

Owner:常熟裕顺机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com