Automatic quenching device for demolded motorcycle aluminum alloy hub

A technology of aluminum alloy wheel hub and quenching device, which is applied in the field of heat treatment, can solve the problems of affecting the quenching effect, difficult temperature control, temperature speed rise, etc., and achieve the effects of reducing fuel consumption, stabilizing temperature and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

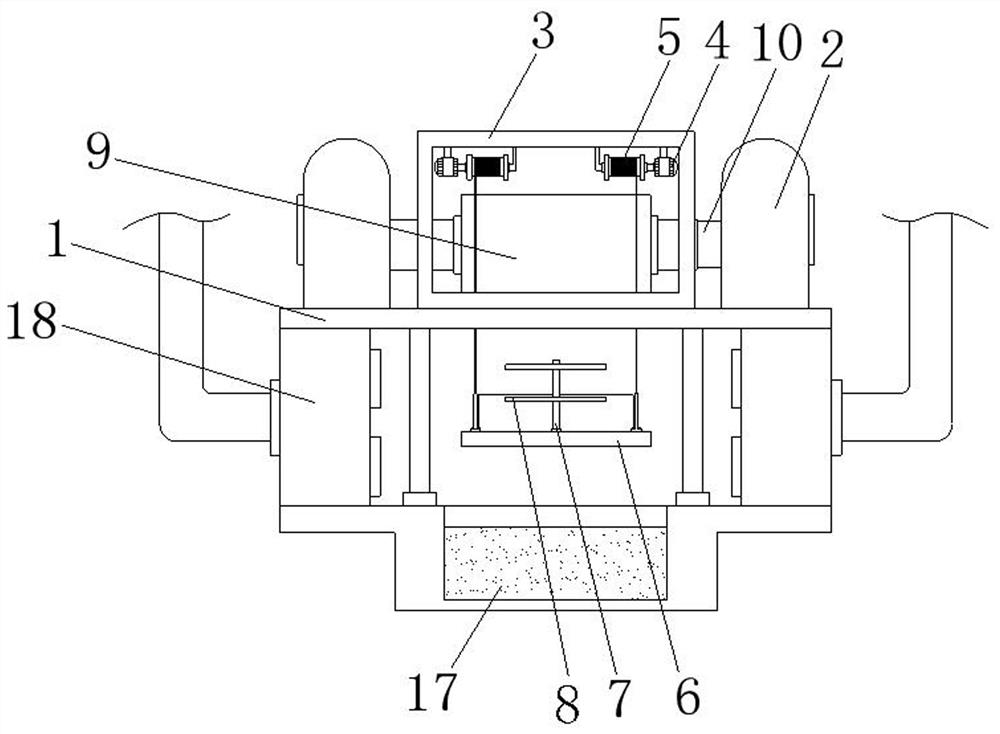

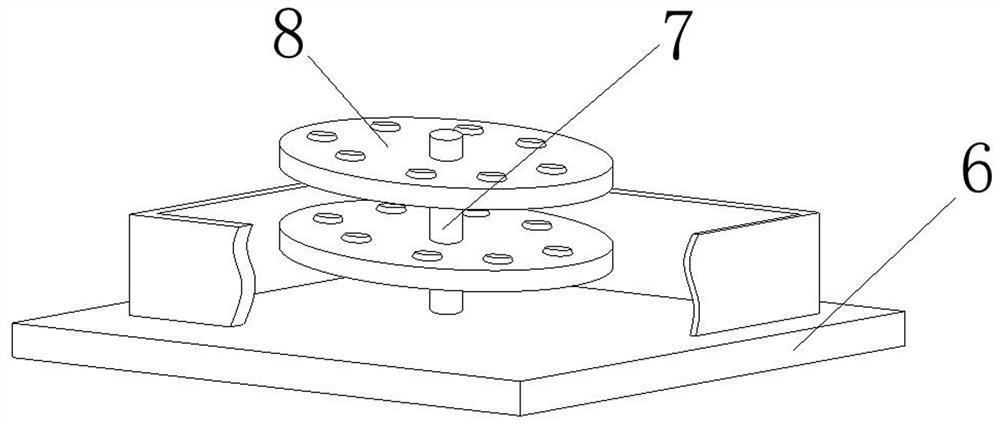

[0025] Example 1, such as figure 1 , Figure 3-4 , before quenching, start the furnace 2 for preheating, and at the same time, place the hubs that need to be quenched one by one on the disc 8 where the bumps are set, and through the intervals of the bumps, each hub can be placed on the circle at intervals Disk 8, when each wheel hub is quenched, it will not affect each other, which facilitates the loading and unloading of the wheel hub. When quenching, the wire roller 5 drives the supporting plate 6 to move upward under the drive of the motor 4. After the rectangular frame is placed inside the heating chamber 9, a closed space is formed between the heating chamber 9 and the supporting plate 6, and an insulation layer 16 is arranged inside the heating chamber 9 to ensure that the internal temperature of the heating chamber 9 is stable, and the wheel hub can be well maintained. Quenching treatment.

Embodiment 2

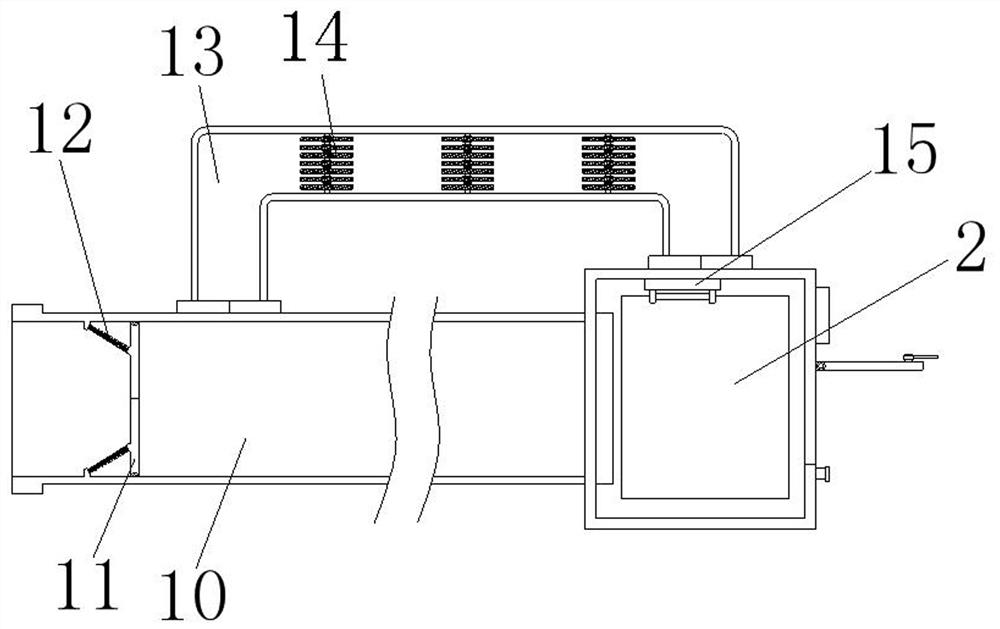

[0026] Example 2, such as figure 2, when the inside of the furnace 2 is heated, as the internal air pressure increases, when the air pressure reaches a certain value, the baffle plate 11 will be pushed away, and hot air will be sent out to heat the inside of the heating chamber 9, while part of the heat The air flow enters the heat recovery pipe 13, rotates by driving the fan wheel 14, and under the drive of the fan wheel 14, flows back into the furnace 2, so that the air pressure of the heating chamber 9 can be reduced, and at the same time, the returned hot air flow is generated on the inside of the furnace 2. The supercharging effect allows the fuel inside the stove 2 to be fully burned, improving the utilization efficiency of the fuel.

Embodiment 3

[0027] Example 3, such as figure 1 , when the pallet 6 descends, the heat-treated wheel hub contacts the cooling liquid inside the cooling pool 17 and generates a large amount of steam. Since the cooling pool 17 is set below the ground, the steam that escapes upwards is drawn out by the ventilation equipment 18 and sent to Cooperate with the outside, and then use it to improve energy utilization efficiency. At the same time, due to the influence of the location of the cooling pool 17, the ventilation equipment 18 will not be set at an excessively high position, which improves the safety and facilitates the installation of the ventilation equipment 18. overhaul.

[0028] Working principle: After the hubs to be quenched are placed equidistantly on the disc 8 through the bumps set on the disc 8, each hub can be placed on the disc at intervals through the bumps, so that each hub can be quenched. During quenching, they will not affect each other, which facilitates the loading and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com