Camshaft high-frequency quenching device capable of effectively absorbing and removing water vapor

A high-frequency quenching and camshaft technology, applied in the direction of quenching device, improving process efficiency, improving energy efficiency, etc., can solve problems such as affecting the observation or operation of the quenching device, unfavorable normal operation of the quenching device, high humidity, etc. Adsorption range, easy collection, avoid the effect of excessive humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

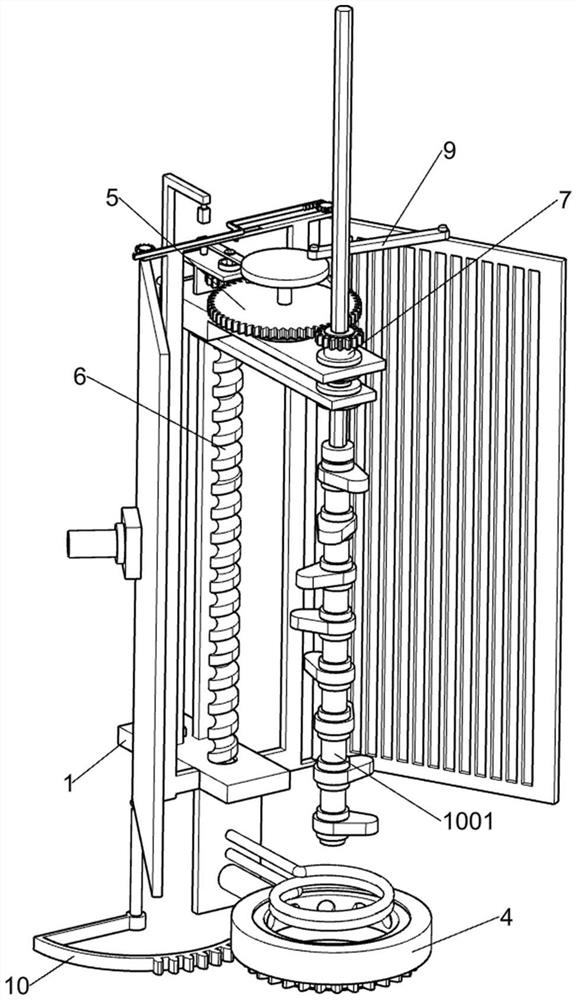

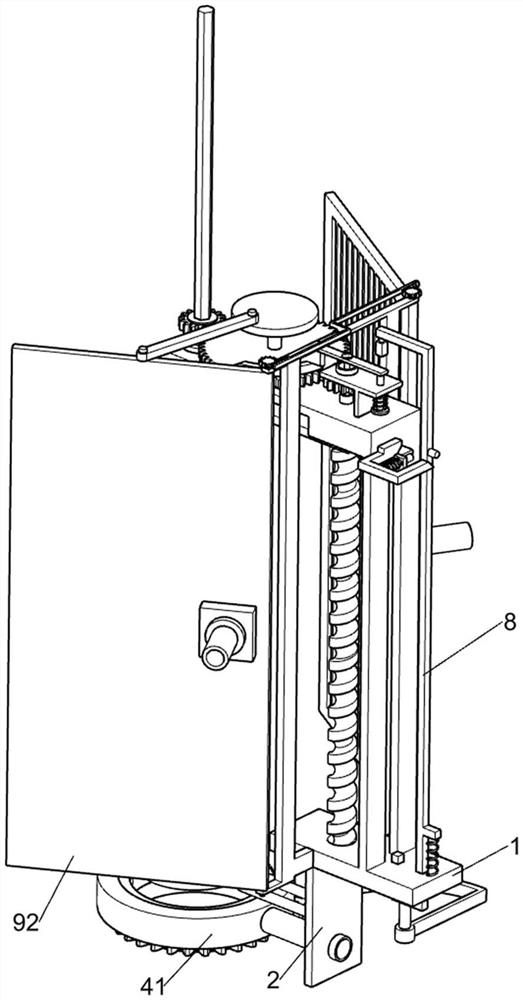

[0036] A camshaft high-frequency quenching device that can effectively absorb water vapor, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, it includes a slotted guide plate frame 1, a vertical plate 2, an induction heating hollow copper tube 3, a heat dissipation part 4, a driving part 5, a conveying part 6, a rotating part 7 and an adsorption part 8, and the slotted guide plate frame 1 A vertical plate 2 is fixed on the bottom, an induction heating hollow copper tube 3 is fixed on the front side of the vertical plate 2, and a heat dissipation part 4 is arranged on the vertical plate 2, and the heat dissipation part 4 is used for the camshaft 1001 during the quenching process. For cooling, the slotted guide plate frame 1 is provided with a driving member 5, the slotted guide plate frame 1 is provided with a conveying member 6, and the conveying member 6 is used to intermittently transport the camshaft 1001 downward, and the slotted gu...

Embodiment 2

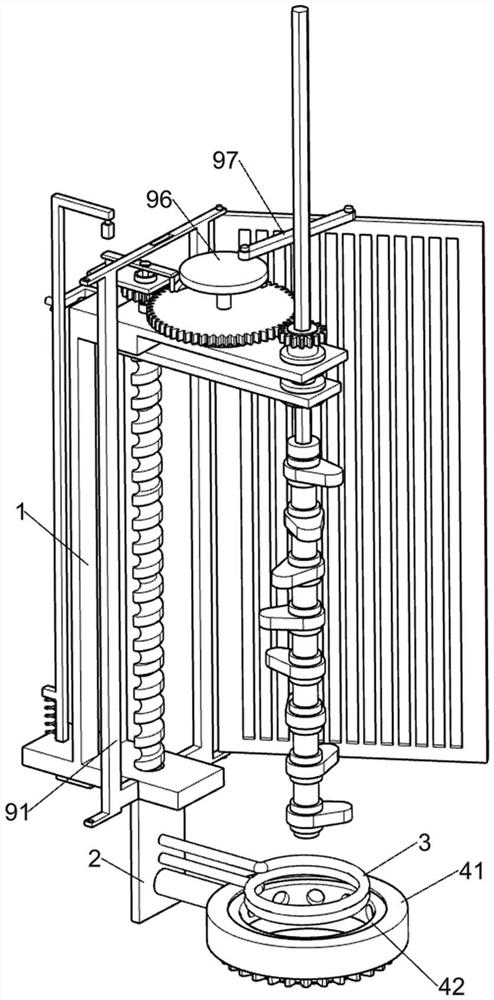

[0045] On the basis of Example 1, as Figure 7 As shown, it also includes a water vapor absorbing member 9, which is arranged on the slotted guide plate frame 1 and connected with the drive shaft 52. For water vapor suction, the water vapor suction part 9 includes a fixed frame 91, a swing adsorption plate 92, a conveying pipe 93, a rotating gear 94, a Z-shaped rack 95, a rotating disk 96 and a connecting rod 97, and the slotted guide plate frame 1 A fixed frame 91 is fixedly connected to the lower part, and two swing adsorption plates 92 are rotatably connected to the fixed frame 91. The swing adsorption plates 92 are symmetrically arranged, and the two swing adsorption plates 92 will swing synchronously. The swing adsorption plate 92 is used for adsorption and quenching process. The water vapor generated around the middle camshaft 1001 avoids excessive humidity in the air. The outer side of the swing adsorption plate 92 is fixed with a conveying pipe 93, which is connected t...

Embodiment 3

[0048] On the basis of Example 2, as Figure 8 As shown, the spraying angle adjustment part 10 is also included. The spraying angle adjustment part 10 is arranged on the swing adsorption plate 92 on the left and is connected with the opening rotating ring 42. The spraying angle adjusting part 10 is convenient for adjusting the opening of the opening rotating ring 42. The water spraying position ensures that the surface of the camshaft 1001 can be fully contacted with water. The spraying angle adjustment component 10 includes a gear ring 101, a transmission shaft 102 and an arc-shaped rack 103. The bottom of the open-hole rotating ring 42 is welded with a gear ring 101. The bottom of the swing adsorption plate 92 on the left is fixedly connected with a transmission shaft 102 , the lower part of the transmission shaft 102 is connected with an arc-shaped rack 103 by welding, and the arc-shaped rack 103 meshes with the ring gear 101 .

[0049] During the reciprocating swing of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com