Solid-solution pre-treatment method for improving strength and plasticity and toughness of aluminum lithium alloy thin sheet and heat treatment method thereof

A heat treatment method and aluminum-lithium alloy technology, which is applied in the field of aluminum-lithium alloys, can solve the problems that limit the wide application of aluminum-lithium alloys, low plasticity and toughness, and severe alloy anisotropy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

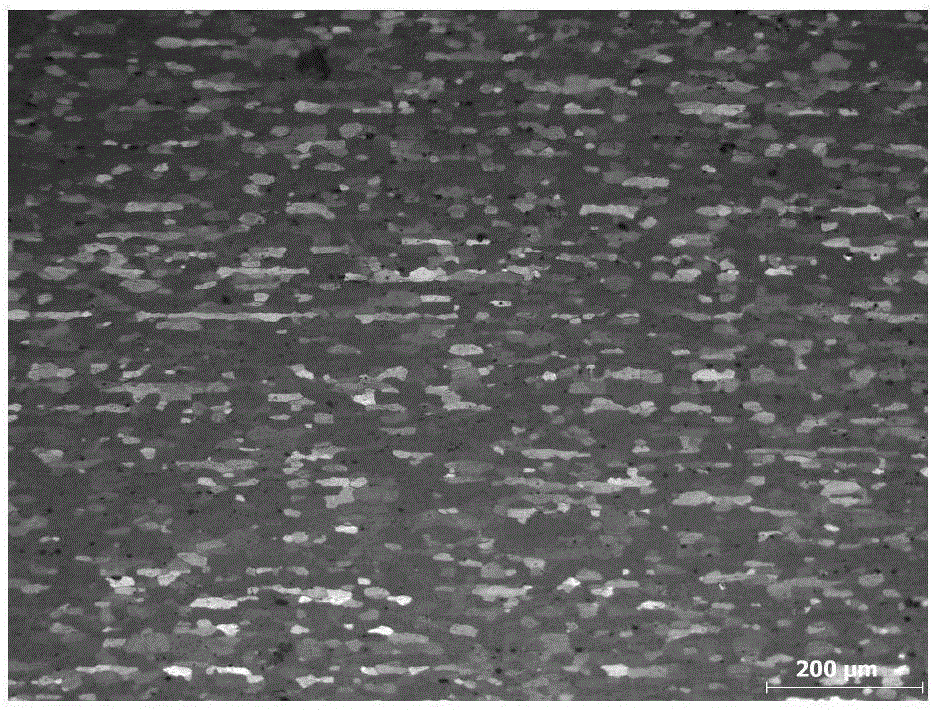

[0079] Al-Cu-Li aluminum alloy thin plate, containing 3.6% Cu, 1.0% Li and 0.12% Zr, the rest is Al, the thickness of the thin plate is 2mm, obtained by 70% cold deformation treatment.

[0080] The above-mentioned aluminum-lithium alloy is subjected to a solid solution pretreatment method of controlling the heating rate, and the temperature is raised from 20°C to 500°C with the furnace, and the heating rate is controlled at 2°C / min, and then directly carried out in the salt bath furnace heated to 500°C for 40 minutes. After the solution treatment at 500°C, place it in 5°C water for 5 minutes of quenching treatment. After the quenching treatment, perform 3% pre-deformation treatment, and then directly perform artificial aging treatment. The aging temperature is 150°C and the time is 16 hours. Heat treatment of Al-Li alloys.

[0081] A tensile mechanical property test was carried out, and the test results showed that the tensile strength was 591MPa, the yield strength was 570MPa, ...

Embodiment 2

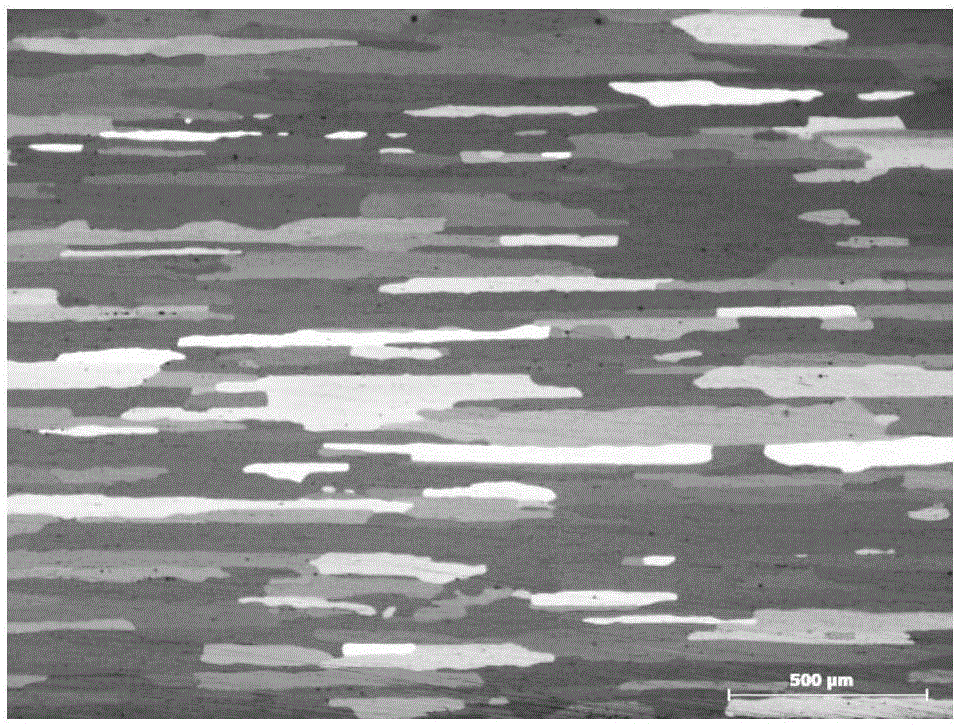

[0083] Al-Cu-Li aluminum alloy thin plate, containing 3% Cu, 1.2% Li and 0.12% Zr, the rest is Al, the thickness of the thin plate is 5mm, obtained by 50% cold deformation treatment.

[0084] The above-mentioned aluminum-lithium alloy is subjected to a solid solution treatment method of controlling the heating rate. The temperature is raised from 25°C to 510°C with the furnace, and the heating rate is controlled at 4°C / min. After the solid solution treatment at 50°C, quenching treatment was carried out in 50°C water for 1 min. After the quenching treatment, 3% pre-deformation treatment was performed, and then artificial aging treatment was directly carried out. The aging temperature was 175°C, and the time was 12h. Heat treatment of Al-Li alloys.

[0085] A tensile mechanical property test was carried out, and the test results showed that the tensile strength was 567MPa, the yield strength was 544MPa, and the elongation was 8.6%.

Embodiment 3

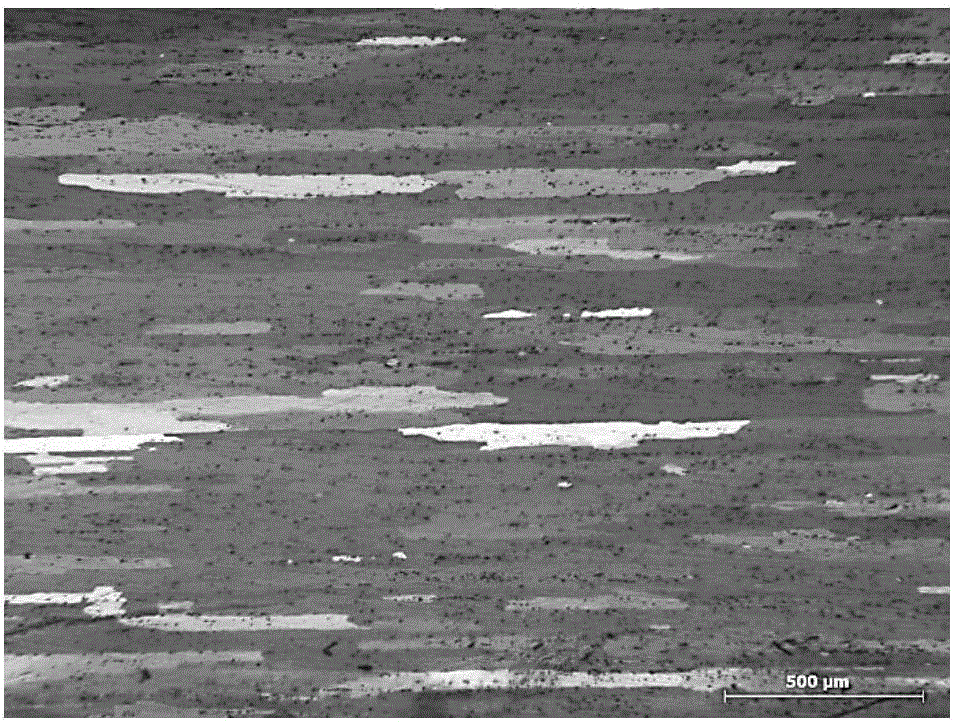

[0087] Al-Cu-Li aluminum alloy thin plate, containing 3.6% Cu, 0.6% Li and 0.15% Zr, the rest is Al, the thickness of the thin plate is 6mm, obtained by 50% cold deformation treatment.

[0088] The above-mentioned aluminum-lithium alloy is subjected to a solid solution treatment method of controlling the heating rate. From 20 ° C to 500 ° C with the furnace, the heating rate is controlled at 7 ° C / min, and then directly in the salt bath furnace heated to 500 ° C for 40 minutes. After the solid solution treatment at 26°C, it was quenched in water at 26°C for 2.5 minutes. After the quenching treatment, it was subjected to 3% pre-deformation treatment, and then it was directly subjected to artificial aging treatment. The aging temperature was 150°C, and the time was 16 hours. Heat treatment of the aluminum-lithium alloy.

[0089] A tensile mechanical property test was carried out, and the test results showed that the tensile strength was 569MPa, the yield strength was 546MPa, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com