Steel powder and die using same

A powder and mold technology, applied in the field of steel powder, can solve the problems of no involvement, low corrosion resistance, low thermal conductivity, etc., and achieve the effect of cooling efficiency and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

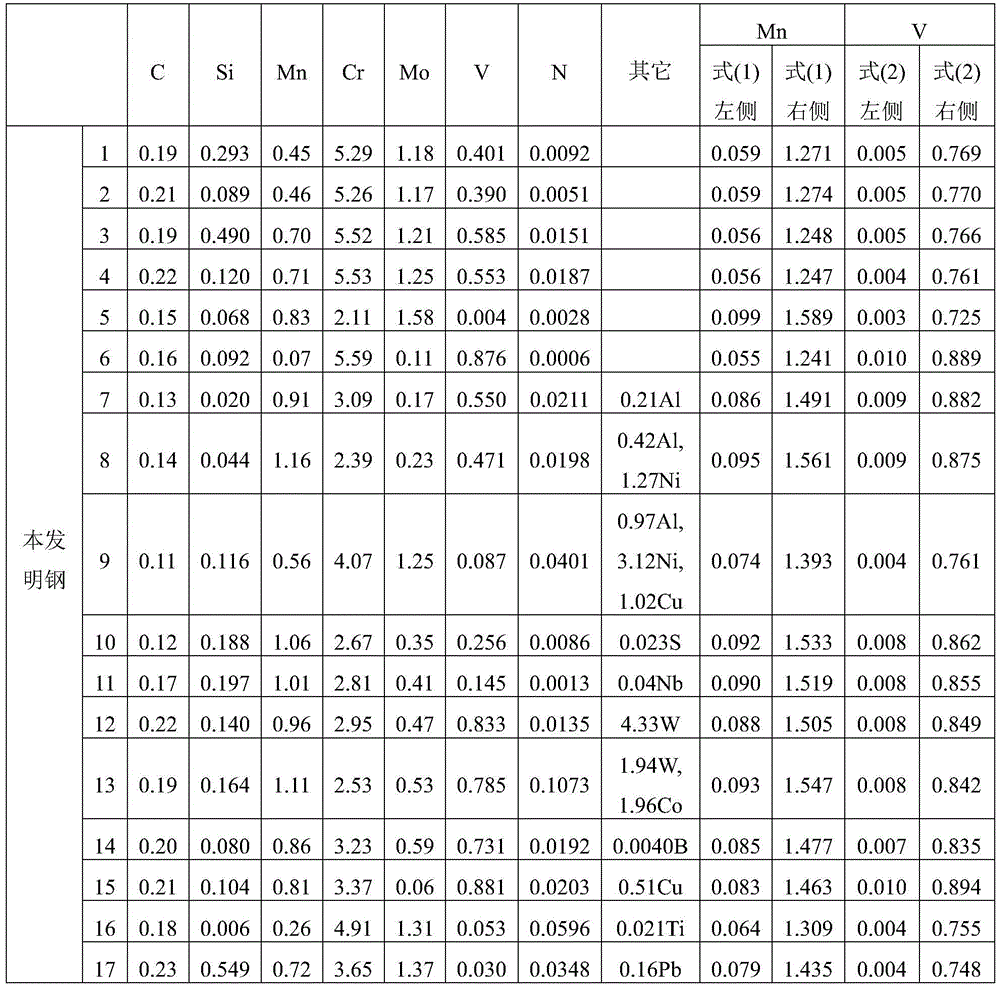

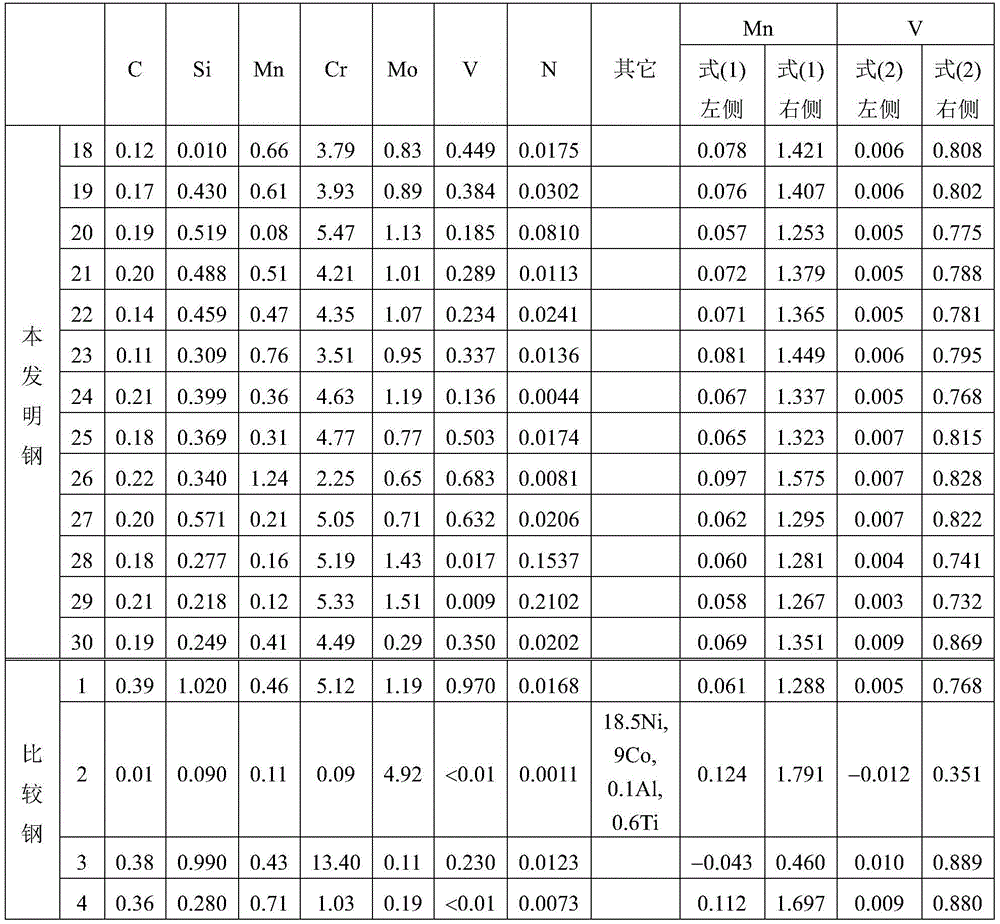

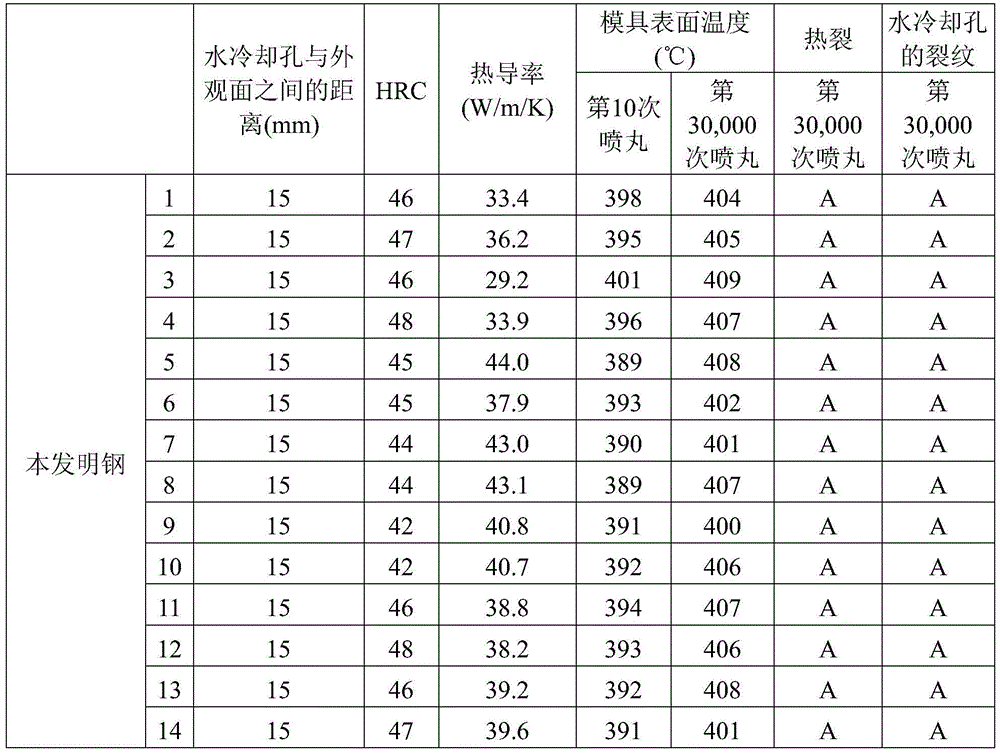

[0153] Dies and test pieces were produced by the lamination molding method by using 34 kinds of steel powders shown in Table 1, and various tests were performed. Specifically, tests for evaluating hardness, thermal conductivity, mold surface temperature, thermal cracking, and cracking of water cooling holes were performed.

[0154] Some of the steel powders shown in Table 1 contain elements not shown in the table within the range specified as the amount of impurities.

[0155] In Table 1, Comparative Steel 1 is JISSKD61-type steel, Comparative Steel 2 is 18Ni maraging steel, Comparative Steel 3 is martensitic stainless steel SUS420J2, and Comparative Steel 4 is steel SCM435 for machine structure. In each comparative steel, the amounts of at least two elements were outside the range specified by the present invention.

[0156] Table 1: Chemical composition (mass %) (balance: Fe)

[0157]

[0158] Table 1 (continued) chemical composition (mass%) (balance: Fe)

[0159]

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic limit | aaaaa | aaaaa |

| Orientation degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com