Bolt assembly of shape memory alloy cable clamp

A memory alloy, bolt assembly technology, applied in the direction of connecting components, washers, mechanical equipment, etc., can solve problems such as consumption of manpower and material resources, line connection relaxation, power grid accidents, etc., to reduce contact resistance, meet anti-corrosion requirements, increase Effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

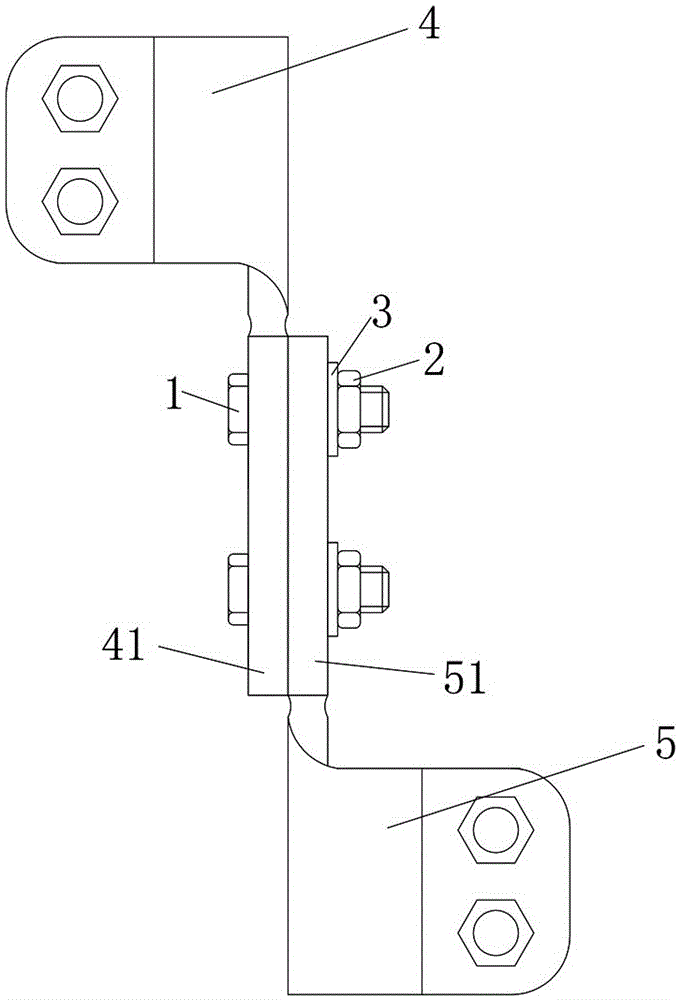

[0022] Such as figure 1 As shown, a shape memory alloy clamp bolt assembly includes a bolt 1 used to connect the drain plate of two clamps (the first clamp 4 and the second clamp 5 ), and a nut 2 threaded with the bolt 1 And the disc gasket 3 arranged between the nut 2 and one of the drain plates, the disc gasket 3 is in a flattened state after installation, the disc gasket 3 is made of a shape memory alloy material, When the heating temperature of the clamp is equal to or exceeds the austenite initial phase transition temperature of the shape memory alloy material, the disc-shaped gasket 3 in the flattened state starts to recover towards its original shape (disc shape), and the two The drain plate of the cable clamp is pressed tightly.

[0023] In this embodiment, the shape memory alloy material is a nickel-titanium memory alloy, and its austenite transformation temperature is 43° C.; in this nickel-titanium memory alloy, the atomic ratio of Ni to Ti is 51.8:48.2. Including...

Embodiment 2

[0028] Such as figure 1 As shown, a shape memory alloy clamp bolt assembly includes a bolt 1 used to connect the drain plate of two clamps (the first clamp 4 and the second clamp 5 ), and a nut 2 threaded with the bolt 1 And the disc gasket 3 arranged between the nut 2 and one of the drain plates, the disc gasket 3 is in a flattened state after installation, the disc gasket 3 is made of a shape memory alloy material, When the heating temperature of the clamp is equal to or exceeds the austenite initial phase transition temperature of the shape memory alloy material, the disc-shaped gasket 3 in the flattened state starts to recover towards its original shape (disc shape), and the two The drain plate of the cable clamp is pressed tightly.

[0029] In this embodiment, the shape memory alloy material is a nickel-titanium memory alloy, and its austenite initial transformation temperature is 33° C.; in this nickel-titanium memory alloy, the atomic ratio of Ni to Ti is 51.9:48.1. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com