Quenching device for bearing support production

A technology of quenching device and bearing support, which is applied in the field of bearing support, can solve the problems of unguaranteed worker safety, high index, and reduced production efficiency, and achieve the effects of easy operation, simple use, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

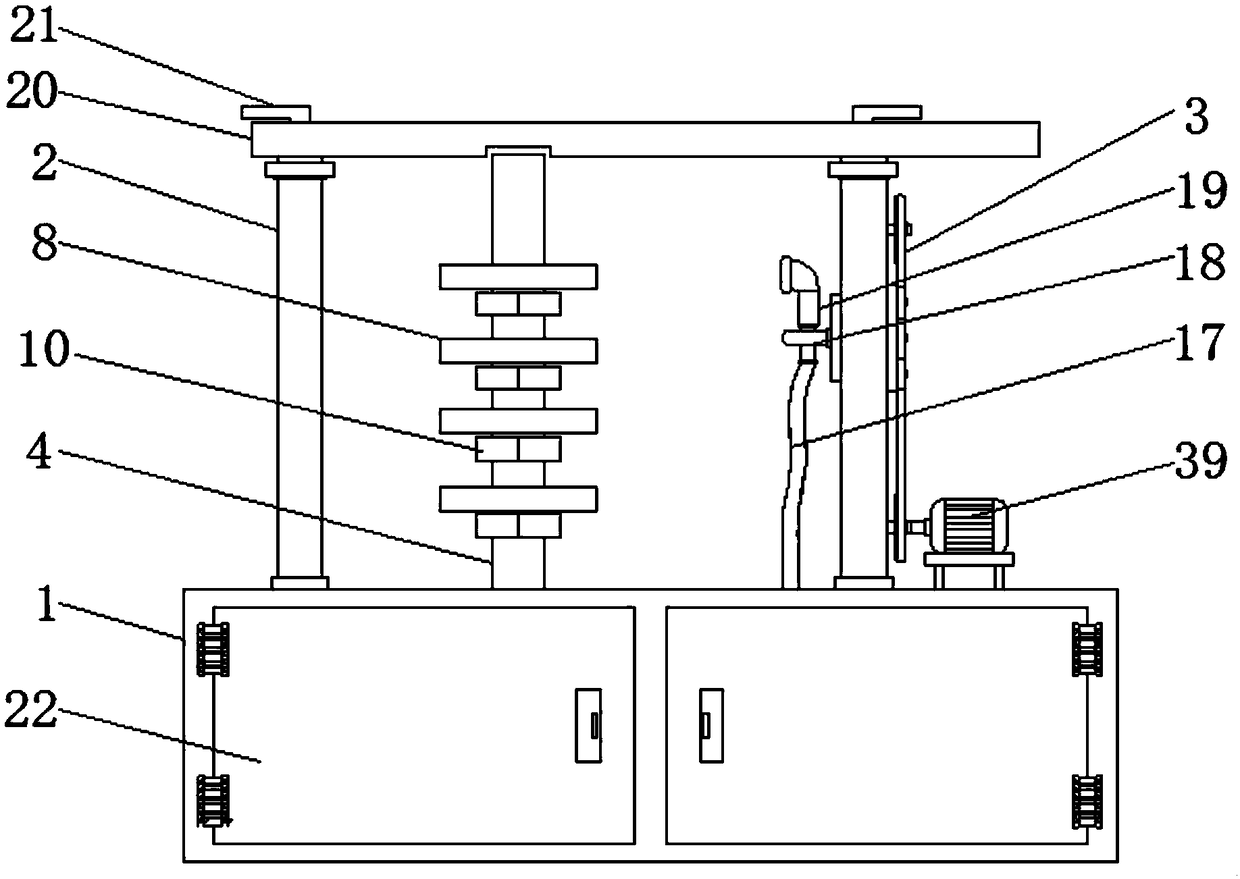

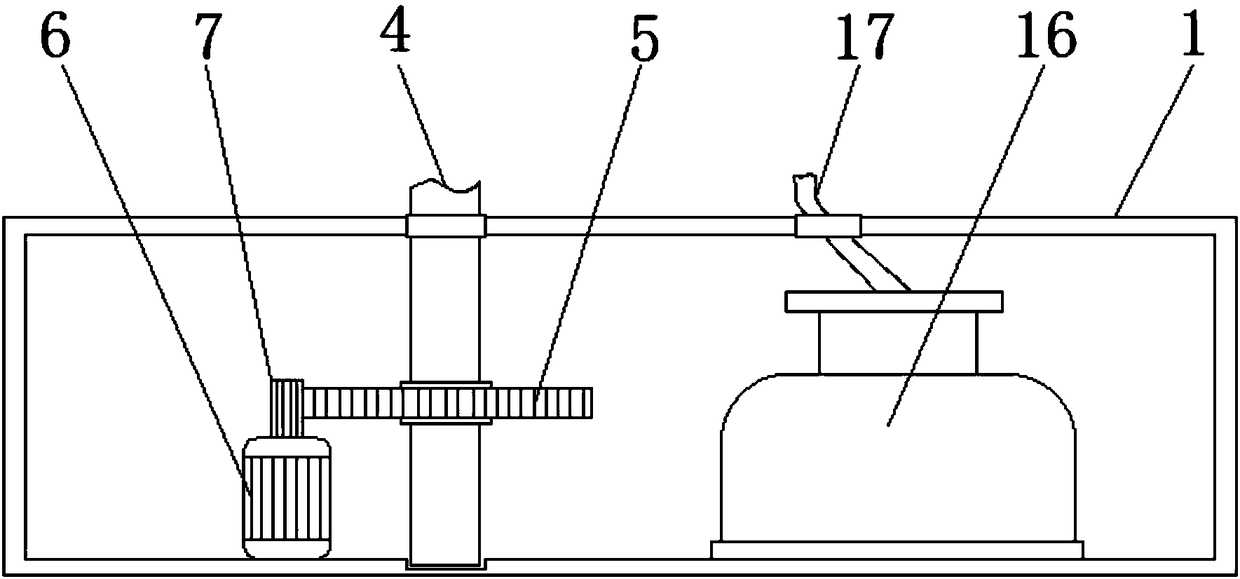

[0029] see Figure 1-6 , the present invention provides a technical solution: a quenching device for bearing support production, including a box body 1, a gas tank 16 is fixedly connected to the bottom side of the inner wall of the box body 1, and a connecting pipe 17 is connected to the top of the gas tank 16 to communicate with The end of the pipe 17 away from the gas tank 16 runs through the top of the inner wall of the box body 1 and extends to the outside of the box body 1. The top side of the box body 1 is fixedly connected with a support column 2, and the top of the support column 2 runs through a top plate 20. The support column The top of 2 is movably connected with an L-shaped fixed rod 21, and the L-shaped fixed rod 21 passes through the top plate 20 to be connected with the support column 2, so that the L-shaped fixed rod 21 can play the role of fixing the top plate 20. The top plate 20 is detachable, so that the bearing supports 8 can be conveniently covered one b...

Embodiment 2

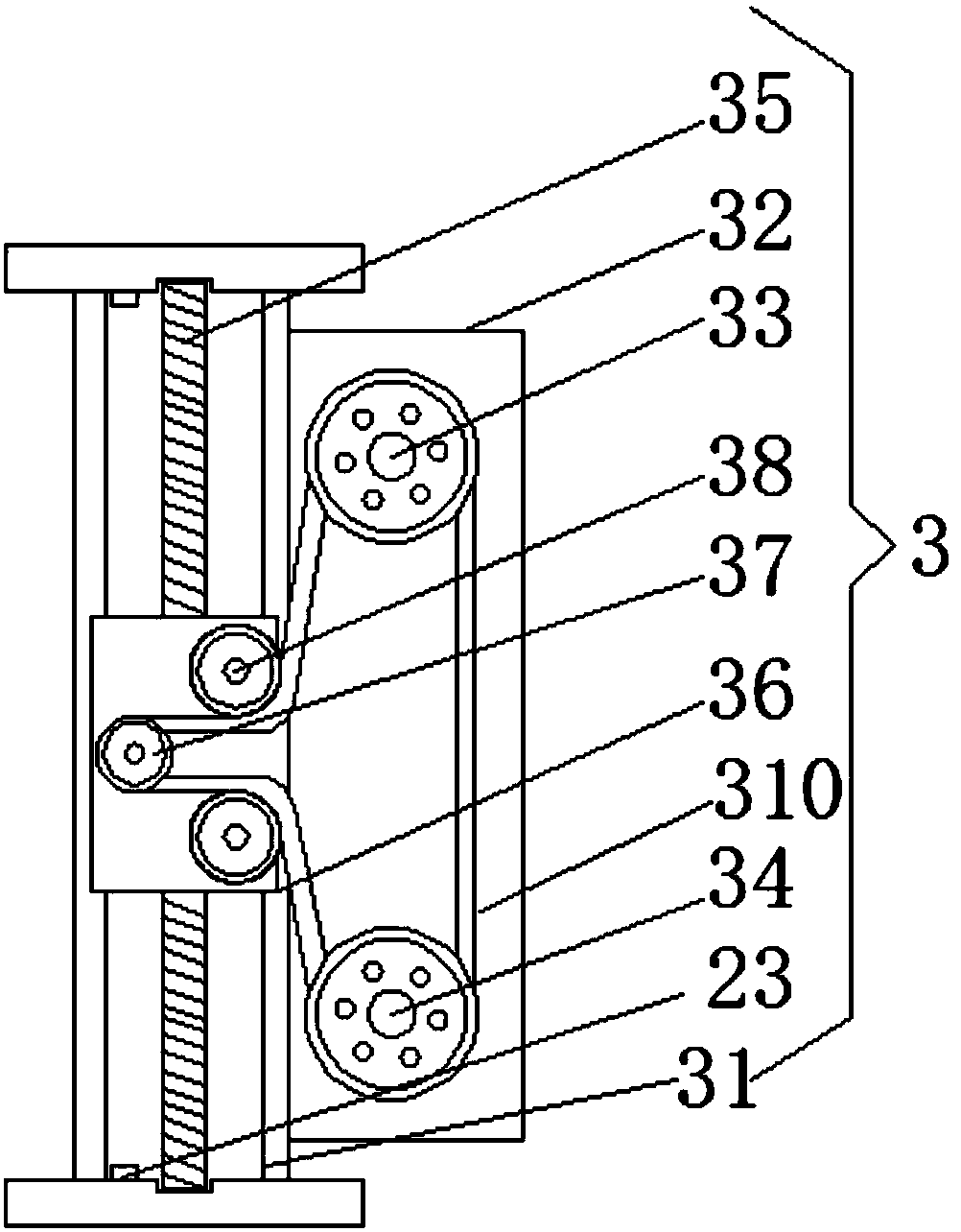

[0035] The difference between this embodiment and embodiment 1 is, as Figure 7 As shown, the sliding rod 35 is fixedly connected to the top and bottom of the inner wall of the slide plate 31 , the surface of the sliding rod 35 is provided with a gear block 350 , and the roller 37 is provided with a gear matching the gear block 350 . During work, the gear on the roller 37 rolls on the gear tooth block 350, thereby realizing that the slide block 36 drives the fire nozzle 19 to move up and down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com