Anti-scald pollution-free quenching machine

A quenching machine, pollution-free technology, applied in the field of quenching machines, can solve the problems of heavy workload of workers and low quenching efficiency of bearing rings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

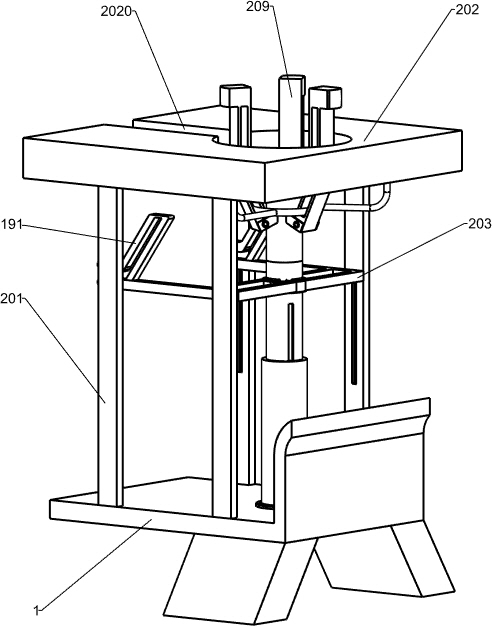

[0033] A non-polluting quenching machine for preventing scalding, such as figure 1 Shown, comprise bottom frame 1, lifting mechanism 2 and quenching mechanism 3, the top of bottom frame 1 is equipped with lifting mechanism 2, and lifting mechanism 2 is provided with quenching mechanism 3, and lifting mechanism 2 cooperates with quenching mechanism 3.

[0034] When the bearing ring needs to be quenched, the user places the bearing ring on the lifting mechanism 2, and the bearing ring is placed in the quenching mechanism 3 through the lifting mechanism 2, and then the user starts the quenching mechanism 3 to quench the bearing ring , when the quenching of the bearing ring is completed, the user moves the bearing ring out of the quenching mechanism 3 through the lifting mechanism 2, and then the user removes and replaces the bearing ring on the lifting mechanism 2, so that the next bearing ring can be easily Quenching, when all the bearing rings are quenched, the user closes the ...

Embodiment 2

[0036] A non-polluting quenching machine for preventing scalding, such as figure 1 Shown, comprise bottom frame 1, lifting mechanism 2 and quenching mechanism 3, the top of bottom frame 1 is equipped with lifting mechanism 2, and lifting mechanism 2 is provided with quenching mechanism 3, and lifting mechanism 2 cooperates with quenching mechanism 3.

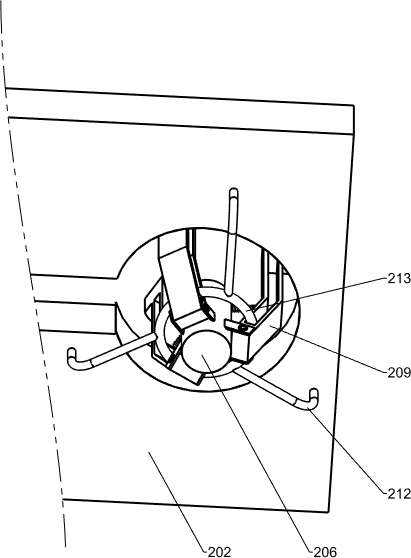

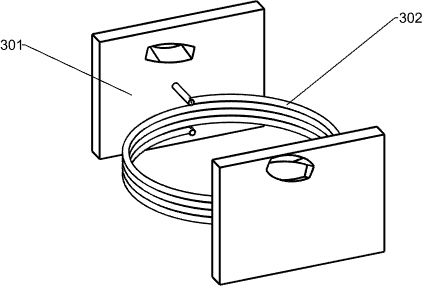

[0037] Such as Figure 1-4As shown, the lifting mechanism 2 includes a support plate 201, a support frame 2001, a placement plate 202, a first sliding frame 203, a sliding tube 204, a first sliding rod 205, a first spring 206, a bearing, a swing seat 208, and a swing frame 209. , the second spring 211, the connecting rod 212 and the ring 213, four support plates 201 are installed on the top of the bottom frame 1, four support frames 2001 are installed on the top of the bottom frame 1 on the left side of the support plate 201, and the four support frames 2001 A placement plate 202 is installed between the tops of the four suppor...

Embodiment 3

[0042] A non-polluting quenching machine for preventing scalding, such as figure 1 Shown, comprise bottom frame 1, lifting mechanism 2 and quenching mechanism 3, the top of bottom frame 1 is equipped with lifting mechanism 2, and lifting mechanism 2 is provided with quenching mechanism 3, and lifting mechanism 2 cooperates with quenching mechanism 3.

[0043] Such as Figure 1-4 As shown, the lifting mechanism 2 includes a support plate 201, a support frame 2001, a placement plate 202, a first sliding frame 203, a sliding tube 204, a first sliding rod 205, a first spring 206, a bearing, a swing seat 208, and a swing frame 209. , the second spring 211, the connecting rod 212 and the ring 213, four support plates 201 are installed on the top of the bottom frame 1, four support frames 2001 are installed on the top of the bottom frame 1 on the left side of the support plate 201, and the four support frames 2001 A placement plate 202 is installed between the tops of the four suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com