Hardening method and hardening device

A technology of quenching device and shaft, applied in the direction of quenching device, coil device, electric heating device, etc., can solve the problem of complex workpiece and achieve good quenching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

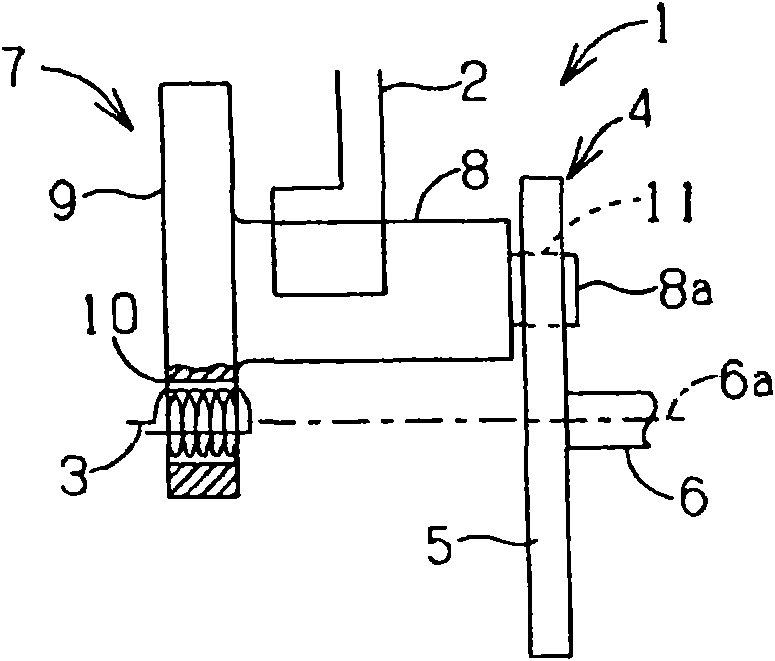

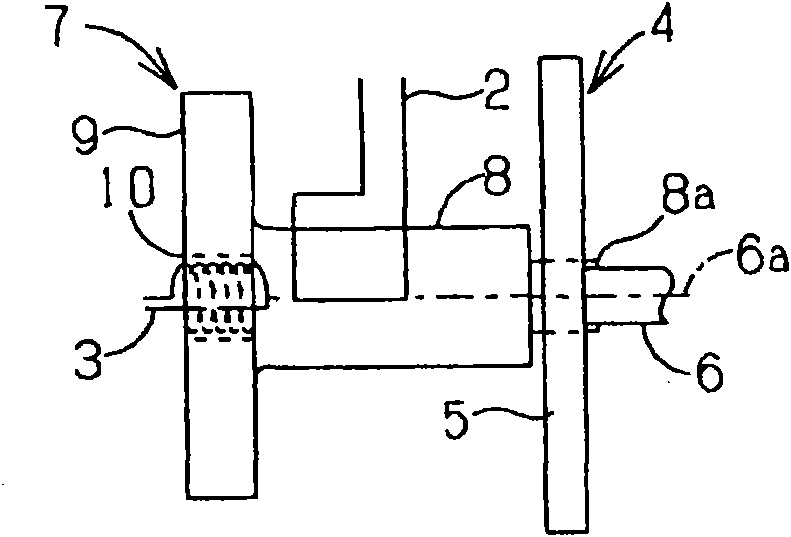

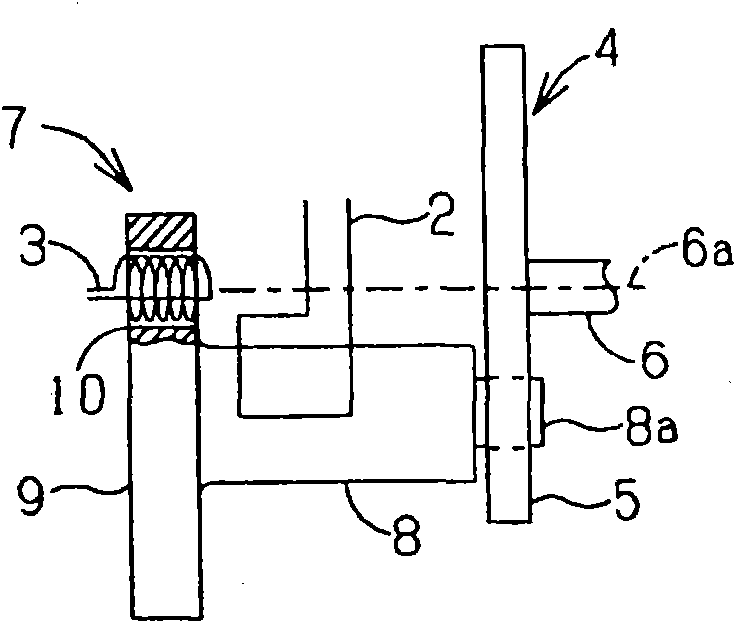

[0059] As shown in FIG. 1( a ), the workpiece 7 to be quenched by the quenching device 1 is composed of a flat plate portion 9 and a shaft portion 8 . The flat plate portion 9 is disc-shaped, and the shaft portion 8 is provided at the center thereof. That is, the shaft portion 8 stands upright on the central portion of the flat plate portion 9 .

[0060] In addition, a hole 10 is provided in the flat plate portion 9 , and the hole 10 is close to the shaft portion 8 . That is, the center of the flat plate portion 9 does not coincide with the center of the hole 10 , and the hole 10 is provided at a position away from the center of the disc-shaped flat plate portion 9 .

[0061] The workpiece 7 having such a shape is used, for example, as a component (component 51 ) of the composite crankshaft 50 shown in FIG. 13( a ). The workpiece 7 is quenched with the quenching device 1 .

[0062] Next, first, the structure of the quenching device 1 will be described, and then the operatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com