Heat treatment technology for forging coupler yoke

A hooktail frame and process technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of wide heat treatment range, control, unfavorable mechanical performance indicators, etc., achieve stable mechanical performance indicators, reduce heat treatment energy consumption, Optimizing the effect of holding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

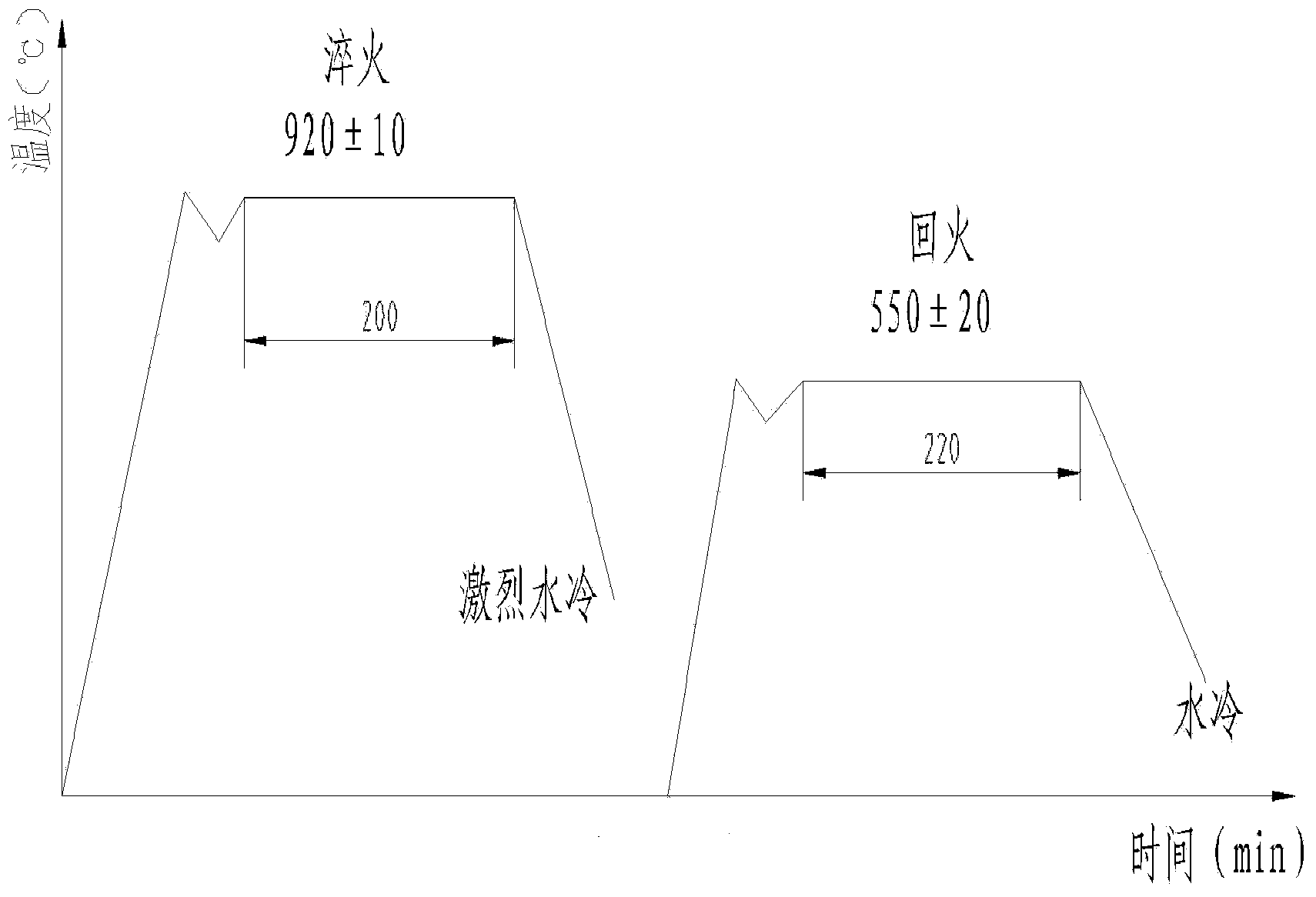

[0020] The material of the forged steel part of the hook tail frame in this embodiment is 25MnCrNiMoA low-alloy steel, and its heat treatment process is carried out as follows:

[0021] (1) Quenching: Place the processed forged steel part of the hook tail frame in a heating furnace, heat it to 910°C, keep it warm for 200 minutes, and directly cool it with intense water after keeping it warm;

[0022] ⑵Tempering: Put the forged steel part of the coupler frame after quenching in the tempering furnace, heat it to 530°C, keep it warm for 220 minutes, and then water cool it after keeping it warm.

Embodiment 2

[0024] The material of the forged steel part of the hook tail frame in this embodiment is 25MnCrNiMoA low-alloy steel, and its heat treatment process is carried out as follows:

[0025] (1) Quenching: Place the processed forged steel part of the hook tail frame in a heating furnace, heat it to 930°C, keep it warm for 200 minutes, and directly cool it with intense water after keeping it warm;

[0026] ⑵ Tempering: Put the forged steel part of the coupler frame after quenching in the tempering furnace, heat it to 570°C, keep it warm for 220 minutes, and then cool it with water after keeping it warm.

Embodiment 3

[0028] The material of the forged steel part of the hook tail frame in this embodiment is 25MnCrNiMoA low-alloy steel, and its heat treatment process is carried out as follows:

[0029] (1) Quenching: Place the processed forged steel part of the hook tail frame in a heating furnace, heat it to 910°C, keep it warm for 200 minutes, and directly cool it with intense water after keeping it warm;

[0030] ⑵ Tempering: Put the forged steel part of the coupler frame after quenching in the tempering furnace, heat it to 570°C, keep it warm for 220 minutes, and then cool it with water after keeping it warm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com