An Aging Process for Improving the Microstructure and Properties of 7n01 Aluminum Alloy

A technology for improving the performance of aluminum alloys, which is applied in the field of aging technology to improve the microstructure and properties of 7N01 aluminum alloys. Mechanical properties, reducing stress corrosion susceptibility, and reducing the effect of heat treatment energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

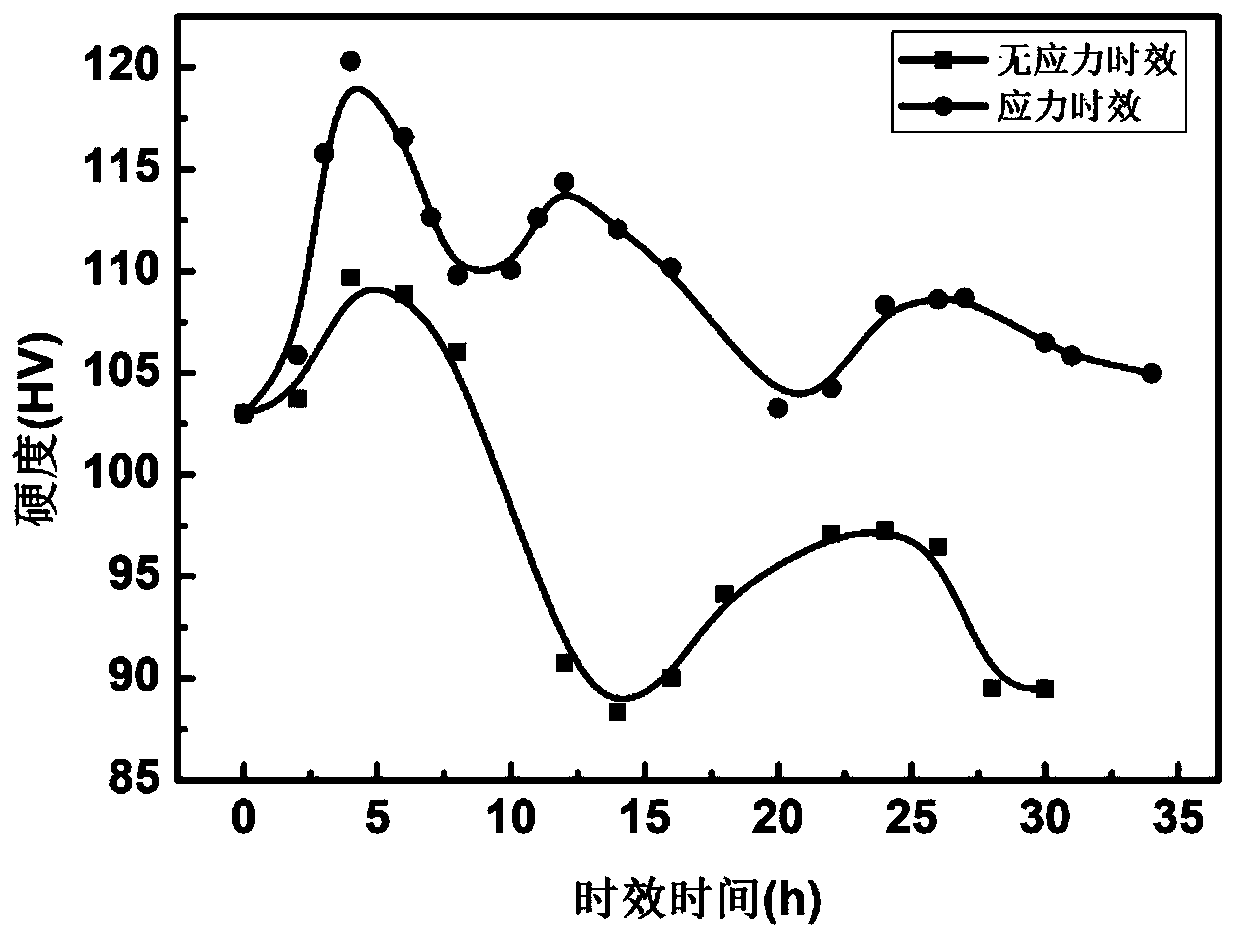

Embodiment 1

[0026] In this embodiment, the implementation process of 7N01 aluminum alloy stress aging:

[0027] 1) The 7N01 aluminum alloy raw material is smelted in a resistance furnace. The designed 7N01 aluminum alloy composition is, in terms of element mass percentage, zinc: 4.13%, magnesium: 1.31%, manganese: 0.30%, chromium: 0.21%, zirconium: 0.10 %, titanium: 0.06%, the balance is aluminum and unavoidable impurities.

[0028] 2) The prepared 7N01 aluminum alloy ingot was heated to 470° C. in a box-type resistance furnace, kept for 24 hours, and then air-cooled to room temperature.

[0029] 3) The 7N01 aluminum alloy ingot was preheated at 450°C for 1 hour, and then extruded. The extrusion die temperature was 420°C, the extrusion speed was 10m / min, and the extrusion ratio was 22, and then water cooled to room temperature immediately.

[0030] 4) Naturally aging the extruded 7N01 aluminum alloy plate at room temperature for 60 days.

[0031] 5) The naturally aged 7N01 aluminum allo...

Embodiment 2

[0034] The difference from Example 1 is:

[0035] 1) The extruded 7N01 aluminum alloy plate was naturally aged at room temperature for 30 days.

[0036] 2) The naturally aged 7N01 aluminum alloy was kept at 150° C. for different times, and a tensile stress of 100 MPa was applied while keeping it warm.

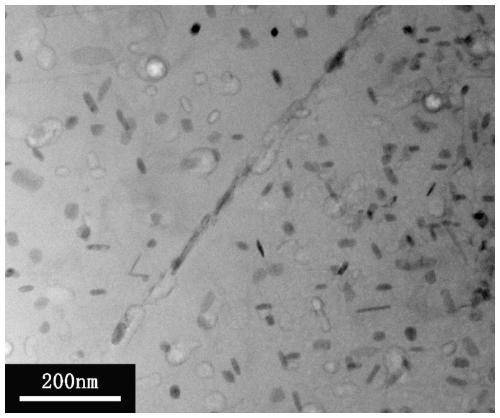

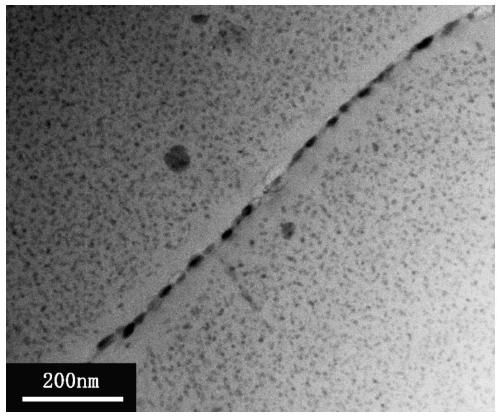

[0037] The technical indicators of this embodiment are as follows: the hardness range is 98-117HV, the average long-axis size range of intragranular precipitated phases is 8-14nm, and the average precipitated phase number density range is 4100-4700 / μm 2 , The average width of the grain boundary precipitated phase ranges from 16 to 22 nm.

Embodiment 3

[0039] The difference from Example 1 is:

[0040] 1) The extruded 7N01 aluminum alloy plate was naturally aged for 90 days at room temperature.

[0041] 2) The naturally aged 7N01 aluminum alloy was kept at 170°C for different times, and a tensile stress of 75MPa was applied while keeping it warm.

[0042] The technical indicators of this embodiment are as follows: the hardness range is 101-127HV, the average long-axis size range of intragranular precipitates is 11-17nm, and the average precipitated phase number density range is 4000-5100 / μm 2 , The average width of the grain boundary precipitated phase ranges from 16 to 24 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com