A kind of high-speed steel roll and preparation method thereof

A technology of high-speed steel and roll, applied in the direction of roll, metal rolling, metal rolling, etc., can solve the problems affecting the performance of high-speed steel, and achieve the effect of cost reduction and less addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

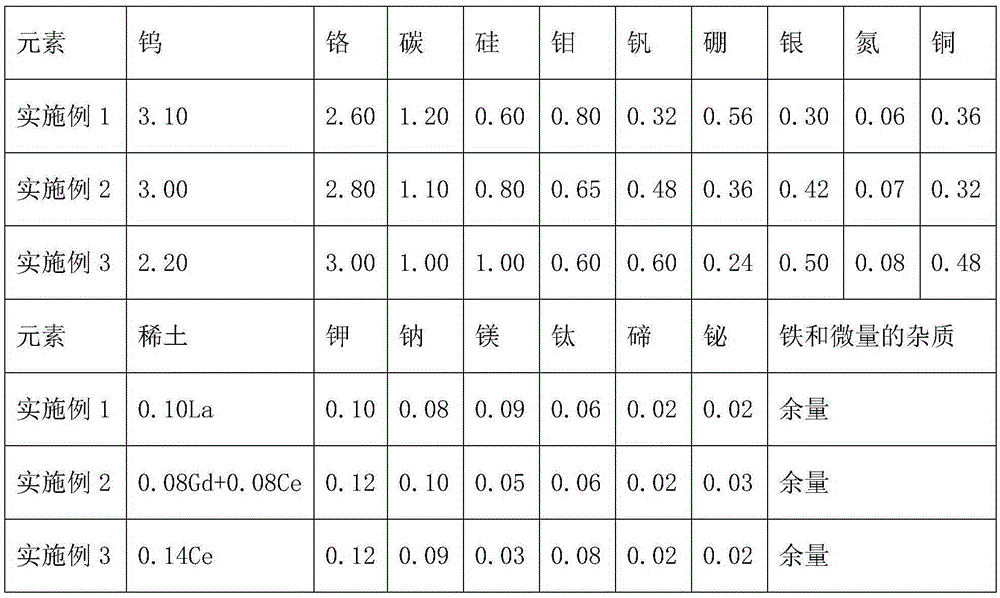

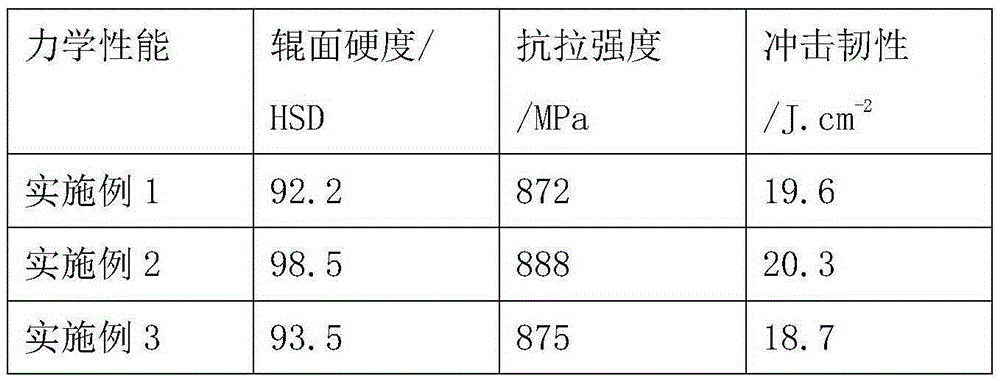

Embodiment 1

[0034] Melting the high-speed steel roll material of the present invention with 750 kilograms of medium-frequency induction furnaces, the specific preparation process steps are as follows:

[0035] 1) Mix and heat scrap steel, recarburizer, ferrochrome, copper plate, ferrotungsten and ferromolybdenum, add ferrosilicon after molten steel is melted, add silver and nitrogen-containing ferrochrome when the temperature rises to 1548°C, and then add ferrovanadium in sequence , ferroboron and ferrotitanium, after adjusting the ingredients before the furnace to pass, the temperature of the molten steel is raised to 1580°C, and the slag is removed from the furnace.

[0036] 2) Crushing iron bismuth, copper telluride master alloy, potassium carbonate and rare earth magnesium alloy (the rare earth element is lanthanum) into small pieces with a particle size of less than 8mm, dried at 120°C to constant weight, and placed at the bottom of the ladle, Composite modification of molten steel i...

Embodiment 2

[0042] Melting the high-speed steel roll material of the present invention with 500 kilograms of medium-frequency induction furnaces, the specific preparation process steps are as follows:

[0043] 1) Mix and heat scrap steel, recarburizer, ferrochrome, copper plate, ferrotungsten and ferromolybdenum, add ferrosilicon after molten steel is melted, add silver and nitrogen-containing ferrochrome when the temperature rises to 1548°C, and then add ferrovanadium in sequence , ferroboron and ferrotitanium, after adjusting the ingredients before the furnace to pass, the temperature of the molten steel is raised to 1580°C, and the slag is removed from the furnace.

[0044] 2) Crushing iron bismuth, copper telluride master alloy, potassium carbonate and rare earth magnesium alloy (the specific rare earth elements are gadolinium and cerium) into small pieces with a particle size of less than 8mm, dried at 120°C to constant weight, and placed in a ladle At the bottom, the molten steel is...

Embodiment 3

[0050] Melting the high-speed steel roll material of the present invention with 1000 kilograms of medium-frequency induction furnaces, the specific preparation process steps are as follows:

[0051] 1) Mix and heat scrap steel, recarburizer, ferrochrome, copper plate, ferrotungsten and ferromolybdenum, add ferrosilicon after molten steel is melted, when the temperature rises to 1540°C, add silver and nitrogen-containing ferrochrome, and then add ferrovanadium in sequence , ferroboron and ferrotitanium, after adjusting the ingredients before the furnace to pass, the temperature of the molten steel is raised to 1580°C, and the slag is removed from the furnace.

[0052] 2) Crushing iron bismuth, copper telluride master alloy, potassium carbonate and rare earth magnesium alloy (the rare earth element is cerium) into small pieces with a particle size of less than 8mm, dried at 200°C to constant weight, and placed at the bottom of the ladle, Composite modification of molten steel is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com