A method of heat treatment of wood under high pressure and humidity

A technology of wood heat treatment and high pressure, applied in the direction of impregnated wood, wood impregnation, wood processing appliances, etc., can solve the problems of insufficient degradation of nutrients, long heat treatment time, wood cracking, etc., achieve complete degradation, reduce energy consumption, and avoid cracking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

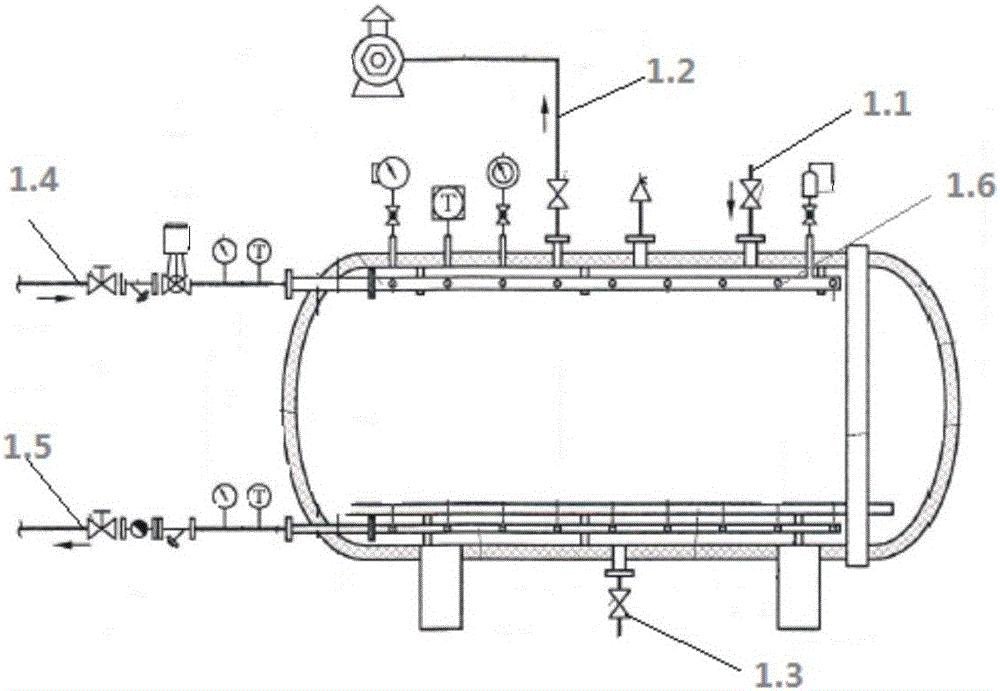

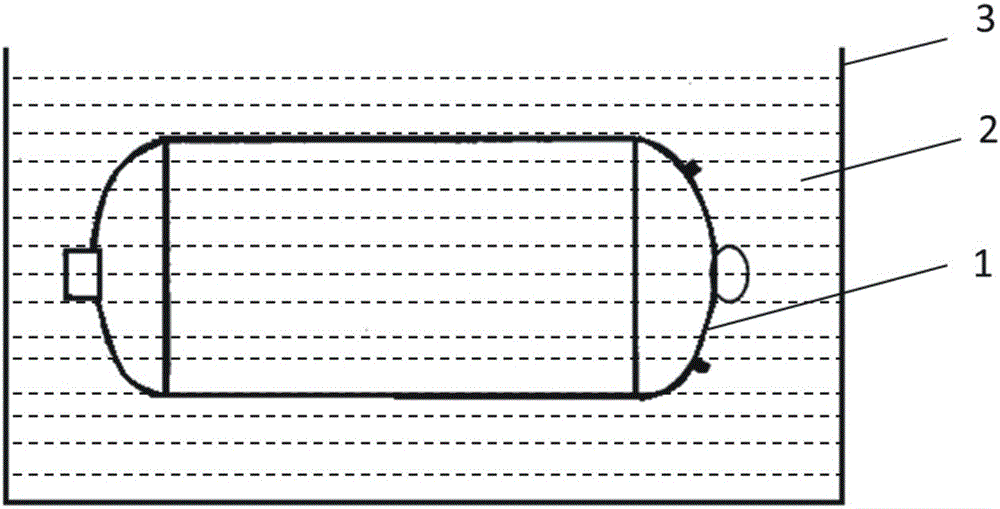

[0025] The equipment used in the humid-heat high-pressure wood heat treatment equipment of the present invention includes a pressure tank (1) and an oil pool (3). Inlet and drain valve (1.3), air inlet and control valve (1.4), air outlet and control valve (1.5), reversible fan (1.6), including the following steps: (1) bamboo bundle preparation, (2) bamboo Bunch drying, (3) Bamboo bundle heat treatment, (4) Bamboo bundle balance treatment:

[0026] (1) material preparation stage, (2) preheating stage, (3) heating stage, (4) heat preservation stage, (5) cooling stage:

[0027] (1) Preparation stage

[0028] Saw the wood into sawn timber according to GB / T11917-1989, soak the sawed sawn timber in water, and after reaching the saturated moisture content, put it into the pressure tank according to the grain direction or cross-stack, and close the pressure tank door ;

[0029] (2) Preheating stage

[0030] Open the air inlet, let the saturated steam into the pressure tank, contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com