Raw material for shot-peening materials, finished wire, method of manufacturing shot-peening materials, and shot-peening materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

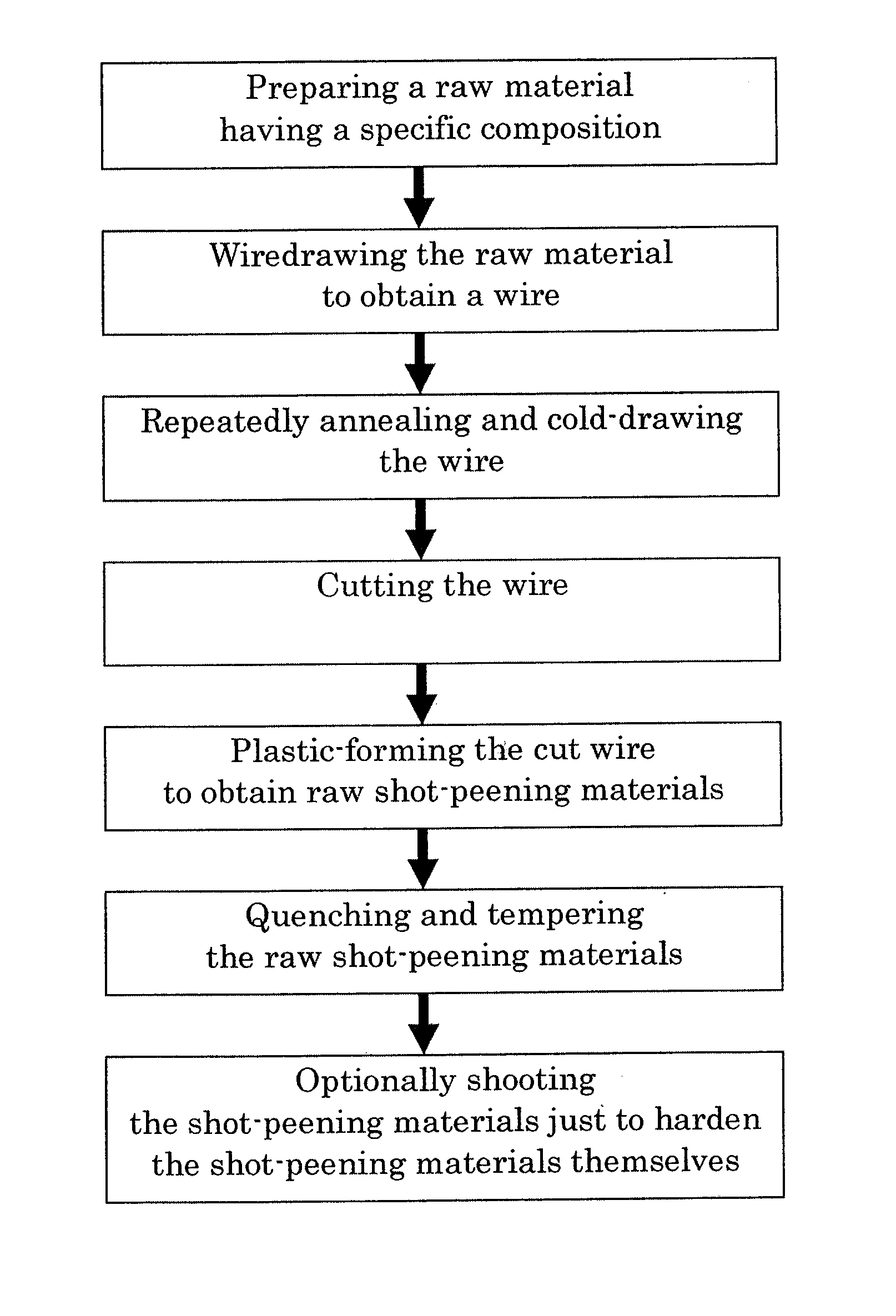

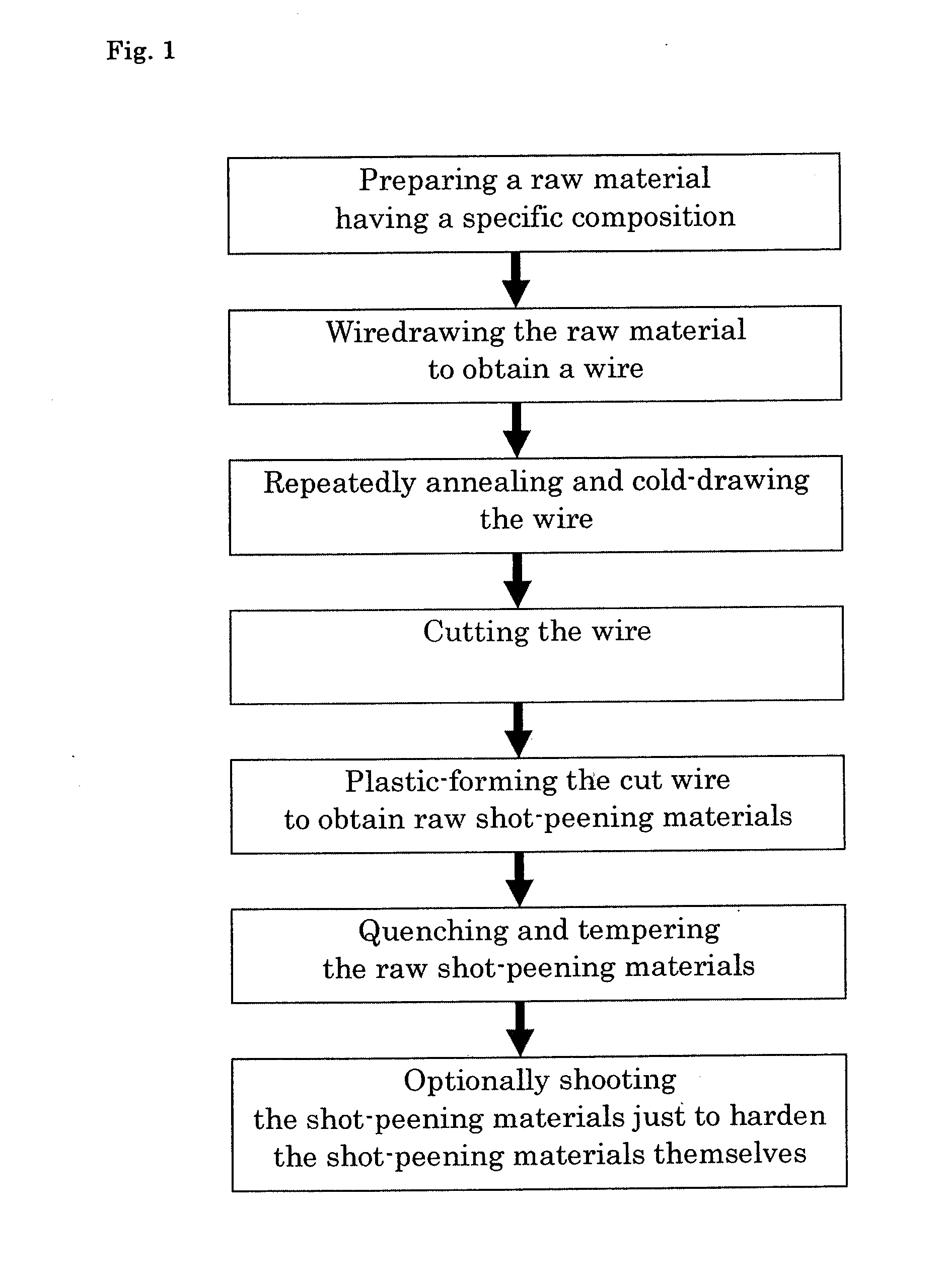

[0031]The flowchart of manufacturing shot-peening materials by using the raw material for the shot-peening materials of the present inventions is shown in FIG. 1. By reference to FIG. 1, manufacturing shot-peening materials is described below. As in the flowchart, at a first step a raw material having the components of Table 1 is prepared. At a second step the raw material is wiredrawn to be a wire. At a third step the wire is repeatedly annealed and cold-drawn. At a fourth step the wire is cut. At a fifth step the cut wire is subject to plastic formation. At a sixth step it is quenched and tempered. At a seventh step it is shot just to harden the shot-peening materials themselves.

[0032]Comparisons between example 1 and the bearing steel of Table 2, SUJ of JIS G4805, during the first three steps, are shown in Table 3. The wire after the wiredrawing of the second step has a diameter of 1.6 mm and a hardness of 320 HV.

TABLE 3Working ExampleComparative ExampleContaining 0.95-1.10% carb...

example 2

[0043]The conditions and results of shot-peening in which the shot-peening materials of the present inventions are shot against a work are shown in Table 10. Example 2 shows that the shot-peening materials of the present inventions, of which the hardness is 950 HV, cause a smaller amount to be scraped off when they are shot against a hard work. They also cause work-hardening and larger residual stress in the work (see Experiment Nos. 11-17). The hardness of the materials is initially 950 HV, but possibly increases to 1050 HV after shot-peening.

[0044]The amount being scraped off is measured as follows:

A Method of Measuring an Amount Being Scraped Off

[0045]The diameter of a work before shot-peening and that after shot-peening are measured by a laser dimension-measuring device. The amount is calculated by the following equation. It is the mean value of ten measurements (n=10). The measurement is performed at the center of the target of the shot (where the maximum amount being scraped o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com