Oil pool quenching equipment

A technology of quenching equipment and oil pool, applied in the direction of quenching equipment, heat treatment equipment, manufacturing tools, etc., can solve the problems of low cooling speed, low work efficiency, complex structure, etc., to reduce energy consumption, improve work efficiency, and reasonable design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

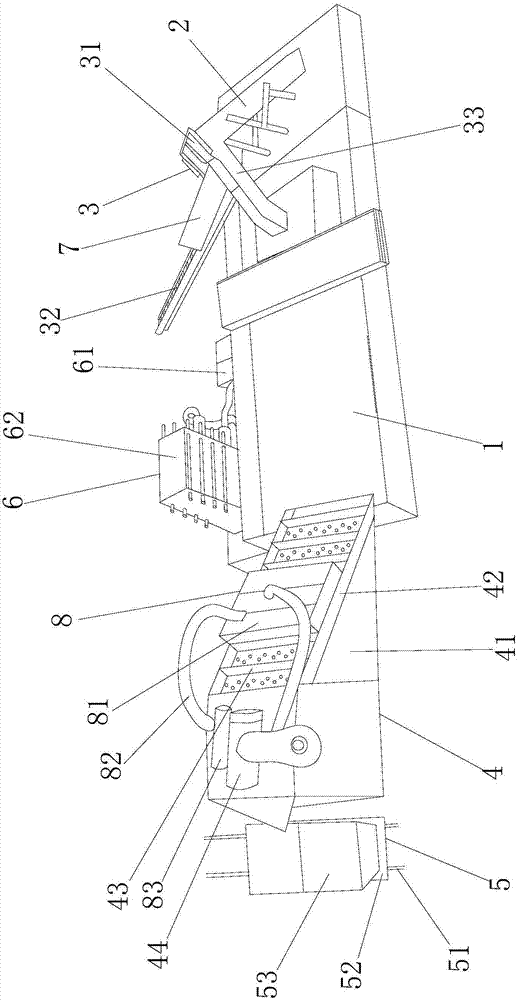

[0016] Such as figure 1 As shown, the oil pool quenching equipment includes an oil pool 1, a feed pipe 2 arranged at one end of the oil pool 1, a material distribution mechanism 3 connected to the feed pipe 2, and a discharge mechanism 4 arranged at the other end of the oil pool 1 , the receiving mechanism 5 arranged on one side of the discharging mechanism 4, the oil liquid heat exchange mechanism 6 arranged on one side of the oil pool 1, and the said distributing mechanism 3 includes two outlets arranged on the feeding pipeline 2 31. The transmission long plate 32 and the quenching cylinder 33 are separately arranged on the two discharge ports 31. A baffle 7 is provided between the two discharge ports 31. The discharge mechanism 4 includes a lifting bracket 41, which is located on the The conveyor belt 42 on both sides of the lifting bracket 41, the dividing plate 43 connected to the conveyor belt 42, the motor 44 provided on the lifting bracket 41 for driving the movement o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com