General induction quenching device for shafts and discs

A technology of induction hardening equipment and discs, which is applied in the direction of quenching equipment, heat treatment equipment, furnace types, etc., can solve the problems of complicated equipment implementation, overblown equipment, and complicated equipment settings, and achieve the effect of simple and easy quenching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

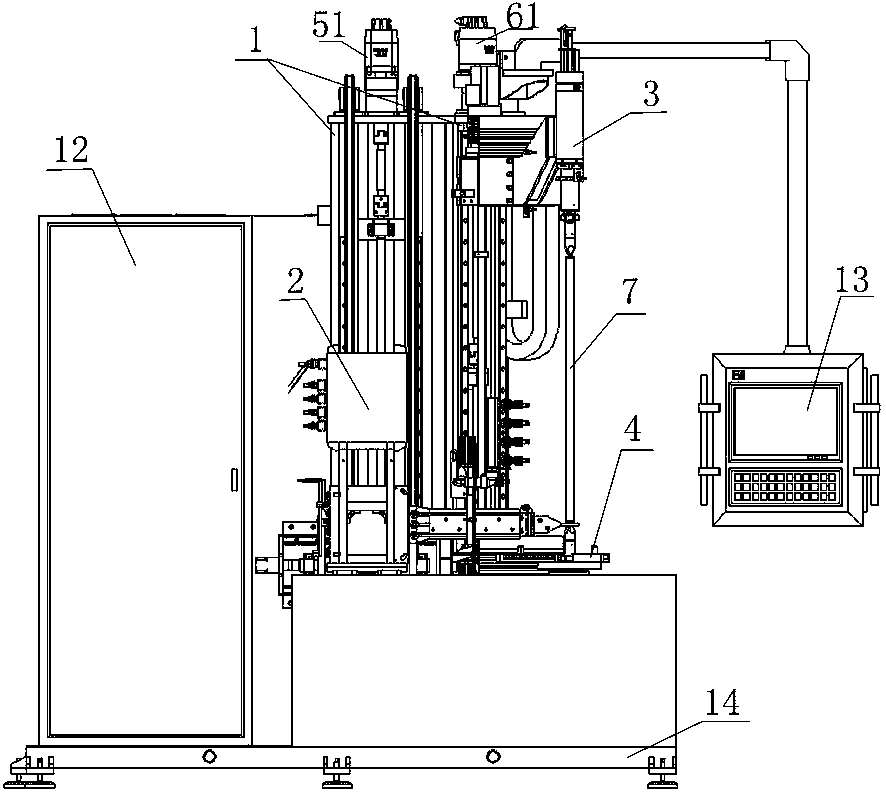

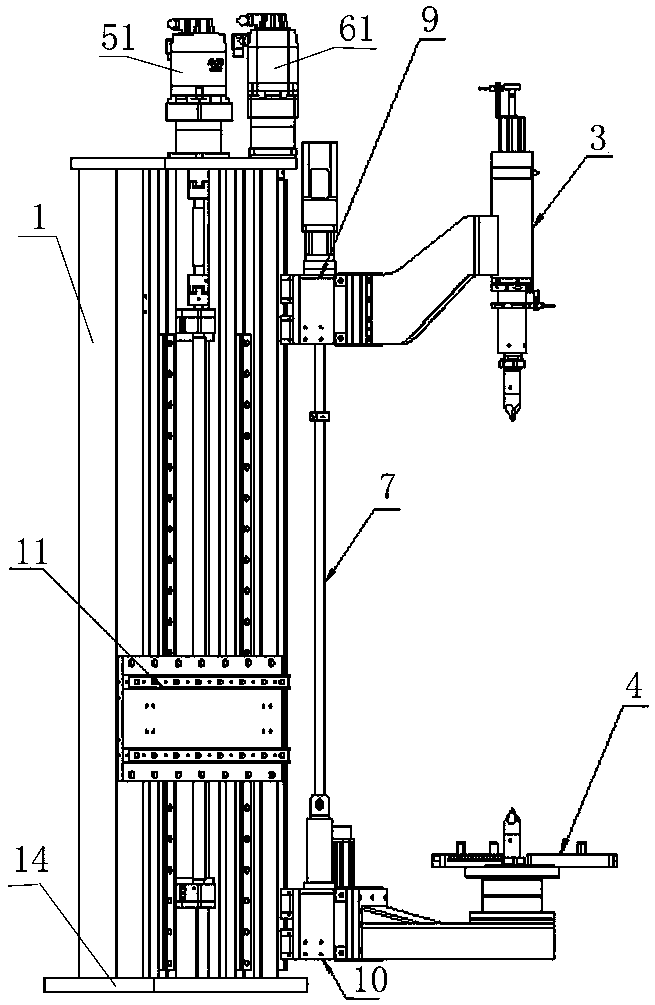

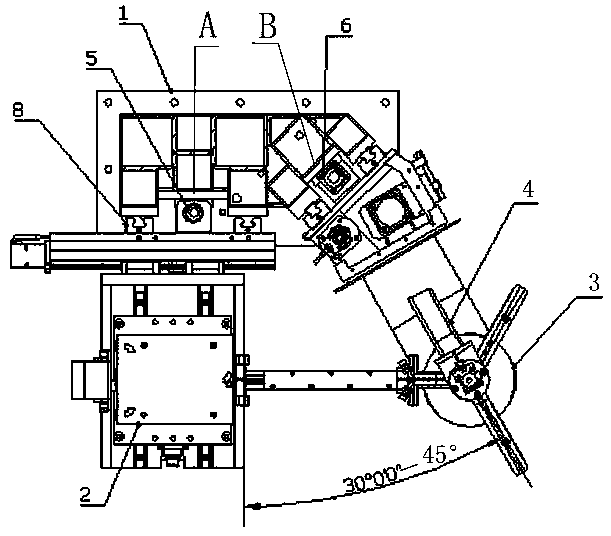

[0033] The present invention as Figure 1-5 shown.

[0034] A common induction hardening equipment for shafts and discs, including a column structure 1, the column structure 1 is welded by steel, and welded on the base 14, and designed as two sides facing the direction of the station, wherein the two sides are clamped Angle structure setting, the first side A is vertically provided with a first guide rail body 8, a load slide 11 is provided through the first guide rail body 8, and a A ball screw 5, the top of the ball screw 5 is provided with a drive motor 51 for driving the load slide 11 to move up and down along the first guide rail body 8;

[0035] A ball screw 2 6 is provided between the upper top slide table 9 and the second guide rail body 81, and the top of the ball screw 2 6 is provided with a drive motor 2 61;

[0036] The base 14 is provided with a lower top slide 10, and the lower top 4 of the lower top slide 10 corresponds to the upper top 3, wherein the lower to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com