Patents

Literature

30results about How to "Low expansion properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hexadecyl trimethyl ammonium bromide expansive soil improvement agent

InactiveCN1850702AImprove the nature of the projectReduce negative chargeSoil propertiesRoom temperature

The invention is a palmityl trimethyl ammonium bromide expansive soil modifier, characterized in comprising the preparing steps of: (1) at room temperature, preparing saturated lime water solution; (2) weighing the needed palmityl trimethyl ammonium bromide in the mass ratio of palmityl trimethyl ammonium bromide to dry soil = 0.5 : 99.5; (3) dissolving the palmityl trimethyl ammonium bromide in the saturated lime water solution, where it needs to notice that the dosage of the saturated lime water solution is able to completely dissolve the palmityl trimethyl ammonium bromide. And the advantages: making the soil property still able to reach the specified standard under the water influence; improving engineering property of expansive soil; unable to cause environmental pollution. And its construction method uses osmotic modification principle and fully uses multi-crack property of expansive soil and is simple and convenient.

Owner:HOHAI UNIV

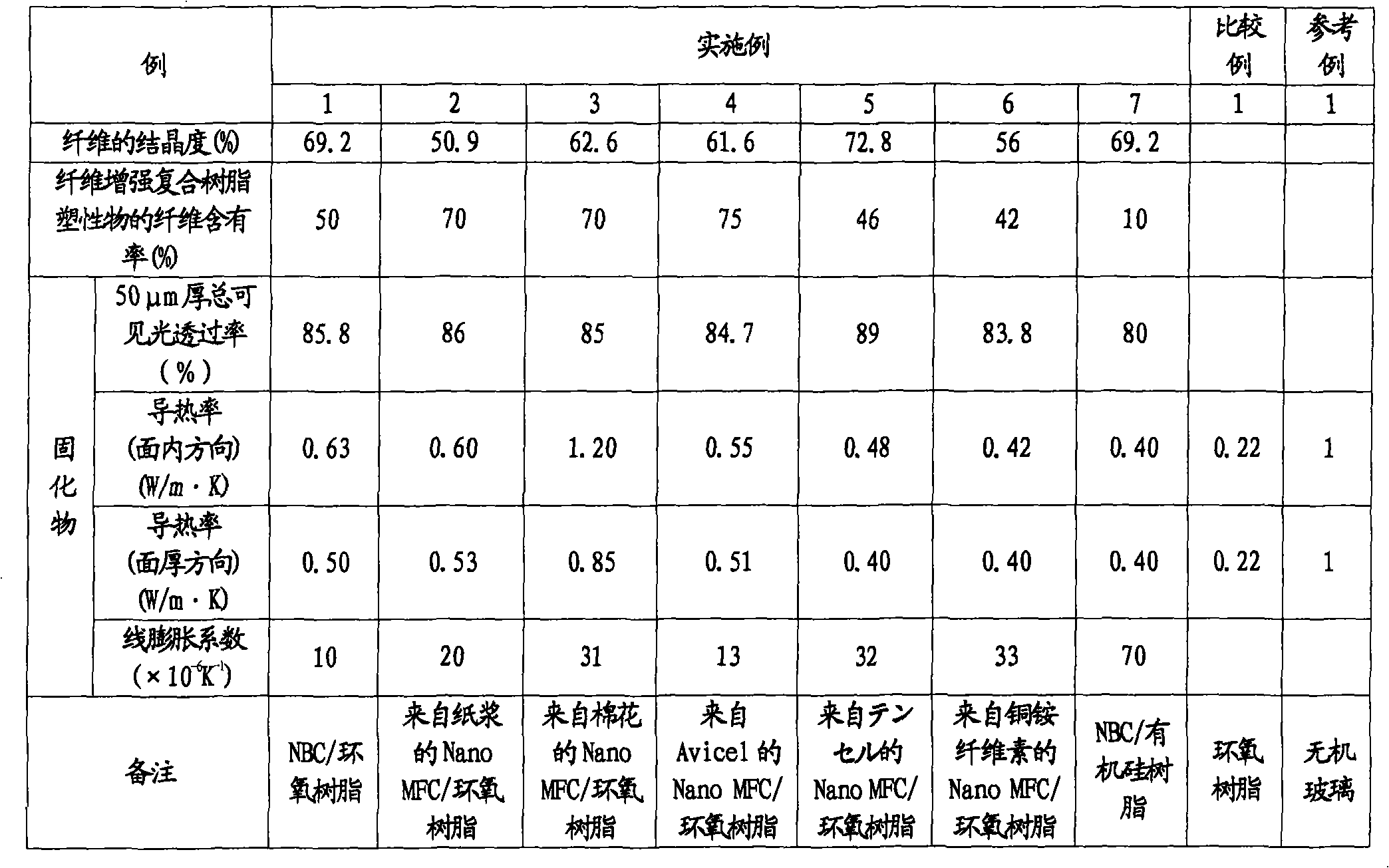

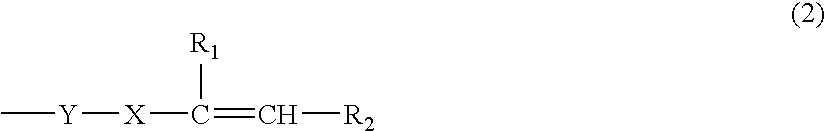

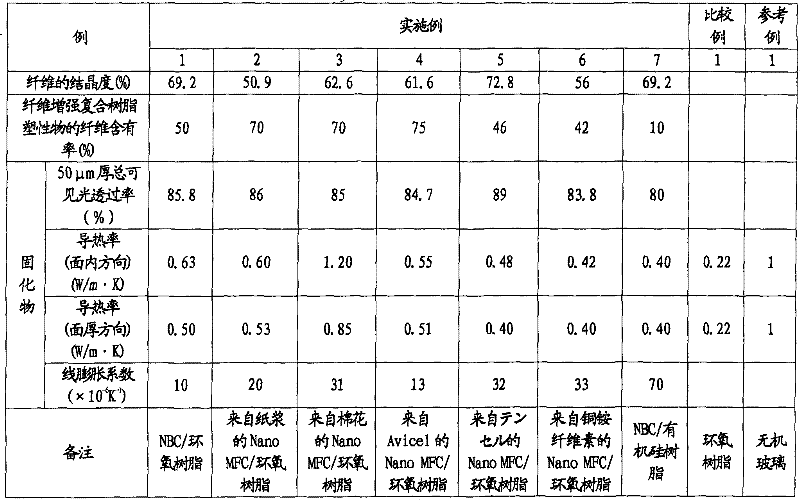

Fiber-reinforced composite resin composition, and adhesive and sealing agent

InactiveCN101297000AHigh transparencyLow coefficient of linear thermal expansionCellulose adhesivesPolymer scienceAdhesive

Owner:ROHM CO LTD +2

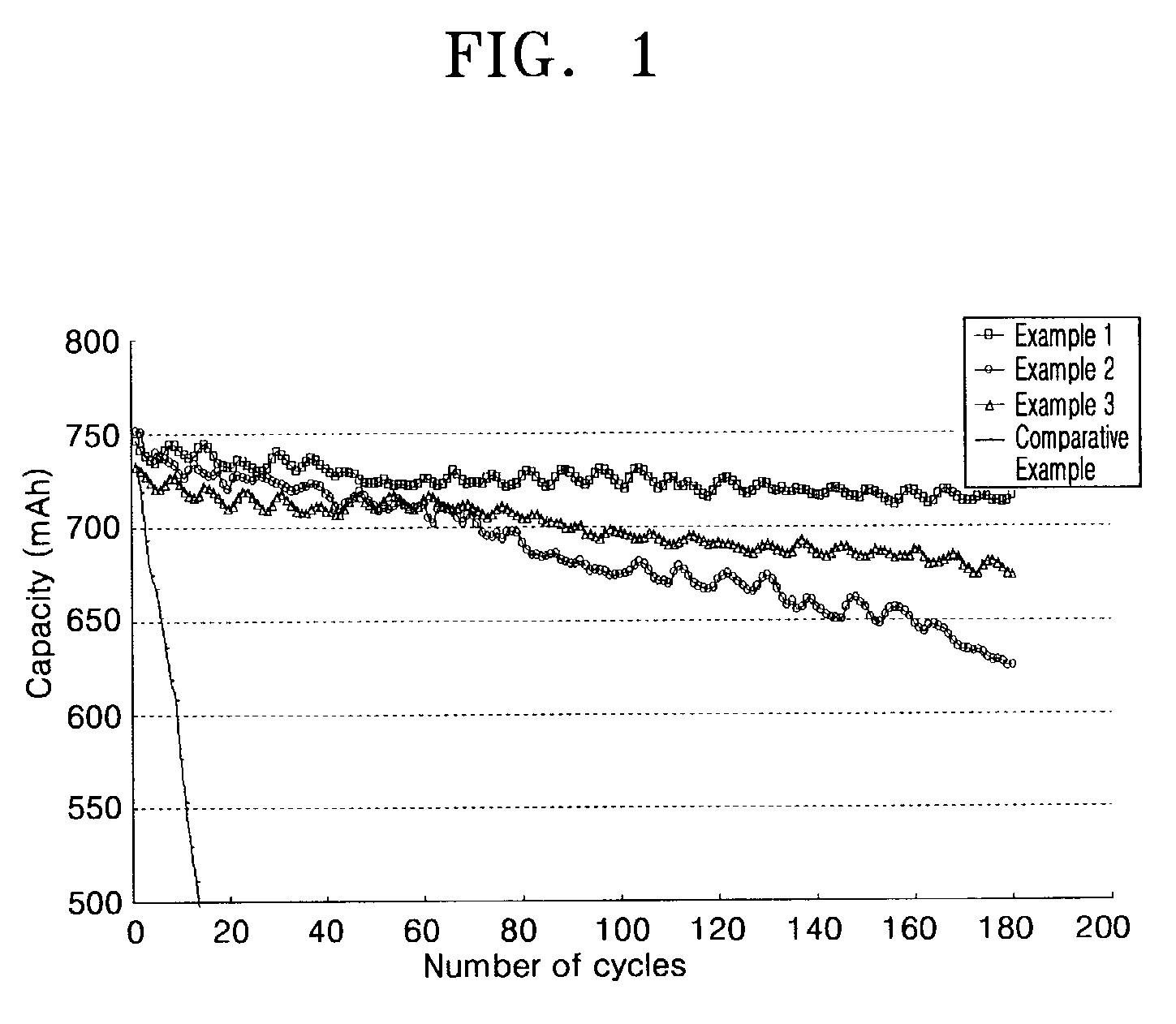

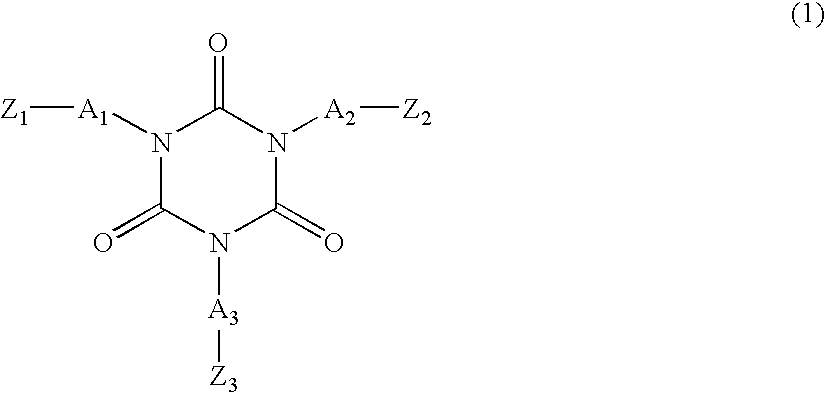

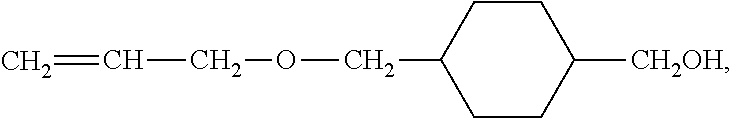

Polymer electrolyte and lithium battery using the same

ActiveUS7387852B2Improve cycle lifeImprove securitySolid electrolytesOrganic electrolyte cellsPolymer scienceOrganic solvent

A polymer electrolyte extends the cycle life, improves the safety, and reduces the swelling of a battery, compared with a polymer electrolyte containing a poly(alkylene oxide) polymer. Also, a lithium battery utilizes the polymer electrolyte. The polymer electrolyte contains a polymerized product from a polymer electrolyte forming composition containing a multifunctional isocyanurate monomer of a particular structure, a lithium salt, and a non-aqueous organic solvent.

Owner:SAMSUNG SDI CO LTD

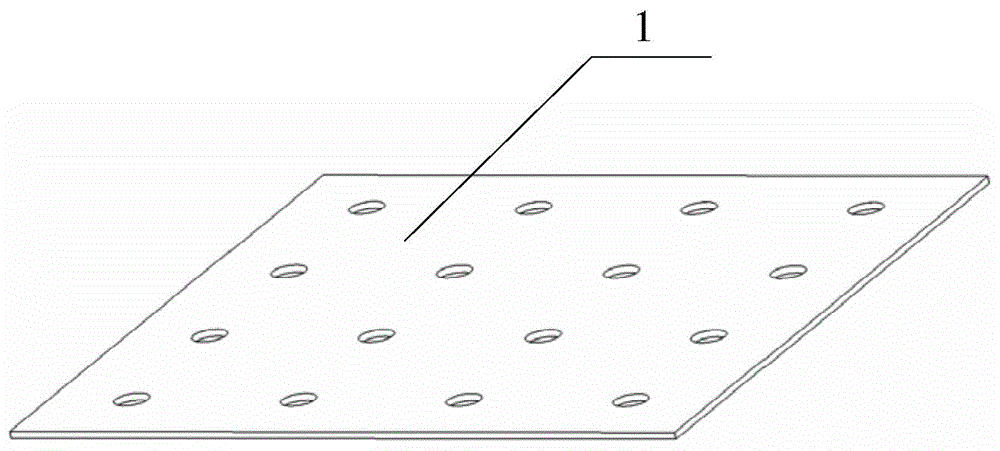

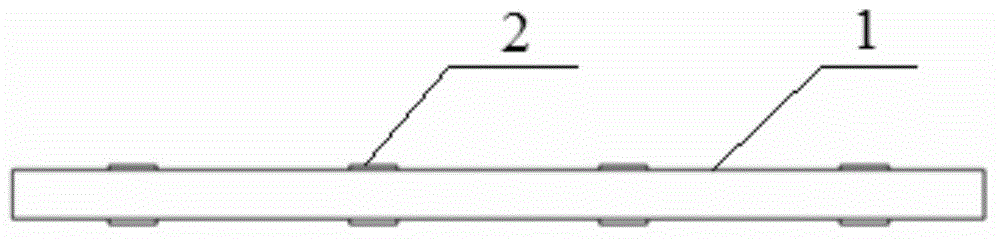

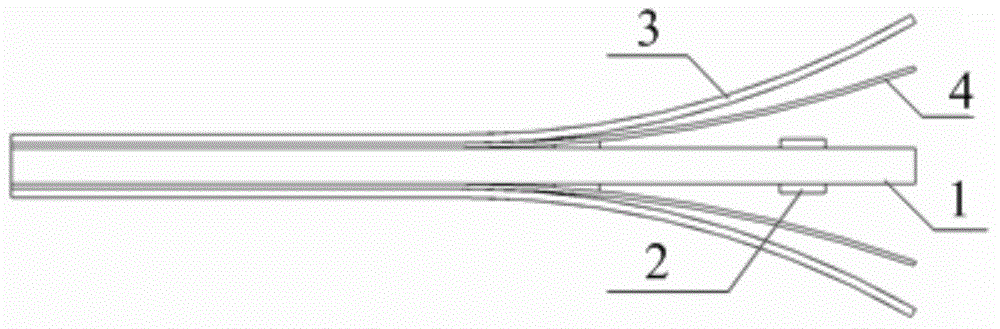

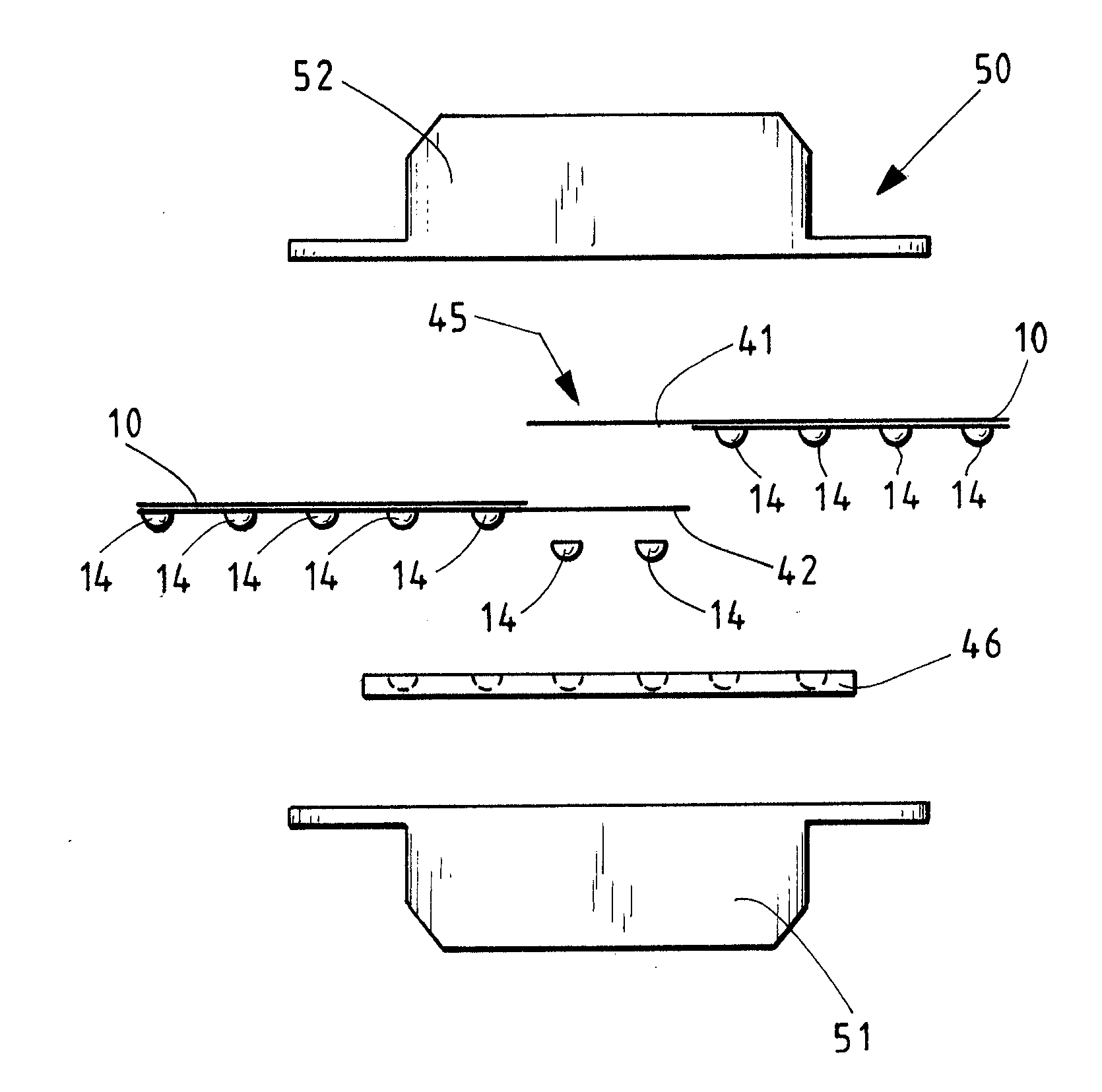

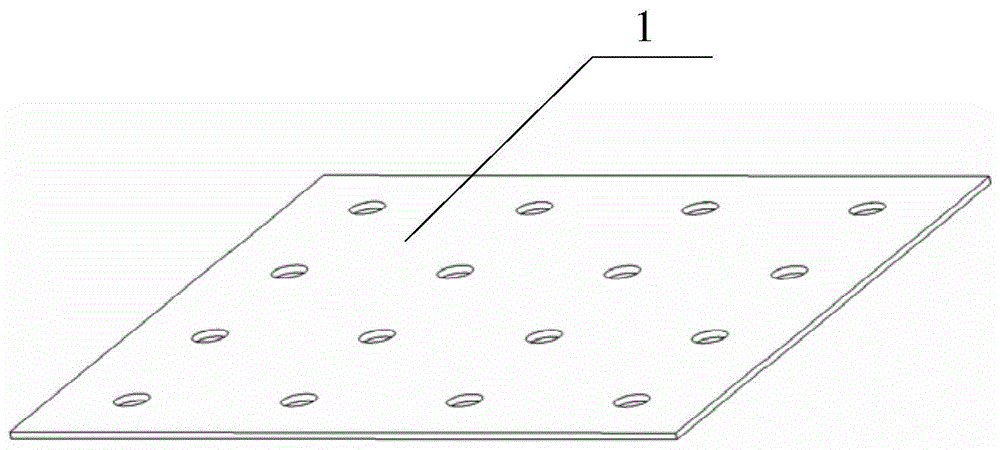

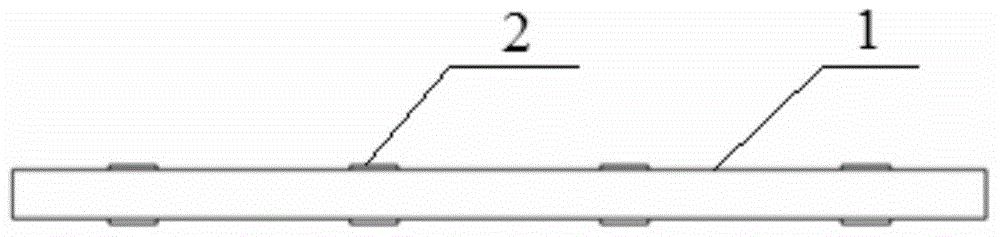

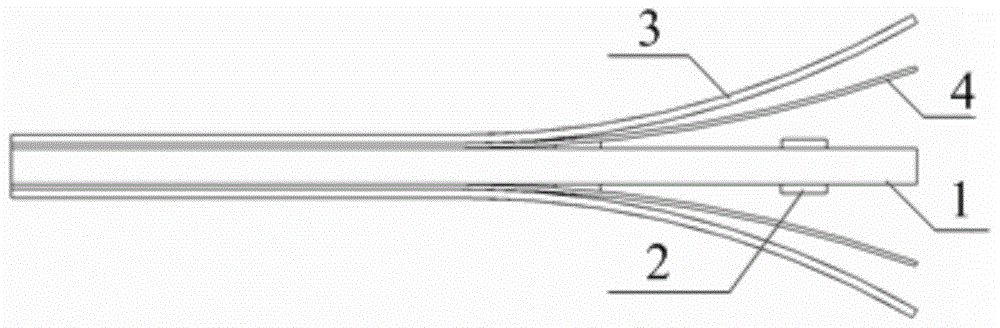

Heat-conducting polymer-base composite material and preparation method thereof

InactiveCN104553105AGood thermal conductivityImprove mechanical propertiesSynthetic resin layered productsLaminationFilling materialsHeat conducting

The invention relates to a heat-conducting polymer-base composite material and a preparation method thereof. The invention aims to solve the problems of high cost of the existing preparation method and poor heat conductivity of the obtained polymer-base composite material. The product is composed of a through-hole-bearing composite material plate, a filling material filled in the through hole of the through-hole-bearing composite material plate, film material layers positioned on the upper and lower surfaces of the through-hole-bearing composite material plate, and adhesive layers for bonding the film materials and the through-hole-bearing composite material plate. The method comprises the following steps: 1. preparing the through-hole-bearing composite material plate; 2. preparing a precuring plate; 3. preparing the composite plate; 4.preparing the cleaned composite plate; and 5. preparing the heat-conducting polymer-base composite material. The heat conductivity coefficient of the heat-conducting polymer-base composite material can reach 200-250 W / (m.K).

Owner:HARBIN INST OF TECH

Wear-resistant antibacterial ceramic and processing method thereof

InactiveCN111792913AImprove quality requirementsGood antibacterial effectClaywaresAir atmospherePyrophyllite

The invention relates to wear-resistant antibacterial ceramic and a processing method thereof. The processing method includes the steps that a body material is fired for the first time to form a plainbody, then glaze is applied to the two faces of the plain body to form glaze layers, and firing is conducted for the second time, and then the wear-resistant antibacterial ceramic is obtained, wherein the body material is made of raw materials such as sodium bentonite, coke gemstone, pyrophyllite, dolomite, and the like, the glaze is prepared from silicon dioxide, potassium fluoroaluminate, boronoxide, barium oxide, yttrium oxide, titanium-silicon co-doped graphene, large ball mud and other raw materials. Wherein the second firing comprises three-stage heating and heat preservation and three-stage cooling, each heating and heat preservation is sequentially carried out in an air atmosphere, a nitrogen atmosphere and a hydrogen atmosphere, and the three-stage cooling is natural cooling, rapid cooling and natural cooling. The obtained ceramic product has excellent antibacterial performance and wear resistance, and meets the high-quality requirements of ceramics.

Owner:许洁

Composite ceramic material for LED energy-saving lamp base

The invention discloses a composite ceramic material for an LED energy-saving lamp base. The composite ceramic material is calcined from such components as 12-15 parts of nano-zinc oxide, 5-10 parts of silicon dioxide, 6-8 parts of magnesium carbonate, 80-100 parts of active kaolin, 15-18 parts of magnesium oxide, 10-12 parts of titanium dioxide, 100-120 parts of silicon nitride, 50-60 parts of silicon carbide and 3-5 parts of magnesium nitride. The composite ceramic material for the LED energy-saving lamp base has the characteristics of high thermal conductivity and low expansion; the formed composite ceramic material is improved in thermal conductivity, reduced in thermal expansion and enhanced in heat dissipation capability to the environment; as a result, the working temperature of an LED semiconductor chip can be reduced, the luminous efficiency of the same can be improved; the structural stress of the LED semiconductor chip and the base is reduced and the working service life of the LED energy-saving lamp is prolonged.

Owner:GUANGDONG HHH OPTOELECTRONICS TECH CO LTD

Sapphire insulator metal shell and production process thereof

InactiveCN110767609AHigh strengthHigh hardnessSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectronic component

The invention relates to the technical field of electronic components and discloses a sapphire insulator metal shell. The sapphire insulator metal shell comprises a frame body and a cover plate; a bottom plate is fixedly installed at the bottom of the frame body; a carrier located in the frame body is fixedly installed at the top of the bottom plate; an annular frame is fixedly installed at the top of the frame body; a connecting ring is fixedly installed on the right side of the frame body; and a lead is fixedly installed in the connecting ring. According to the sapphire insulator metal shelland the production process thereof disclosed in the invention, through the material, the structure, the connection process and the like of a semiconductor integrated circuit packaging shell in the prior art, the purpose of improving the using performance of the semiconductor integrated circuit packaging shell is achieved, and the problems that when an existing semiconductor integrated circuit packaging shell is used, the connecting performance between packaging shell structures is common, the sealing welding process is not perfect, a selected insulating medium cannot bear ultrahigh withstoodvoltage, and the using performance is reduced are solved.

Owner:泰州联鑫电子科技有限公司

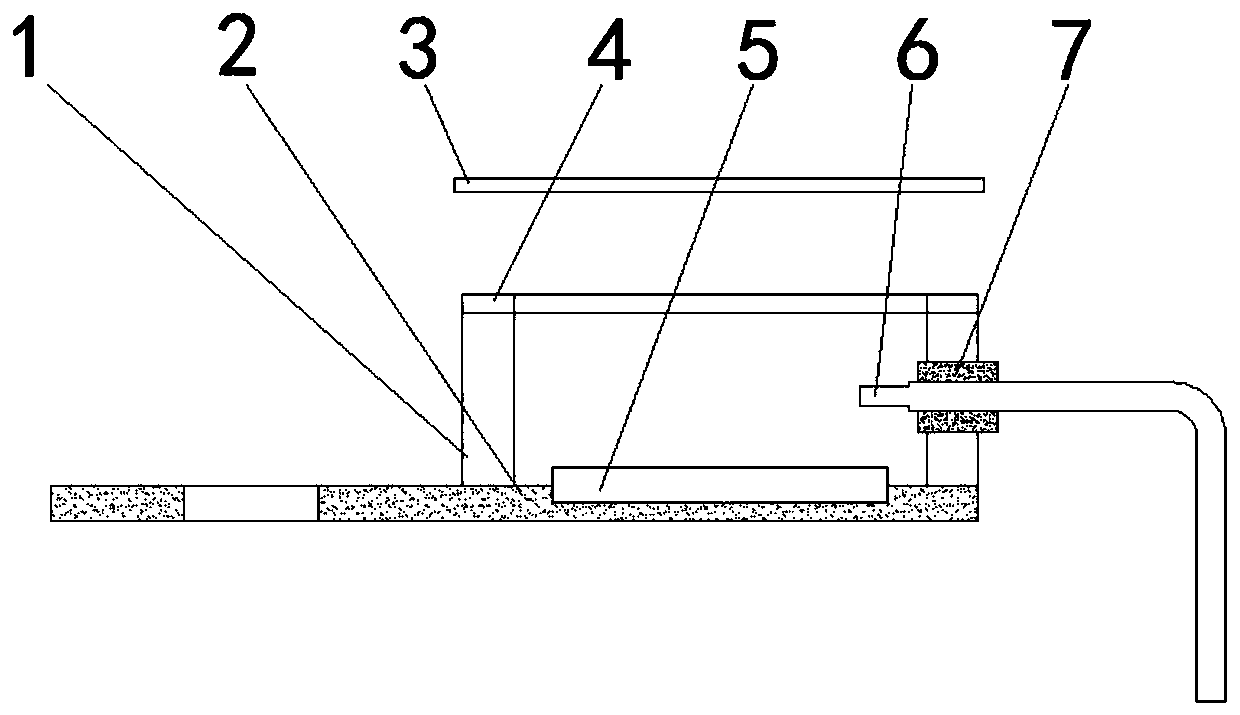

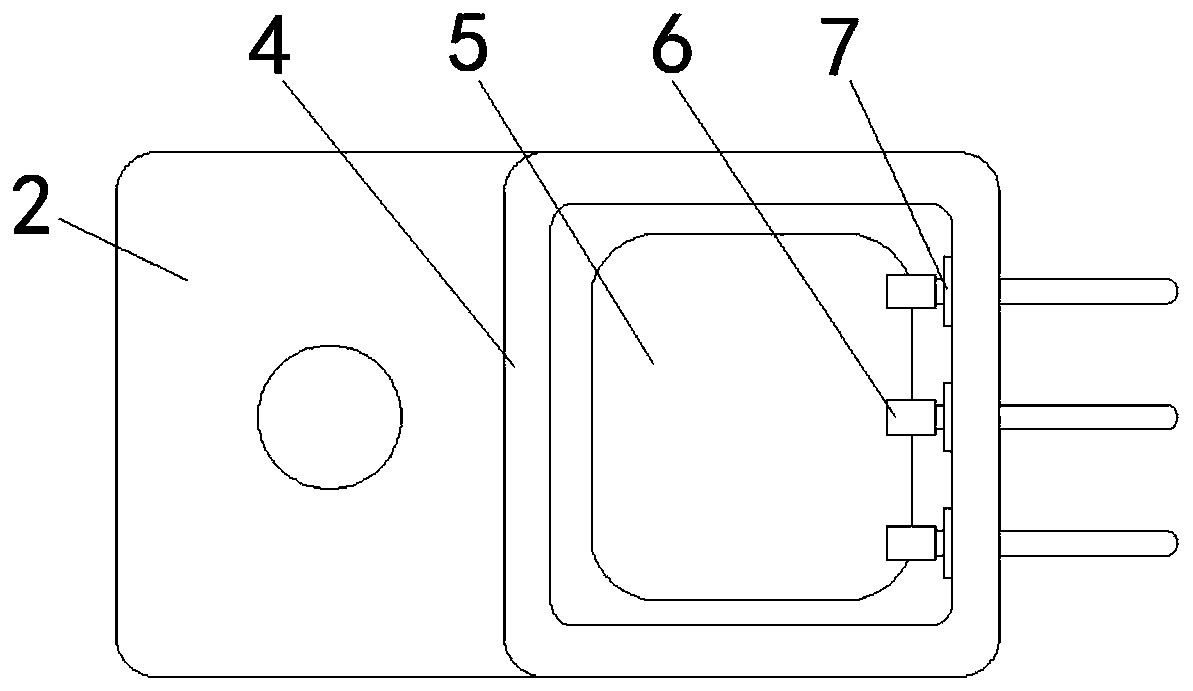

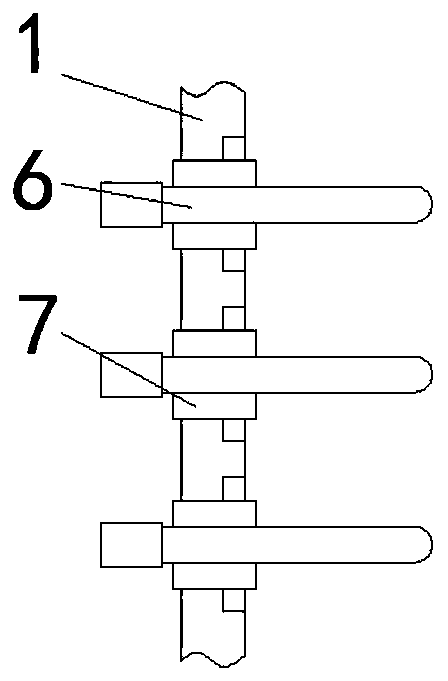

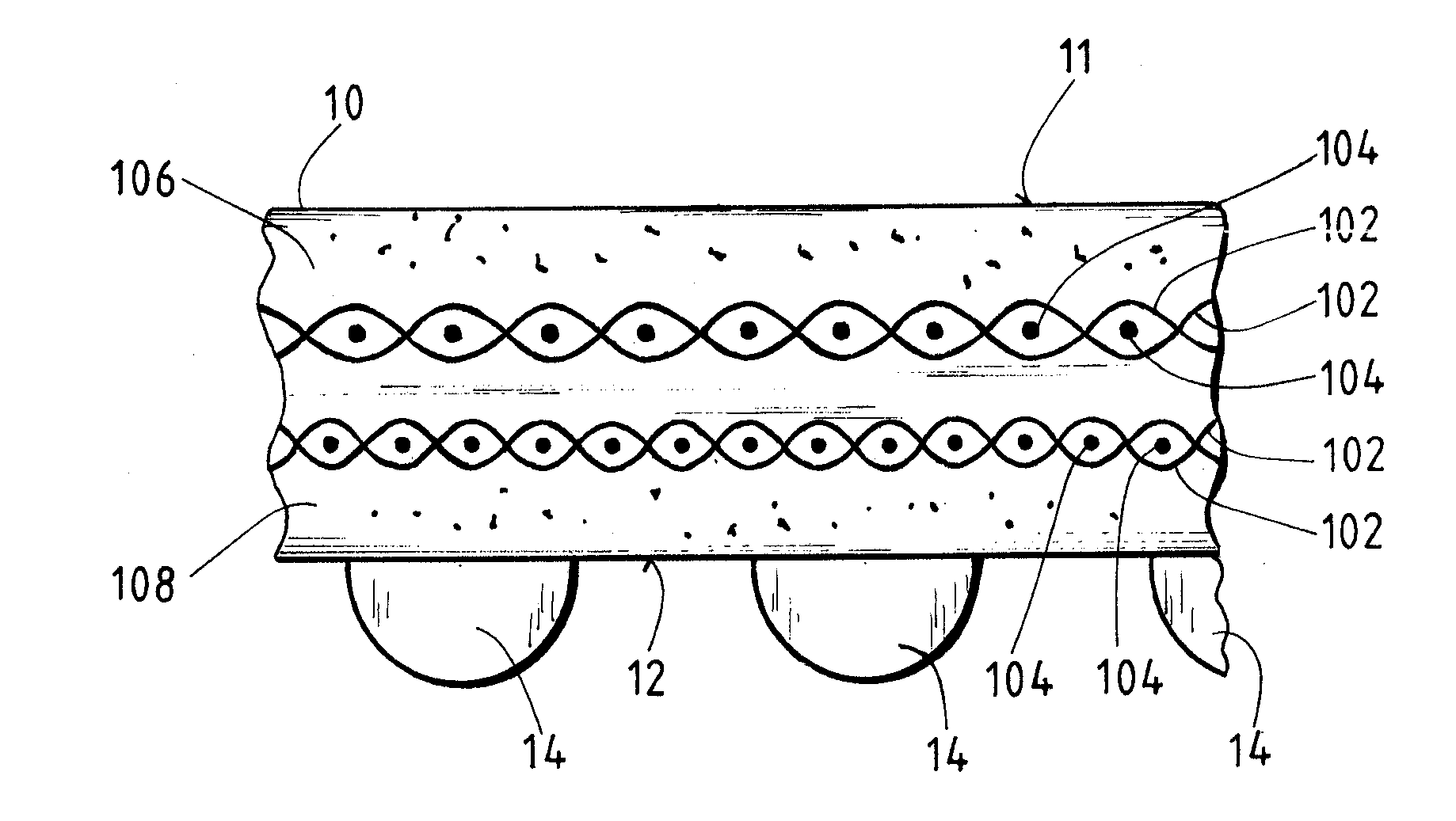

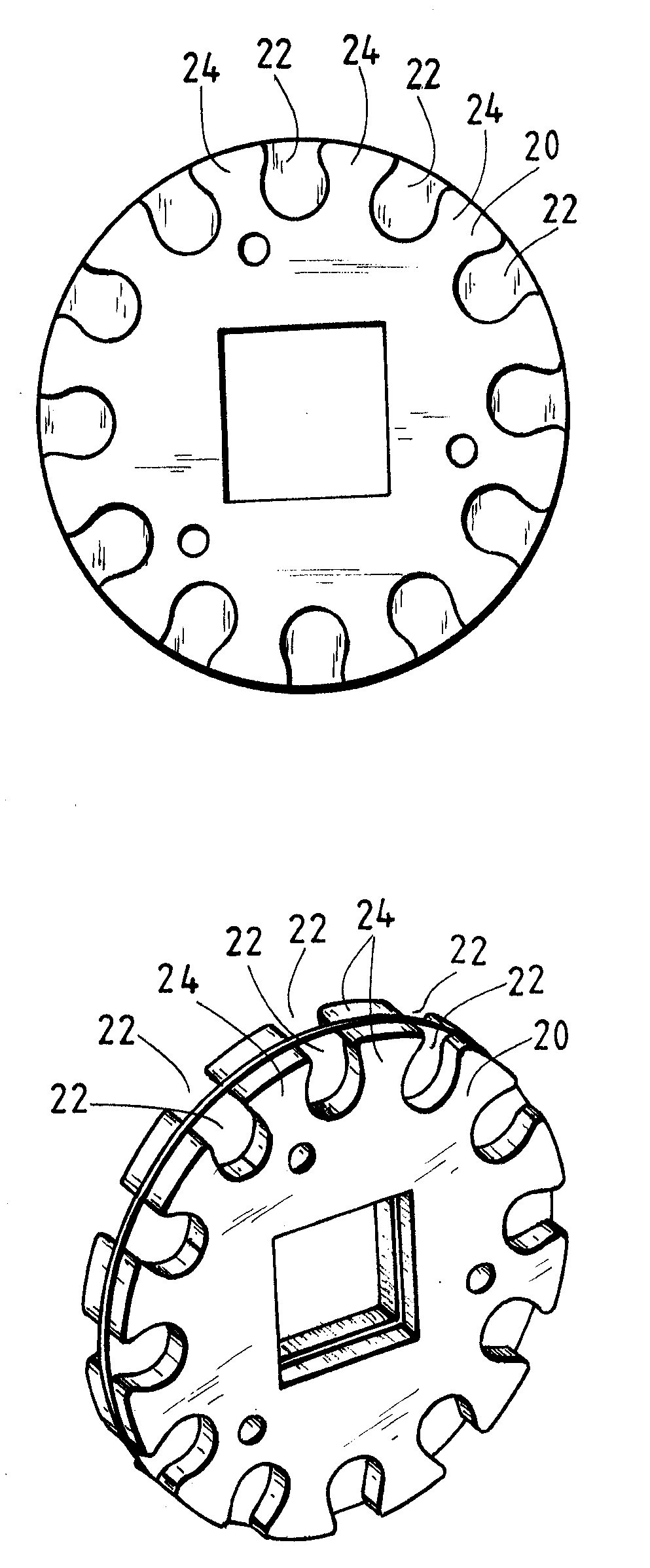

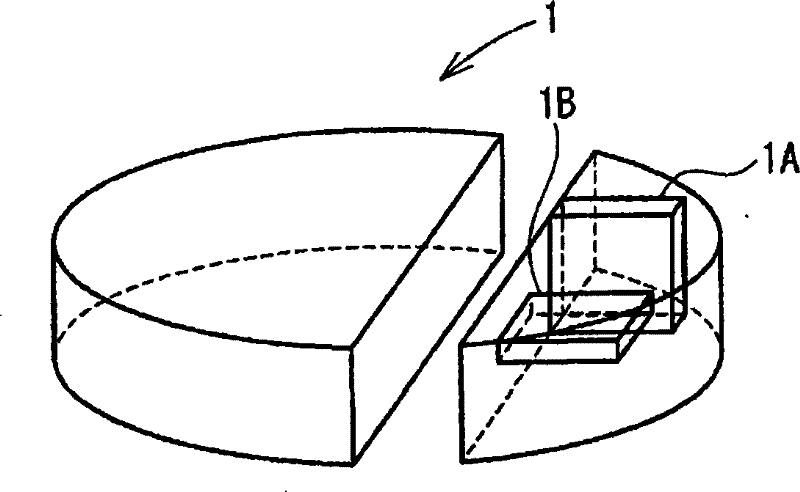

Conveying equipment for tobacco materials

InactiveCN102583006AIncrease conveying widthLow expansion propertiesConveyorsCigarette manufactureBearing surfaceEquipment use

The present invention relates to a conveyer (10) which is applied to conveying equipment (F) in tobacco processing industry and used for conveying tobacco materials. The conveyer (10) is characterized in that: the conveyer (10) is designed into a fabric strip (10) having warps (102) and wefts (104), wherein the fabric strip (10) has an inner side operating surface (12) and an outer side bearing surface (11) used for receiving the tobacco materials to be conveyed, wherein the inner side operating surface (12) is provided with a projection (14) which is engaged with a projection containing part (22) of a conveying wheel (20). In addition, the present invention also relates to a transmission gear of the conveyer (10) used for conveying the tobacco materials, the conveying equipment used for conveying the tobacco materials in the tobacco processing industry, and a method used for manufacturing the conveyer (10) which is applied to the conveying equipment in the tobacco processing industry and used for conveying the tobacco materials.

Owner:HAUNI MASCHINENBAU AG

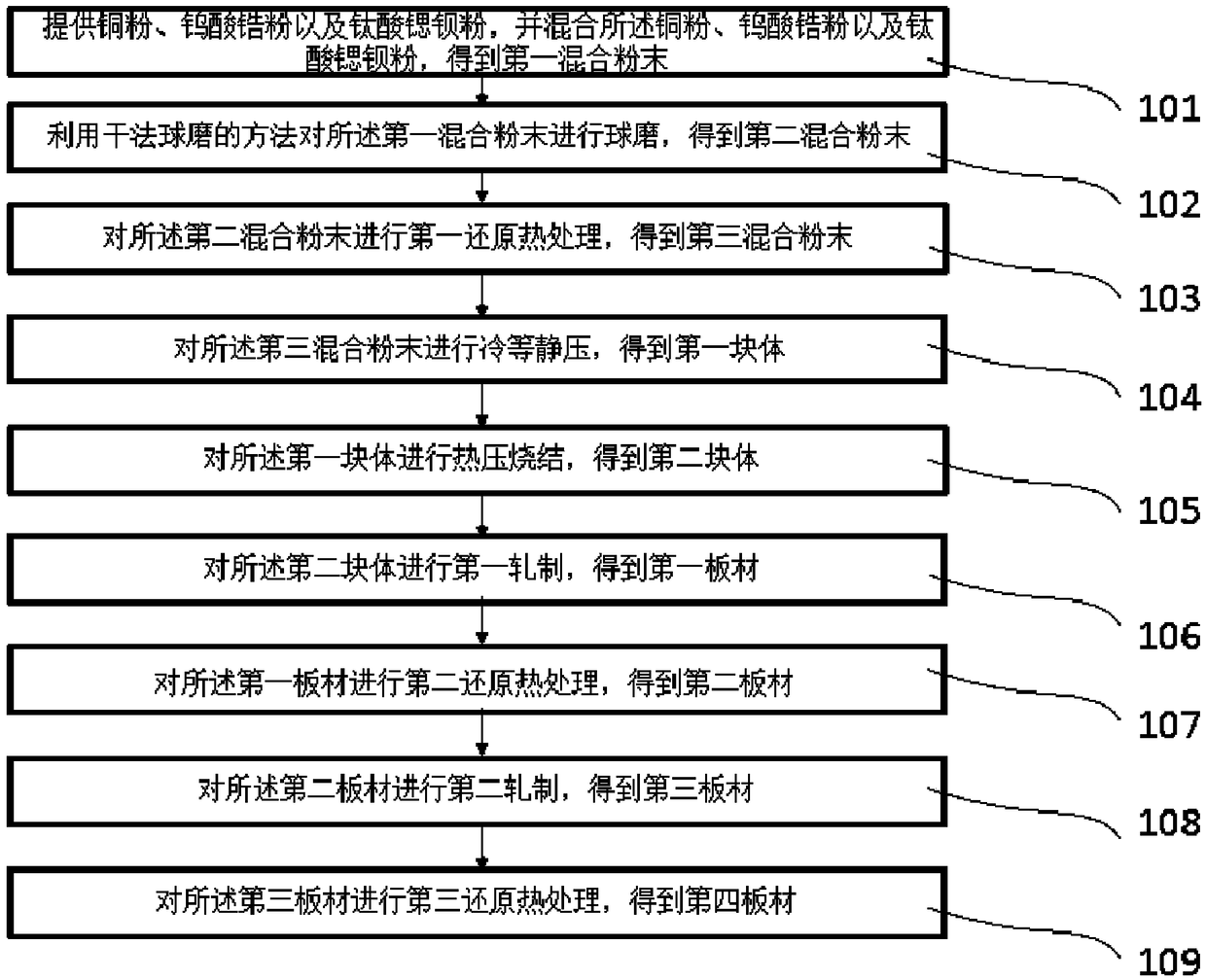

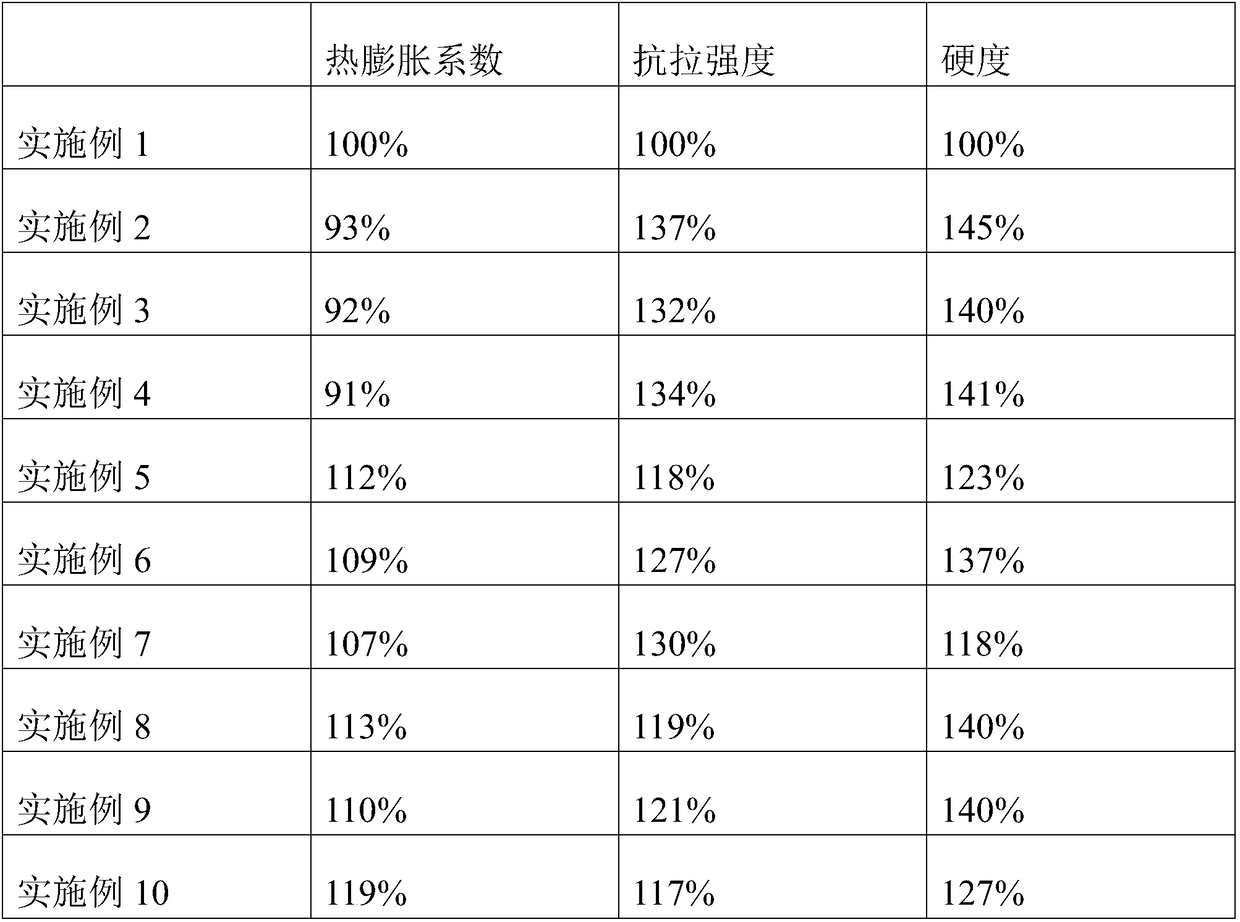

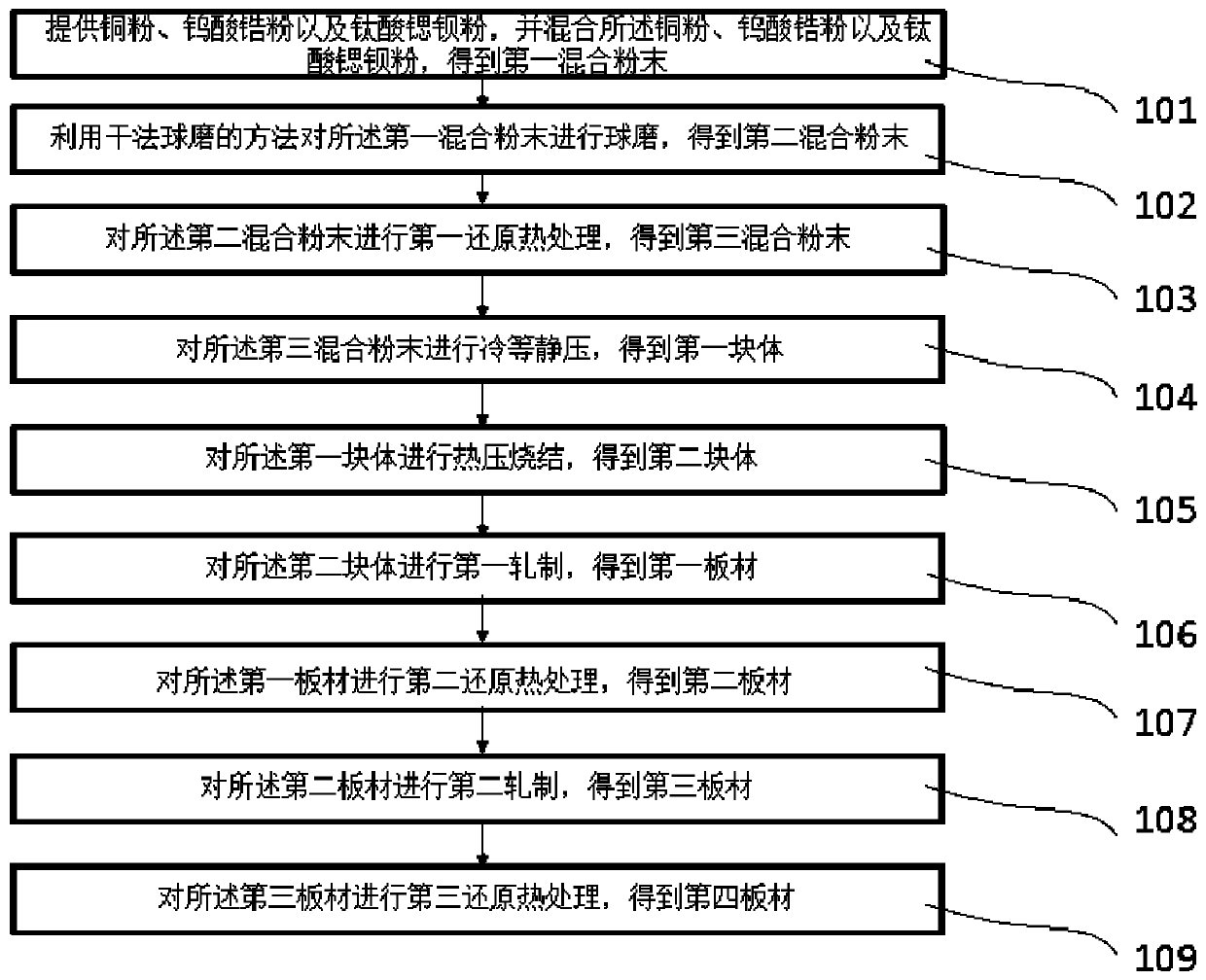

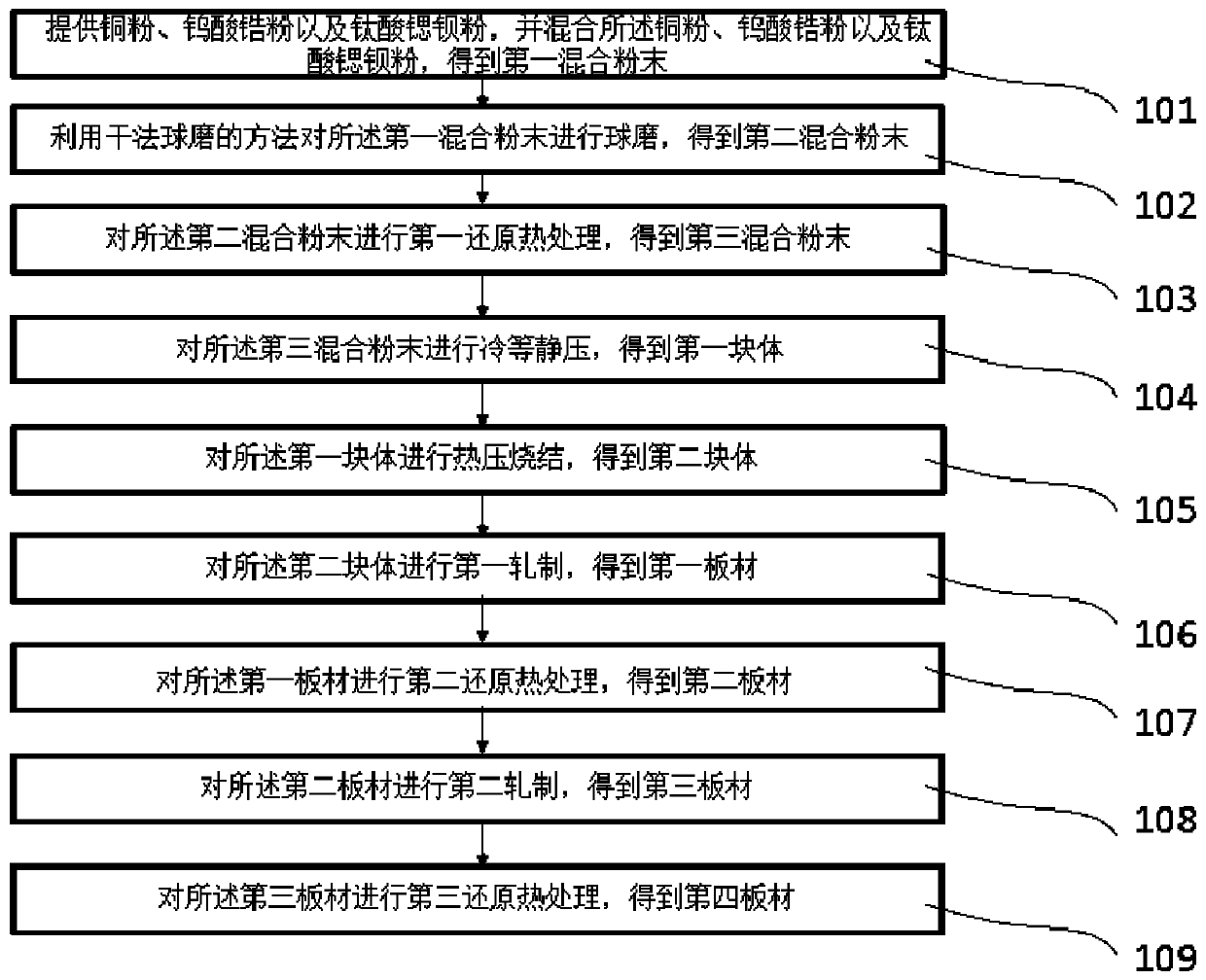

Copper-based composite and preparation method thereof

ActiveCN108103350AHigh tensile strengthHigh hardnessTransportation and packagingMetal-working apparatusStrontiumOxygen content

The invention provides a preparation method of a copper-based composite. The preparation method comprises the steps as follows: copper powder, zirconium tungstate powder and barium strontium titanatepowder are provided and mixed, and first mixed powder is obtained; the first mixed powder is subjected to ball milling with a dry ball milling method, and second mixed powder is obtained; the second mixed powder is subjected to first reduction heat treatment, and third mixed powder is obtained; the third mixed powder is subjected to cold isostatic pressing, and a first block is obtained; the firstblock is subjected to hot press sintering, and a second block is obtained; the second block is rolled. The dry powder mixing process is used, so that the powder mixing efficiency and powder mixing effect are improved. The reduction process is designed specially, so that powder oxidized in the powder mixing process can be accurately reduced to the original state while oxide powder cannot be reduced and the oxygen content in oxide cannot deviate from the ideal value. The common hot press sintering method is used, the technology is simple and mature, and the cost is low.

Owner:国工恒昌新材料(义乌)有限公司

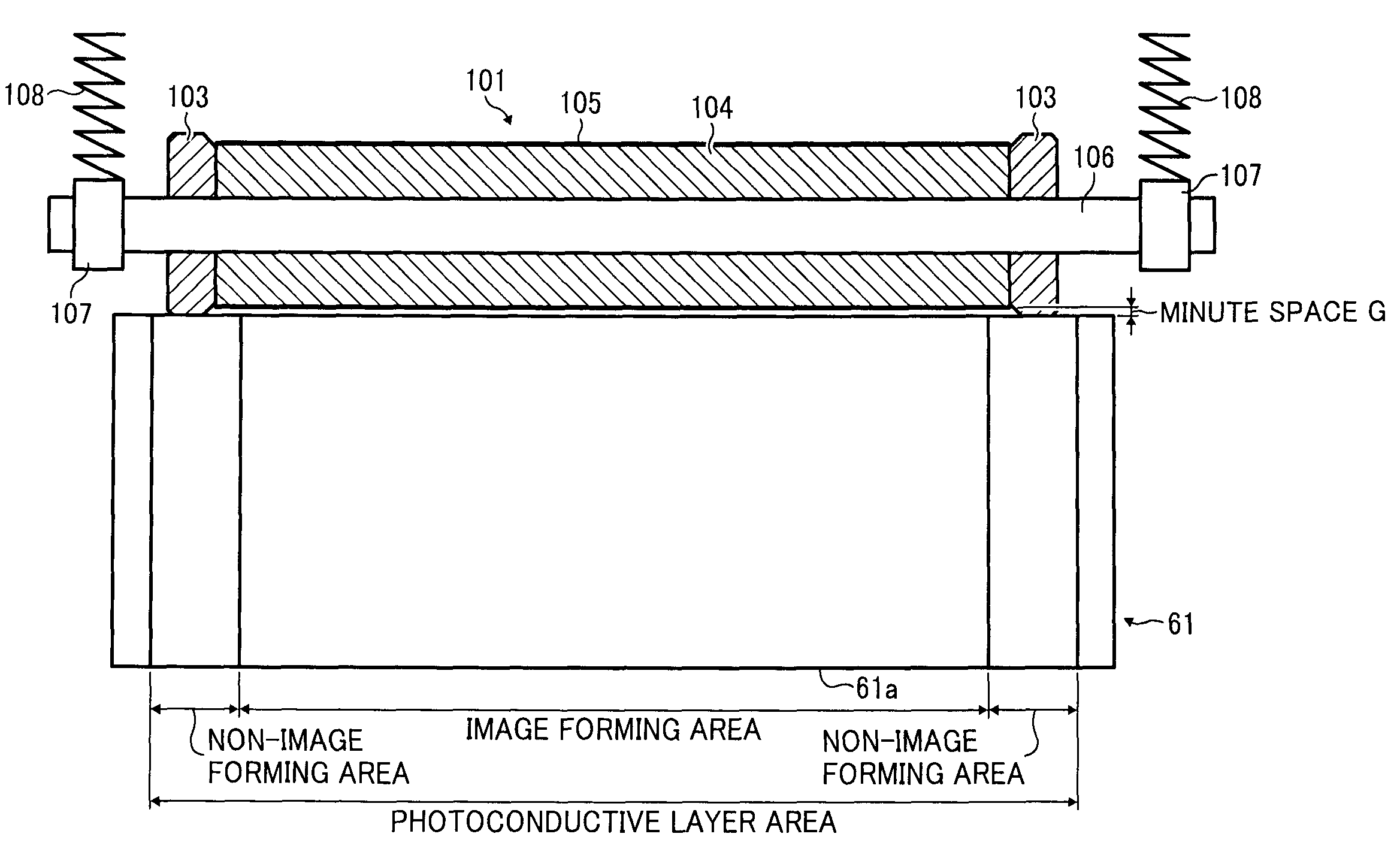

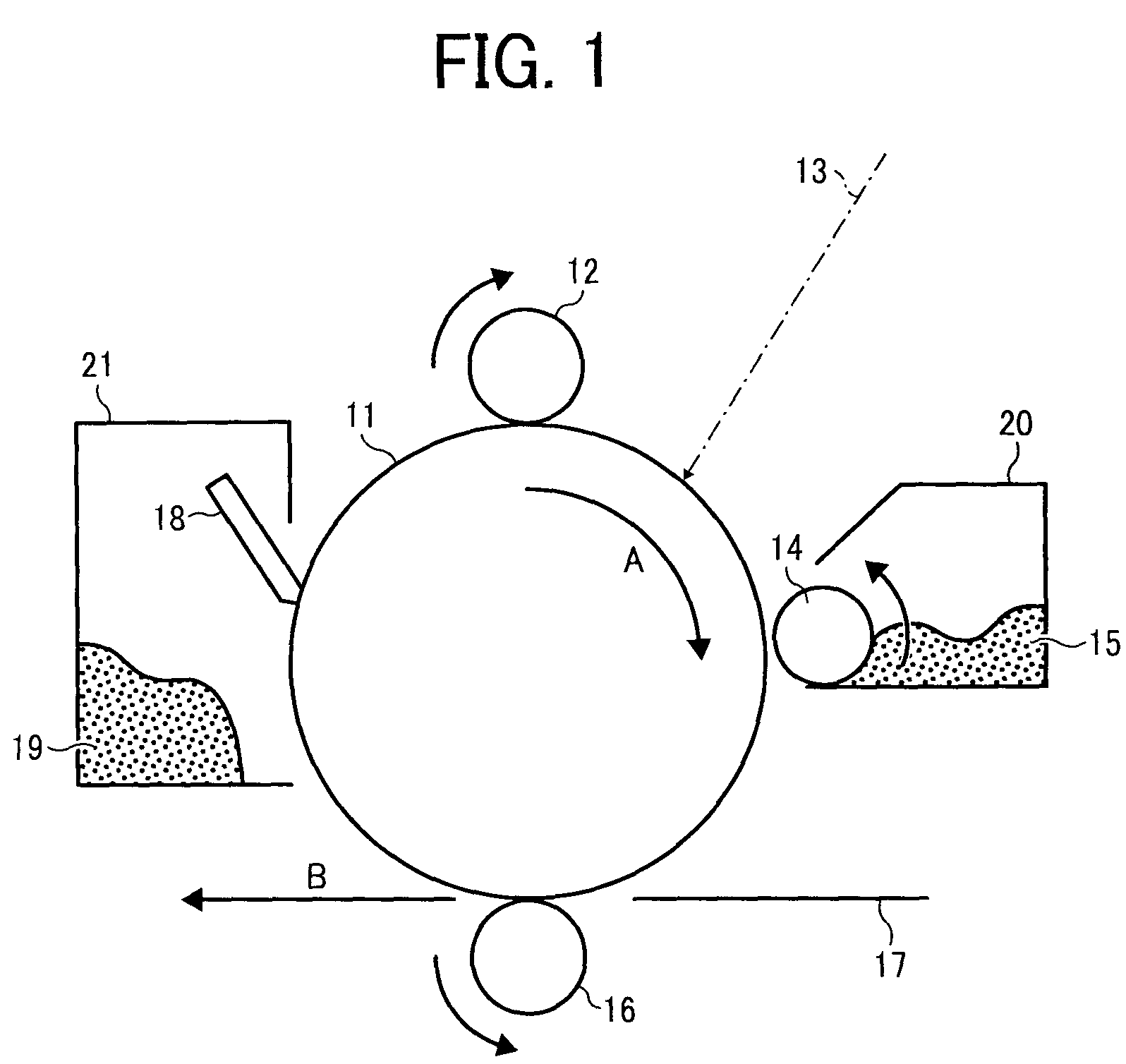

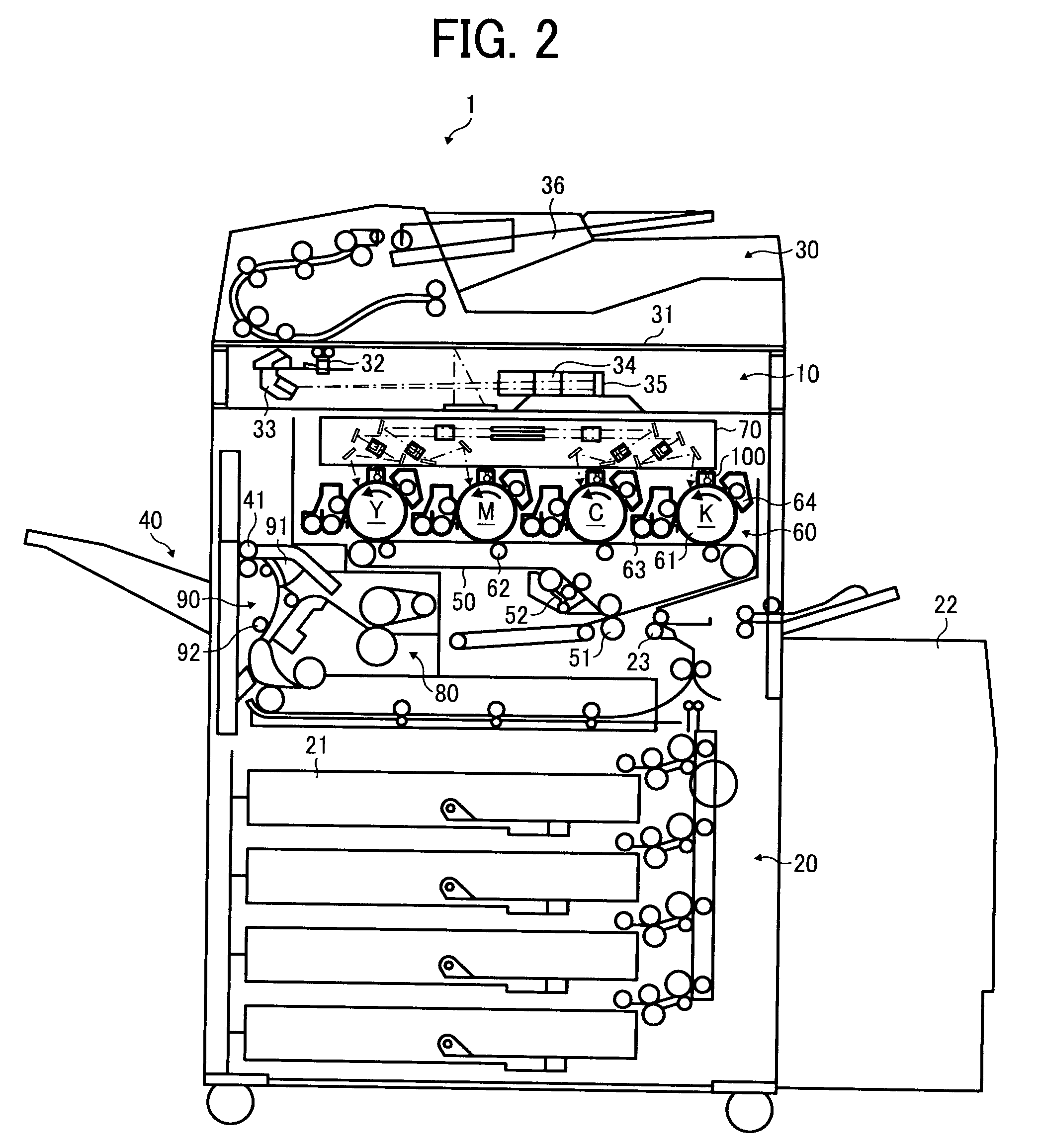

Conductive member, process cartridge using the conductive member, and image forming device using the process cartridge

InactiveUS8064804B2Improve the immunityImprove suppression propertiesElectrographic process apparatusCorona dischargeElectrical resistance and conductancePolymer science

A conductive member includes, a conductive supporting body, an electric resistance-adjusting layer formed in the conductive supporting body, and a space holding member which is formed on each end of the electric resistance-adjusting layer and has a material different from a material of the electric resistance-adjusting layer, the space holding member constantly maintaining a space between an image carrier and the electric resistance-adjusting layer, and the electric resistance-adjusting layer including a resin composition having a thermoplastic resin (A) containing at least an ether group, a fibrous polymer (B), which do not melt in (A) and has an aromatic skeleton in a molecule, and an electrolyte salt (C).

Owner:RICOH KK

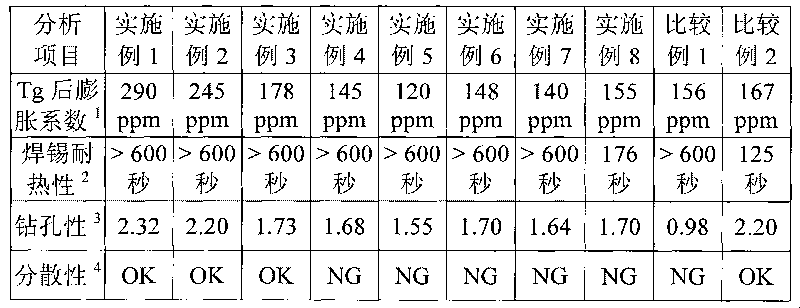

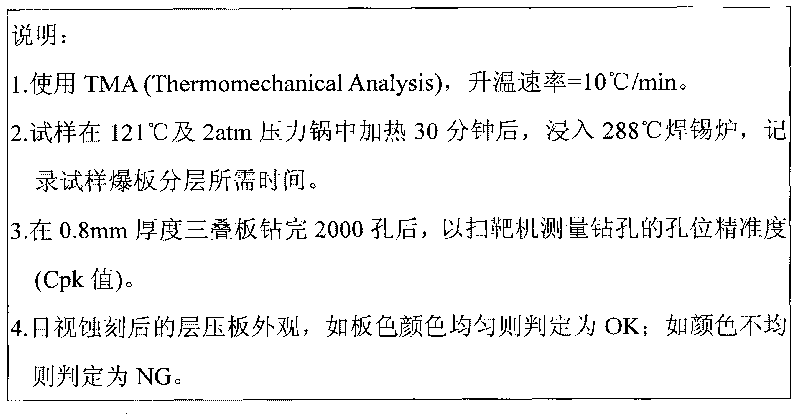

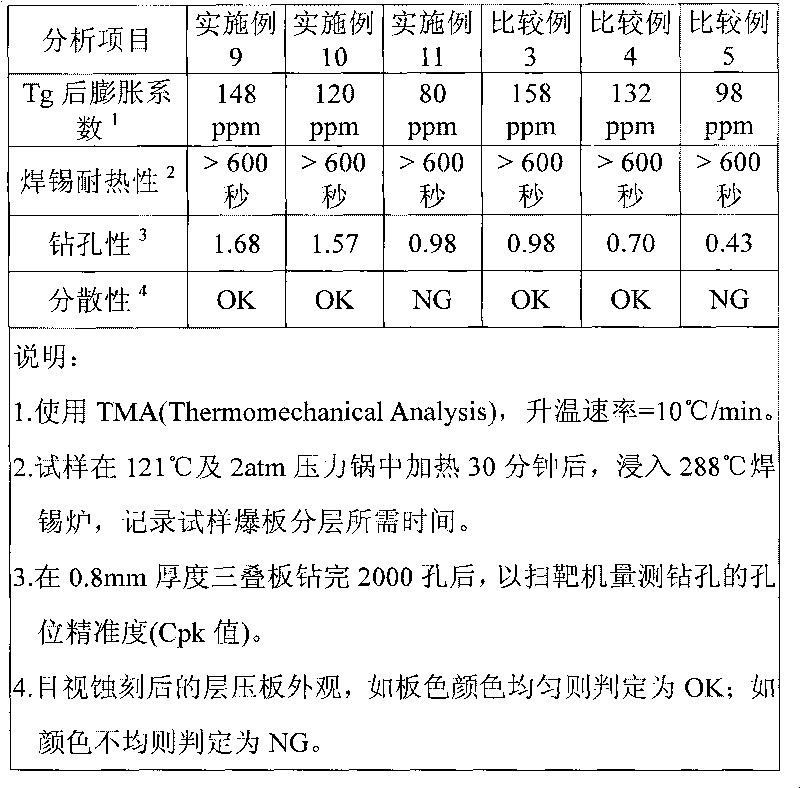

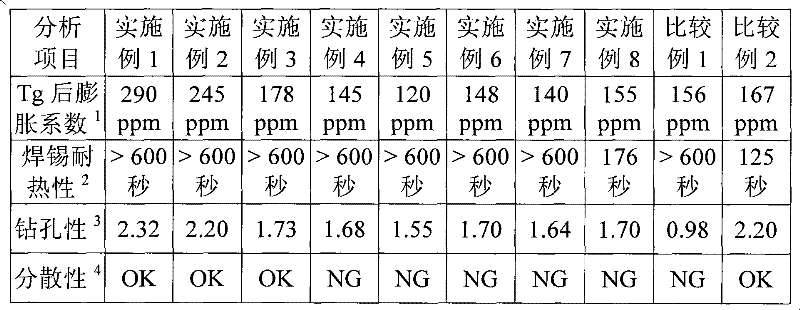

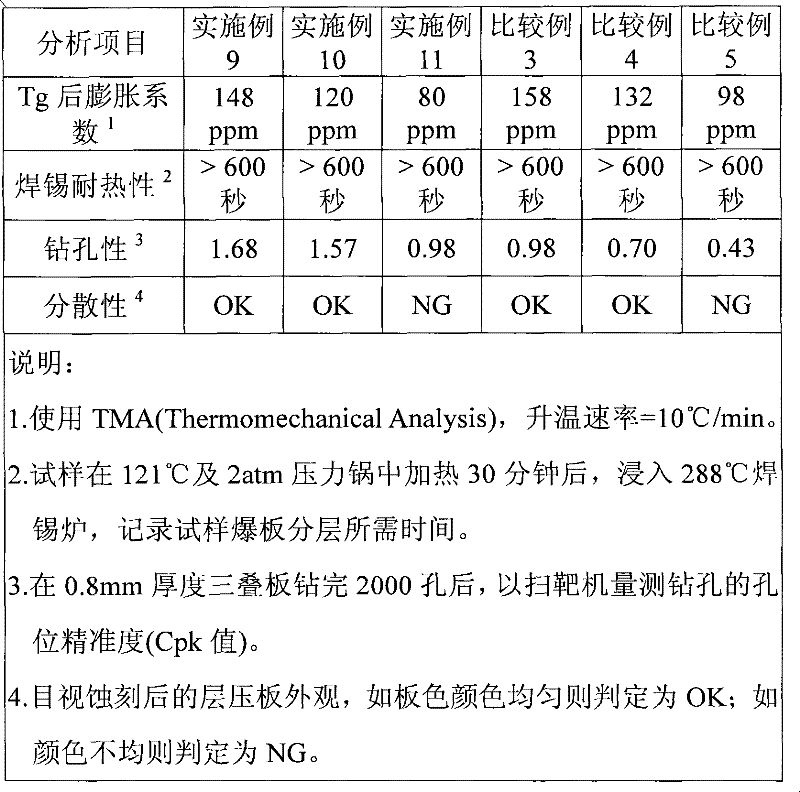

Thermosetting epoxy resin composition

The invention discloses a thermosetting epoxy resin composition, which contains modified silicon dioxide and therefore can be used in the preparation of epoxy resin laminated boards with a low expansion coefficient property and excellent drilling processability. The modified silicon dioxide does not contain crystal water, has a low expansion coefficient property and comprises 40 to 80 weight percent of silicon dioxide and 60 to 20 percent of inorganic additive. And the modified silicon dioxide is prepared by sintering and melting at a high temperature above 1,000 DEG C and crushing.

Owner:NANYA PLASTICS CORP

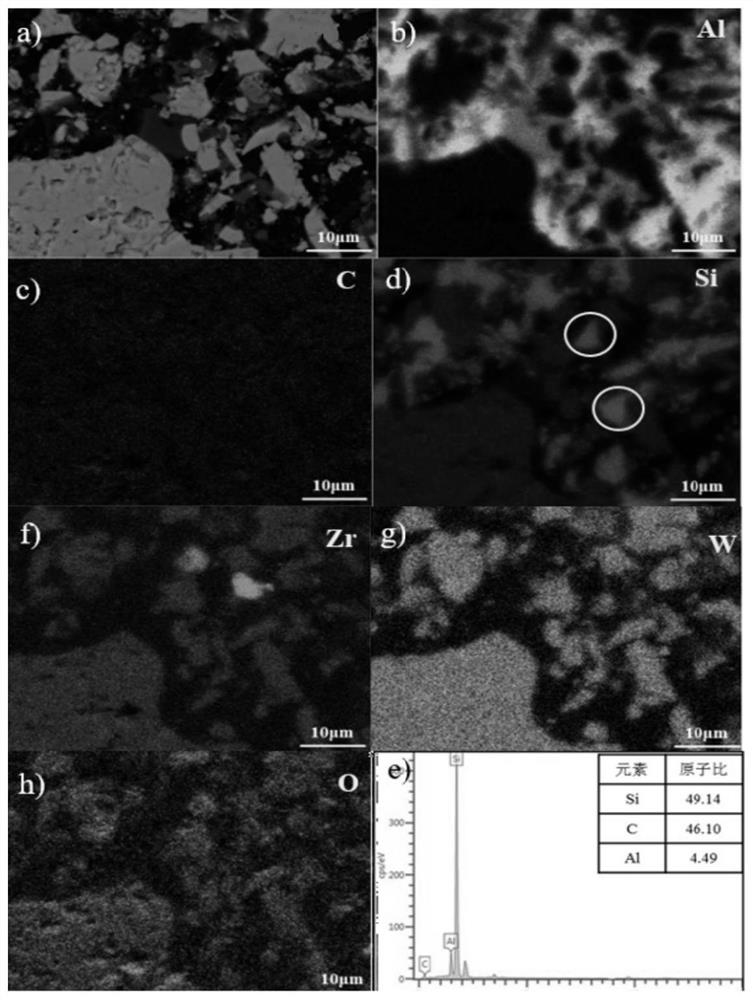

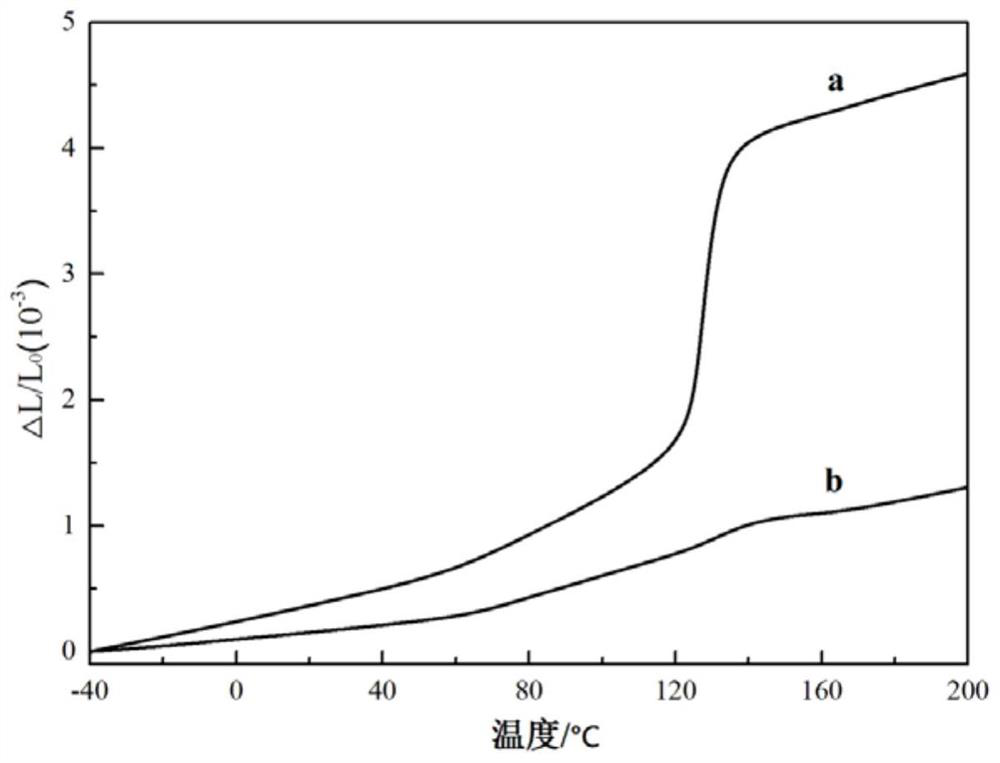

Preparation method of zirconium tungstate-containing aluminum-based composite material with high comprehensive performance

The invention discloses a preparation method of a zirconium tungstate-containing aluminum-based composite material with high comprehensive performance, and relates to a preparation method of a ZrW2O8 aluminum-based composite material. The problems that an existing ZrW2O8 / Al composite material is low in strength, and the thermal expansion coefficient of the composite material is large due to the fact that the content of gamma-ZrW2O8 is too high are solved. The method comprises the following steps: weighing ZrW2O8 powder, high-strength ceramic powder and an aluminum matrix as raw materials; the preparation method comprises the following steps: mixing high-strength ceramic powder and ZrW2O8 powder, carrying out ball milling, pre-pressing to obtain a reinforcement preform, preheating, preparing a molten metal matrix, carrying out liquid aluminum infiltration, and carrying out annealing treatment on the composite material. The volume fraction of a reinforcement is increased by adopting a mixing ratio of various particle sizes, internal stress is reduced through stress relief annealing treatment, so that the thermal expansion coefficient of the composite material is reduced, and the comprehensive performance of the composite material is improved.

Owner:HARBIN INST OF TECH

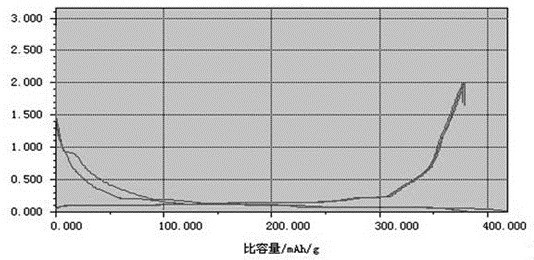

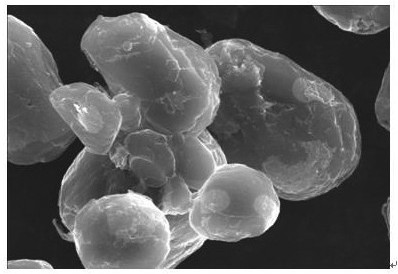

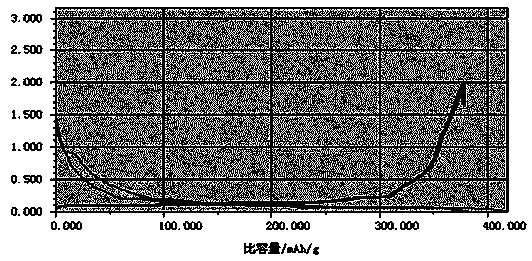

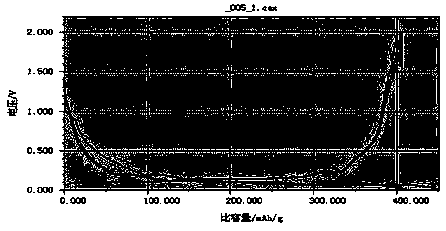

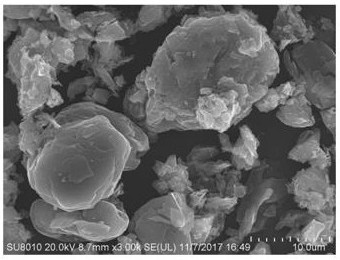

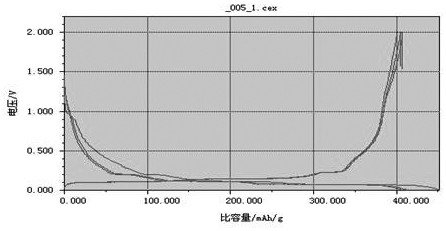

A kind of method for preparing tin-carbon lithium ion negative electrode material

ActiveCN108493437BLow expansion propertiesGranulation realizationCell electrodesTin dioxideCopper oxide

The invention discloses a method for preparing a cathode material of tin-carbon lithium ion cathode material. The method comprises the following steps: (1) performing doping modification on tin dioxide, namely weighing certain amounts of nano tin dioxide and red copper oxide in a ratio of 100:(10-50), performing dry-method ball milling for 1 hour; and performing carbon heat reduction in an atmosphere furnace; (2) performing composite pelletizing on a tin dioxide modification product with graphite; (3) performing secondary wrapping modification. According to the method, as the tin dioxide is subjected to doping modification with the red copper oxide, the expansion property of a tin-carbon compound can be degraded, and the circulation property can be improved; due to two times of pelletization with processes of molding, roasting and dispersion formation, the method is short in time, simple in process and easy in industrial large-scale production; meanwhile, advantages of pelletization oftin dioxide and graphite and graphite and graphite can be achieved, and a function of surface modification upon the graphite with the tin dioxide can be also achieved; due to two times of coating, surface defects caused in the two times of pelletization process can be remarkably alleviated, and the first efficiency and the circulation property of a product can be improved.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

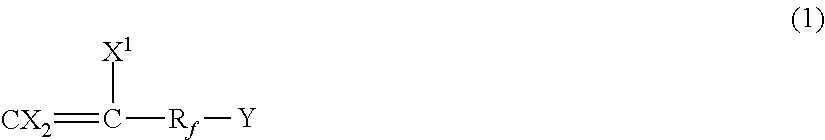

Electrode mixture

ActiveUS9444103B2Improve adhesionGood swelling propertiesNon-aqueous electrolyte accumulator electrodesTetrafluoroethyleneOrganic solvent

The present invention aims to provide an electrode mixture which shows little change in viscosity even after 24 hours from the preparation of the mixture and enables production of an electrode having a high electrode density and excellent flexibility and is capable of giving excellent electric properties to the resulting cell. The present invention relates to an electrode mixture including a powdery electrode material; a binder; and an organic solvent, the binder including polyvinylidene fluoride and a fluorine-containing polymer including a polymer unit based on vinylidene fluoride and a polymer unit based on tetrafluoroethylene, the fluorine-containing polymer including the polymer unit based on vinylidene fluoride in an amount of 80.0 to 90.0 mol % based on all the polymer units, the polyvinylidene fluoride having a number average molecular weight of 150,000 to 1,400,000.

Owner:DAIKIN IND LTD

Method for preparing cathode material of tin-carbon lithium ion cathode material

ActiveCN108493437ALow expansion propertiesImprove cycle performanceCell electrodesPelletizingSurface modification

The invention discloses a method for preparing a cathode material of tin-carbon lithium ion cathode material. The method comprises the following steps: (1) performing doping modification on tin dioxide, namely weighing certain amounts of nano tin dioxide and red copper oxide in a ratio of 100:(10-50), performing dry-method ball milling for 1 hour; and performing carbon heat reduction in an atmosphere furnace; (2) performing composite pelletizing on a tin dioxide modification product with graphite; (3) performing secondary wrapping modification. According to the method, as the tin dioxide is subjected to doping modification with the red copper oxide, the expansion property of a tin-carbon compound can be degraded, and the circulation property can be improved; due to two times of pelletization with processes of molding, roasting and dispersion formation, the method is short in time, simple in process and easy in industrial large-scale production; meanwhile, advantages of pelletization oftin dioxide and graphite and graphite and graphite can be achieved, and a function of surface modification upon the graphite with the tin dioxide can be also achieved; due to two times of coating, surface defects caused in the two times of pelletization process can be remarkably alleviated, and the first efficiency and the circulation property of a product can be improved.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

Method for preparing copper-antimony-doped tin-carbon-lithium ion cathode material

ActiveCN108807873ALow expansion propertiesGranulation realizationCell electrodesSecondary cellsTin dioxideGraphite

The invention discloses a method for preparing a copper-antimony-doped tin-carbon-lithium ion cathode material. The method comprises the following steps: (1) carrying out doping modification on tin dioxide, namely weighing certain amounts of tin dioxide, copper and antimony, and carrying out dry-method ball-milling mixing for 0.5-1.5 hours in a ratio of 100:(5-20):(5-20); (2) carrying out composite pelletizing on a tin dioxide modified product and graphite; (3) carrying out secondary coating modification. By adopting the method, copper and antimony are adopted to carry out doping modificationon the tin dioxide, so that the expansion properties of a tin-carbon compound can be degraded, and circulation properties can be improved; secondary pelletizing is carried out through isostatic compaction, roasting and dispersion shaping processes, and the method is short in time, simple in process and easy in industrial large-scale production; meanwhile, the advantage of pelletizing of tin dioxide and graphite and graphite and graphite can be taken into play, and a function that surface modification of the graphite with the tin dioxide can be also achieved; due to two times of coating, surface defects caused in a secondary pelletizing process can be remarkably alleviated, and the first-time frequency and the circulation properties of a product can be improved.

Owner:SHENZHEN XIANGFENGHUA TECH CO LTD +1

Fiber-reinforced composite resin composition, and adhesive and sealing agent

InactiveCN101297000BHigh transparencyLow coefficient of linear thermal expansionCellulose adhesivesAdhesiveTransmittance

Disclosed is a fiber-reinforced composite resin composition which can be used as a sealing agent, an adhesive or a filler, specifically a fiber-reinforced composite resin composition which has low thermal expansion, high strength light weight and high thermal conductivity at such levels that have been required recently, particularly which has a high isotropic thermal conductivity at a satisfactory level. The composition comprises a fiber having an average fiber diameter of 4 to 200 nm. When the composition is cured in a plate-like shape, the cured product has a total light transmittance of 70% or higher per 50 [mu]m thickness as measured at an wavelength of 400 to 700 nm and thermal conductivities both in a thickness-wise direction and a plane-wise direction of 0.4 W / m. K or higher. In the cured product, the fiber is oriented randomly.

Owner:ROHM CO LTD +2

Composite ceramic material for LED energy-saving lamp base

InactiveCN104557051BExtend working lifeImprove thermal conductivityComposite ceramicSemiconductor chip

The invention discloses a composite ceramic material for an LED energy-saving lamp base. The composite ceramic material is calcined from such components as 12-15 parts of nano-zinc oxide, 5-10 parts of silicon dioxide, 6-8 parts of magnesium carbonate, 80-100 parts of active kaolin, 15-18 parts of magnesium oxide, 10-12 parts of titanium dioxide, 100-120 parts of silicon nitride, 50-60 parts of silicon carbide and 3-5 parts of magnesium nitride. The composite ceramic material for the LED energy-saving lamp base has the characteristics of high thermal conductivity and low expansion; the formed composite ceramic material is improved in thermal conductivity, reduced in thermal expansion and enhanced in heat dissipation capability to the environment; as a result, the working temperature of an LED semiconductor chip can be reduced, the luminous efficiency of the same can be improved; the structural stress of the LED semiconductor chip and the base is reduced and the working service life of the LED energy-saving lamp is prolonged.

Owner:GUANGDONG HHH OPTOELECTRONICS TECH CO LTD

Thermosetting epoxy resin composition

The invention discloses a thermosetting epoxy resin composition, which contains modified silicon dioxide and therefore can be used in the preparation of epoxy resin laminated boards with a low expansion coefficient property and excellent drilling processability. The modified silicon dioxide does not contain crystal water, has a low expansion coefficient property and comprises 40 to 80 weight percent of silicon dioxide and 60 to 20 percent of inorganic additive. And the modified silicon dioxide is prepared by sintering and melting at a high temperature above 1,000 DEG C and crushing.

Owner:NANYA PLASTICS CORP

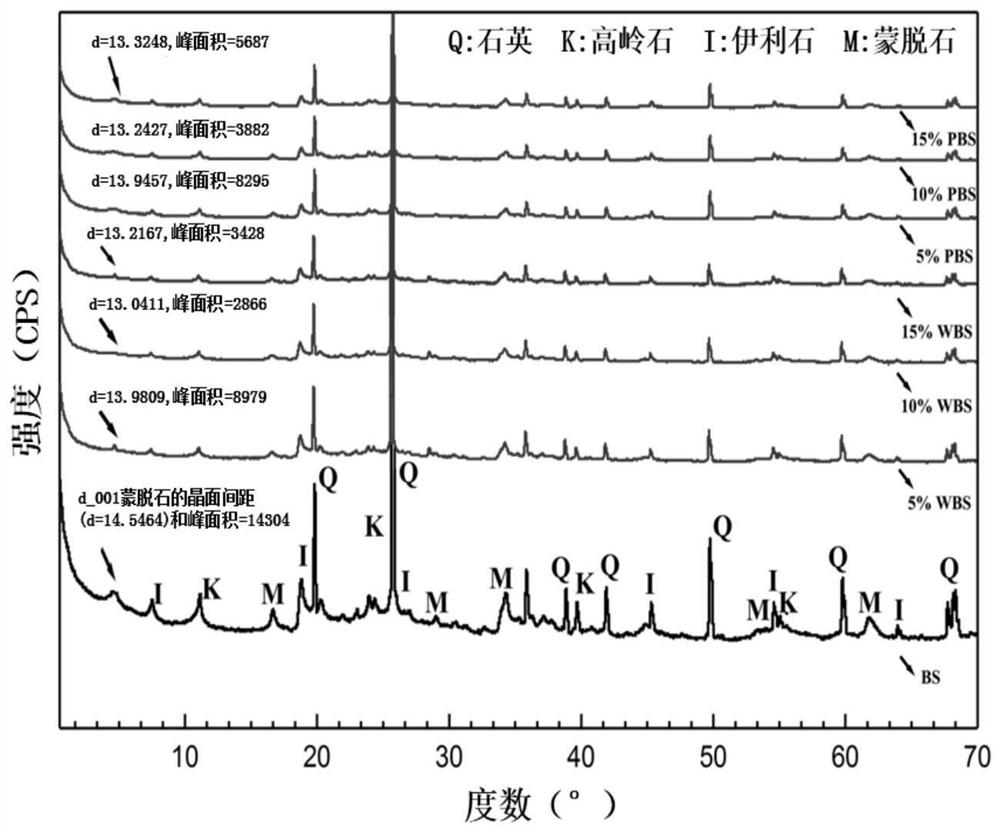

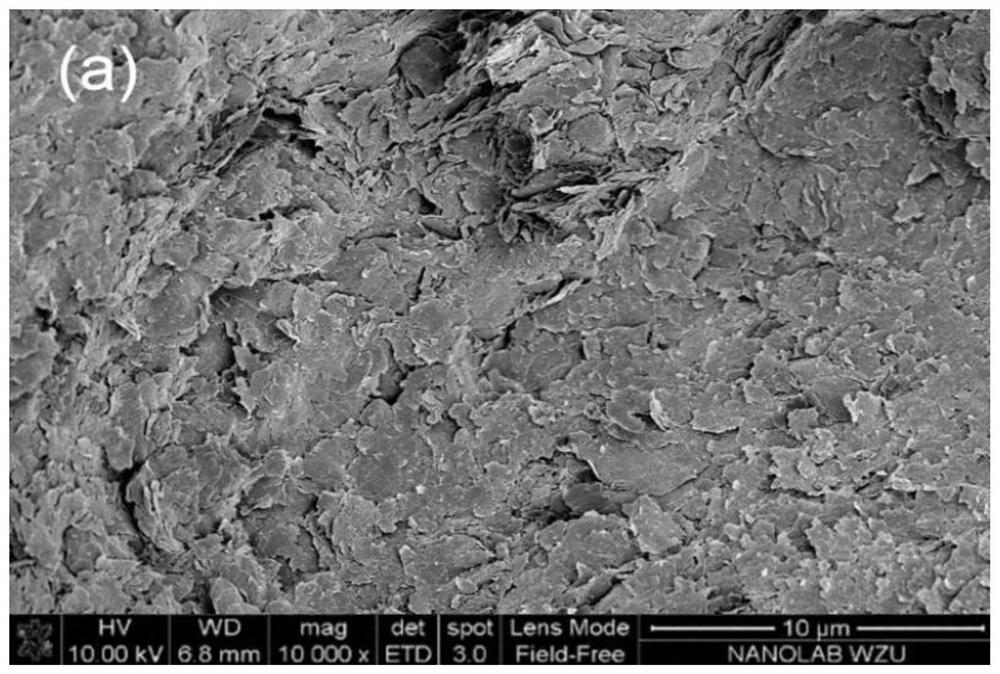

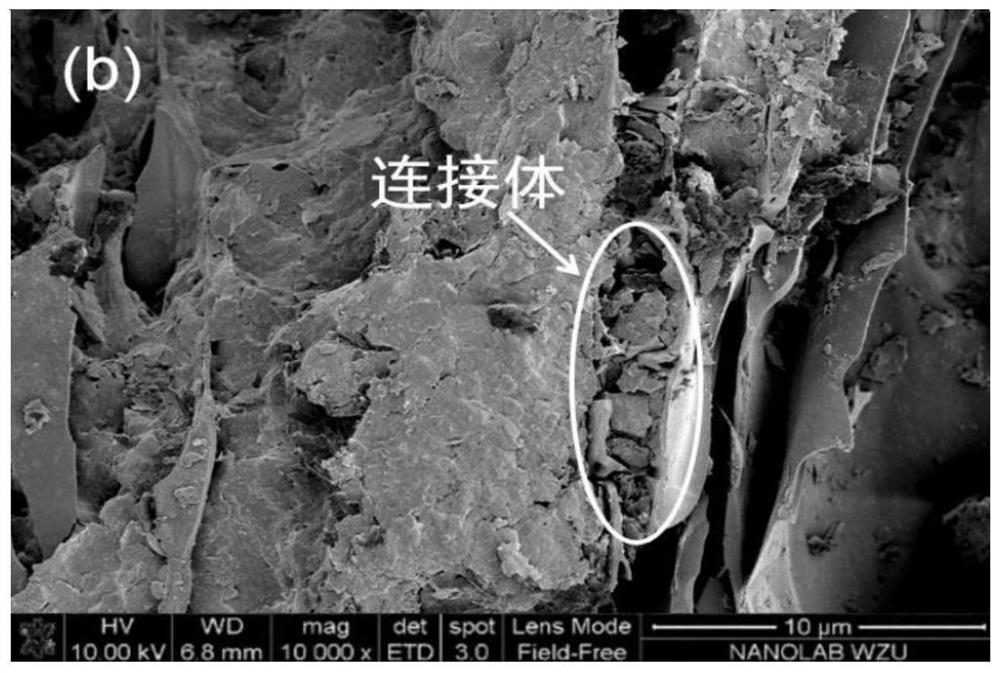

Expansive soil improver, improved expansive soil and preparation method

InactiveCN113773842AMaterials are readily availableLow costBuilding constructionsOrganic fertilisersSoil scienceEnvironmental engineering

The invention provides an expansive soil improver. The expansive soil improver comprises 5-15% of biochar based on the total weight of dry expansive soil to be improved by the expansive soil improver, and the biochar is any one of wood chip biochar or pig manure biochar. The invention also provides a preparation method of the expansive soil improver. The method comprises the following steps of: pyrolyzing the biochar for two hours at the temperature of 400 DEG C under an anoxic condition; hammering the pyrolyzed biochar; sieving the pyrolyzed biochar by a 2mm sieve; and placing the biochar in a drying oven at the temperature of 105 DEG C for more than 15 hours. The invention also provides improved expansive soil and a preparation method thereof. The improved expansive soil is prepared by mixing the following raw materials in parts by weight: 100 parts of dry expansive soil to be improved; 5-15 parts of expansive soil improver; and a plurality of parts of deionized water. The expansive soil improver disclosed by the invention has the advantages of easily available materials, low cost, environmental friendliness, easiness in mixing and the like; and the improved expansive soil obtained according to the expansive soil improver is good in mechanical and engineering performance, and the expansion and shrinkage rate is inhibited.

Owner:GUANGXI UNIV

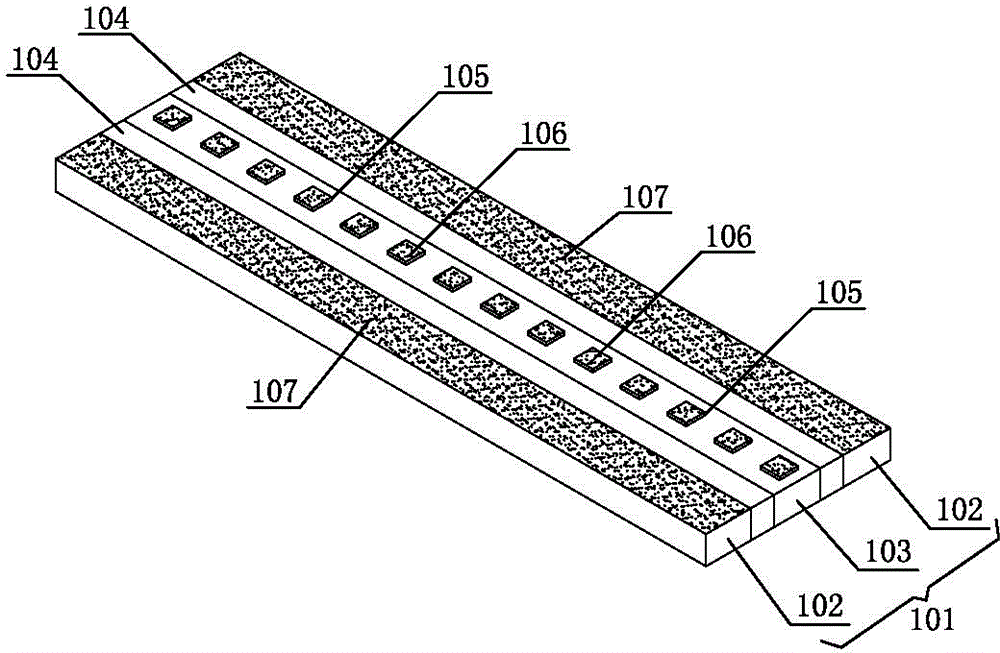

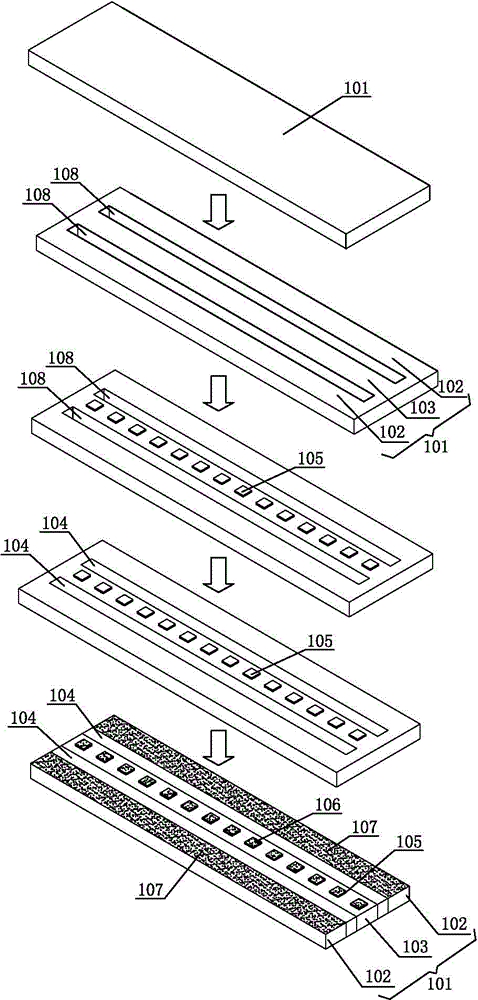

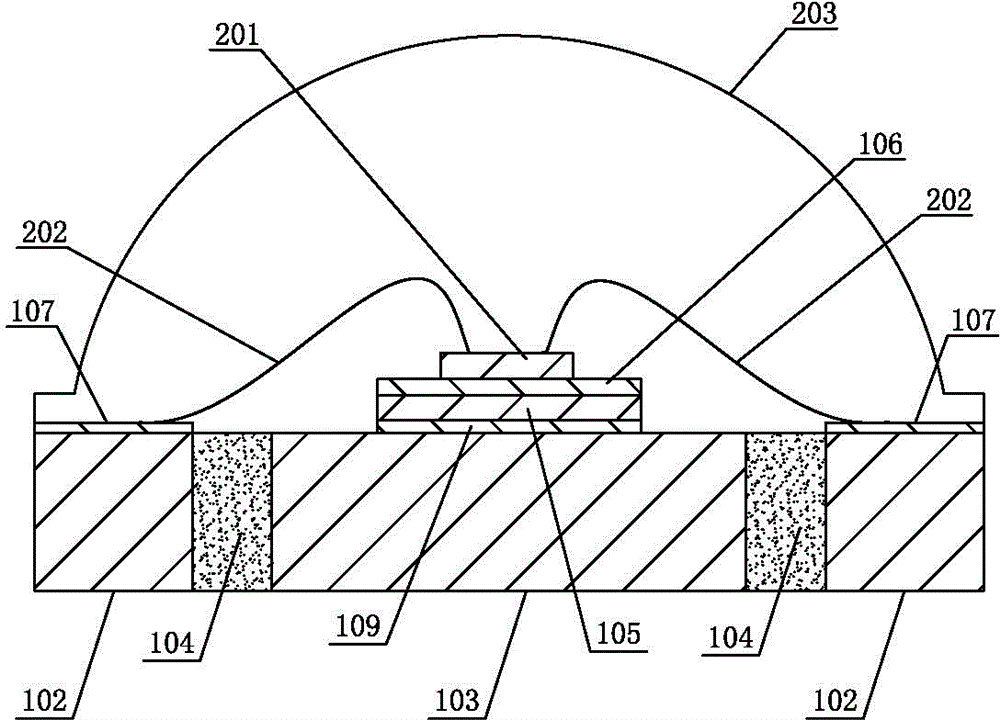

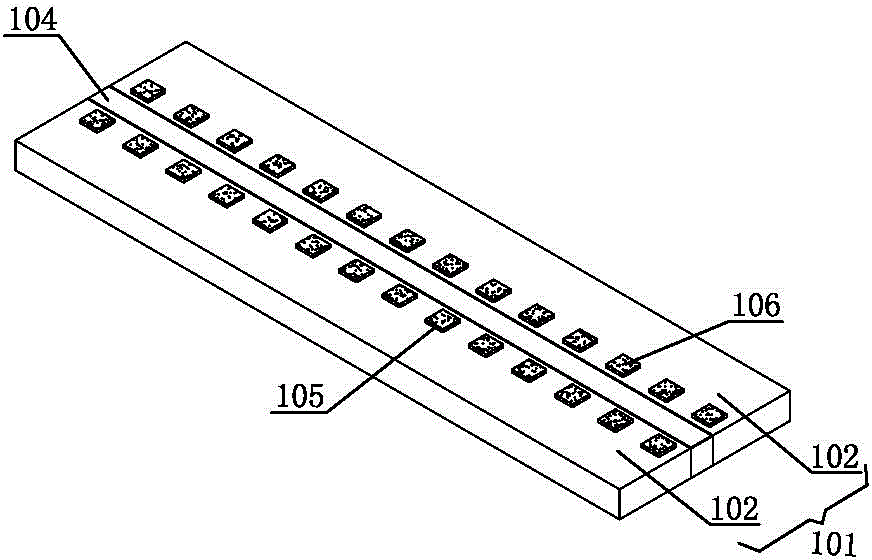

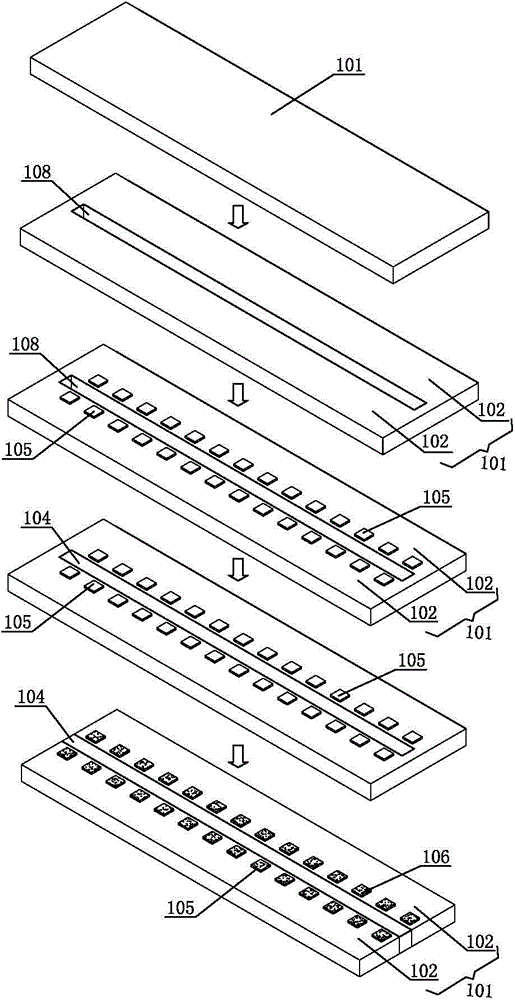

Package substrate and its manufacturing method and LED package structure based on the package substrate

ActiveCN103035819BSimple structureSimple manufacturing processSolid-state devicesSemiconductor devicesEngineeringHeat sink

The invention provides a package substrate which comprises a copper heat sink plate. Two insulating belts are inlaid on the copper heat sink plate, and the copper heat sink plate is divided into three areas, respectively an electrode area, a welding belt area and an electrode area by the two insulating belts. Tungsten-copper alloy bosses used for fixing light-emitting diode (LED) chips are welded on the welding belt area, and electroplated layers are respectively arranged on the tungsten-copper alloy bosses and the surfaces of the two electrodes. The package substrate is simple in structure, capable of simplifying manufacturing process of the package substrate and greatly reducing manufacturing cost of an LED package substrate. Installation height of the LED chip in a lamp is increased by the tungsten-copper alloy bosses, and therefore light emitted by the LED chips can directly light on working faces of package lenses. The problem that a light extracting rate can be influenced by bonding glue of lenses of a traditional ceramic substrate is solved, and a light emitting rate of an LED bead is increased.

Owner:ELEC TECH OPTOELECTRONICS TECHWUHUCO

Flip-chip substrate, manufacturing method thereof, and LED packaging structure based on the flip-chip substrate

ActiveCN103022332BSimple structureSimple manufacturing processSemiconductor devicesAdhesiveHeat sink

The invention provides a flip-chip substrate which comprises a copper heat sink plate. An insulating tape is embedded in the copper heat sink plate, and the copper heat sink plate is divided into two electrodes by the insulating tape; and tungsten-copper alloy bosses for fixing LED (Light Emitting Diode) chip are respectively welded on the two electrodes, and electroplating layers are arranged on the surfaces of the tungsten-copper alloy bosses. The flip-chip substrate is simple in structure, the manufacturing process flow of the substrate is simplified, and the production cost is greatly lowered; the installation height of the LED chips in a lamp can be enhanced by the tungsten-copper alloy bosses, so that more light emitted from the LED chips can be perpendicularly incident on the working surface of a packaged lens, and the problem that an adhesive for the lens of the conventional ceramic substrate influences a light out-coupling efficiency is solved; and furthermore, the positive and negative poles of the LED chips are directly and conductively connected with the tungsten-copper alloy bosses, a gold wiring process of the conventional process is avoided, and thus the packaging process flow of the LED chips can be further simplified.

Owner:ELEC TECH OPTOELECTRONICS TECHWUHUCO

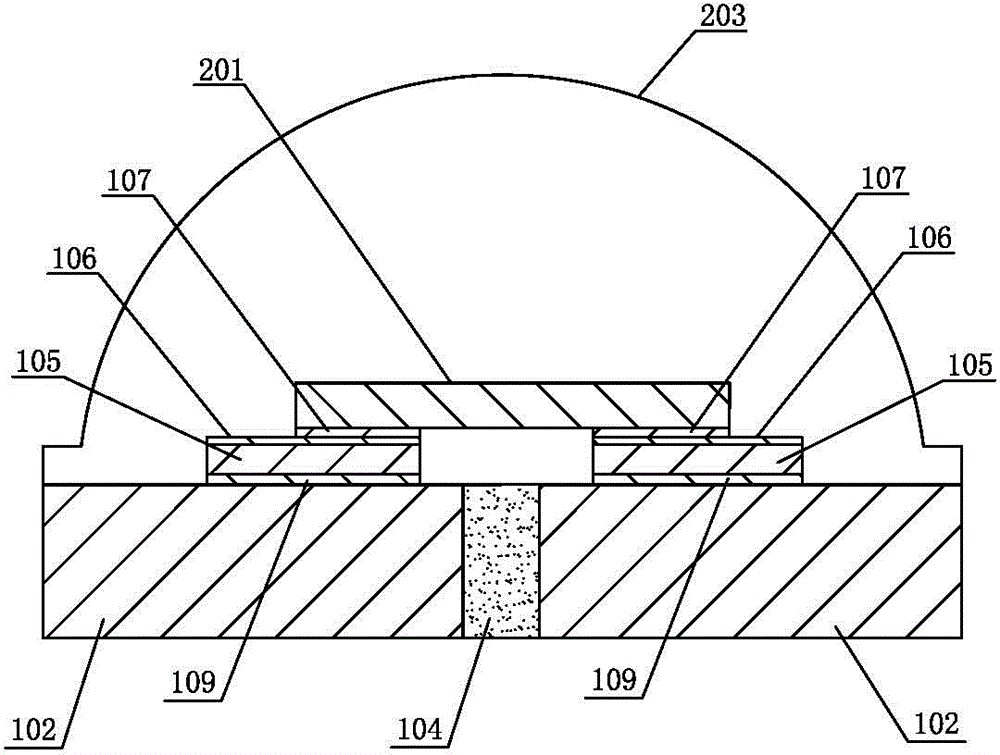

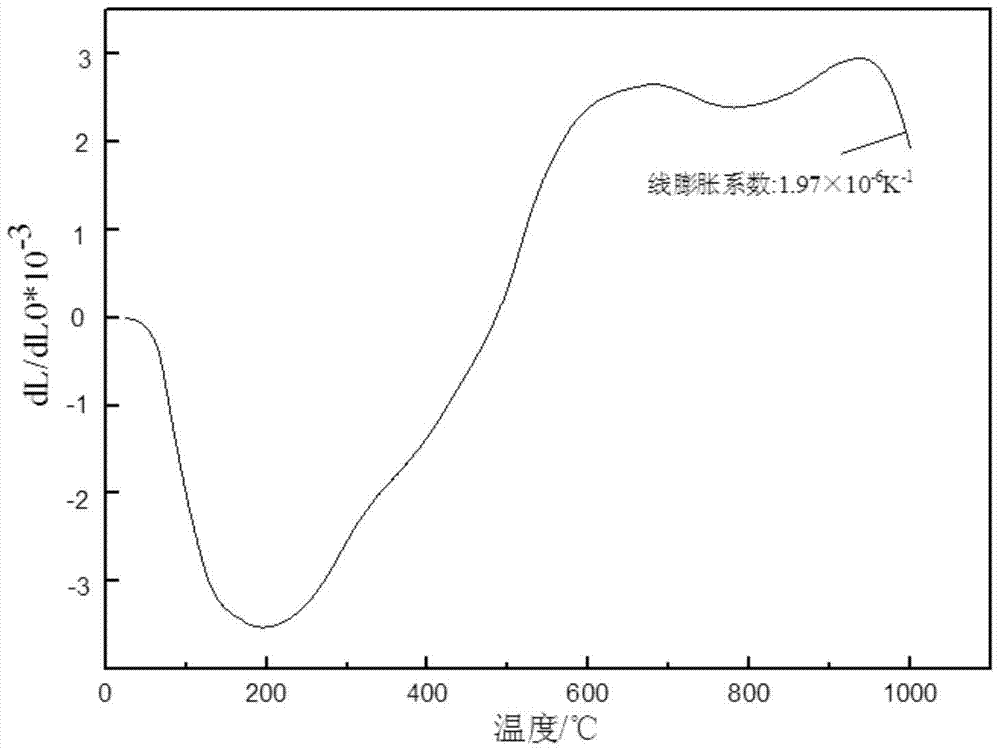

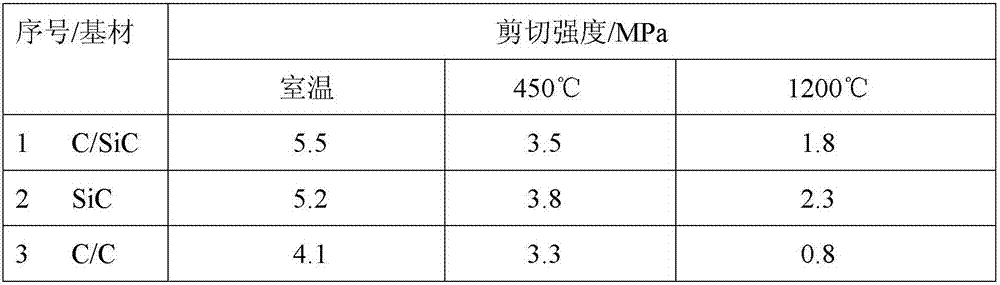

Preparation method of low expansion high temperature resistant adhesive

The invention discloses a preparation method of a low-expansion high-temperature-resistant adhesive, relating to an adhesive and a preparation method thereof. The invention aims to solve the problems of low heat-resistant level of the existing silicone resin adhesive, complex technological conditions required for the formation of glued joints, poor high-temperature stability and poor thermal shock resistance of the glued joints. The adhesive includes silicone resin, silane coupling agent, curing agent, high temperature resistant filler, inorganic fiber and organic solvent. Method: 1. Dissolve the first part of silicone resin in an organic solvent, then add methyltriethoxysilane, stir to obtain component A; 2. Dissolve the second part of silicone resin in an organic solvent, add water, silane Coupling agent, high temperature resistant filler, reaction, drying under reduced pressure to obtain surface-modified filler, after drying, mixed by planetary ball mill; 3. Mix modified filler, curing agent and inorganic fiber to obtain component B; 4. 1. Mix component A and component B to obtain a low-expansion high-temperature-resistant adhesive. The invention is used for preparing adhesives.

Owner:HARBIN INST OF TECH

A thermally conductive polymer-based composite material and its preparation method

InactiveCN104553105BGood thermal conductivityImprove mechanical propertiesSynthetic resin layered productsLaminationAdhesive cementConductive polymer

Owner:HARBIN INST OF TECH

Hexadecyl trimethyl ammonium bromide expansive soil improvement agent

InactiveCN100341979CImprove the nature of the projectReduce negative chargeBuilding constructionsExcavationsRoom temperatureDry soil

The invention is a palmityl trimethyl ammonium bromide expansive soil modifier, characterized in comprising the preparing steps of: (1) at room temperature, preparing saturated lime water solution; (2) weighing the needed palmityl trimethyl ammonium bromide in the mass ratio of palmityl trimethyl ammonium bromide to dry soil = 0.5 : 99.5; (3) dissolving the palmityl trimethyl ammonium bromide in the saturated lime water solution, where it needs to notice that the dosage of the saturated lime water solution is able to completely dissolve the palmityl trimethyl ammonium bromide. And the advantages: making the soil property still able to reach the specified standard under the water influence; improving engineering property of expansive soil; unable to cause environmental pollution. And its construction method uses osmotic modification principle and fully uses multi-crack property of expansive soil and is simple and convenient.

Owner:HOHAI UNIV

Copper matrix composite material and preparation method thereof

ActiveCN108103350BHigh tensile strengthHigh hardnessTransportation and packagingMetal-working apparatusBarium titanateOxygen content

Owner:国工恒昌新材料(义乌)有限公司

Composite heat dispersing material for LEDs

The invention discloses a composite heat dispersing material for LEDs. The composite heat dispersing material comprises, by mass, 63-65 parts of aluminum, 15-18 parts of iron, 5-8 parts of vanadium boride, 1-2 parts of zirconium boride, 4-5 parts of ferrochrome slag, 8-10 parts of gold tailings, 1-3 parts of glycerol, 1-2 parts of triethanolamine, 0.5-0.8 part of boric acid, 12-14 parts of organic chelated titanium, 15-18 parts of aluminum nitride, 1-2 parts of barium carbonate, 6-8 parts of calcite, 10-12 parts of talcum, 3-5 parts of medical stone, 1-2 parts of manganese sulfide, 1-3 parts of zinc gluconate, 1-3 parts of antioxidant and 4-5 parts of auxiliaries. The composite heat dispersing material for LEDs can improve the heat dispersion performance of materials and obtain good service properties.

Owner:NINGBO GOLDEN CLASSIC LIGHTING

A method for preparing copper-antimony-doped tin-carbon lithium ion negative electrode material

ActiveCN108807873BLow expansion propertiesGranulation realizationCell electrodesSecondary cellsCarbon compositesTin dioxide

The invention discloses a method for preparing copper-antimony-doped tin-carbon-lithium ion anode materials, which includes the following steps: (1) tin dioxide doping modification: weighing a certain weight of tin dioxide, copper and antimony 100:(5-20):(5-20) ratio for dry ball milling and mixing for 0.5-1.5h; (2) Composite granulation of tin dioxide modified products and graphite; (3) Secondary coating modification . The present invention adopts copper and antimony to carry out doping modification to tin dioxide, reduces the expansion characteristic of tin-carbon composite, improves cycle performance; Short, simple process, easy to realize industrialized large-scale production; at the same time realize the advantages of granulation between tin dioxide and graphite, graphite and graphite, and can realize the function of surface modification of tin dioxide and graphite; adopt secondary packaging Coating can significantly improve the surface defects generated in the secondary granulation process, and improve the first-time efficiency and cycle performance of the product.

Owner:SHENZHEN XIANGFENGHUA TECH CO LTD +1

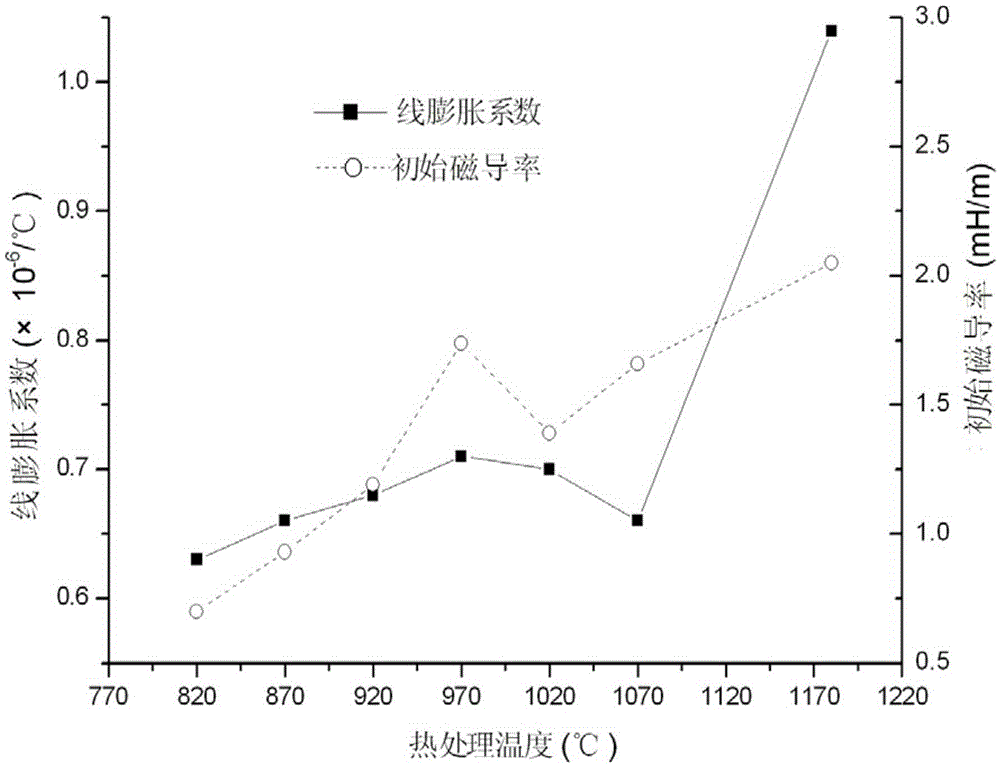

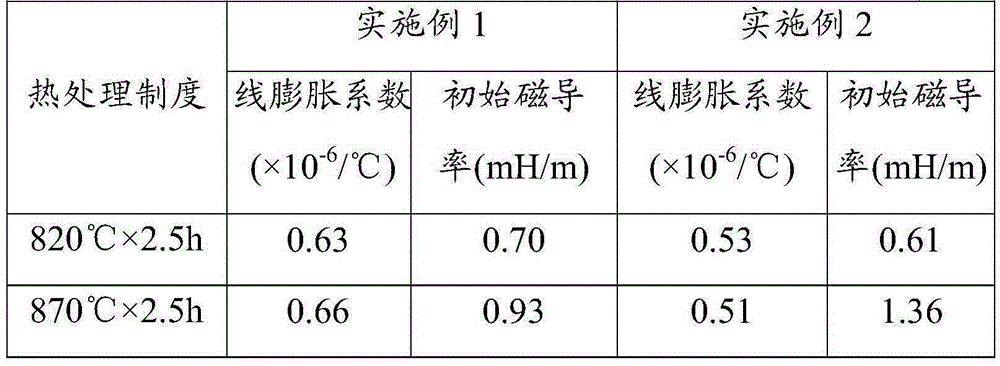

A low-expansion magnetic shielding alloy and its preparation method

The invention belongs to the field of precision alloy, and particularly relates to a low-expansion magnetic shielding alloy for an optical fiber loop skeleton, and a preparation method thereof. The alloy comprises the following chemical components in percentage by weight: 32.0-35.2% of Ni, 3.0-3.5% of Co, 0.10-0.25% of Mn, less than or equal to 0.15% of Si, less than or equal to 0.02% of Cu, less than or equal to 0.01% of C, less than or equal to 0.01% of P, less than or equal to 0.01% of S, and the balance of Fe. The preparation method of the low-expansion magnetic shielding alloy comprises the following steps sequentially: preparation of high-purity raw materials, proportioning of ingredients, smelting of a vacuum induction furnace and vacuum arc remelting, forging and processing, sampling, thermal treatment, and performance test. The thermal treatment system comprises the steps of under protection of high-purity hydrogen gas, carrying out furnace heating to 970+ / -10DEG C, preserving heat for 2.5-3h, cooling to 550+ / -10DEG C at the speed of 200-250DEG C / h, rapidly cooling to 300DEG C below for discharging. Compared with the existing low-expansion alloy 4J32 and on the premise that low-expansion characteristic is kept, the low-expansion magnetic shielding alloy has high initial magnetic conductivity, integrates the two advantages of low expansion property and high magnetic shielding property, namely within the temperature range of -45DEG C to 75DEG C, the expansion coefficient of the alloy is 1.0*10<-6> / DEG C below; the initial magnetic conductivity is higher than 1.5mH / m.

Owner:CENT IRON & STEEL RES INST

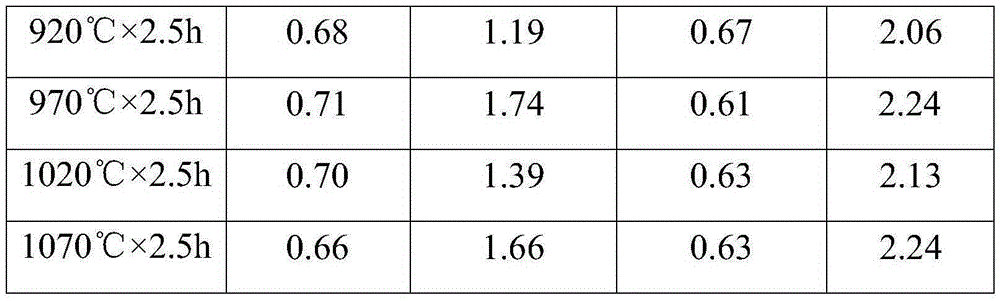

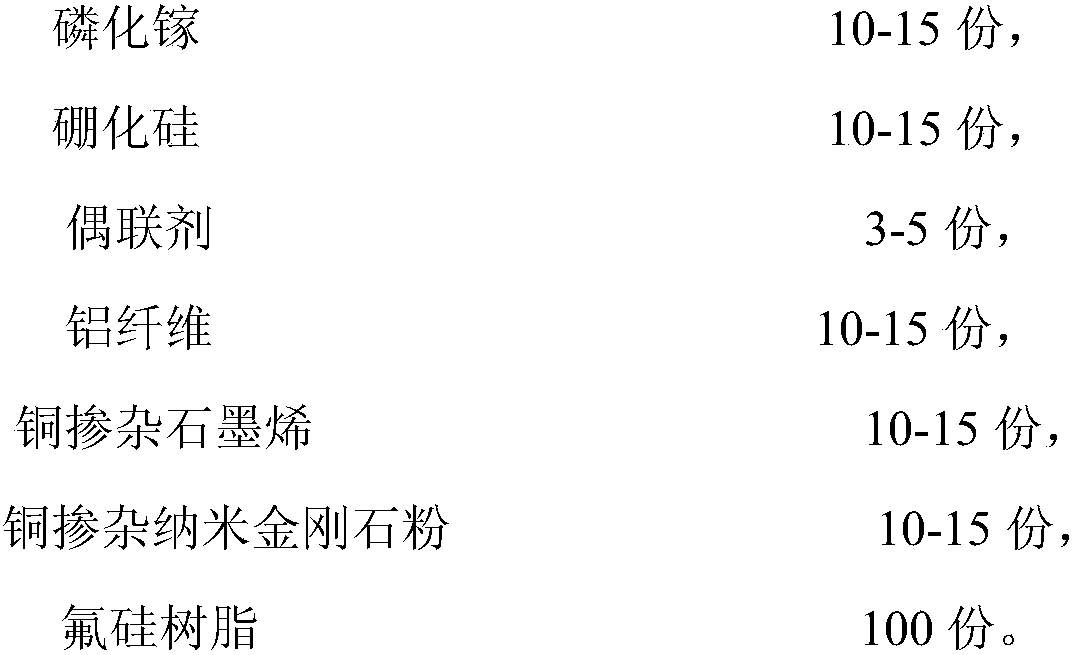

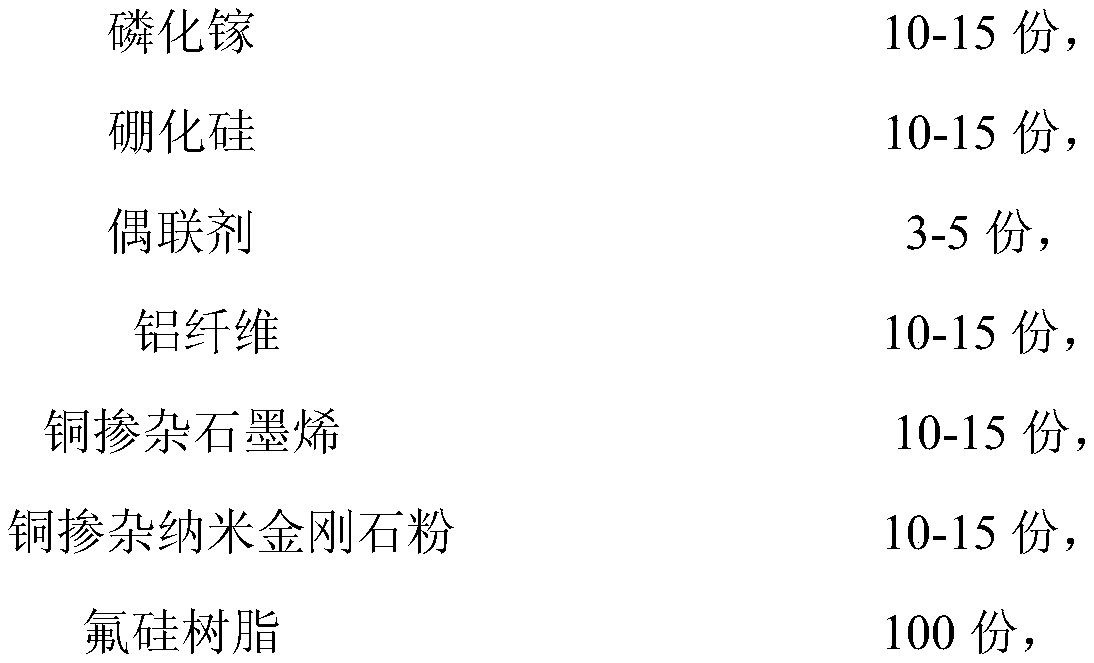

Heat sink material for energy-saving LED lamp

InactiveCN107674432AImprove cooling effectExtended service lifeHeat-exchange elementsFiberDoped graphene

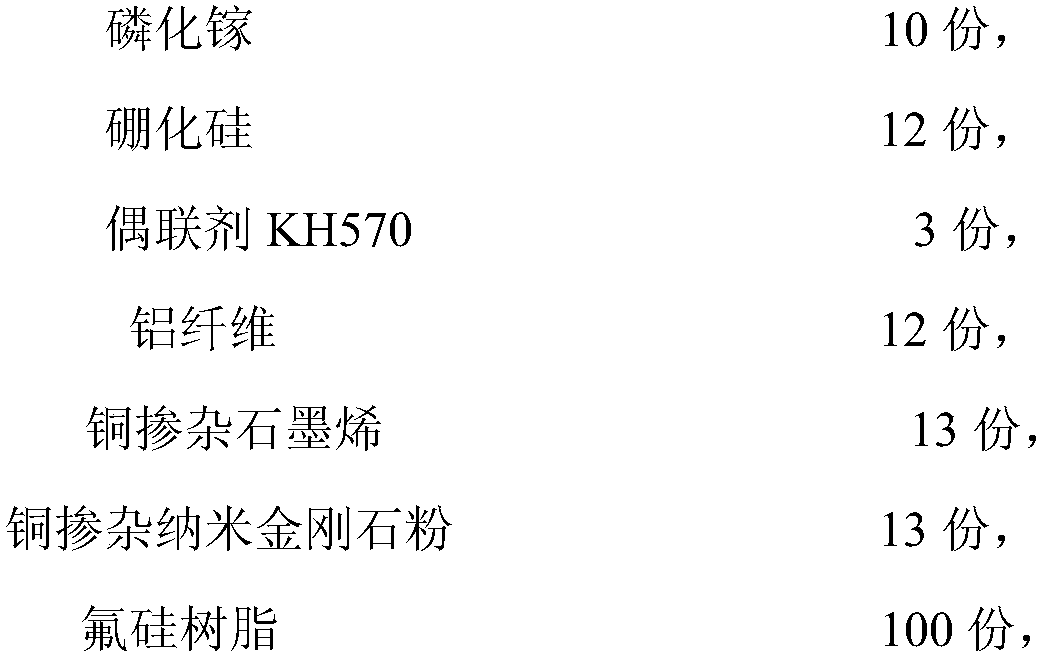

The invention discloses a heat sink material for anenergy-saving LED lamp. The material comprises the following components in parts by weight: 10 to 15 parts of gallium phosphide, 10 to 15 parts of silicon boride, 3 to 5 parts of a coupling agent, 10 to 15 parts of aluminum fiber, 10 to 15 parts of copper doped graphene, 10 to 15 parts of copper doped nanometer diamond particles, and 100 parts offluorosilicon resin. The coupling agent adopts one or more in KH570, KH550, KH560, KH151 and KH171. The material has excellent characteristics of high thermal conductivity, low expansion property, andhigh and stable heat dissipation potential to the environment.

Owner:贵州眯果创意科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com