A low-expansion magnetic shielding alloy and its preparation method

A low-expansion, magnetic-shielding technology, applied in the field of precision alloys, can solve problems such as inability to match optical fibers and have no magnetic shielding function, and achieve the effects of low-expansion magnetic shielding performance and high initial permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

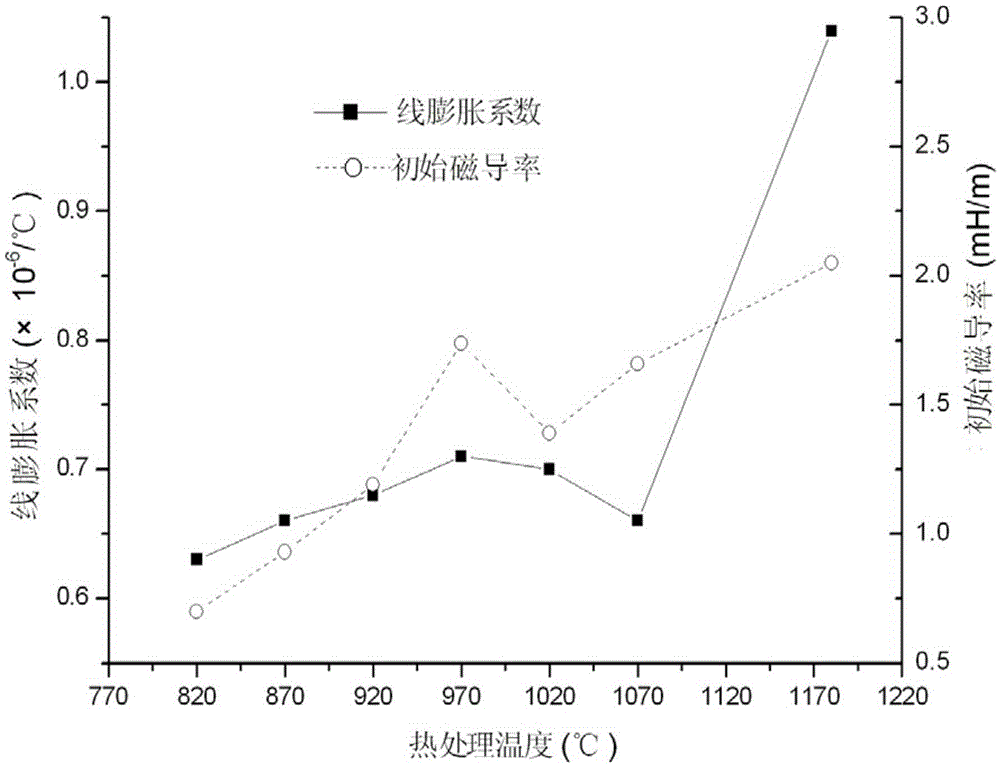

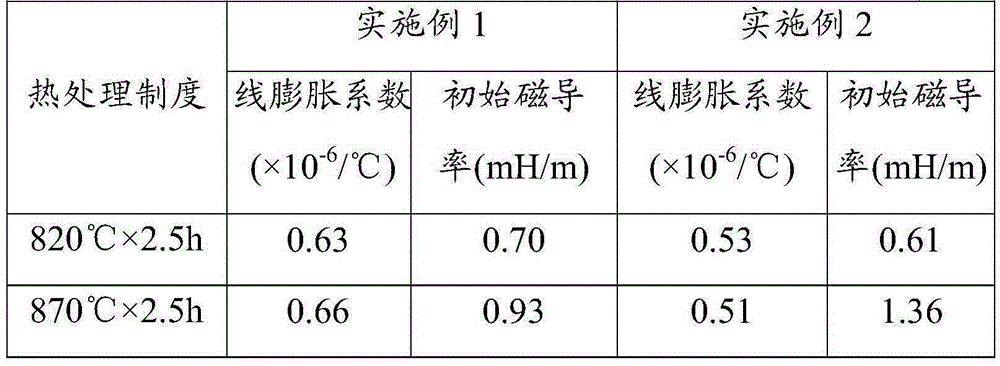

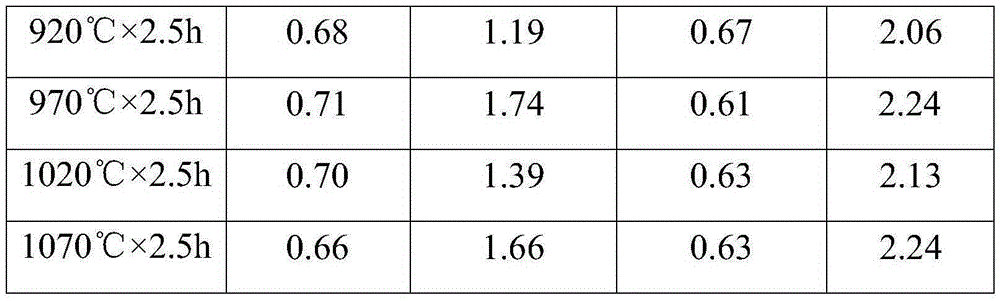

[0033] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0034] The specific process steps of the low-expansion magnetic shielding alloy for making the optical fiber ring skeleton of the present invention are as follows:

[0035] a) Purify pure Fe with a 200kg vacuum induction furnace, remove impurities such as gas and C, S, P therein, and remove the surface oxide layer of metal Ni, Co and Fe through polishing;

[0036] b) The alloy is smelted in a 25kg vacuum induction furnace and a consumable electric arc furnace. The vacuum degree is better than 0.2Pa. The composition of the main alloy elements is strictly controlled during the smelting process. The actual composition of the alloy after smelting is listed in Table 1;

[0037] Chemical composition (wt%) of table 1 smelting alloy

[0038] Numbering Ni co mn Si Cu C P S Fe Example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com