Ion response gel applicable to cement silicate self-repairing systems, preparation method and application

A silicate and self-repairing technology, which is applied in the field of cement self-repairing, can solve the problems that cracks cannot be self-repairing, reduce the mechanical properties of cement, and poor interface adhesion, etc., and achieve the effects of shortening the main body time, low cost and accelerating deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

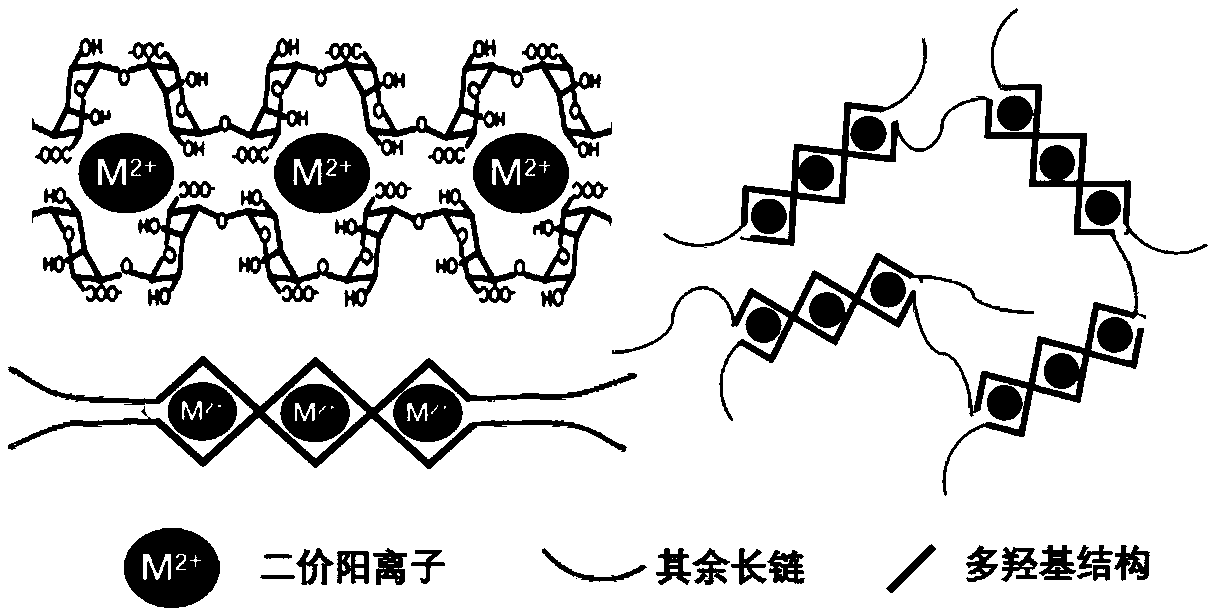

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing an ion-responsive gel suitable for a cement silicate self-repairing system, comprising the following steps:

[0031] (1) configuration mass fraction is the chitosan aqueous solution of 1%;

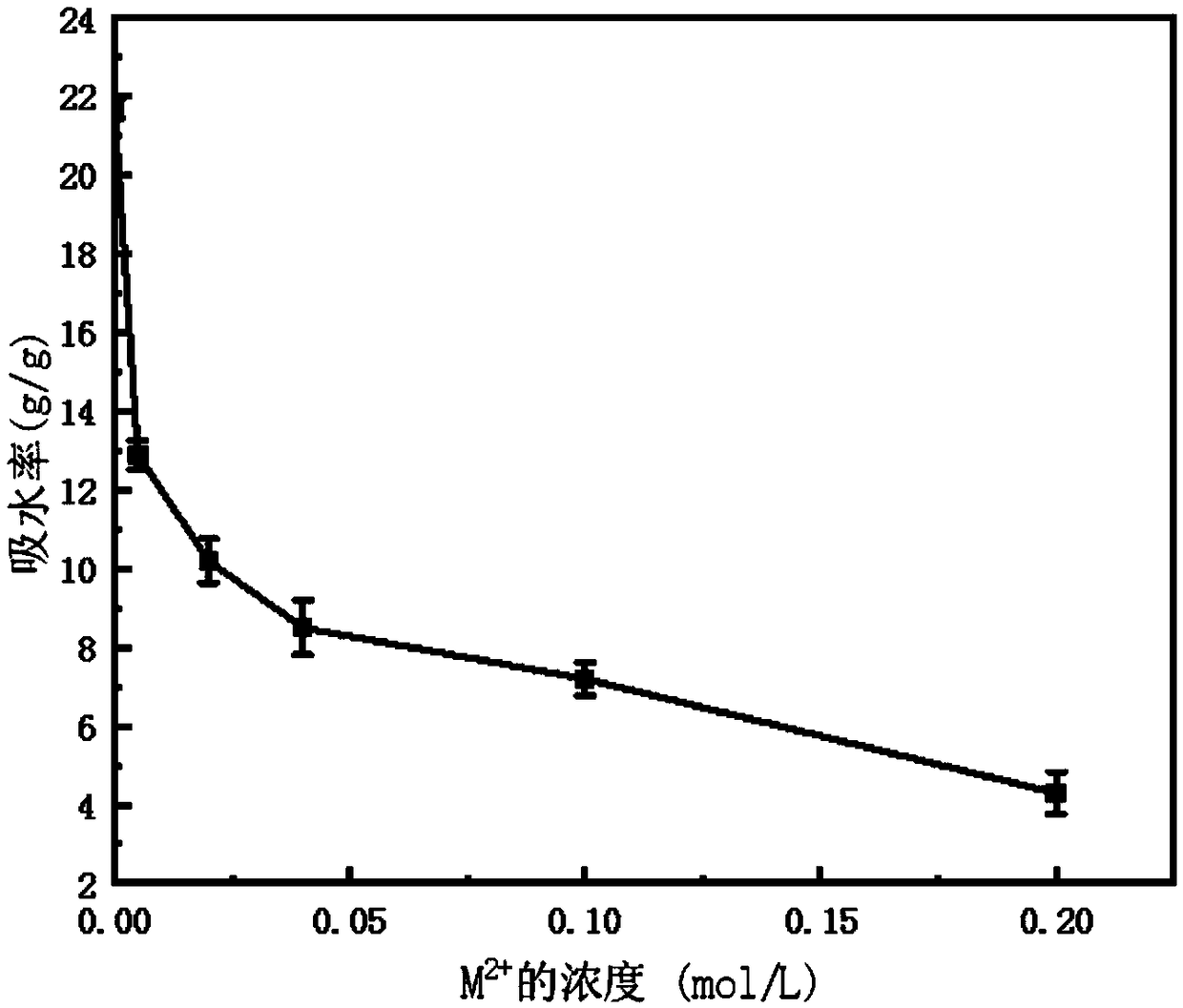

[0032] (2) Under stirring, the chitosan aqueous solution obtained in step (1) is dropped into a 0.25mol / L magnesium chloride aqueous solution in a ratio of 1:2 by volume, and left for 24 hours, freeze-dried to obtain silicic acid suitable for cement Ion-responsive gels for salt self-healing systems.

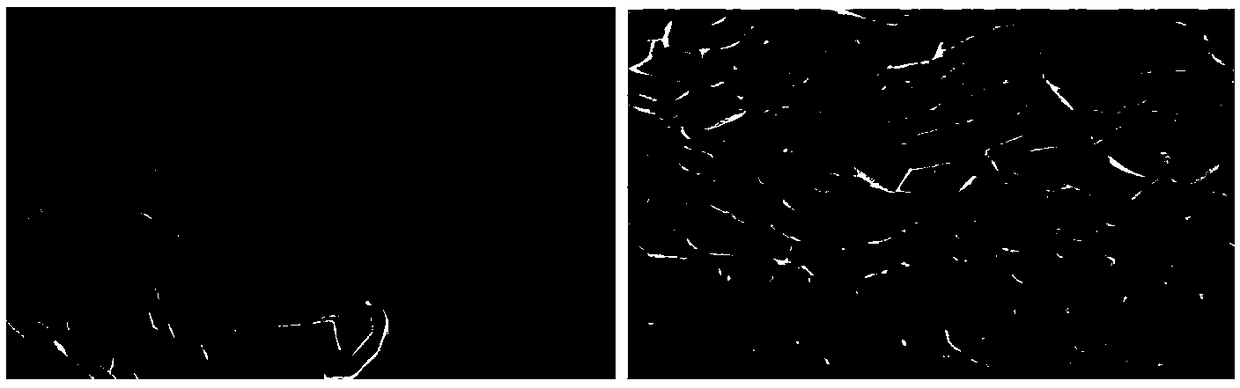

[0033] Mix 2.5g of the ion-responsive gel suitable for the cement silicate self-repairing system obtained in this example into 500g of Jiahua G grade oil well cement powder, add water according to the water-cement mass ratio of 0.44, and mix the slurry uniformly at room temperature Cement blocks were obtained after curing for 7 days. A crack with a width of about 120 μm was obtained through a compressive test. An aqueous solution of sodium silicate with a mass f...

Embodiment 2

[0035] A method for preparing an ion-responsive gel suitable for a cement silicate self-repairing system, comprising the following steps:

[0036] (1) configuration mass fraction is the carrageenan aqueous solution of 0.5%;

[0037] (2) Under stirring, drop the carrageenan aqueous solution obtained in step (1) into a 0.02mol / L calcium chloride aqueous solution at a ratio of 1:2 by volume, place it for 12 hours, and freeze-dry to obtain silicic acid suitable for cement. Ion-responsive gels for salt self-healing systems.

[0038] The repair experiment is the same as in Example 1, and the effect is similar to that of Example 1.

Embodiment 3

[0040] A method for preparing an ion-responsive gel suitable for a cement silicate self-repairing system, comprising the following steps:

[0041] (1) configuration mass fraction is 2% sodium alginate aqueous solution;

[0042] (2) Under stirring, drop the sodium alginate aqueous solution obtained in step (1) into a 0.5mol / L calcium chloride aqueous solution at a volume ratio of 1:4, leave it for 24 hours, and freeze-dry to obtain silica gel suitable for cement. Ion-responsive gels for salt self-healing systems.

[0043] Pectin was used instead of sodium alginate in this example, and the others were the same as in this example to obtain an ion-responsive gel suitable for cement silicate self-repairing systems.

[0044] The repair experiment is the same as in Example 1, and the effect is similar to that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com